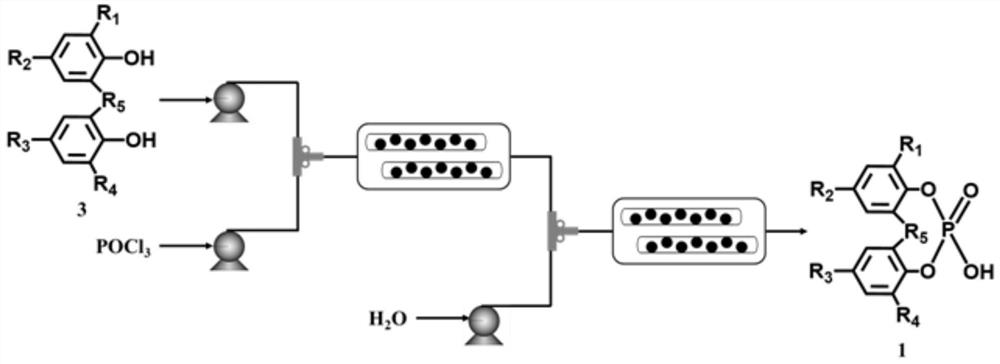

Continuous preparation method of substituted diaryl phosphate compound

A technology of diarylphosphoric acid and compound, which is applied in the field of continuous preparation of substituted diarylphosphoric acid compounds, can solve the problems of low production efficiency, long reaction time, low safety and the like, and achieves high production efficiency and short reaction time. , the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

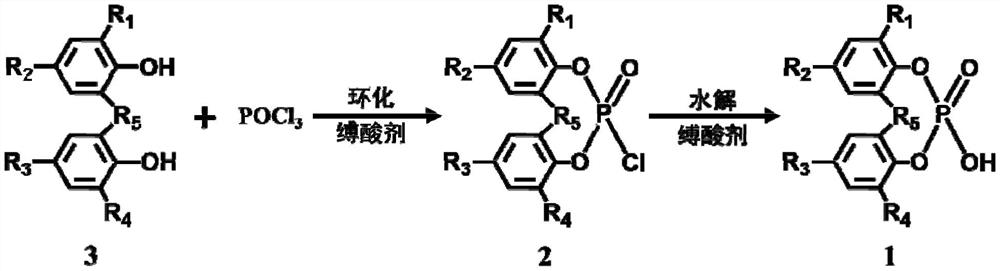

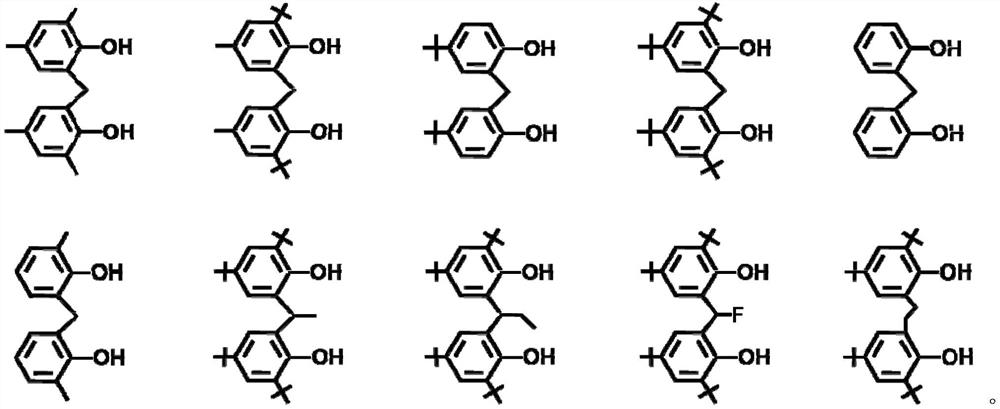

Method used

Image

Examples

Embodiment 1

[0039]

[0040] Weigh 2,2'-methylene-bis(4,6-di-tert-butyl)phenol (0.025mol, 10.63g) and triethylamine (0.15mol, 20.85mL), dissolve with 80mL toluene and load in a raw material tank. Phosphorus oxychloride (0.0275 mol, 2.56 mL) was dissolved with 40 mL of toluene and charged in another raw material tank. The reaction solution in the two raw material tanks, under the action of the feed pump, continuously enters the vibrating reactor filled with spherical stainless steel internals with an inner diameter of 5mm and a length of 8m through the Y-shaped mixer. The vibration mode is pneumatic and the frequency is 10Hz. The temperature is controlled at 10°C, normal pressure, the residence time is 180s, and the material is discharged into the Y-type mixer; 30mL of water and triethylamine (0.075mol, 10.42mL) are placed in a raw material tank, under the action of the feed pump Enter the Y-type mixer, mix with the discharge material and continuously enter the vibrating reactor filled ...

Embodiment 2

[0042] Weigh 2,2'-methylene-bis(4,6-di-tert-butyl)phenol (0.025mol, 10.63g) and triethylamine (0.15mol, 20.85mL), dissolve with 80mL toluene and load in a raw material tank. Phosphorus oxychloride (0.0275 mol, 2.56 mL) was dissolved with 40 mL of toluene and charged in another raw material tank. The reaction liquid in the two raw material tanks, under the action of the feed pump, continuously enters the vibrating reactor filled with cylindrical stainless steel internals with an inner diameter of 5 mm and a length of 8 m through a Y-shaped mixer. The vibration mode is electromagnetic vibration and the frequency is 10 Hz. , the reaction temperature is controlled at 10°C, normal pressure, the residence time is 180s, and the discharge enters the Y-shaped mixer; 30mL of water and triethylamine (0.075mol, 10.42mL) are placed in a raw material tank, and the feed pump Under the action, it enters the Y-type mixer, mixes with the discharge material and continuously enters the vibrating...

Embodiment 3

[0044] Weigh 2,2'-methylene-bis(4,6-di-tert-butyl)phenol (0.025mol, 10.63g) and triethylamine (0.15mol, 20.85mL), dissolve in 100mL of toluene and load in a raw material tank. Phosphorus oxychloride (0.0275 mol, 2.56 mL) was dissolved with 50 mL of toluene and charged in another raw material tank. The reaction solution in the two raw material tanks, under the action of the feed pump, continuously enters the vibrating reactor with an inner diameter of 8 mm and a length of 10 m filled with vertical spiral stainless steel internals through a Y-shaped mixer. The reactor remains static and the reaction temperature Controlled at 10°C, normal pressure, residence time of 180s, the discharge enters the Y-shaped mixer; 30mL of water and triethylamine (0.075mol, 10.42mL) are placed in a raw material tank, and enter under the action of the feed pump Y-shaped mixer, mixed with the output material and continuously enters the vibrating reactor with an inner diameter of 8mm and a length of 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com