Patents

Literature

66results about How to "Production Technology Science" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bridge structural steel plate and producing method thereof

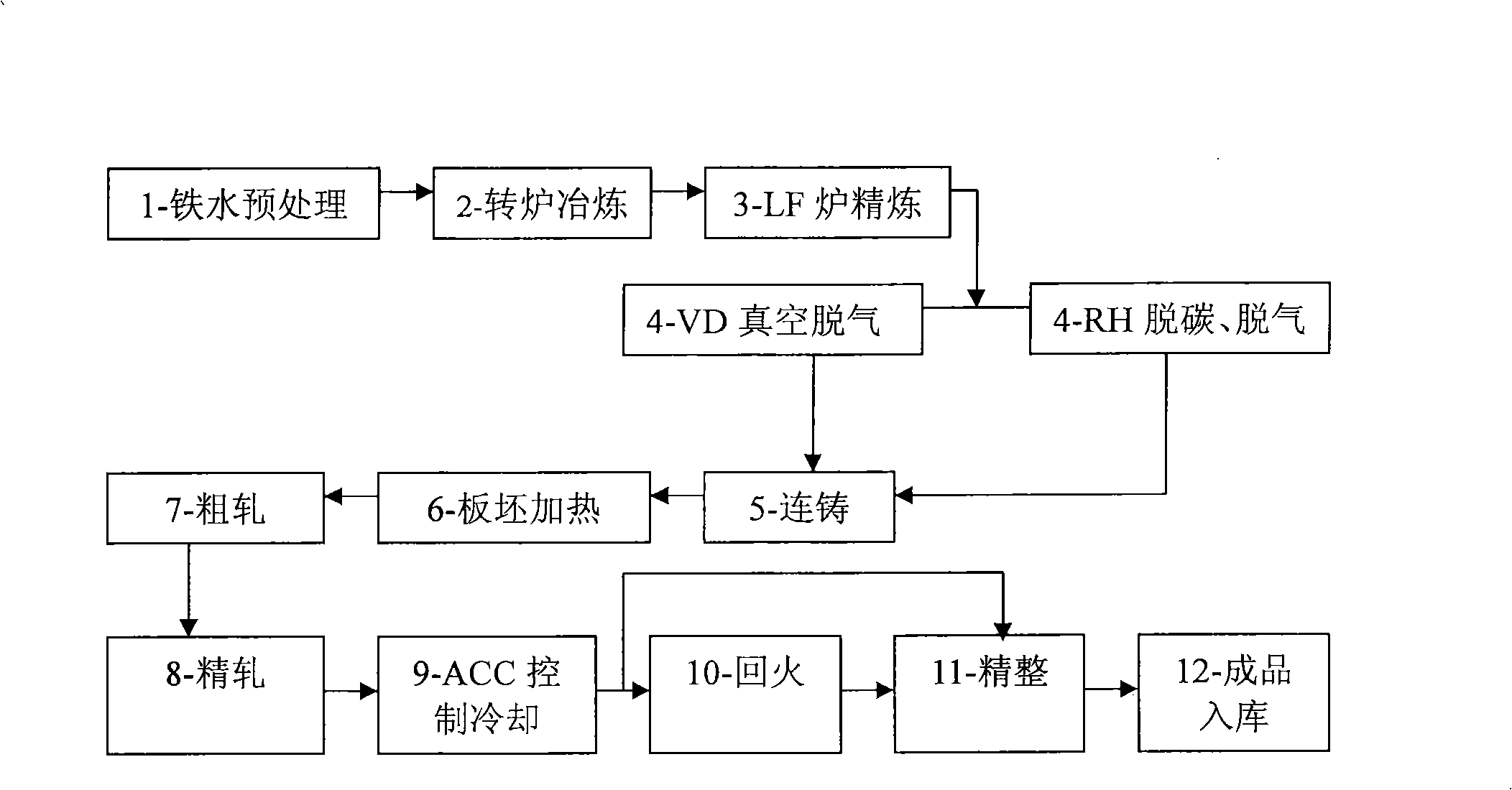

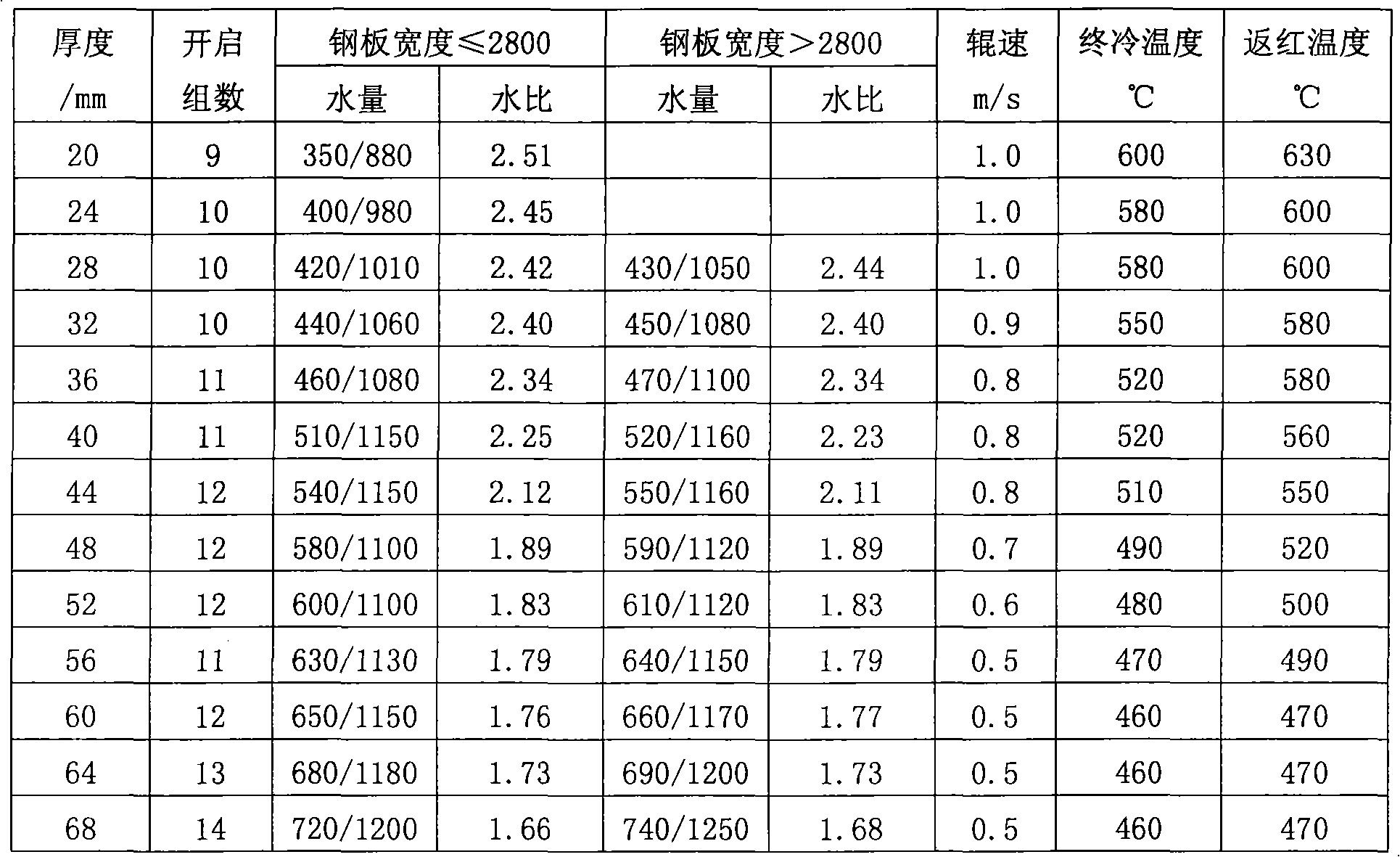

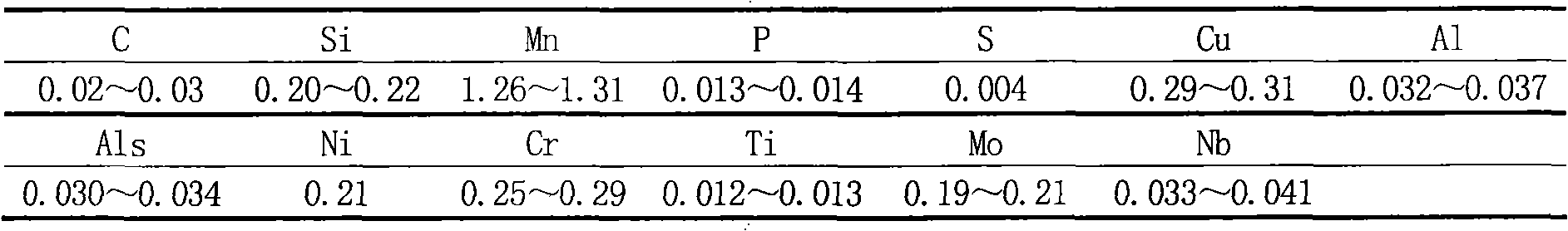

The invention relates to a high performance bridge structure steel plate as well as a production method. The steel comprises the chemical constituents, in weight percent: 0.02 percent to 0.06 percent of carbon, 0.15 to 0.25 percent of silicon, 1.40 percent to 1.60 percent of manganese, phosphorus<=0.02 percent, sulfur<=0.010 percent, 0.025 percent to 0.045 percent of niobium, 0.008 to 0.020 percent of titanium, 0.020 percent to 0.050 percent of aluminum, 0.15 to 0.30 percent of nickel, 0.25 to 0.35 percent of chromium, 0.15 to 0.30 percent of molybdenum, 0.25 to 0.35 percent of copper, nitrogen<=0.005 percent, balance iron. The method has the production processes of: 1. hot metal pretreatment, 2. converter smelting, 3. LF refining, 4. VD vacuum degassing or RH decarburization degassing, 5. continuous casting, 6. slab heating, 7. rough rolling, 8. finish rolling, 9. cooling control by ACC, 10. tempering, 11. finishing, and 12. warehousing to finished products.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Chinese patent medicine for treating diabetes and technique for producing the same

InactiveCN101461887AIncreased sensitivityObvious stable curative effectAnthropod material medical ingredientsMetabolism disorderLiver and kidneyAdditive ingredient

The invention relates to a Chinese traditional patent medicine (the trade name being Rehmanniae Diabetes Capsule) for treating diabetes. The medicine comprises the following raw materials by weight portion: 30 to 60 portions of dwarf lilyturf tuber (also named dwarf lilyturf root), 30 to 60 portions of asparagus root (also named asparagus), 40 to 70 portions of figwort (also named radix scrophulariae), 70 to 150 portions of coptis root, 50 to 100 portions of oriental waterplantain rhizome, 20 to 50 portions of tuckahoe, 70 to 150 portions of cortex lycii radicis, 50 to 100 portions of tragacanth (also named radix astragali), 40 to 100 portions of cornus (also named cornus pulp), 30 to 60 portions of medlar, 50 to 100 portions of dry rehmanniae (also named fresh rehmanniae), 40 to 90 portions of prepared radix rehmanniae (also named prepared rhizome of rehmanniae), 20 to 60 portions of trichosanthin, 30 to 80 portions of panax, 20 to 40 portions of pilose antler and 50 to 100 portions of white muscardine silkworm. The Chinese traditional patent medicine plays a role in enhancing the sensibility of human body against insulin, reducing blood sugar and blood fat, regulating viscera and nourishing liver and kidney; moreover, the Chinese traditional patent medicine has scientific manufacturing process and can extract effective ingredients in raw materials.

