Method for improving yield of TC17 titanium alloy rods

A technology of TC17 and titanium alloy, which is applied in the field of forging technology, can solve the problems of forging temperature sensitivity, surface quality, yield effect, and high requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

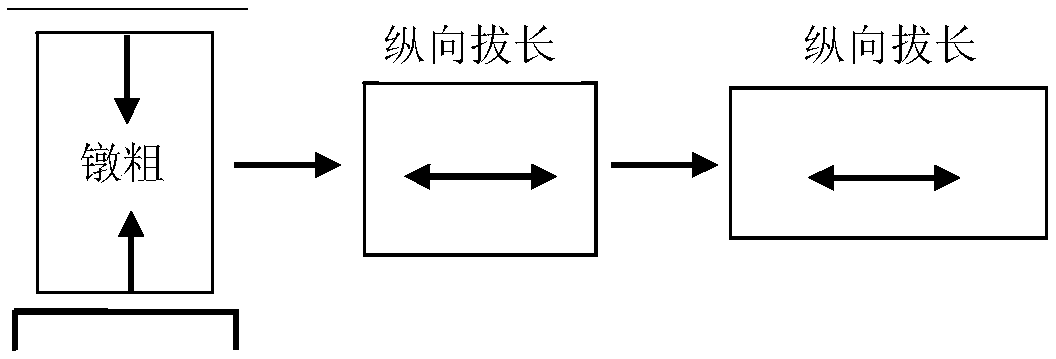

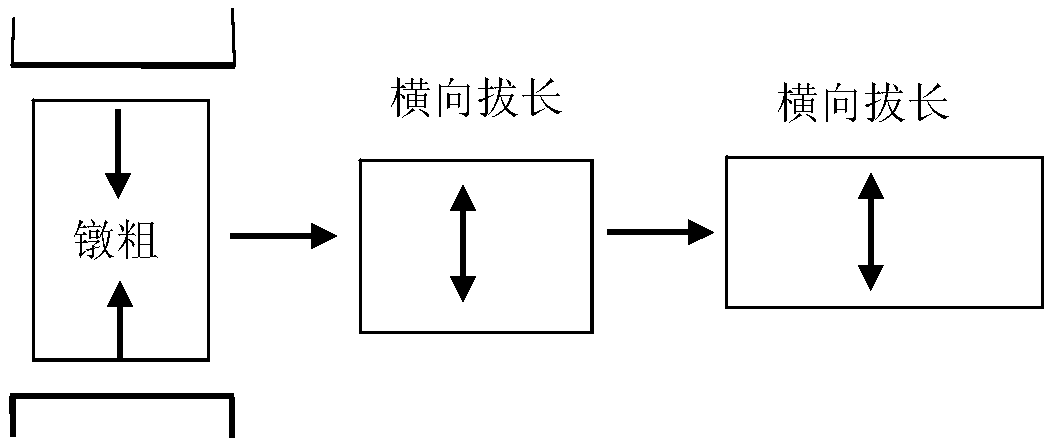

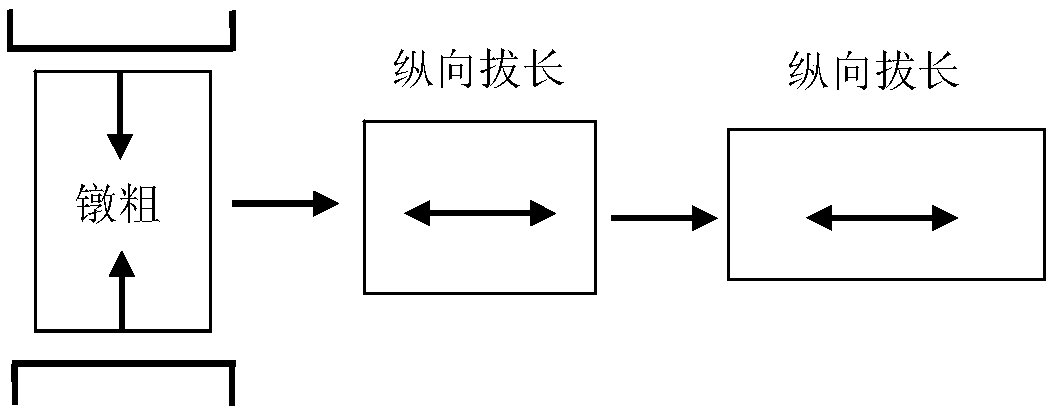

[0047] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0048]The embodiment of the present invention uses blank 650 octagonal * 1400mm as raw material.

[0049] 1) Before production, the first thing to ensure is the uniformity of the heating furnace temperature, and prepare the required insulation cotton and glue. Before the steel ingot is loaded into the furnace, the iron oxide scale in the furnace is cleaned. The purpose is to make the billet heating temperature uniform. Time can be loaded;

[0050] 2) Heating, after the heating furnace is heated to 100℃±10℃, the steel ingot is put into the furnace, and the coating is applied after holding the heat for 0.5 hours. ℃ steel ingot into the furnace, uniformly heated for 6 hours and held for 2 hours, and then released to 850℃±10℃, the middle part of the steel ingot is wrapped with thermal insulation cotton, and after wrapping, it is returned to the furnace for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com