Method for separating FeOOH and sulfur and applications of sulfur free FeOOH

A technology for iron oxyhydroxide and separation of hydroxyl groups, which is applied in the direction of iron oxide/iron hydroxide, separation methods, chemical instruments and methods, etc. It can solve the problems such as the decline of desulfurization ability of iron oxyhydroxide, and achieve the effect of ensuring desulfurization properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a method for separating ferric oxyhydroxide and sulfur, comprising the steps of:

[0037] (1) Air-drying sulfur-containing iron oxyhydroxide at 10°C until its water content is 5wt%;

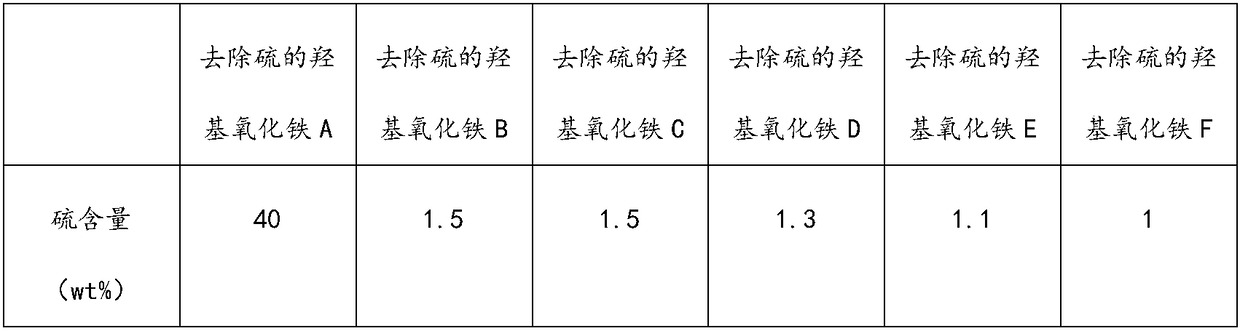

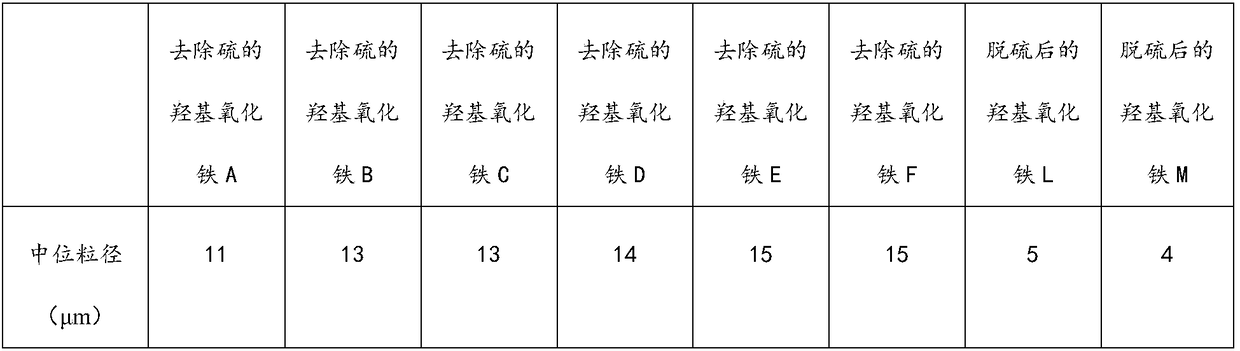

[0038] (2) Stir and mix the air-dried sulfur-containing iron oxyhydroxide and ethylbenzene at 90° C. for 2 hours according to the mass ratio of 1:10, and separate the solid and liquid to obtain a sulfur-containing solvent and iron oxyhydroxide A from which sulfur has been removed;

[0039] (3) The sulfur-containing solvent is cooled and crystallized at a temperature of 5° C., and the solid and liquid are separated to obtain sulfur A.

Embodiment 2

[0041] This embodiment provides a method for separating ferric oxyhydroxide and sulfur, comprising the steps of:

[0042] (1) drying sulfur-containing iron oxyhydroxide at 90°C until its water content is 0.1wt%;

[0043] (2) stirring and mixing the air-dried sulfur-containing ferric oxyhydroxide and methylcyclohexane at 80° C. for 1 hour according to a mass ratio of 1:30, and separating the solid and liquid to obtain the first sulfur-containing solvent and the first ferric oxyhydroxide;

[0044] (3) stirring and mixing the first iron oxyhydroxide and methylcyclohexane at 80° C. for 1 hour according to the mass ratio of 1:30, and separating the solid and liquid to obtain the second sulfur-containing solvent and the second iron oxyhydroxide;

[0045] (4) Stir and mix the second iron oxyhydroxide and methylcyclohexane at 80°C for 1 hour according to the mass ratio of 1:30, and separate the solid and liquid to obtain the third sulfur-containing solvent and iron oxyhydroxide B from...

Embodiment 3

[0048] This embodiment provides a method for separating ferric oxyhydroxide and sulfur, comprising the steps of:

[0049] (1) air-drying sulfur-containing iron oxyhydroxide at 25°C until its water content is 4wt%;

[0050] (2) stirring and mixing the air-dried sulfur-containing ferric oxyhydroxide and trichloroethane at a mass ratio of 1:7 at 50° C. for 3 hours, and separating the solid and liquid to obtain the first sulfur-containing solvent and the first ferric oxyhydroxide;

[0051] (3) stirring and mixing the first iron oxyhydroxide and trichloroethane according to a mass ratio of 1:7 at 50° C. for 3 hours, and separating the solid and liquid to obtain the second sulfur-containing solvent and the second iron oxyhydroxide;

[0052](4) Stir and mix the second iron oxyhydroxide and trichloroethane according to the mass ratio of 1:7 at 50° C. for 3 hours, and separate the solid and liquid to obtain the third sulfur-containing solvent and iron oxyhydroxide C from which sulfur h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water content | aaaaa | aaaaa |

| Water content | aaaaa | aaaaa |

| Water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com