Owner:连德峰

Steel for non-magnetic drilling tool and production method thereof

InactiveCN101597721AMeet the use requirementsProduction process economyChemical compositionMetallurgy

The invention discloses steel for non-magnetic drilling tools and a production method thereof. The steel for non-magnetic drilling tools comprises the following chemical compositions in percentage by weight: Fe, less than or equal to 0.06% of C, 17.00-23.00% of Mn, less than or equal to 0.80% of Si, less than or equal to 0.025% of P, less than or equal to 0.015% of S, 12.00-20.00% of Cr, less than or equal to 1.0% of Mo, 0.20-1.20% of N, less than or equal to 2.30% of Ni and less than or equal to 0.025% of Al, wherein, N equivalent weight=Ni+0.6Mn+0.18Cr+9.69(C+N)-0.11SI2 is greater than or equal to 16. Compared with the prior art, the invention provides an economic and scientific production method with stable austenite so as to be subject to use requirement, production cost requirement and the like. The steel for non-magnetic drilling tools of the invention is also suitable for other applicable fields.

Owner:ZHONGYUAN SPECIAL STEEL

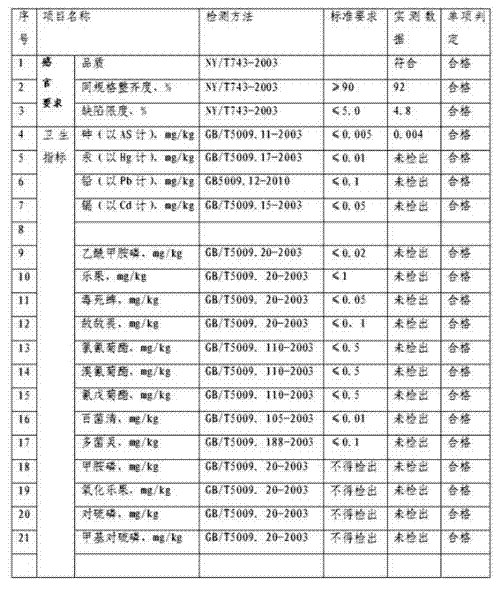

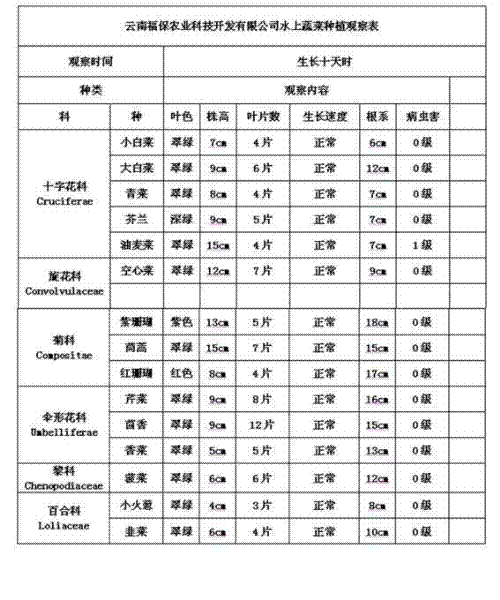

Method for planting vegetables in eutrophic water in floating way

InactiveCN102172144AImprove eutrophic water qualityProduction Technology ScienceCultivating equipmentsSoilless cultivationPhosphatePotassium

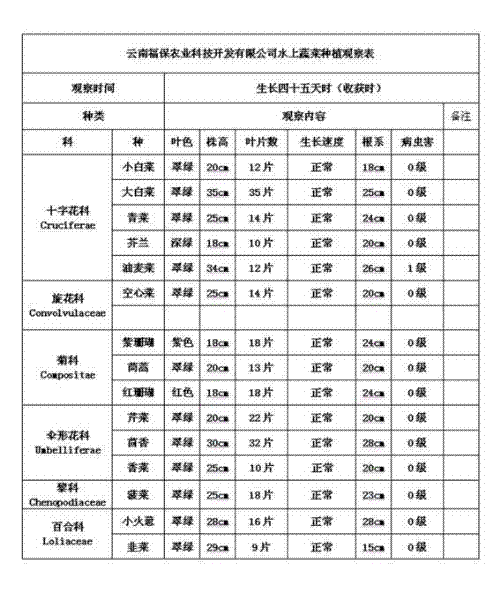

The invention relates to a method for planting vegetables in eutrophic water in a floating way. The method comprises the following steps: selecting a vegetable planting area; (2) detecting the quality of water in the vegetable planting area; (3) tidying the vegetable planting area; (4) selecting the variety of vegetables which are suitable for being planted in different seasons in turns; (5) selecting the variety of vegetables; (6) installing foamed floating vegetable planting beds; (7) preparing a matrix which comprises a component A, a component B and a component C; (8) breeding small vegetable seedlings in a vegetable seedling breeding house; (9) breeding the small vegetable seedlings in a floating way; (10) transplanting the small vegetable seedlings to planting holes of the foamed floating vegetable planting beds, fixing by the matrix, putting the foamed floating vegetable planting beds, in which vegetables are planted, in a selected water area in the vegetable planting area, arranging orderly, leaving working channels and fixing the small vegetable seedlings with rods; (11) managing: when nitrogen, phosphate and potassium in cultivating water are decreased, discharging a part of low-nutrient water and adding eutrophic water so that the nitrogen, phosphate and potassium in the cultivating water are increased; (12) harvesting; and (13) detecting to see whether the vegetables are in line with national related standards. The eutrophic water area is fully utilized to cultivate traditional excellent vegetables popular to people for people, and the eutrophic water quality is also improved effectively. The method adopts the scientific production process and the advanced technology and is a novel method for planting vegetables.

Owner:YUNNAN ZHONGHAI FISHERIES

Wuziyansheng plant teabag and production technology thereof

ActiveCN102793030AImprove sub-health effectNo side effectsPre-extraction tea treatmentBiotechnologyGreen teas

The invention discloses Wuziyansheng plant teabag and a production technology thereof. The Wuziyansheng plant teabag is prepared from the following raw materials in parts by weight: 1,500-2,500 parts of fructus phyllanthi, 1,000-1,100 parts of fructus mori, 1,000-1,100 parts of fructus lycii, 500-700 parts of semen raphani, 400-600 parts of semen cassiae and 3,000-4,000 parts of green tea. The production technology comprises the following steps of: performing water extraction and alcohol precipitation and concentration of the fructus phyllanthi, fructus mori, fructus lycii, semen raphani and semen cassiae to obtain extract, and mixing the extract with the green tea ground into coarse powder; performing wet granulation; and drying and sub-packing to obtain teabag. By utilizing the production technology disclosed by the invention, the produced Wuziyansheng plant teabag can be used for improving sub-health and preventing the toxic side effect, and can be taken for a long term; and the production technology is simple and scientific, and can be used for maintaining the activity of the active ingredients in each component.

Owner:天马(安徽)国药科技股份有限公司

Economic and environment-friendly damping plate with high damping property and preparation method thereof

The invention discloses an economic and environment-friendly damping plate with high damping property. The economic and environment-friendly damping plate with high damping property is prepared from the following raw materials: a polyurethane elastomer, coal ash, mica, hydrogenated C5 petroleum resin, glass fiber, carbon black, an anti-aging agent and an antioxidant in a mass ratio of (200-250):(410-500):(400-475):(40-80):(4-10):(20-100):5:5. The economic and environment-friendly damping plate with high damping property has the advantages that materials are well chosen, waste coal ash is adopted as a functional damping filler, a waste material is changed into things of value, environment-friendly polyurethane is adopted for replacing harmful asphalt, energy conservation, emission reduction and ecological environmental protection are realized, production cost is low, period is short, a production technology is scientific, the economic and environment-friendly damping plate with high damping property is convenient to manufacture, and the product has good damping and soundproof effects, high damping coefficient, strong aging resistance, long service life and wide applicability and is beneficial to large-scale industrial production.

