A method for reclaiming sulfur on iron oxyhydroxide and application of iron oxyhydroxide for sulfur removal

A technology of iron oxyhydroxide and iron oxide, which is applied in the direction of iron oxide/iron hydroxide, chemical instruments and methods, separation methods, etc., and can solve the problems such as the decline of desulfurization ability of iron oxyhydroxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a method for recovering sulfur on iron oxyhydroxide, which includes the following steps:

[0037] (1) Dry the sulfur-containing iron oxyhydroxide under normal pressure at 55°C until its water content is 5wt%;

[0038] (2) Mix the dried sulfur-containing iron oxide oxyhydroxide and 1,3,5-trimethylbenzene at a mass ratio of 1:10 at 90℃ for 2h, and separate the solid and liquid to obtain a sulfur-containing solvent and sulfur removal Iron oxyhydroxide

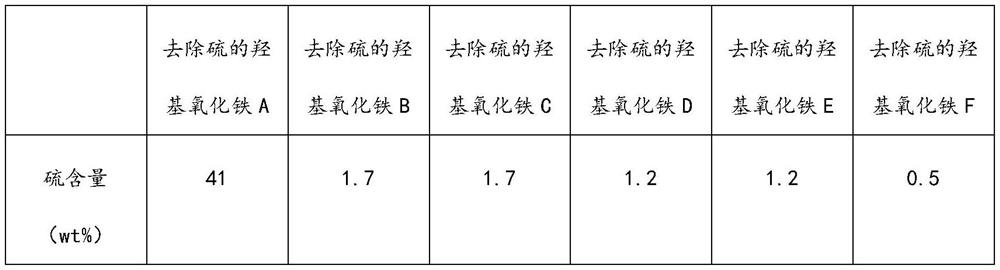

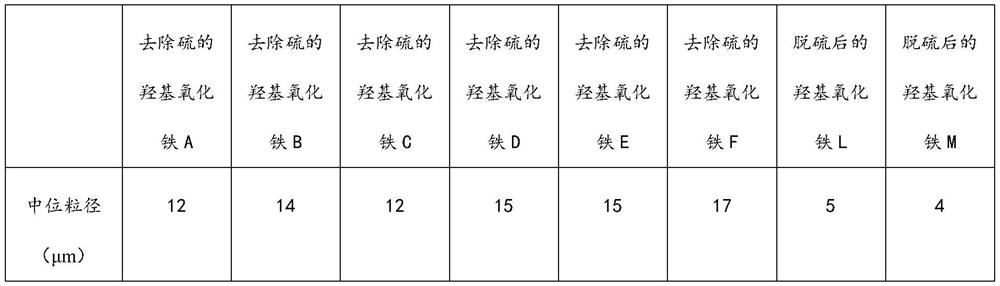

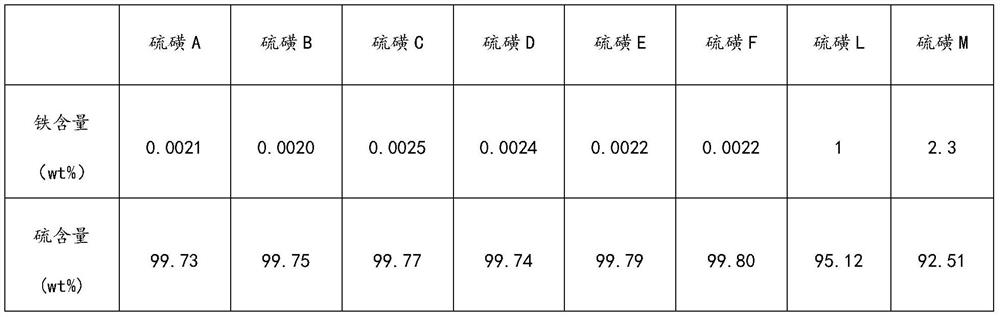

[0039] (3) Dry the iron oxyhydroxide from which sulfur is removed at 65°C to obtain iron oxyhydroxide A; the sulfur-containing solvent is cooled and crystallized at a temperature of 5°C, and solid-liquid separation is performed to obtain sulfur A.

Embodiment 2

[0041] This embodiment provides a method for recovering sulfur on iron oxyhydroxide, which includes the following steps:

[0042] (1) First centrifugal treatment of sulfur-containing iron oxyhydroxide to remove water initially, and then dry the sulfur-containing iron oxyhydroxide at a temperature of 45°C and a pressure of 20Kpa to a water content of 0.1wt%;

[0043] (2) Stir and mix the dried sulfur-containing iron oxyhydroxide and methylcyclohexane at a mass ratio of 1:30 at 80°C for 1 hour, and separate the solid and liquid to obtain the first sulfur-containing solvent and the first iron oxyhydroxide;

[0044] (3) The first iron oxyhydroxide and methylcyclohexane were stirred and mixed at 80° C. for 1 hour at a mass ratio of 1:30, and solid-liquid separation was performed to obtain a second sulfur-containing solvent and a second iron oxyhydroxide;

[0045] (4) Mix the second iron oxyhydroxide and methylcyclohexane at a mass ratio of 1:30 at 80° C. for 1 h, and separate solid-liquid t...

Embodiment 3

[0048] This embodiment provides a method for recovering sulfur on iron oxyhydroxide, which includes the following steps:

[0049] (1) Centrifugal treatment of sulfur-containing iron oxyhydroxide, preliminary dewatering, and then drying the sulfur-containing iron oxyhydroxide at a temperature of 85°C and a pressure of 80Kpa to a water content of 4wt%;

[0050] (2) The dried sulfur-containing iron oxyhydroxide and trichloroethane were stirred and mixed at 50°C for 3 hours at a mass ratio of 1:7, and solid-liquid separation was performed to obtain the first sulfur-containing solvent and the first iron oxyhydroxide;

[0051] (3) The first ferric oxyhydroxide and trichloroethane were stirred and mixed at a mass ratio of 1:7 at 50°C for 3 hours, and solid-liquid separation was performed to obtain a second sulfur-containing solvent and a second ferric oxyhydroxide;

[0052] (4) Mix the second iron oxyhydroxide and trichloroethane at a mass ratio of 1:7 at 50°C for 3 hours, and separate the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com