Preparation method and application of iron oxide red

A technology of iron oxide red and iron ions, applied in the preparation of iron compounds, iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of uneven coloring, inorganic pigments are kneaded into agglomerates, difficult to disperse, etc. Simple process and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

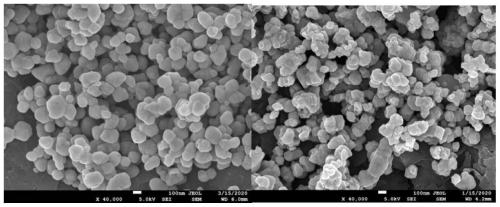

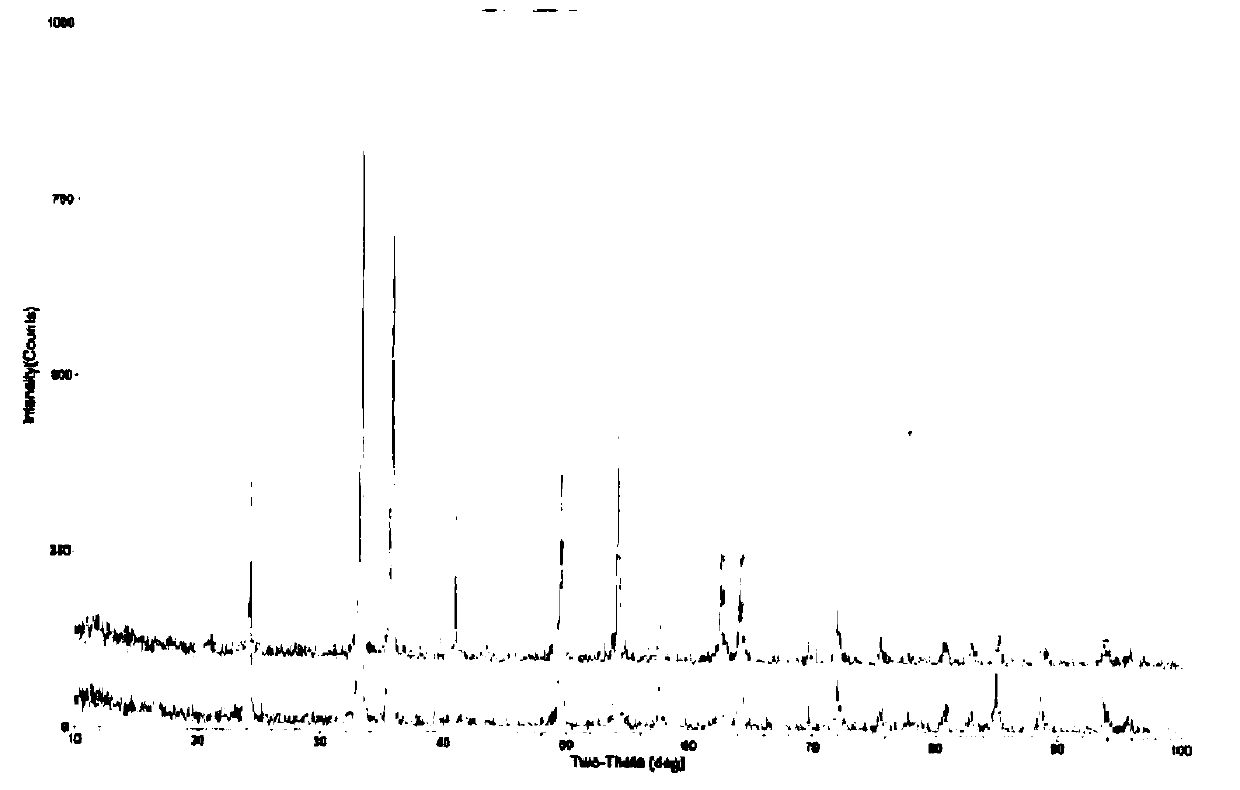

Image

Examples

Embodiment 1

[0046] Add 1000ml of an aqueous solution containing 5% iron ions into the iron extractor, and at 30°C, use tributyl phosphate TBP / sulfonated kerosene (wt)=45:55 as the extraction system, and the oil phase is compared with water O / A = 1:1, after a first-stage extraction, the oil phase containing high-purity iron ions is obtained, and then directly enters the iron oxide red synthesis kettle, and 20% sodium hydroxide solution is added to the system to prepare iron precipitation, and finally iron oxide is obtained through post-treatment red.

Embodiment 2

[0048] Add 1000ml of an aqueous solution containing 20% iron ions into the extractor, and at 30°C, use tributyl phosphate TBP / sulfonated kerosene (wt)=45:55 as the extraction system, and the oil phase water ratio O / A= 1:1, after two stages of extraction, the oil phase containing high-purity iron ions is obtained, and then directly enters the iron oxide red synthesis kettle, and 20% sodium hydroxide solution is added to the system to prepare iron precipitation, and finally the iron oxide red is obtained through post-processing .

[0049] The component analysis of the iron oxide red prepared by the present embodiment is as following table 1:

[0050] Table 1 Iron oxide red composition (ppm)

[0051] Fe 2 o 3 (%)

Ca Mg Al mn V Cr Ti Si co 99.89 1.2 1.1 1.6 0.9 - - - 0.02 0.01 Ni Cu Zn Cd Hg Pb As Se Sb Ba 0.37 0.54 0.59 - - - - - - -

[0052] Note: -: not detected

[0053] As can be seen from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com