Owner:JIANGSU TONGMENG AUTO PARTS IND CO LTD

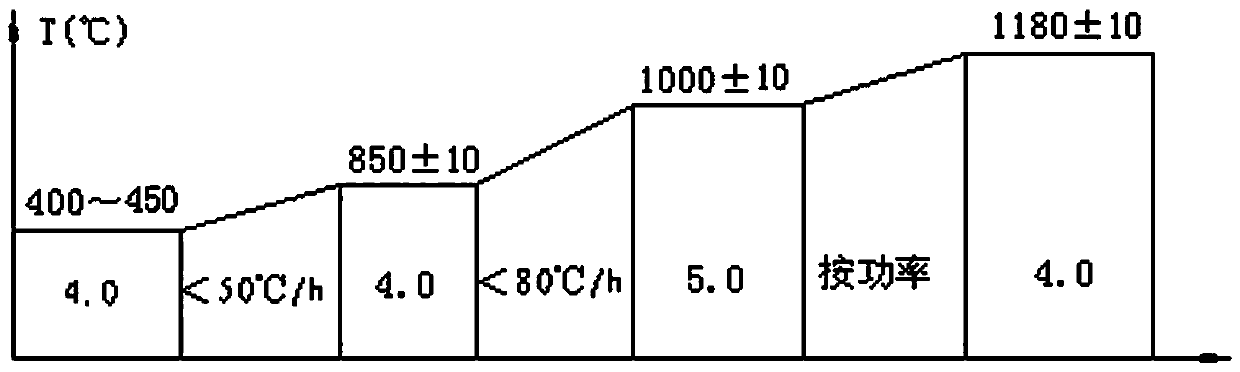

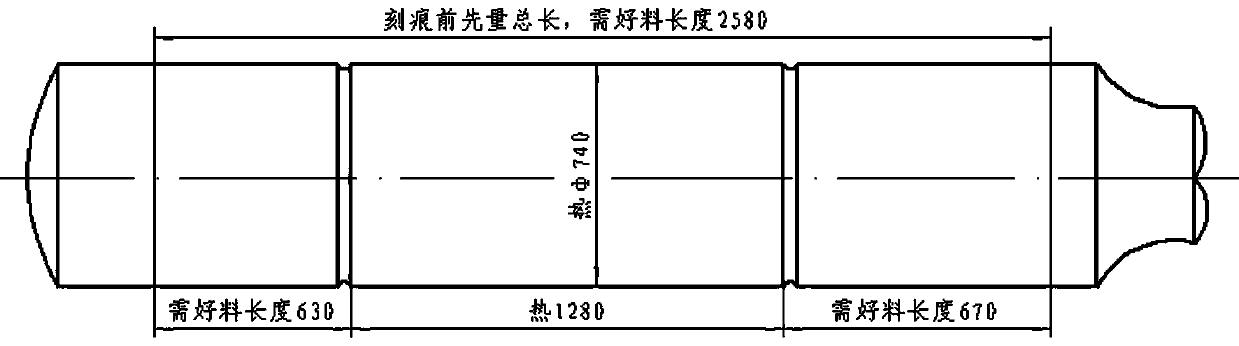

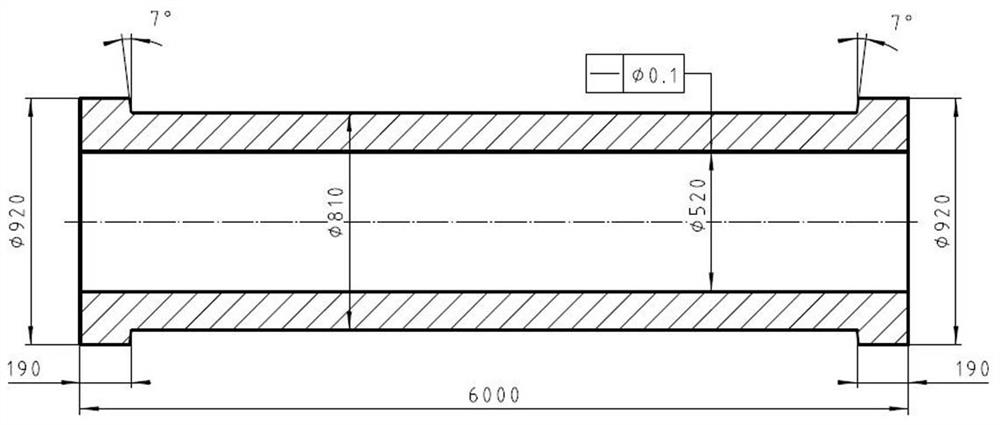

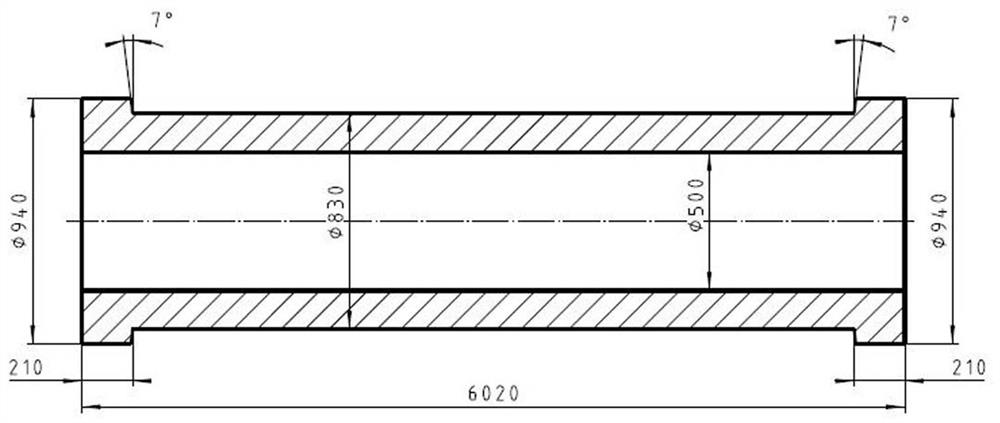

Forging method for large-specification crystallization roller steel forged piece

ActiveCN107617713AImprove forgeabilityImprove toughnessEngine componentsHeating/cooling devicesDeformation controlToughness

The invention relates to a forging method for a large-specification crystallization roller steel forged piece. The forging method comprises the steps that a raw material is fed into a furnace and thensubjected to heat preservation at the temperature of 400-450 DEG C, the temperature is increased to 850+ / -10 DEG C at the rate of no greater than 50 DEG C / h, then preserved, then increased to 1000+ / -10 DEG C at the rate of no greater than 80 DEG C / h, afterwards increased to 1180+ / -10 DEG C and preserved, and the piece is discharged out of the furnace and forged, specifically, the upsetting speedis controlled during forging, the piece is forged on an upper flat anvil being 700 mm wide and a lower V-shaped anvil of 135 degrees while being subjected to drawing deformation, the rolling reductionof the first pass is controlled to be 30-50 mm, the rolling reduction of the second pass is controlled to be 50-80 mm, then main deformation of high rolling reduction is conducted, the rolling reduction of each pass is 120-150 mm, the anvil stagger amount of each pass is at least 50 mm, and forging deformation is in a pulling impact or pushing impact mode; and nicking is conducted after the pieceis drawn to be of a certain dimension, a hammer is changed to perform forging deformation on upper and lower flat anvils being 700 mm wide, pushing impact forging is conducted from the end portion tothe inside, deformation control is conducted in a half anvil feeding mode with small rolling reduction, forging cracking and end surface pits can be avoided, the problems of post-forging coarse grains and unqualified ultrasonic exploration can be solved, and the requirements for texture, strength and toughness after tempering can be met.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

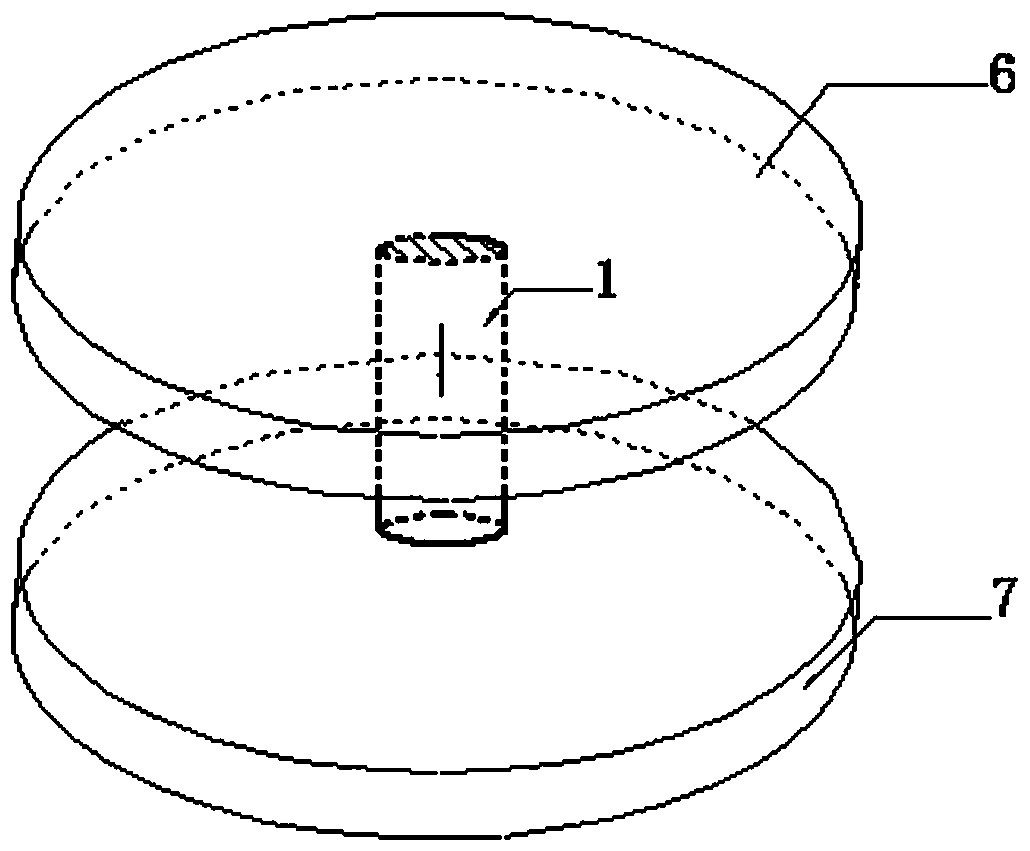

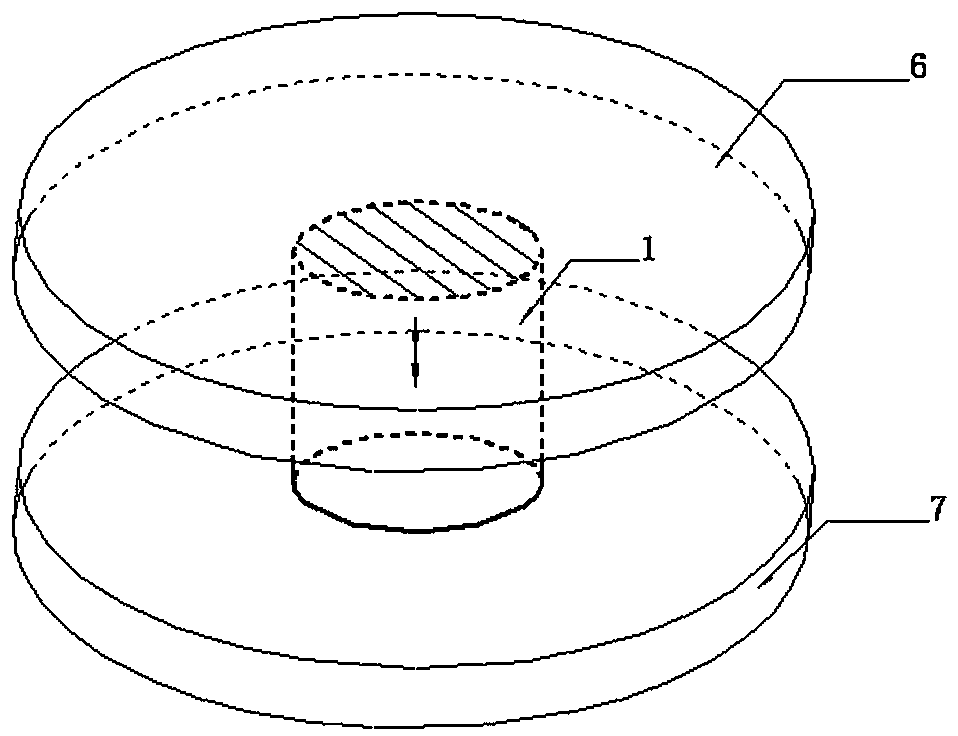

Forging method capable of efficiently, integrally and uniformly compacting deformation

