Titanium dioxide hydrolysis waste acid recycling treatment process

A treatment process, titanium dioxide technology, applied in the field of titanium dioxide hydrolysis waste acid resource utilization treatment process, can solve the problem of large amount of alkali, achieve the effect of reducing emissions and solving blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

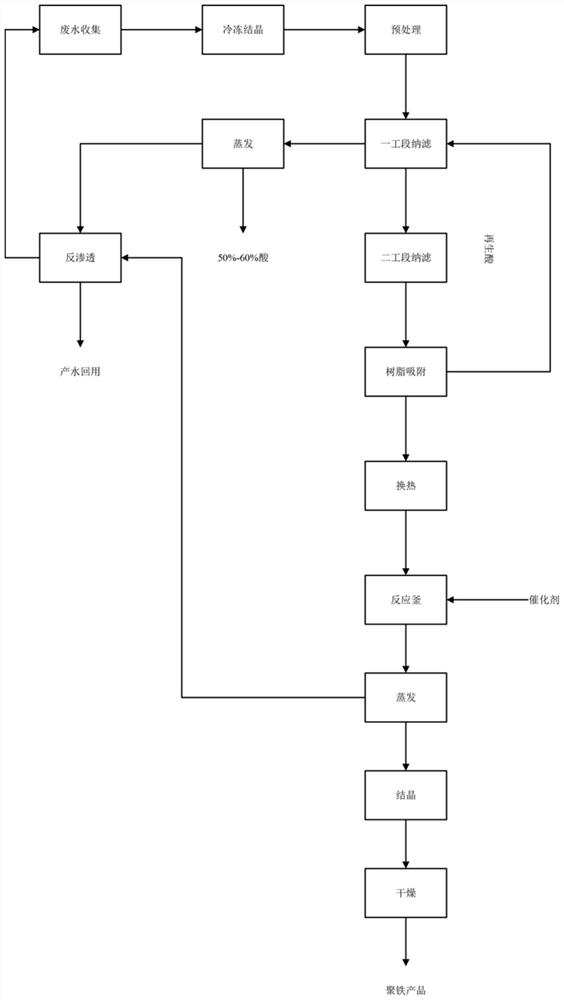

[0030] The present invention is described in further detail with reference to the accompanying drawings and specific embodiments.

[0031] Titanium dioxide hydrolysis waste acid is produced during the hydrolysis process of titanium dioxide. The resource utilization treatment process of titanium dioxide hydrolysis waste acid includes: collecting the generated waste water, removing ferrous sulfate solid particles in the waste water through freezing and crystallization, and then heat exchange to 25~ 50°C, and then pretreated to remove titanium dioxide particles in the wastewater, the effluent SDI≤5, meeting the water quality requirements for subsequent nanofiltration membranes; the pretreated water enters the nanofiltration unit of the first stage for concentration treatment, most of the ferrous The ions are trapped in the concentrated solution of the nanofiltration unit in the first section, while the sulfuric acid passes through the nanofiltration membrane and exists in the nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com