Forging control method of large-specification stepped shaft component

A control method and large-scale technology, applied in the field of steel material forging, can solve the eccentricity problems of shafts with large step difference, and achieve the effect of avoiding the eccentricity of forgings, improving the utilization rate of product materials and production efficiency, and solving the eccentricity problem.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

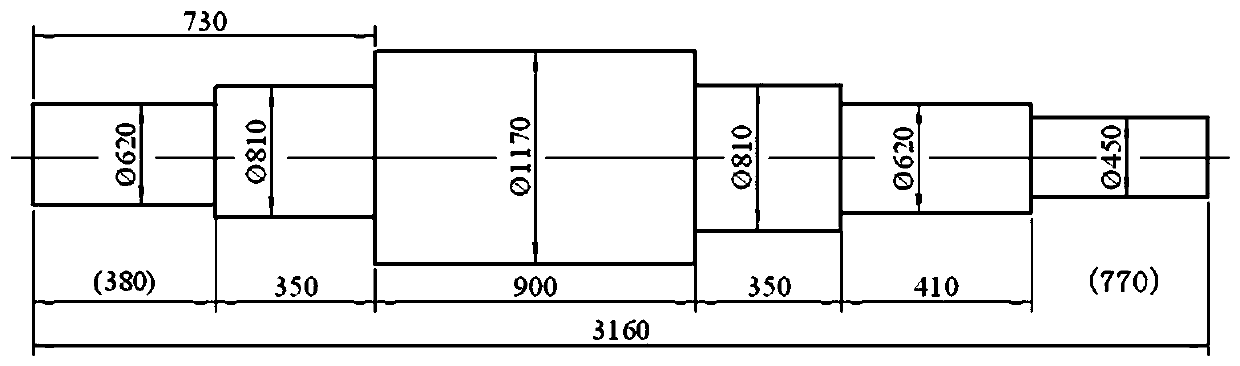

[0019] As shown in the figure, the forging of large-scale shafts is taken as an example, that is, the manufacture of 20CrMo4 roller shaft forgings with a specification of φ1170mm is taken as an example to illustrate.

[0020] Such as figure 1 As shown, in the forging blank drawing of the roller shaft, the unit of dimension in the drawing is mm. Depend on figure 1 It can be seen that the forging of the roller shaft has a large diameter and a large step difference (720mm). In order to improve the utilization rate of materials, reduce the number of times of upsetting, and improve forging efficiency, 2 times the size of forging is used in production, and the utilization rate of materials is increased to 73% (the utilization rate of materials in traditional forging methods is about 65%).

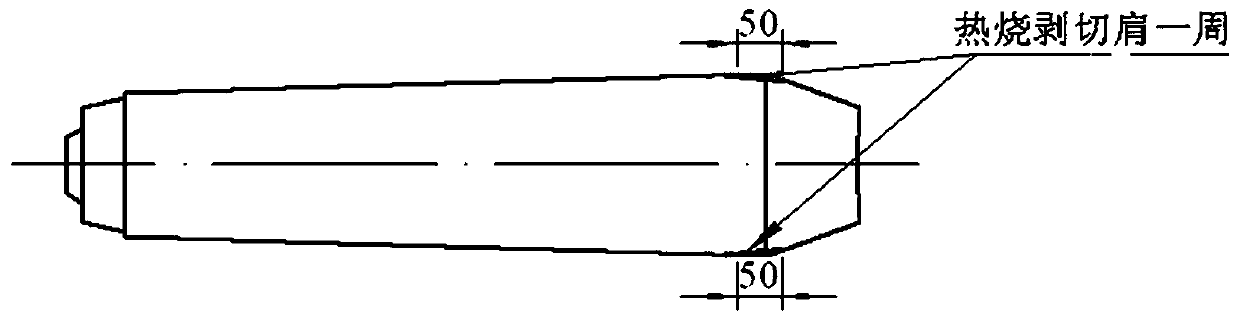

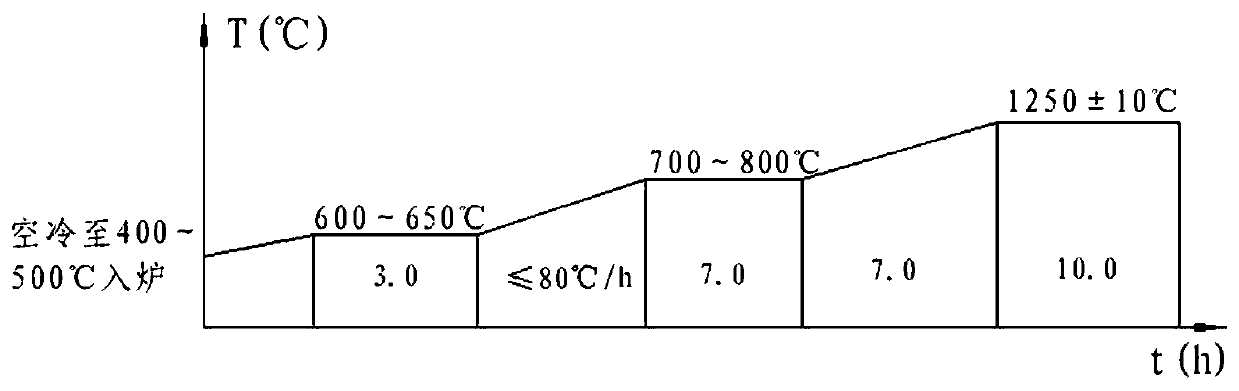

[0021] Such as figure 2 As shown in the shoulder cutting diagram of the steel ingot, before heating in the furnace, the riser of the steel ingot should be cut first: use a carbon arc gouging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com