InactiveCN108465762AImprove forgeabilityImprove forging efficiencyMetal-working apparatusIngotDeformation Problem

The invention relates to a forging method capable of efficiently, integrally and uniformly compacting deformation, and the forging method can uniformly refine compacting deformation and the structureof a large forged piece product. The forging method is characterized in that special upper and lower wide plates are adopted for upsetting and forging a forged piece, so that forging main deformationis completed; then, finishing forming is performed on upper and lower anvils; a special wide plate is utilized for integrally forging, so that forging permeability is greatly improved, and the problemthat forging deformation is uneven at positions such as each hammer head, and a joint of the hammer heads during upper and lower anvil forging is also overcome, and therefore, the inner part of the forged piece is forged thoroughly and compacted, and a uniform fine grain structure is obtained; upset electroslag ingots are mainly deformed on upper and lower wide plates, and integral once formationis performed until design dimensions at every pass in a wide plate forging process, and reduction is controlled to be 25%-40%; the electroslag ingots are integrally forged until deformed to the designed dimensions between upper and lower flat plates after being turned over by 90 degrees, and 700mm-wide upper and lower nails are adopted for forging and forming so as to conveniently erecting angles, so that the uneven forging deformation problem of the hammer head during main deformation is avoided, forging permeability is improved, anvil replacing times are reduced, forging time is saved by about 1 / 2, forging production efficiency is improved, production cost is reduced, and product quality stability is high.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

