Preparation method and application of nanofiber loaded heteropolyacid salt catalyst

A technology for supporting heteropolyacids and nanofibers, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc. To achieve the effect of mild conditions, improved desulfurization efficiency, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of PMoV-1 catalyst:

[0029] 14.4g MoO 3 with 1.8188g V 2 o 5 Mixed, added to 250mL deionized water, condensed and refluxed, heated to 100°C and stirred continuously, 1.15g of 85wt% phosphoric acid was added dropwise to it, stirred at 100°C for 24h, and then dried at 70°C to obtain H 5 PMo 10 V 2 o 40 catalyst.

[0030] Mix 1g PAN, 0.5g melamine and 9g DMF, stir for 2h, the temperature is 90℃; 0.1g prepared H 5 PMo 10 V 2 o 40 The catalyst was dissolved in the above solution, stirred at room temperature for 2 hours, and spun at 19kV and 30°C. The distance between the jet apex and the receiving plate was 20cm to obtain nanofibers, and the spun nanofibers were calcined in oxygen (250°C ) for 3h, and then calcined (800°C) for 2h in argon to finally obtain the nanofiber-supported heteropolyacid salt catalyst H 5 PMo 10 V 2 o 40 / NFs, denoted as PMoV-1.

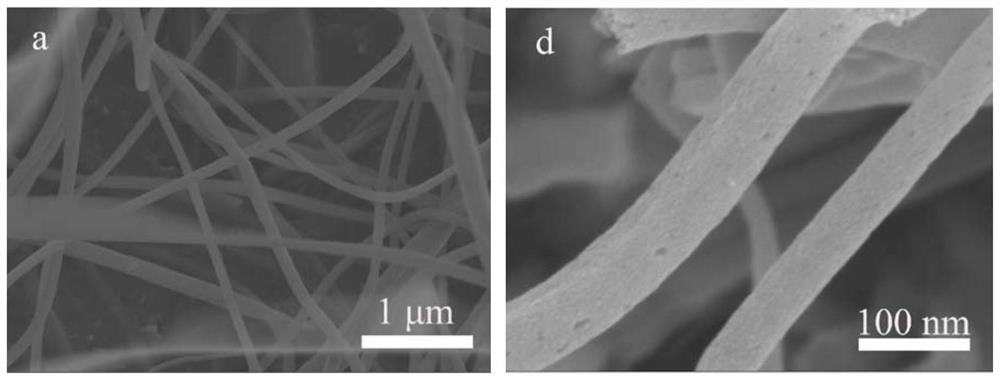

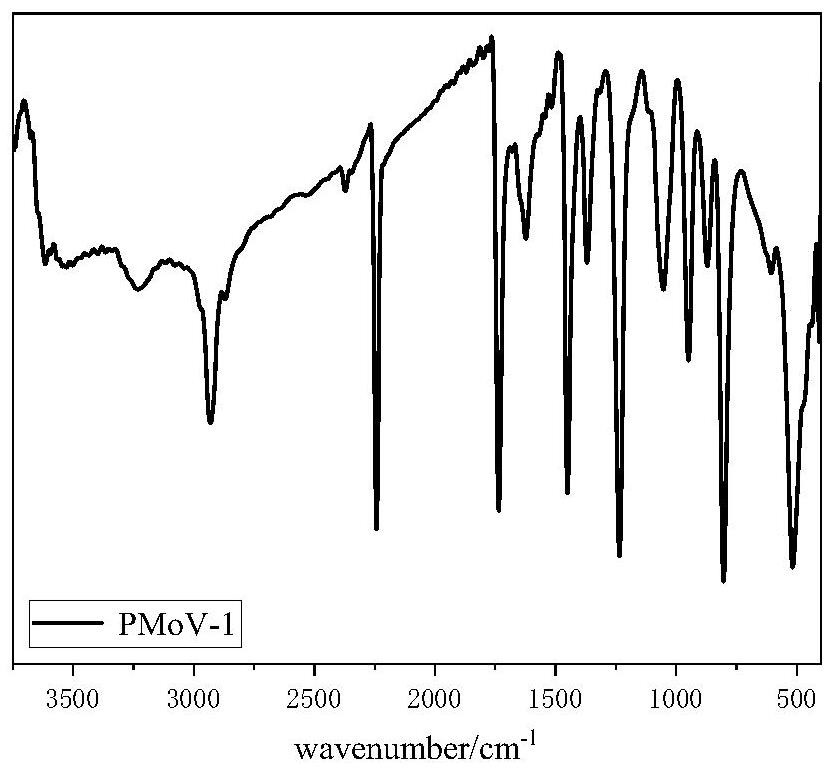

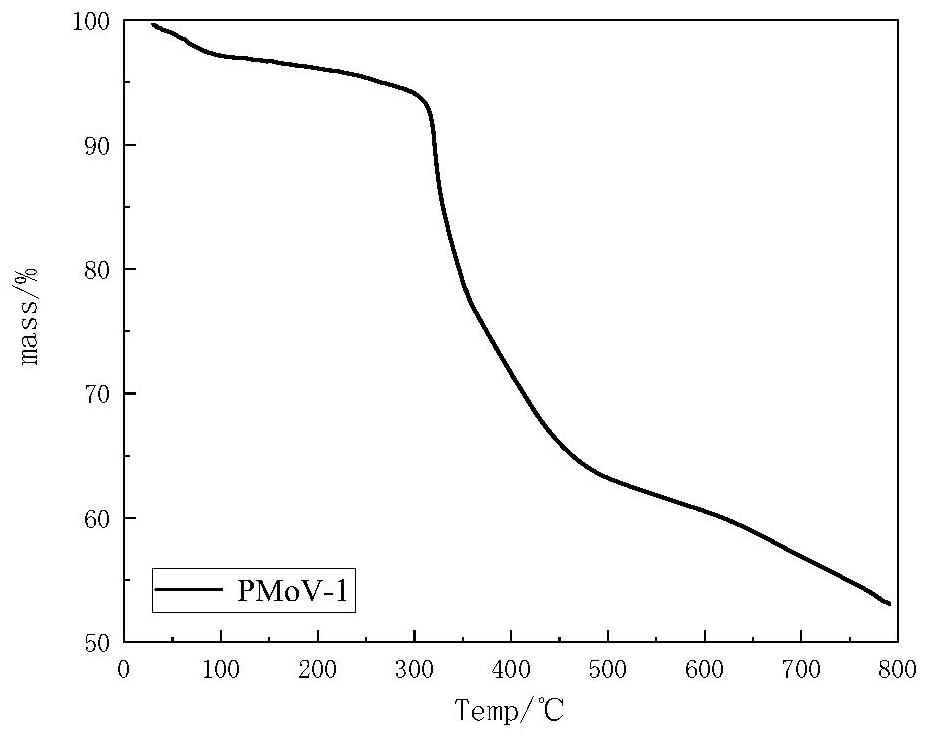

[0031] figure 1 It is a scanning electron microscope image (SEM). The fiber diameter in pictu...

Embodiment 2

[0033] 14.4g MoO 3 with 1.8188g V 2 o 5 Mixed, added to 250mL deionized water, condensed and refluxed, heated to 100°C and stirred continuously, 1.15g of 85wt% phosphoric acid was added dropwise to it, stirred at 100°C for 24h, and then dried at 70°C to obtain H 5 PMo 10 V 2 o 40 catalyst.

