Resourceful treatment method for hot galvanizing pickling waste liquid

A technology for pickling waste liquid and treatment methods, which is applied in the preparation of zinc compounds, zinc oxide/zinc hydroxide, iron halide, etc., can solve the problems of low added value of products, large consumption of ammonia water, etc., and achieve easy maintenance and management, The effect of avoiding water pollution and simple operation of impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

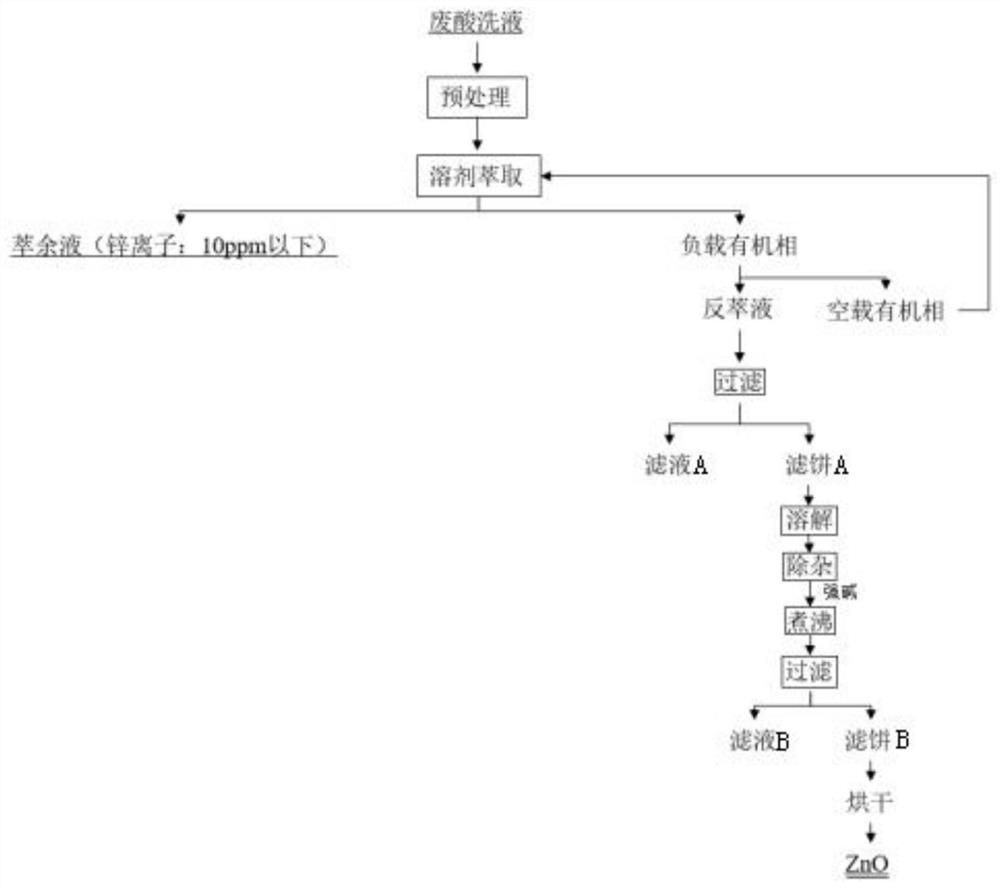

Method used

Image

Examples

Embodiment 1

[0049] The content of each chemical component in the hot-dip galvanizing pickling waste solution Zn: 17.6 g / L, Fe 2+ : 141.1 g / L, Fe 3+ : 2.1g / L and HCl: 51.1g / L.

[0050] Processing procedure:

[0051] (1) Add reduced iron powder to the pickling waste liquid according to the weight ratio of reducing agent and pickling waste liquid at 1:50, stir and reduce for 2 hours, and then filter out insoluble matter and unreacted iron powder.

[0052] (2) Prepare 15% extractant, compared with O / A=1:1, extraction time is 10 minutes, countercurrent extraction stage is 3, zinc ion content in raffinate is 9.5ppm, saturated zinc extraction of organic phase The capacity is 11.4g / L.

[0053] (3) The stripping agent used is 0.5M NaOH solution, at the ratio of O / A=1:1.5, the stripping time is 15 minutes, the primary stripping efficiency is 98.6%, and then the stripping solution is filtered.

[0054] (4) Dissolve the filter cake with dilute hydrochloric acid solution obtained by distillation, ...

Embodiment 2

[0056] The content of each chemical component in the hot-dip galvanizing pickling waste solution Zn: 30.2 g / L, Fe 2+ : 148.4 g / L, Fe 3+ : 2.5g / L and HCl=69.4g / L.

[0057] Processing procedure:

[0058] (1) Add reducing agent according to the ratio of reduced iron powder to pickling waste liquid at 1:100, stir and reduce for 2 hours, then filter out insoluble matter and unreacted iron powder.

[0059] (2) Prepare 20% extractant, compared with O / A=1.5:1, extraction time is 10 minutes, countercurrent extraction stage is 4, zinc ion content in raffinate is 8.4ppm, saturated zinc extraction of organic phase The capacity is 15.2g / L.

[0060] (3) The stripping agent used is 0.5M ammonia solution, compared to O / A=1:1, the stripping time is 15 minutes, the primary stripping efficiency is 98.8%, and then the stripping solution is filtered.

[0061] (4) Dissolve the filter cake with the dilute hydrochloric acid solution obtained by distillation, then add ammonium chloride-ammonia wat...

Embodiment 3

[0063] The content of each chemical component in the hot-dip galvanizing pickling waste solution Zn: 25.6 g / L, Fe 2+ : 145.2 g / L, Fe 3+ : 2.5g / L and HCl: 46.2g / L.

[0064] Processing procedure:

[0065] (1) Add reducing agent according to the ratio of reduced iron powder to pickling waste liquid at 1:80, stir and reduce for 1.5 hours, then filter out insoluble matter and unreacted iron powder.

[0066] (2) Prepare 10% extractant, compared to O / A=2:1, countercurrent extraction for 7 minutes, the extraction stage is 5, the zinc ion content in the raffinate is 6.5ppm, the saturated zinc extraction capacity of the organic phase It is 7.4g / L.

[0067] (3) The stripping agent used is 1MNa 2 CO 3 Solution, compared to O / A=1:2, the stripping time is 10 minutes, the primary stripping efficiency is 97.8%, and then the stripping liquid is filtered.

[0068] (4) Dissolve the filter cake with the dilute hydrochloric acid solution obtained by distillation, then add 3% ammonium chlorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com