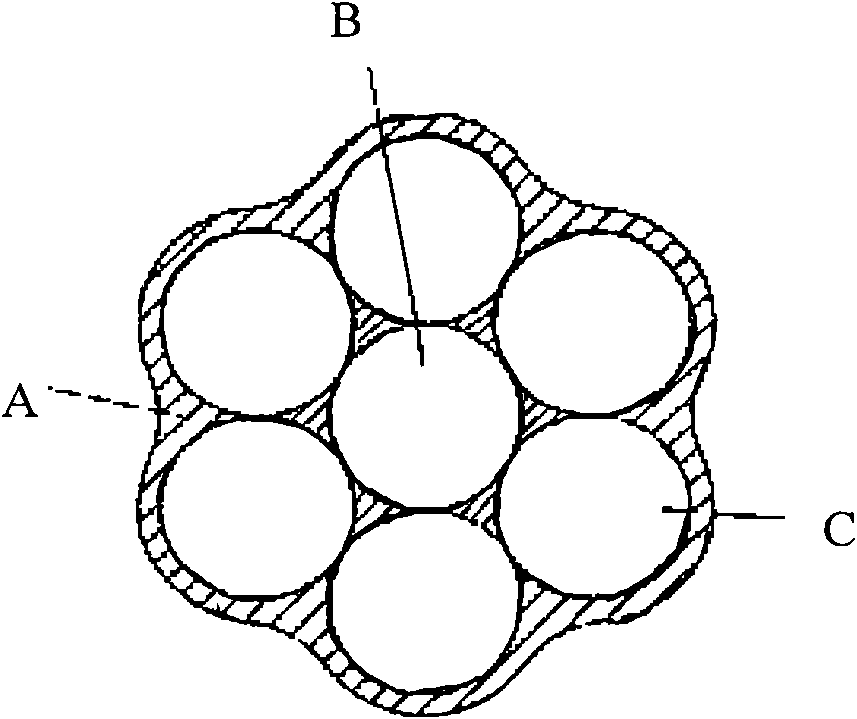

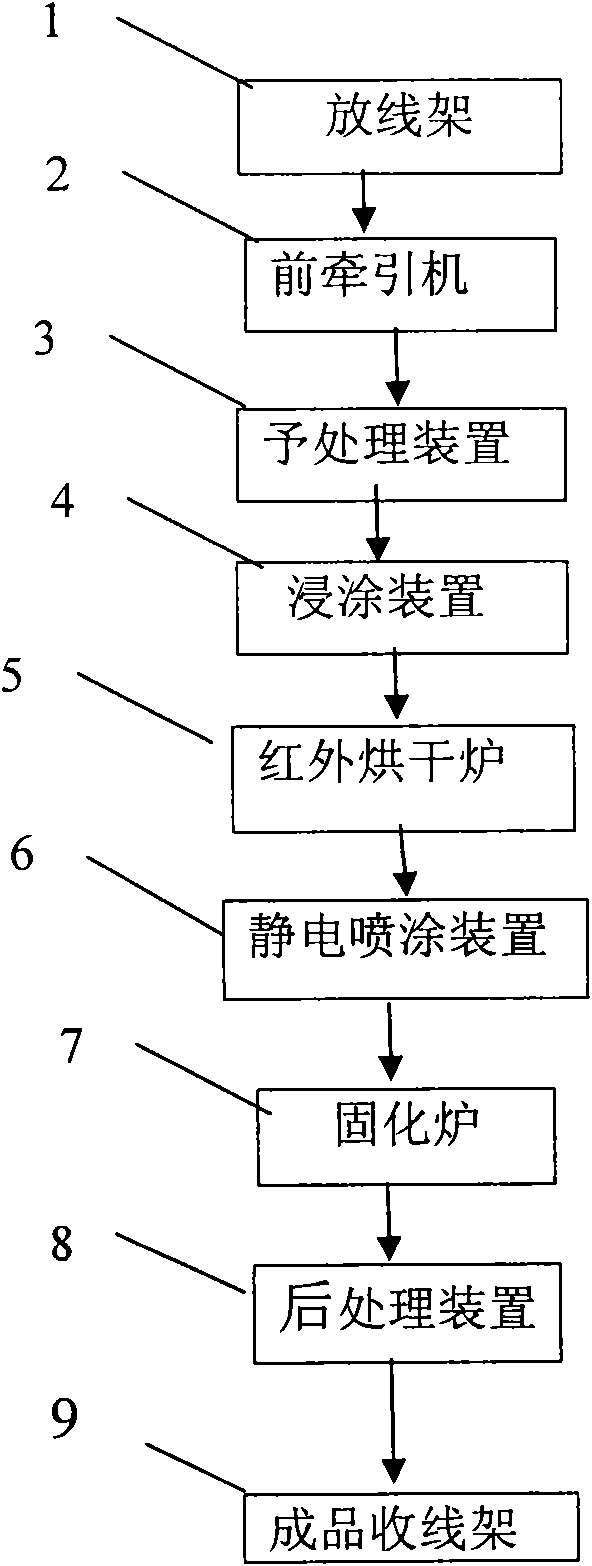

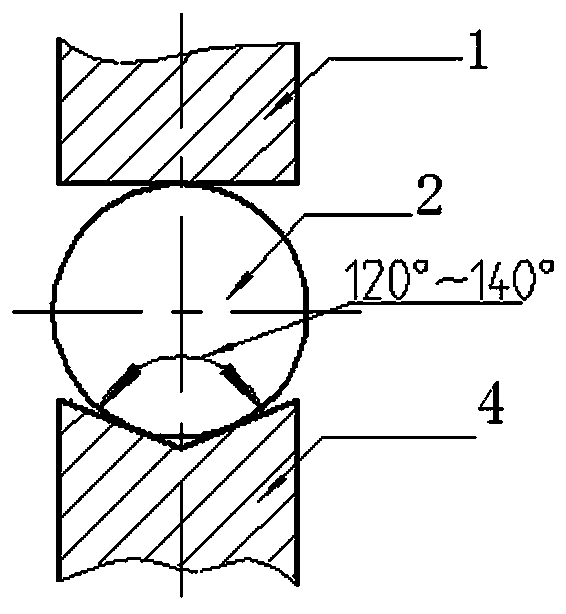

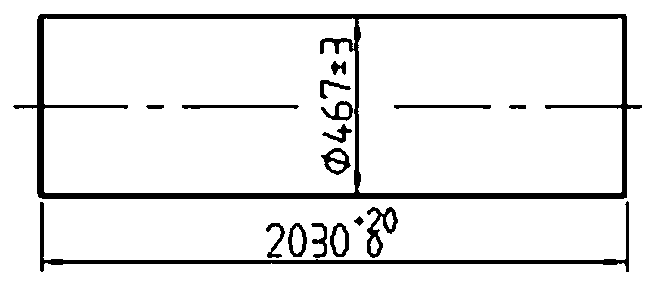

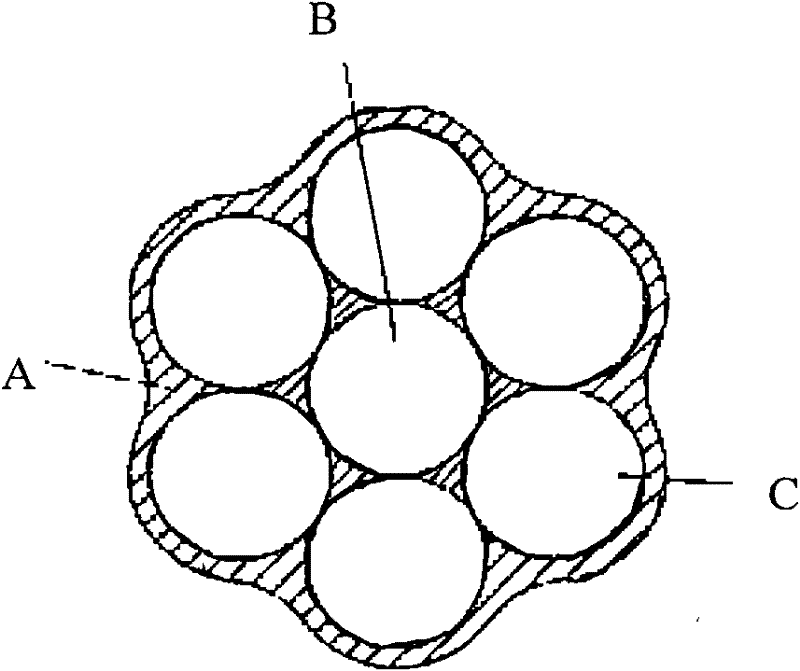

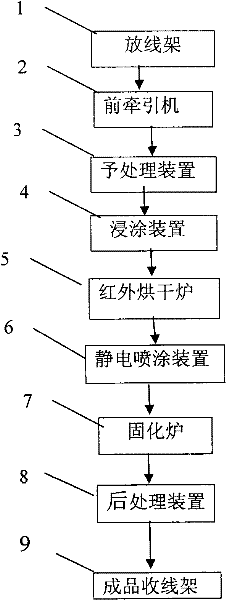

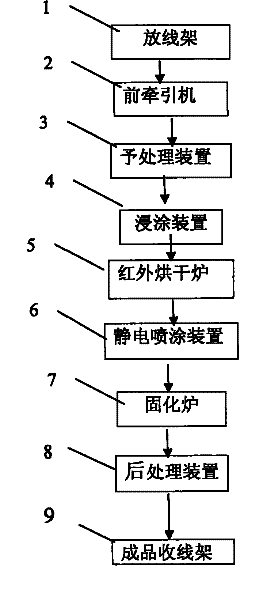

Process for producing filled prestress steel strand of epoxy coating

InactiveCN101671968AGuaranteed mechanical propertiesChemical resistantPretreated surfacesRope making machinesAfter treatmentPre stress

The invention provides a process for producing filled prestress steel strand of an epoxy coating, comprising the following steps: pretreatment process; dip coating process by a chemical precipitationmethod; pre-drying process; spraying process by an electrostatic method; post-drying and curing process; and after-treatment process. The invention has the effects: a layer of epoxy coating is filledand coated inside and outside the common prestress steel strand by adopting the production process so that the steel strand becomes the epoxy-coating filled prestress steel strand. The process coatingmethod does not adopt processes of expanding the steel strand by a device to spray steel wires, then repeatedly twisting again and closing into the steel strand, therefore, the epoxy-coating filled prestress steel strand constructed and produced by the process not only keeps the mechanical property of the original prestress steel strand, but also has due chemical resistance property of the epoxycoating steel strand, and strict, scientific and environment-friendly production process.

Owner:TIANJIN JINBOFA METAL PRODS

Environment-friendly type multifunctional nano modified coating and spraying method thereof

InactiveCN104745025AImprove stabilityImprove sustainabilityLiquid surface applicatorsCoatingsAcrylic resinUltraviolet

The invention relates to environment-friendly type multifunctional nano modified coating and a spraying method thereof, which are used for solving the problems that the existing coating is high in cost and not resistant to ageing. The environment-friendly type multifunctional nano modified coating is prepared from the following components in parts by weight: 50-200 parts of nano titanium dioxide particle slurry, 30-100 parts of an acrylic resin finishing agent, 5-30 parts of a dispersing agent, 10-50 parts of a thickening agent, 5-10 parts of a de-foaming agent and an appropriate amount of water, wherein the nano titanium dioxide particles in the nano titanium dioxide particle slurry are surface-modified anatase titanium dioxide particles with a photocatalysis function and particle diameters of 10nm-50nm. Airflow atomized spraying of the compressed air is as follows: atomizing a paint liquid into mists by virtue of air flow of the compressed air, spraying the mists to the surface of an object, and forming a thin and uniform paint film on the surface of the sprayed object. Such special functions as super-hydrophobicity, ultraviolet ray resistance, bacteria resistance, self-cleaning, air purifying and the like are achieved without affecting the original color and patterns of the substrate, the functionality and the stability of the special functions are still relatively strong after long-term illuminating or multi-time washing, the cost is low, and the ageing resistance is excellent.

Owner:赵杰

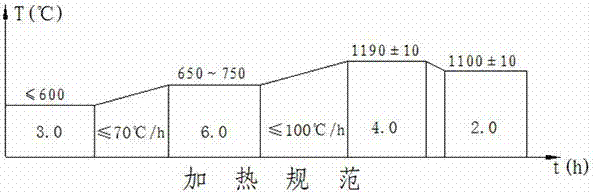

Forging process for steel forging piece for 2Cr11Mo1VNbN steam turbine blade

InactiveCN106903246AImprove toughnessImprove forgeabilityForging press drivesEngine componentsSteam turbine bladeIngot

The invention relates to a forging process for a steel forging piece for a 2Cr11Mo1VNbN steam turbine blade. The forging process comprises the following steps of: during heating before forging, controlling a charging temperature to not exceed 600 DEG C, controlling a low-temperature temperature rise rate to not exceed 70 DEG C / h, preserving heat for 6-8 hours at a temperature of 650-750 DEG C, and heating to 1190 + / -10 DEG C at temperature rising speed not exceeding 100 DEG C / h, cooling to 1100 + / - 10 DEG C after preserving the heat for 4-6 hours at a temperature of 1190 + / -10 DEG C, and tapping and forging after preserving the heat for 2-4 hours; during forging, adopting a A-B-clamping-jaw transverse pulling forging mode or a pushing forging mode through a precision forging machine, clamping the tail end of an ingot after loading, and enabling a dead head end to face towards a chuck B. In order to overcome the defects that a steel structure, produced in the prior art, for the 2Cr11Mo1VNbN steam turbine blade is high in sigma-ferrite content, is extremely liable to crack during forging, and is severely affected in strength and toughness, the invention provides the forging process for the steel forging piece for the 2Cr11Mo1VNbN steam turbine blade, and the forging process solves the cracking problem of the steel forging piece for the 2Cr11Mo1VNbN steam turbine blade, meets the strength and toughness requirements, reduces machining allowance and improves production efficiency.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

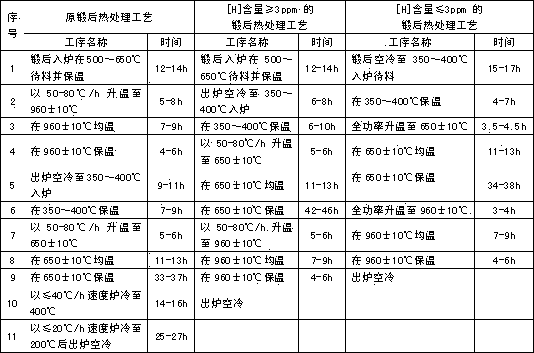

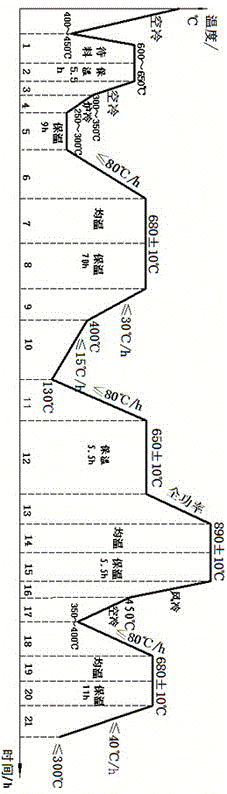

Process for heat treatment of 12Cr1MoVG high pressure tubes after forging

ActiveCN104017976AProduction process economyProduction Technology ScienceFurnace typesHeat treatment furnacesRate limitingHydrogen

The invention relates to a process for heat treatment of 12Cr1MoVG high pressure tubes after forging. After vacuum degassing, [H] contents are detected by online hydrogen determination, so that processes for heat treatment of the 12Cr1MoVG high pressure tubes after forging for are respectively formulated against two conditions that [H] is greater than or equal to 3ppm and [H] is less than 3ppm; a process of hydrogen diffusion and then normalizing is adopted for the 12Cr1MoVG high pressure tube of which [H] content is greater than or equal to 3ppm detected by online hydrogen determination, a rate-limiting cooling stage in the original process is cancelled, the hydrogen diffusion time at 650 DEG C is appropriately prolonged, and temperature rise is directly carried out after hydrogen diffusion is ended so as to carry out normalizing, and the workpiece is hoisted down from a lathe after normalizing and is then subjected to air cooling, so that the annealing time is greatly shortened; after vacuum degassing, except for optimizing according to above process, as for the 12Cr1MoVG high pressure tube of which [H] content is less than or equal to 3ppm detected by online hydrogen determination, a heat insulation stage at 500-650 DEGC as well as hydrogen diffusion annealing and normalizing temperature rise rate limiting stages are not required, and thus the annealing process peroid is further shortened. The invention discloses the process for heat treatment of the 12Cr1MoVG high pressure tubes after forging, which has the advantages that the production peroid is effectively shortened, the productivity of high pressure tubes after forging is increased and the normalizing effect is improved.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

