Forging Control Method for Uniformly Refining the Grain Size of Forgings

A control method and grain size technology, which are applied in the field of steel material manufacturing process control, can solve the problems of ultrasonic detection clutter, low mechanical properties, and reduce production costs, and achieve economical production processes, high mechanical performance indicators, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

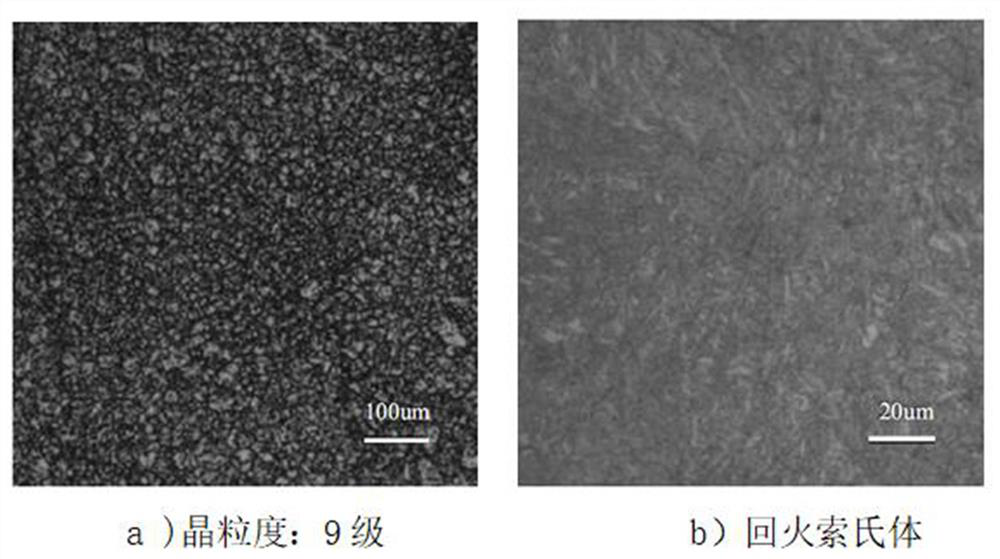

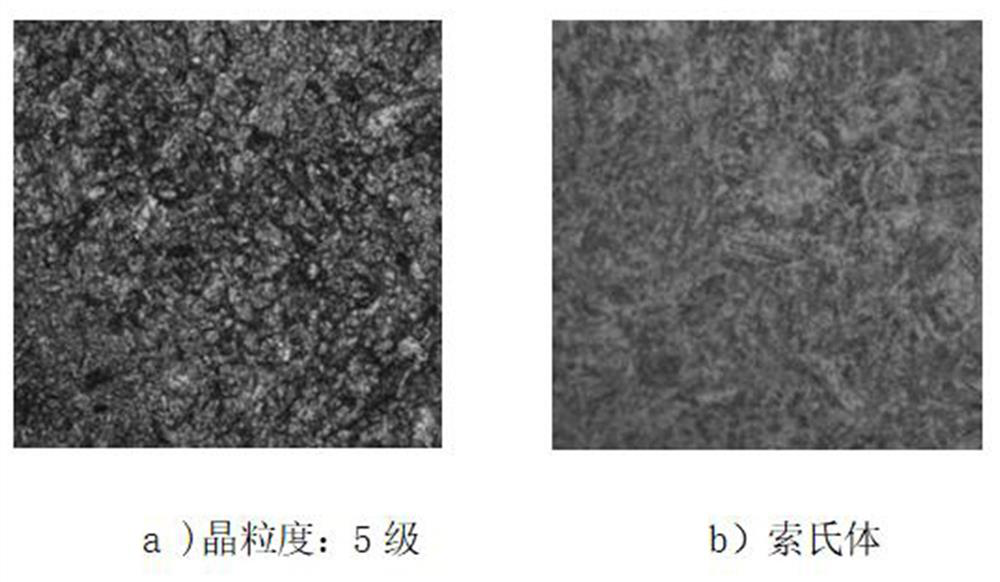

[0018] Take 4330V steel as an example for analysis. A 12.5T electroslag ingot is selected to forge a forging with a size of 570mm×650mm×3250mm.

[0019] Step 1), first, heat the electroslag ingot before forging, and keep it in a high-temperature furnace at 1200°C for 8 hours.

[0020] Step 2), during the first fire forging, the height of the electroslag ingot is upset to 900mm, and then the elongation forging is carried out. After the elongation reaches 800mm×1000mm, the edge is chamfered, and the forging is air-cooled to 650±10°C (with a larger The temperature measured at the center of the surface shall prevail), and put it into a heating furnace at 1200 ° C for 3 hours.

[0021] Step 3), during the second fire forging, first upsetting the height of the intermediate billet to 900mm, drawing it to 800mm×1000mm, chamfering, and air cooling the forging to 650±10°C (based on the temperature measurement at the center of the large surface) , into a 1050 ° C heating furnace for 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com