Iron and Steel Pickling Wastewater Recycling and Zero Discharge Process

A technology for pickling and recycling iron and steel, applied in the field of water treatment, can solve the problems of lowering the pH value of water body, large amount of residues, difficult treatment, etc., and achieve the effect of increasing Fe content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

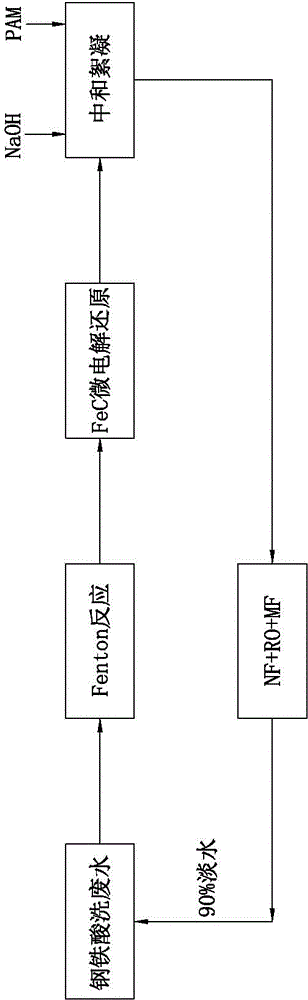

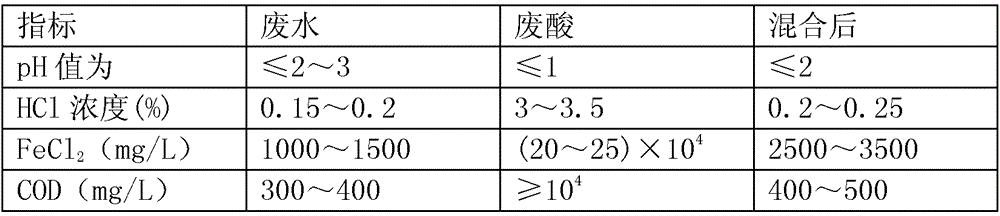

[0039] Such as figure 1 Shown, steel pickling wastewater recycling and zero discharge process, it includes the following process steps:

[0040] (a) Iron and steel pickling wastewater inflow;

[0041] (b) The iron and steel pickling wastewater is subjected to Fenton reaction, so that the COD of the iron and steel pickling wastewater is reduced to ≤60mg / L, and Fe 2+ Convert to Fe 3+ , TDS (total dissolved solids) down to ≤2000mg / L; the H 2 o 2 or O 3 Add to Fenton reactor for Fenton reaction, or use titanium ruthenium electrode Ti-RuO 2 Carry out Fenton reaction;

[0042] (c) Iron and steel pickling wastewater is subjected to FeC micro-electrolytic reduction reaction; after the FeC micro-electrolytic reduction reaction, the pH of the steel pickling wastewater is more than 3.5;

[0043] (d) Neutralization and flocculation: add NaOH and PAM to carry out neutralization and flocculation reaction; after neutralization and flocculation, the pH of steel pickling wastewater is m...

Embodiment 2

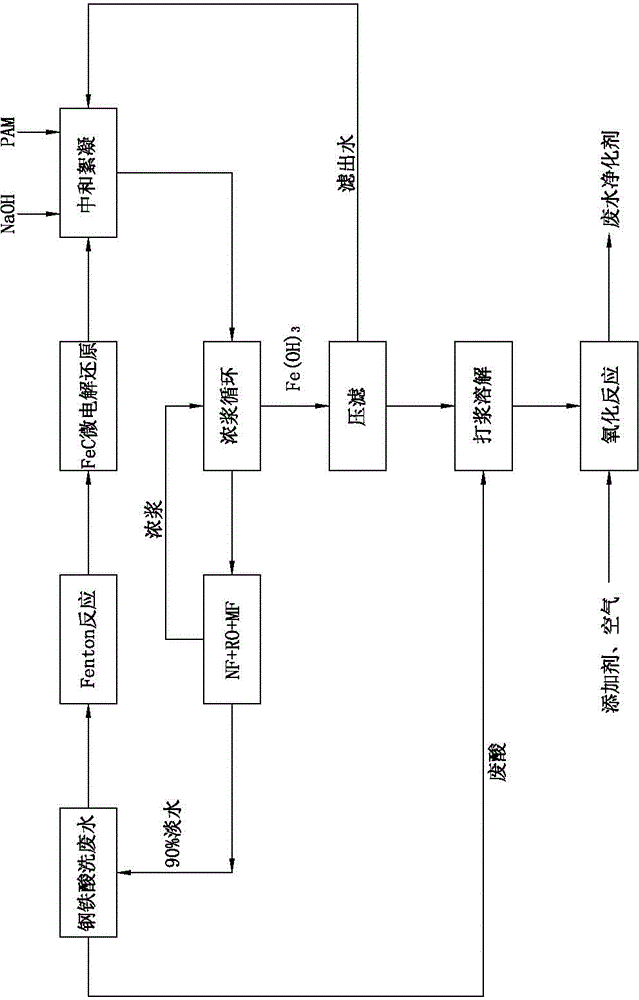

[0062] Such as figure 2 As shown, the difference between the present embodiment and the embodiment 1 is that in the iron and steel pickling wastewater recycling and zero discharge process of the present embodiment, after the step (d) and the flocculation, the step (e) membrane module desalination Before, step (d1) thick slurry circulation is also included; step (d) and flocculated effluent enter step (d1) thick slurry circulation, step (d1) effluent of thick slurry circulation enters step (e) membrane module desalination, step ( e) The thick slurry after the desalination of the membrane module is returned to the thick slurry circulation in step (d1).

[0063] The Fe(OH) produced by step (d1) thick slurry circulation 3 The waste water purifying agent is prepared through filter press, beating, dissolving and oxidation reaction. In the process of beating and dissolving, add steel pickling wastewater; then add additives (such as additives containing rare earth elements) and air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com