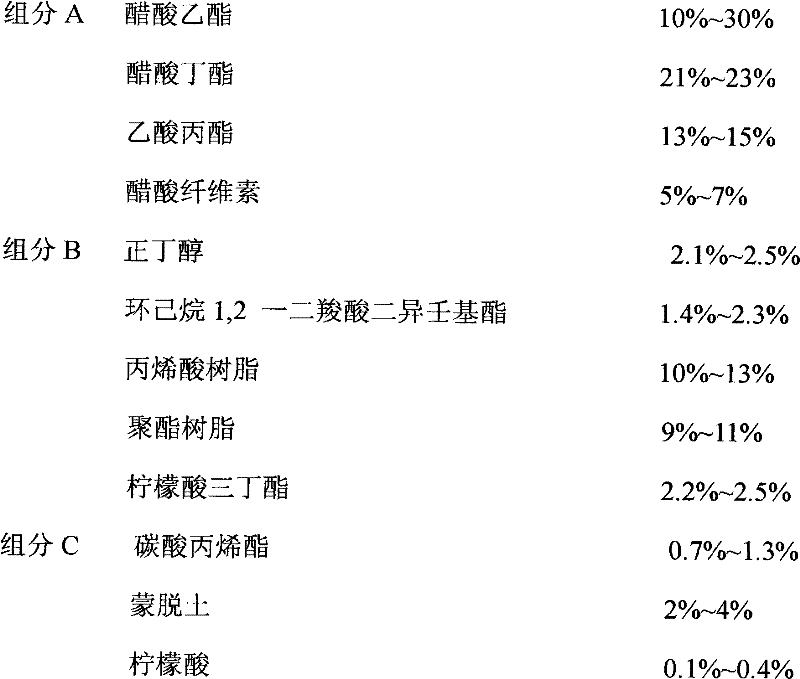

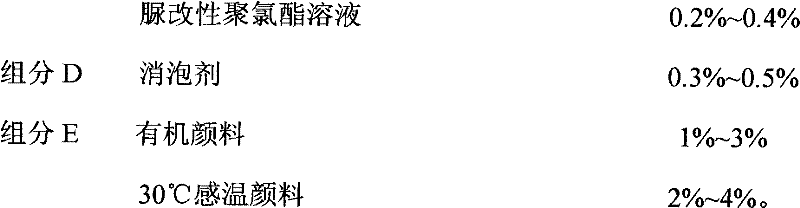

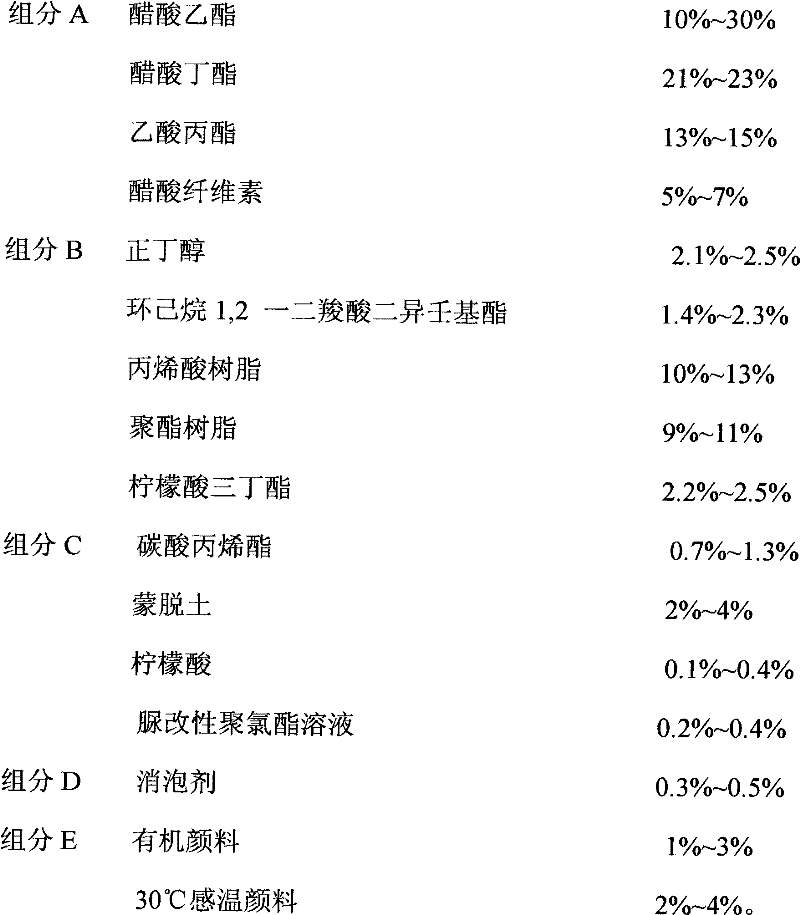

Preparation method for nail polish changing with temperature and nail polish changing with temperature

InactiveCN102512331AMatching scienceRaise the ratioCosmetic preparationsToilet preparationsNail colourMechanical engineering

The invention discloses a preparation method for a nail polish changing with temperature, comprising the following steps of: preparing a component A, a component B, a component C, a component D and a component E, mixing the component A with the component B, and uniformly stirring with a high speed to form a first mixture; adding the component C in the first mixture, uniformly stirring with a high speed, and grinding via a sand grinder to form a second mixture having a grain diameter of 2-3 microns; adding the component D in the second mixture, performing slow stirring and defoaming treatment, and aging for 48 hours at a normal temperature after the defoaming treatment is finished, so as to form a third mixture; taking 70% of the third mixture, performing colour matching with the component E, and uniformly stirring to form a fourth mixture; and mixing and uniformly stirring the remainder third mixture with the fourth mixture, and aging for 48 hours at the normal temperature to form the nail polish changing with temperature. A nail polish changing with temperature is further disclosed, wherein the colour of the nail polish changes when an external temperature is higher than or lower than 30 DEG C.

Owner:袁永欢

Preparation method of hawthorn yogurt

The invention discloses a preparation method of hawthorn yogurt, and belongs to the technical field of yogurt manufacturing method. The hawthorn yogurt is prepared from 70 to 85% of fresh milk, 7 to 15% of hawthorn fruit particle, 3 to 6% of white granulated sugar, and 2 to 4% of a leavening agent. The preparation method comprises steps such raw material pretreatment, blending, homogenizing, inoculating, fermentation, cooling, and after ripening. The hawthorn yogurt is delicious, is abundant in nutrients, is suitable for people of all ages, and possesses healthcare functions.

Owner:郭心仪

Heat insulation coating and production process thereof

The invention relates to a heat insulation coating and a production process thereof. Raw materials for the heat insulation coating comprise, by weight, 80 to 200 parts of organic hollow microspheres, 50 to 125 parts of alumina silicate, 50 to 135 parts of siliceous lime, 2 to 6 parts of a thickening agent, 1 part to 10 parts of an antifoaming agent, 1 part to 10 parts of a dispersant, 8 to 35 parts of glycol, 3 to 10 parts of a wetting agent, 180 to 500 parts of latex paint emulsion and 100 to 350 parts of water. The heat insulation coating provided in the invention is composed of the organic hollow microspheres suspended in inert latex; microstructure of the microspheres is favorable for reflection and scattering of infrared ray, and the microspheres are enclosed hollow balls, having a low coefficient of heat conductivity; the addition of the microspheres into the coating enables considerable microscopic independent heat insulation cavities to be formed, thereby substantially improving heat insulation of a film.

Owner:DALIAN JINZHOU JINHE CHEM BUILDING MATERIALS FACTORY

Method for processing aroma-enhanced Long-xu gynostemma pentaphylla

The invention relates to a method for processing aroma-enhanced Long-xu gynostemma pentaphylla. The method is characterized by comprising the following steps: (a) treating raw materials; (b) performing green-removing treatment; (c) cooling; (d) baking and drying; (e) enhancing aroma; (f) extracting the aroma; (g) screening. The normal apple juice is prepared by crushing and squeezing apples, and filtering and refrigerating the apple juice for later use. The method has the positive effects that 1, the herbal flavor of the common gynostemma pentaphylla tea is avoided, the taste of the gynostemma pentaphylla tea is improved, deep development of sweet gynostemma pentaphylla products is promoted, and the consumer needs are met; 2, the consumer market of the sweet gynostemma pentaphylla is extended, the production of sweet gynostemma pentaphylla raw materials is promoted, and adjustment of industrial structure in rural areas is pushed; 3, the process is suitable for mechanical production, high in effect and stable in quality; 4, the market price of the products in batch production exceeds 6000 yuan per kg, and the product is accepted by consumers of all ages and both sexes and has good development prospects.

Owner:湖北仙芝堂生物科技有限公司

Superfine particle zinc oxide powder production technology

InactiveCN106115765ASimple production processProduction Technology ScienceZinc compounds preparationZinc oxides/hydroxidesZincOxide

The invention discloses a superfine particle zinc oxide powder production technology. The production technology comprises the following steps of 1 leaching, 2 oxidation treating, 3 filtering, 4 replacing and 5 extracting and grinding. The zinc oxide production technology is simple, therefore, energy consumption is low, and the production cost is reduced; the production technology is more scientific, and by adding the replacing step, the prepared zinc oxide product is higher in purity; through grinding treatment of grinding equipment, the diameters of particles of zinc oxide are smaller, the sizes of the particles of zinc oxide are more uniform, and therefore the using range of zinc oxide produced through the scheme is wider.

Owner:安徽省含山县锦华氧化锌厂

Health care type preserved collagen and production process thereof

InactiveCN103393132AWith calcium supplementHas a collagen-replenishing effectFood preparationBiotechnologyCarrageenan

The invention discloses health care type preserved collagen and a production process thereof. The health care type preserved collagen is prepared from the following raw material components in parts by weight: 600-800 parts of emulsified pigskin, 30-50 parts of bone calcium, 200-300 parts of konjac powder, 100-200 parts of carrageenan, 300-400 parts of potato starch, 20-30 parts of cucumber seed powder, 20-30 parts of sodium alginate, 2000-3000 parts of white granulated sugar, 200-300 parts of xylitol and 200-300 parts of sorbitol. Materials such as emulsified pigskin and puffed konjac powder are mixed, alkalization sizing and cleaning are carried out so as to process crisp collagen, and boiling and dipping with a cane sugar solution substituted by partial sugar alcohol, baking and packaging are carried out, so that the preserved collagen is obtained. The produced health care type preserved collagen has the effects of replenishing calcium and replenishing collagen, has no toxic or side effect, can be eaten for a long time, is simple and scientific in production process and maintains activity of active ingredients in each component.

Owner:ANHUI SHENHUA MEAT PROD

Method for manufacturing power cables

InactiveCN103137266AProduction Technology ScienceProduction process economyCable/conductor manufactureCross-linkProduct inspection

The invention relates to a method for manufacturing power cables. The method comprises the steps of wire drawing, softening, stranded wire pressing, cross-linking three-layer co-extrusion, copper strip three-layer wrapping, cabling, distance sleeve extrusion, sheath installation, sheath extruding and printing or installed sheath spark testing, finished product inspection and packaging. The method for manufacturing power cables has the advantages that produced power cables are ensured to be safe and reliable, and a production process is scientific and economic.