[0034] Mix 1g PAN, 1g melamine and 9g DMF, stir for 2h, the temperature is 90℃; 0.3g prepared H 5 PMo 10 V 2 o 40 The catalyst was dissolved in the above solution, stirred at room temperature for 2 hours, and spun at 19kV and 30°C. The distance between the apex of the jet and the receiving plate was 20cm to obtain nanofibers, and the spun nanofibers were placed in oxygen (250°C ) calcined for 3 hours, and then passed into argon (800° C.) for calcination for 2 hours to finally obtain the nanofiber-supported catalyst H 5PMo 10 V 2 o 40 / NFs, denoted as PMoV-2.

Embodiment 3

[0036] Preparation of PMoV-3 catalyst:

[0037] 14.4g MoO 3 with 1.8188g V 2 o 5 Mixed, added to 250mL deionized water, condensed and refluxed, heated to 100°C and kept stirring, 1.15g of 85wt% phosphoric acid was added dropwise to it, stirred at 100°C for 24h, and then dried at 60-75°C to obtain H 5 PMo 10 V 2 o 40 catalyst.

[0038] Mix 1gPAN, 1.5g melamine and 9gDMF, stir for 2h, the temperature is 90℃; 0.5g prepared H 5 PMo 10 V 2 o 40 The catalyst was dissolved in the above solution, stirred at room temperature for 2 hours, and spun at 19kV and 30°C. The distance between the apex of the jet and the receiving plate was 20cm to obtain nanofibers. The spun nanofibers were placed in oxygen (250°C) Calcined for 3 hours, then passed into argon (800°C) and calcined for 2 hours to finally obtain the catalyst H 5 PMo 10 V 2 o 40 / NFs, denoted as PMoV-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com