Forging method capable of efficiently, integrally and uniformly compacting deformation

An overall and uniform technology, applied in the field of forging, to achieve the effect of reducing production cost, saving production time and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

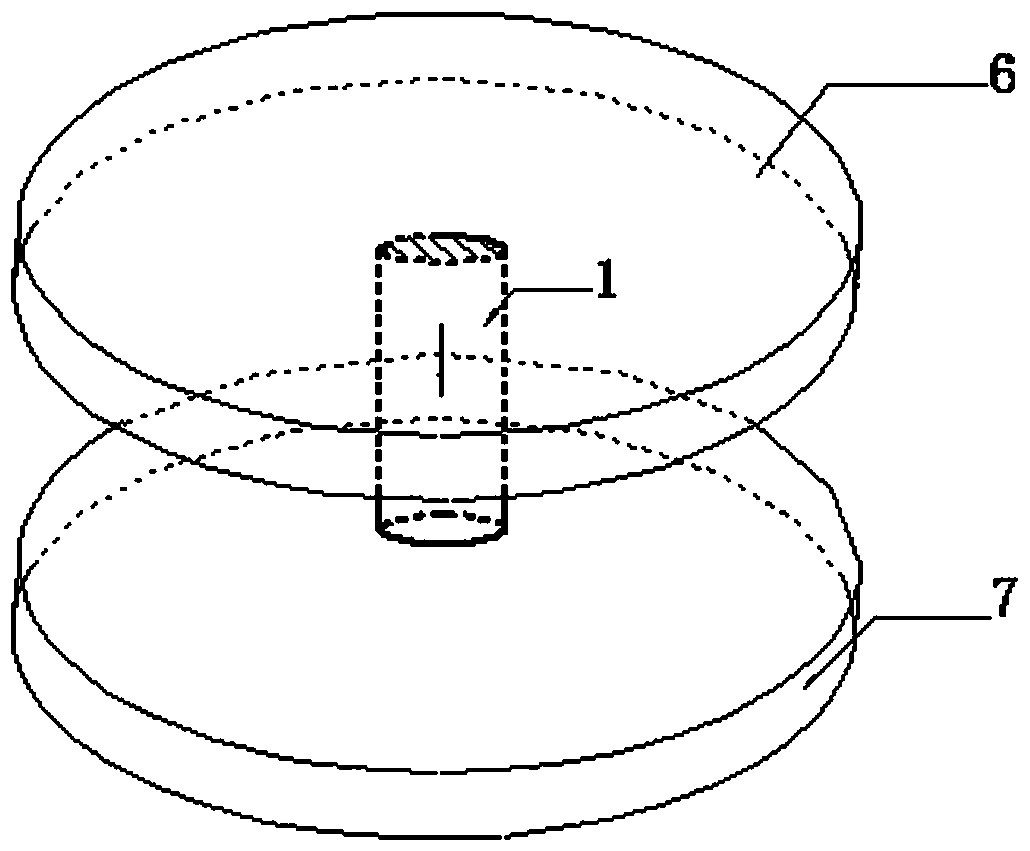

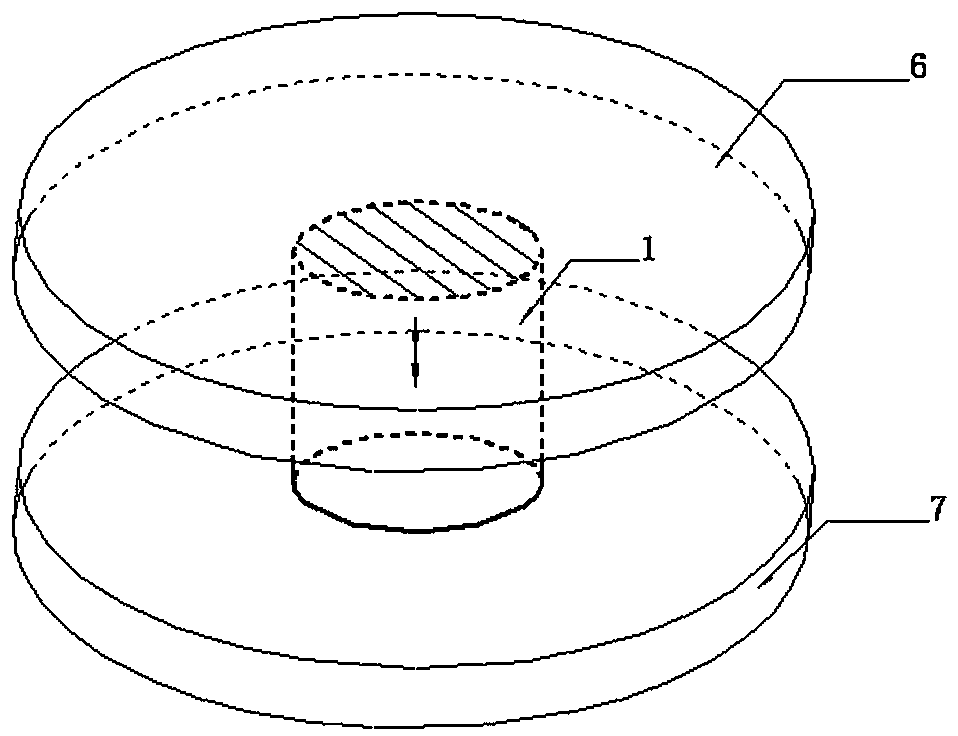

[0025] like figure 2 As shown, in the main deformation forging method of the hydraulic press of the present invention, the double arrows in the figure indicate the fiber direction, that is, the axial direction; the section line of the blank 1 indicates the tail end of the ingot, and the following figures are the same.

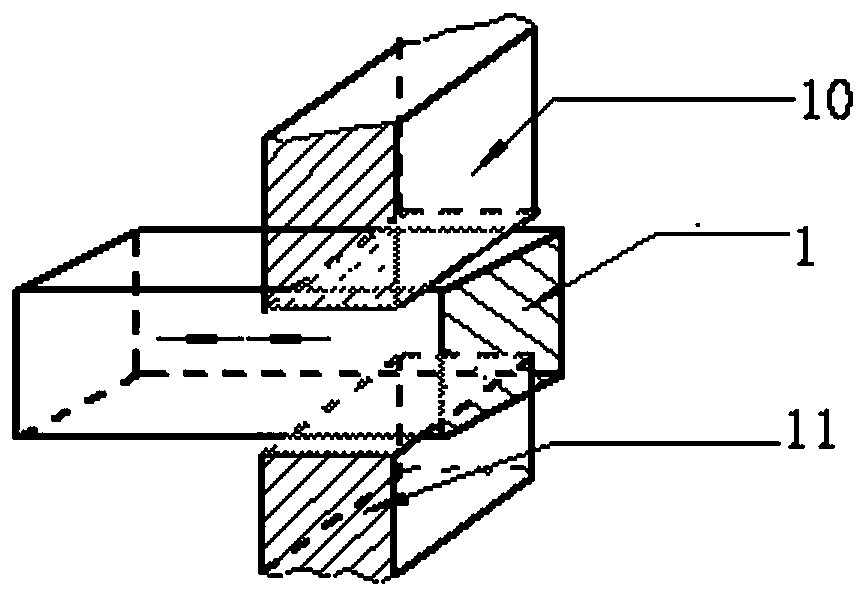

[0026] The implementation of the technical solution of the present invention mainly lies in the design of forging tools, tooling and deformation solutions. According to the size of the forging produced, during forging, the upper and lower wide flat plates (that is, the upper flat plate 4 and the lower flat plate 5) are used for upsetting and main deformation of the blank 1. After forging, post-forging annealing, straightening, inspection, ultrasonic flaw detection, sawing and cutting, etc., and finally machining, quenching and tempering treatment, etc.

[0027] The forging size of the upper and lower wide flat plates here refers to the plate width b of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com