Owner:SHANGHAI PEOPLE ELECTRICAL APPLIANCE GROUP

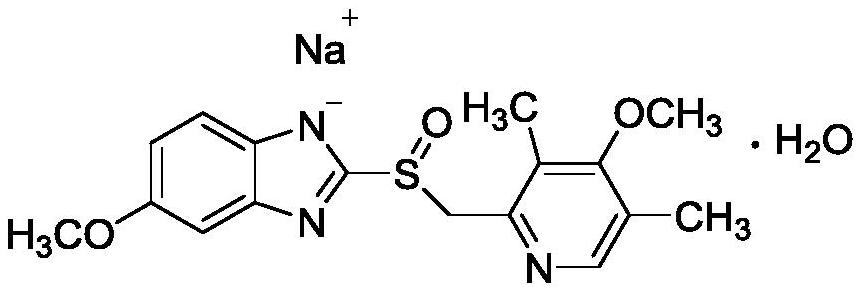

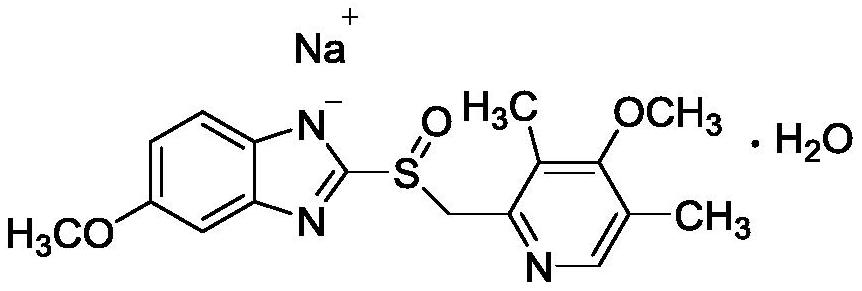

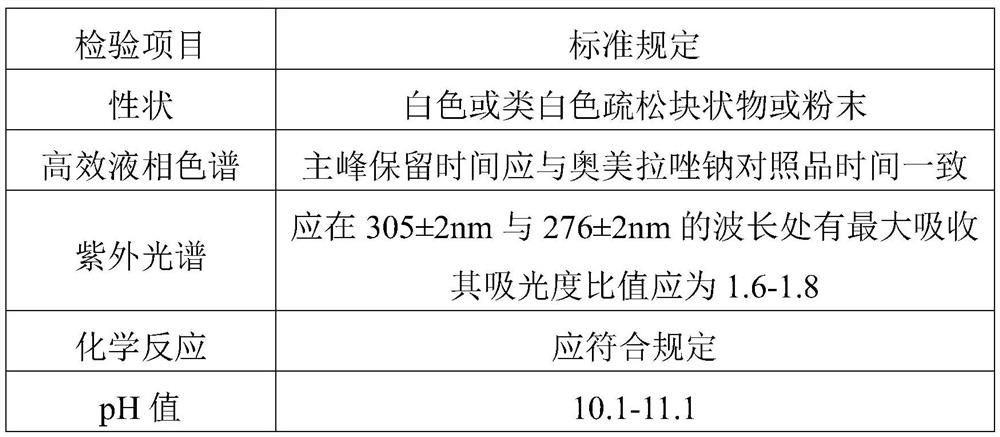

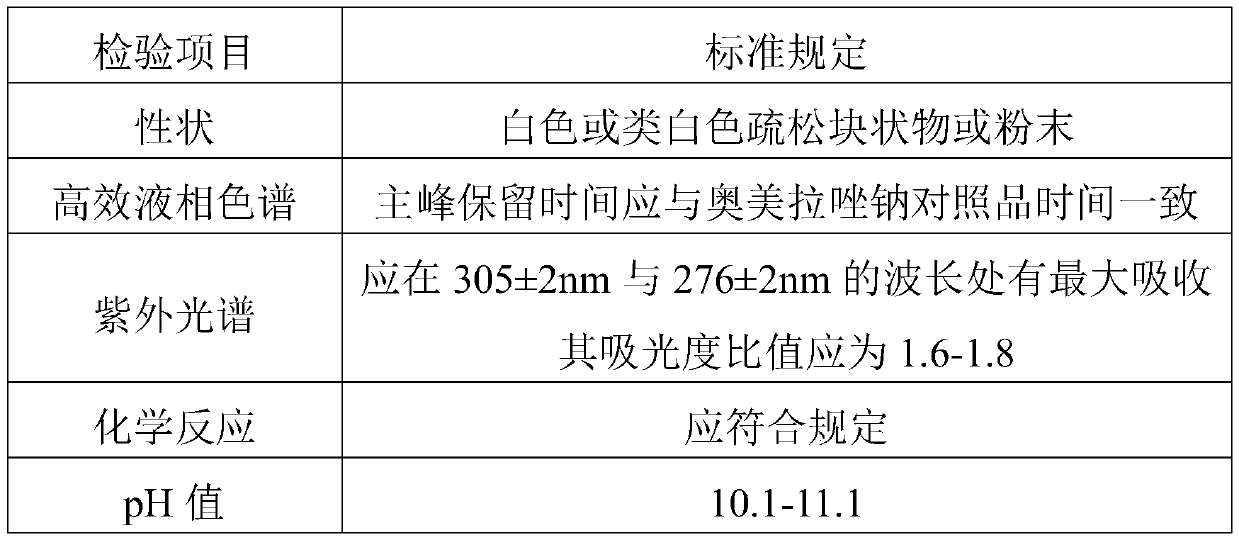

The preparation method of omeprazole sodium for injection

ActiveCN109984998BEasy to prepareEfficient production processOrganic active ingredientsDigestive systemOmeprazole SodiumDisease

The invention provides omeprazole sodium for injection, a preparation method and application of the omeprazole sodium for prevention of aspiration pneumonitis caused by regurgitation of gastric juicein the adaptation disease and belongs to the field of medical preparations. The raw materials of the omeprazole sodium for injection comprise omeprazole sodium, ethylenediamine tetraacetic acid disodium salt and water for injection. The preparation method comprises the steps that the ethylenediamine tetraacetic acid disodium salt and the omeprazole sodium are added to the water for injection in sequence, the pH value of an aqueous solution of sodium hydroxide is adjusted, activated carbon is added for adsorption and heat source removal, remaining water for injection is added, the activated carbon is filtered out and removed or a super membrane is adopted for filtering and removing a heat source, and a semi-finished product is obtained; the content and pH value of the semi-finished productare detected, after the standard is achieved through inspection, sterilization and filtering, quantitative filling and freezing and drying are conducted, and a freeze-dried product is obtained; the freeze-dried product is compressed and subjected to capping, finished product inspection, label attachment and packaging are conducted, and the finished product is obtained. The invention further discloses application of the omeprazole sodium for injection for prevention of aspiration pneumonitis caused by regurgitation of gastric juice for a patient with general anesthesia or a patient with asthenia and coma after surgery in the adaptation disease.

Owner:SHANDONG HEXING PHARMA

Omeprazole sodium for injection, preparation method and application of omeprazole sodium for prevention of aspiration pneumonitis caused by regurgitation of gastric juice in adaptation disease

ActiveCN109984998APrevent Aspiration PneumoniaEasy to prepareOrganic active ingredientsDigestive systemEthylenediamineOmeprazole Sodium

The invention provides omeprazole sodium for injection, a preparation method and application of the omeprazole sodium for prevention of aspiration pneumonitis caused by regurgitation of gastric juicein the adaptation disease and belongs to the field of medical preparations. The raw materials of the omeprazole sodium for injection comprise omeprazole sodium, ethylenediamine tetraacetic acid disodium salt and water for injection. The preparation method comprises the steps that the ethylenediamine tetraacetic acid disodium salt and the omeprazole sodium are added to the water for injection in sequence, the pH value of an aqueous solution of sodium hydroxide is adjusted, activated carbon is added for adsorption and heat source removal, remaining water for injection is added, the activated carbon is filtered out and removed or a super membrane is adopted for filtering and removing a heat source, and a semi-finished product is obtained; the content and pH value of the semi-finished productare detected, after the standard is achieved through inspection, sterilization and filtering, quantitative filling and freezing and drying are conducted, and a freeze-dried product is obtained; the freeze-dried product is compressed and subjected to capping, finished product inspection, label attachment and packaging are conducted, and the finished product is obtained. The invention further discloses application of the omeprazole sodium for injection for prevention of aspiration pneumonitis caused by regurgitation of gastric juice for a patient with general anesthesia or a patient with asthenia and coma after surgery in the adaptation disease.

Owner:SHANDONG HEXING PHARMA

Forging control method for uniformly refining grain sizes of forgings

ActiveCN110684885ASolve the coarse grainSolve the mixed crystal problemMixed crystalIndustrial engineering

The invention relates to a forging control method for uniformly refining grain sizes of forgings. Special forging control and furnace return heating modes are adopted in the forging process of large forgings, so that the surface and heart temperatures of the forgings tend to be consistent, the heart structures of the forgings are totally transformed, and the internal structures of the large forgings are uniformly refined; the before-forging high-temperature heating is adopted; after first heating number upsetting and lengthening forging, the forgings are cooled in air to reach a certain temperature; after the internal and external surface temperatures of the forgings tend to be consistent, the forgings are returned to the high-temperature furnace for heating; after second heating number upsetting and lengthening, the forgings are cooled in air to reach a certain temperature; after the internal and external surface temperatures of the forgings tend to be consistent, the forgings are returned to the low-temperature furnace for heating; the forgings are discharged from the furnace for forging after insulation in the low-temperature furnace by a period of time; and the forging controlmethod can uniformly refine the internal structures of the large forgings under the condition of not increasing the production cost, solves the difficulties of coarse crystals and mixed crystals of the large forgings, greatly reduces the production cost, shortens the production period, and is high in mechanical performance index of the forgings, long in service life and more economical and scientific in production process.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

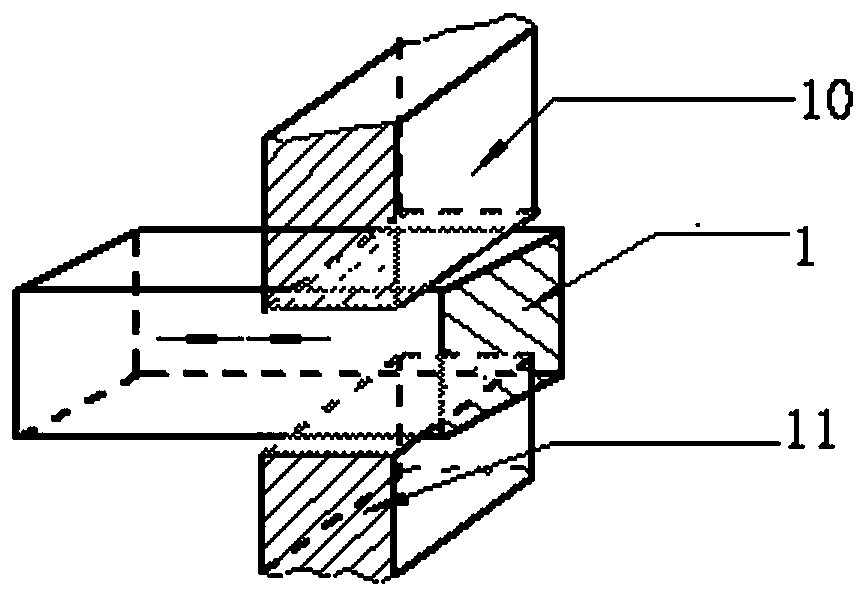

Forging method capable of avoiding general looseness of hollow part forged through continuous casting blank with small deformation amount

