Process for heat treatment of 12Cr1MoVG high pressure tubes after forging

A post-forging heat treatment and high-pressure tube technology, which is applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as poor normalizing effect and affect the progress of mass production of products, achieve fast heating speed, improve product qualification rate, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

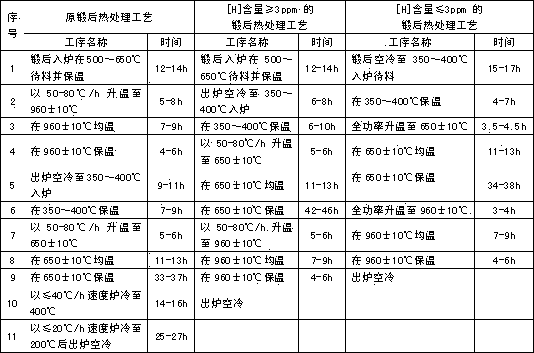

Image

Examples

Embodiment 1

[0060] A post-forging heat treatment process for 12Cr1MoVG high-pressure pipes, the selected steel type is 12Cr1MoVG, C=0.08~0.15%, Si=0.17~0.37%, Mn=0.40~0.70%, Cr=0.90~1.20%, Mo=0.25~0.35% , V=0.15~0.30%, S≤0.010%, P≤0.025%, high-pressure pipe with a specification of φ455mm, after vacuum degassing, online hydrogen determination [H] content, [H]≥3ppm, 12Cr1MoVG high-pressure pipe after forging The steps of the heat treatment process are as follows:

[0061] Step S01: put the forged 12Cr1MoVG high-pressure tube into an annealing furnace at 500°C and keep it warm for 14 hours;

[0062] Step S02: After the heat preservation is completed, the 12Cr1MoVG high-pressure tube is taken out of the furnace and air-cooled until the surface temperature is 350-400°C;

[0063] Step S03: heat the 12Cr1MoVG high-pressure tube after entering the furnace at 350° C. for 10 hours;

[0064] Step S04: put the 12Cr1MoVG high-pressure tube after heat preservation for 10 hours into hydrogen expansion...

Embodiment 2

[0068] A post-forging heat treatment process for 12Cr1MoVG high-pressure pipes, the selected steel type is 12Cr1MoVG, C=0.08~0.15%, Si=0.17~0.37%, Mn=0.40~0.70%, Cr=0.90~1.20%, Mo=0.25~0.35% , V=0.15~0.30%, S≤0.010%, P≤0.025%, high-pressure pipe with a specification of φ455mm, after vacuum degassing, online hydrogen determination [H] content, [H]≥3ppm, 12Cr1MoVG high-pressure pipe after forging The steps of the heat treatment process are as follows:

[0069] Step S01: put the forged 12Cr1MoVG high-pressure tube into an annealing furnace at 575°C and keep it warm for 13 hours;

[0070] Step S02: After the heat preservation is completed, the 12Cr1MoVG high-pressure tube is taken out of the furnace and air-cooled until the surface temperature is 350-400°C;

[0071] Step S03: heat the 12Cr1MoVG high-pressure tube after entering the furnace at 375° C. for 8 hours;

[0072] Step S04: put the 12Cr1MoVG high-pressure tube after heat preservation for 8 hours into hydrogen expansion a...

Embodiment 3

[0076] A post-forging heat treatment process for 12Cr1MoVG high-pressure pipes, the selected steel type is 12Cr1MoVG, C=0.08~0.15%, Si=0.17~0.37%, Mn=0.40~0.70%, Cr=0.90~1.20%, Mo=0.25~0.35% , V=0.15~0.30%, S≤0.010%, P≤0.025%, high-pressure pipe with a specification of φ455mm, after vacuum degassing, online hydrogen determination [H] content, [H]≥3ppm, 12Cr1MoVG high-pressure pipe after forging The steps of the heat treatment process are as follows:

[0077] Step S01: put the forged 12Cr1MoVG high-pressure tube into an annealing furnace at 650°C and keep it warm for 12 hours;

[0078] Step S02: After the heat preservation is completed, the 12Cr1MoVG high-pressure tube is taken out of the furnace and air-cooled until the surface temperature is 350-400°C;

[0079] Step S03: heat the 12Cr1MoVG high-pressure tube after entering the furnace at 400° C. for 6 hours;

[0080] Step S04: Put the 12Cr1MoVG high-pressure tube after heat preservation for 6 hours into hydrogen expansion a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com