Forging and heat treatment method of large size 20simn spindle

A heat treatment method and large-scale technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of unqualified mechanical properties, uneven deformation, insufficient deformation, etc., to achieve high production efficiency, product quality assurance, production The effect of process economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

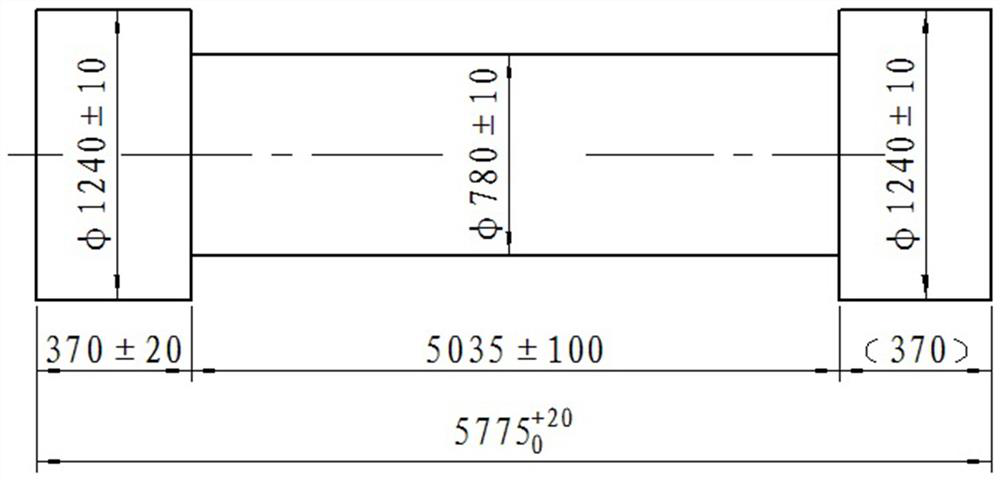

[0036] Example 1: A special steel enterprise implements the present invention. Forging a 20SiMn main shaft with flanges at both ends of Ф1240mm*370mm and a shaft body of Ф780mm*5035mm, the steel ingot is first selected according to the weight of the forging billet. Because the flange specification is large, Taking into account the proportion of scrap materials at both ends, the utilization rate was set at 72%, and 36 tons of refined steel ingots were selected. The specific production process is as follows:

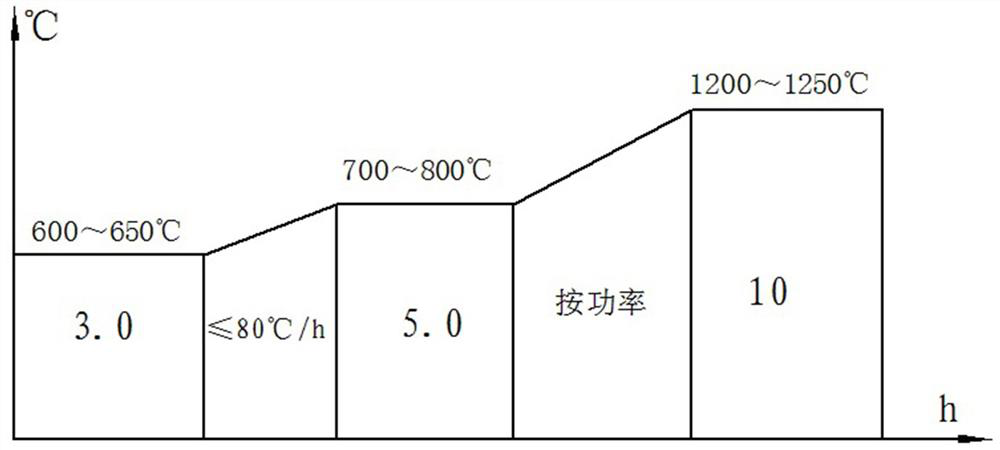

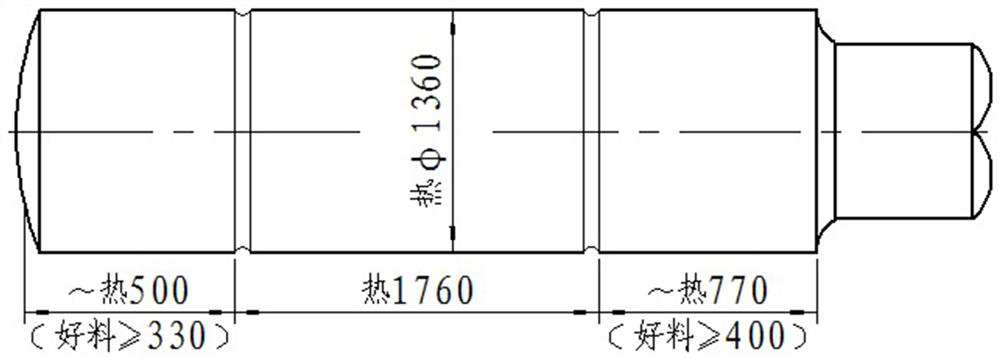

[0037] Step 1: Heating according to the special heating specification: first, heat the steel ingot at a temperature of 600-650°C for 3 hours at a low temperature, then raise the temperature to 700-800°C at a speed not exceeding 80°C / h for 5 hours, and then heat it up to 1200-1250°C, raised to 1200-1250°C and then lifted out of the furnace with a crane to a 5,000-ton hydraulic press to pre-press the tongs, offset the sharp corners of the tail of the ingot, and then return t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com