InactiveCN108723268AReduce manufacturing costLoose Conformity GuaranteeForging/hammering/pressing machinesStressed stateMetal

The invention relates to a forging method capable of avoiding general looseness of a hollow part forged through a continuous casting blank with small deformation amount. Under the insufficient deformation amount, special upper flat and lower V anvil forging is adopted to replace upper and lower flat anvil forging, the stress state of the blank and the flowing direction of metal are changed, the metal deforming characteristics are changed, and the outer layer metal deforming amount is increased; the continuous casting blank is heated and then fed into an oil press machine, the oil press machineadopts an upper flat and lower V anvil for forging, a precision forging machine is adopted for forging forming, after forging, annealing, inspection, ultrasonic flaw detection and discharging are carried out, through the forging method, general looseness of hollow part products like a corrugated roller produced by the continuous casting blank is avoided, production efficiency is improved, comprehensive production cost is reduced, and the product quality stability is high.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Process for producing filled prestress steel strand of epoxy coating

InactiveCN101671968BGuaranteed mechanical propertiesChemical resistantPretreated surfacesRope making machinesAfter treatmentPre stress

The invention provides a process for producing filled prestress steel strand of an epoxy coating, comprising the following steps: pretreatment process; dip coating process by a chemical precipitation method; pre-drying process; spraying process by an electrostatic method; post-drying and curing process; and after-treatment process. The invention has the effects: a layer of epoxy coating is filledand coated inside and outside the common prestress steel strand by adopting the production process so that the steel strand becomes the epoxy-coating filled prestress steel strand. The process coating method does not adopt processes of expanding the steel strand by a device to spray steel wires, then repeatedly twisting again and closing into the steel strand, therefore, the epoxy-coating filled prestress steel strand constructed and produced by the process not only keeps the mechanical property of the original prestress steel strand, but also has due chemical resistance property of the epoxycoating steel strand, and strict, scientific and environment-friendly production process.

Owner:TIANJIN JINBOFA METAL PRODS

Multifunctional coating and productive technology thereof

InactiveCN102391748AIncrease reflectionEasy to scatterAntifouling/underwater paintsPaints with biocidesInfraredPolymer science

The invention relates to a multifunctional coating and a productive technology thereof. The multifunctional coating comprises the following raw material in parts by weight: 50-190 parts of hollow borsal microspheres, 44-125 parts of aluminium silicate, 44-135 parts of siliceous lime, 2-5 parts of thickening agent, 1-10 parts of deforming agent, 1-7 parts of dispersing agent, 8-35 parts of ethylene glycol, 3-10 parts of wetting agent, 180-450 parts of latex paint emulsion and 100-350 parts of water. The multifunctional coating is formed by the hollow borsal microspheres suspended in inertia latex; the microstructures of the microspheres are beneficial to the reflection and scattering of infrared rays; in addition, the microspheres of the invention are hollow closed spheres and have very low coefficient of heat conductivity; the microspheres added to the coating can form a number of independent microscopic heat insulation cavities, thereby greatly increasing the thermal insulation of a paint film; and meanwhile, the multifunctional coating of the invention can supply enough negative ions to ensure indoor air to be good and simultaneously has very good anti-bacterium effect.

Owner:DALIAN JINZHOU JINHE CHEM BUILDING MATERIALS FACTORY

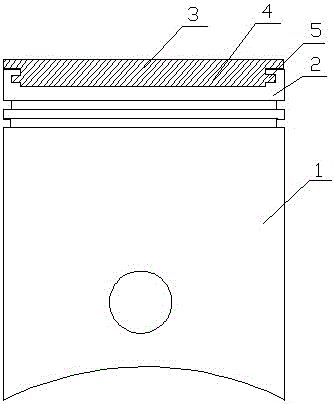

Preparation method for wear-resisting layer embedded at top of diesel engine piston

InactiveCN105863869AProduction Technology ScienceEasy to makeMachines/enginesPistonsCorrosion resistantSilicon nitride

The invention relates to a preparation method for a wear-resisting layer embedded at the top of a diesel engine piston. The preparation method is characterized in that kaolin is adopted as the main raw material, and raw materials such as nanometer zirconium oxide and silicon nitride are added; the production technology is scientific; the manufacturing is convenient; the production cycle is short; the production cost is low; the method is eco-friendly and environment-friendly; the wear-resisting layer at the top of the piston can effectively preventing the influence of high temperature of a combustion chamber on a copper nickel magnesium aluminum alloy piston body; the coefficient of thermal expansion is close to zero; the wear-resisting layer does not absorb water; the insulating property is good; the structure is compact and uniform; the impact resistance and corrosion resistance are good; the compressive strength is high; the shrinkage rate is small; the wear-resisting layer is high temperature resistant and wear resisting, and does not crack; the Mohs hardness of the wear-resisting layer reaches 8.2; the service life is long; the comprehensive performance is excellent; and large-batch industrial production is facilitated.

Owner:JIANGSU TAIPU POWER MACHINERY

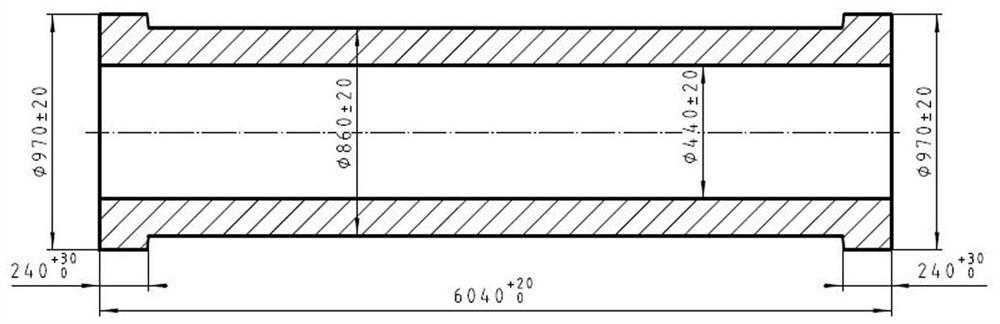

Method for manufacturing wind tunnel ultrahigh-pressure pipe fitting through high-nickel alloy structural steel

ActiveCN114055092ASolve the problem of easy stress deformationSolve wear resistanceProcess efficiency improvementElectric arc furnaceTempering

The invention relates to a method for manufacturing a wind tunnel ultrahigh-pressure pipe fitting through high-nickel alloy structural steel. The method comprises the following steps: smelting by using an electric arc furnace, refining in vacuum, remelting electroslag, forging and forming by using a 5000-ton oil press after heating, annealing after forging, rough machining, double normalizing and tempering, quenching, double tempering, semi-finishing and destressing tempering, finishing to the size of a finished product, laser surface quenching of a connecting contact surface, and checking. The problems of poor performance, coarse grains and unqualified finished product bending can be effectively solved.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

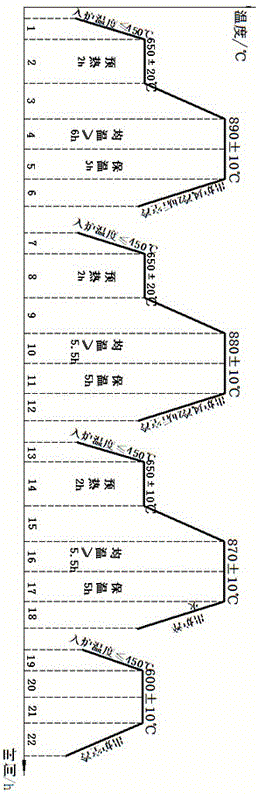

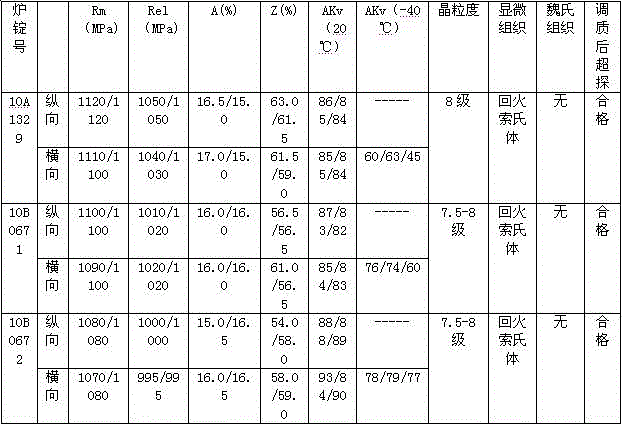

A processing method for grain refinement of crnimov high pressure steel forgings

ActiveCN103981347BHigh low temperature impact toughnessFine grain sizeProcess efficiency improvementTemperature controlChemical composition

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Composition of Yaowan mung bean distilled liquor and manufacturing process thereof

InactiveCN101619283AProduction Technology ScienceScientifically and rationally develop strengths and avoid weaknessesAlcoholic beverage preparationFruit wineSugar

The invention relates to a composition of Yaowan mung bean distilled liquor and a manufacturing process thereof. The mung bean distilled liquor is prepared and blended by Daqu distilled liquor, traditional Chinese medicine juice and rock sugar, wherein the high-quality Daqu distilled liquor is 62-65 degrees and accounts for 56.56 percent; the traditional Chinese medicine juice accounts for 34.29 percent; the rock sugar accounts for 9.15 percent; and the blending ratio accuracies of the Daqu distilled liquo, the traditional Chinese medicine juice and the rock sugar respectively are plus or minus 0.5 percent. The composition of the Yaowan mung bean distilled liquor and the manufacturing process thereof scientifically and reasonably maximize favorable factors and minimize unfavorable ones on the basis of the traditional prescription to better adapt to different modern crowds and have the advantages of wine, fruit wine and tonic wine, therefore, the Yaowan mung bean distilled liquor is more mellow, fragrant and sweet, restorative and pure, and the production process thereof is more reasonable and scientific.

Owner:颜西广

High-strength coke

InactiveCN105623696AProduction Technology ScienceQuality passCoke ovensCoalUltimate tensile strength

The invention relates to the technical field of chemical materials and concretely relates to high-strength coke. The high-strength coke comprises, by weight, 11-22% of 1 / 3 coking coal, 5-10% of ash, 40-60% of coking coal, 0.5-0.7% of sulfur, 10-15% of lean coal, 15-23% of fat coal and 20-25% of a volatile ingredient. The high-strength coke can be produced through a scientific process and has qualified quality.

Owner:王刚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com