Steel, carburized steel component, and method for manufacturing carburized steel component

a carburized steel and component technology, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of high cost of cutting related to the cost of manufacturing carburized steel components, increased contact pressure on forming tools, and disadvantageous cutting, etc., to achieve excellent cold forgeability, high critical compression ratio, and small deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

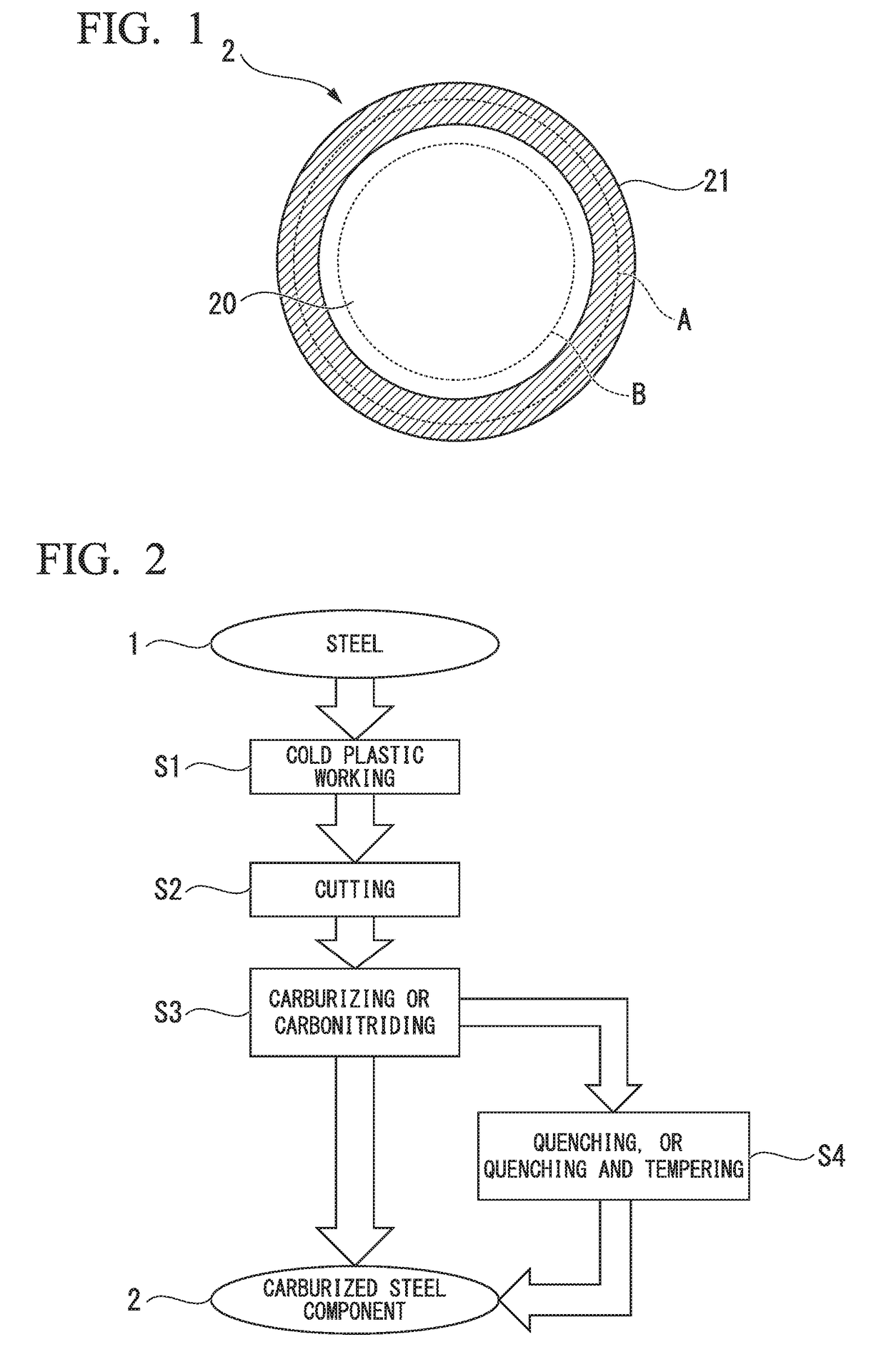

Image

Examples

example 1

[0162]Steels a to aa having the chemical compositions shown in Table 1A and Table 1B were melted and made into ingots using a converter (270 ton), continuous casting was executed using a continuous casting machine, and slabs of 220×220 mm square were manufactured. Here, super-heating of a molten steel inside a tundish was set to 30° C., and the casting speed was set to 1.0 m / min.

[0163]In continuous casting of the slabs, the average cooling rate within the temperature range from the liquidus temperature to the solidus temperature at a position in the depth of 15 mm from a surface of a slab was controlled by changing the quantity of cooling water of a mold. In this manner, slabs a to aa which had the chemical compositions shown in Table 1A and Table 1B were continuously cast. In slab o, slab p, and slab q, the primary arm spacing of dendrite within the range of 15 mm from the surface layer was 600 μm or longer. In other slabs, the primary arm spacing of dendrite within the range of 15...

example 2

[0208]Under the same manufacturing conditions as the steel a and the steel g except for the average cooling rate (hereinafter, will be referred to as the “average cooling rate”) within the temperature range from the liquidus temperature to the solidus temperature at a position in the depth of 15 mm from a surface of the slab, steels for carburizing having the same chemical composition as that of the steel a or the steel g were manufactured, and various evaluations were carried out with respect to these steels for carburizing by the same method as that of the steel a and the steel g. The average cooling rates followed the values shown in Table 3.

TABLE 3Evaluation result of steel for carburizingCriticalAverageHardnesscompressionPresenceDistanceWear amount ofcooling(Hv)ratio (%)densitybetweenflank (mm)TestrateBefore SAAfter SABefore SAAfter SAof sulfideSulfidesBefore SANo.Steel(° C. / min)processprocessprocessprocess(pieces / mm2)(μm)process1a3001191056869 349 23.6 0.121-2a5501151056970* ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com