Forging method capable of avoiding general looseness of hollow part forged through continuous casting blank with small deformation amount

A technology of continuous casting blanks and hollow parts, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., and can solve the problem of reducing the deformation of the core and increasing the deformation of the outer metal, etc. problems, to achieve long service life, improve production efficiency, and reduce overall production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Example of corrugated roll forging:

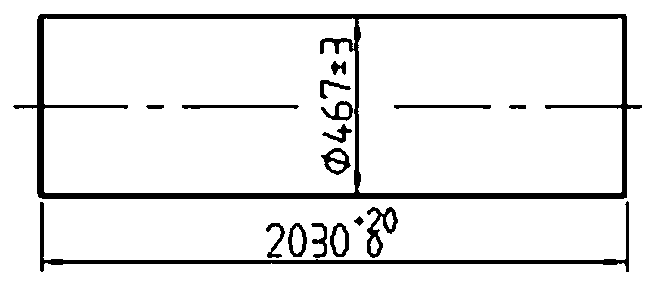

[0021] Take a corrugated roll of φ452mm (outer circle size) × φ300mm (inner hole size) × 2020mm (length size) as an example, for analysis, the forging picture is as follows image 3 (The unit of drawing size is mm).

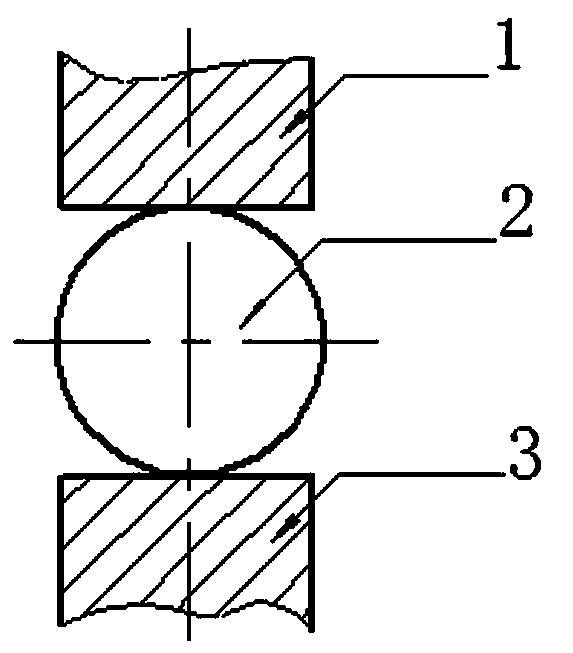

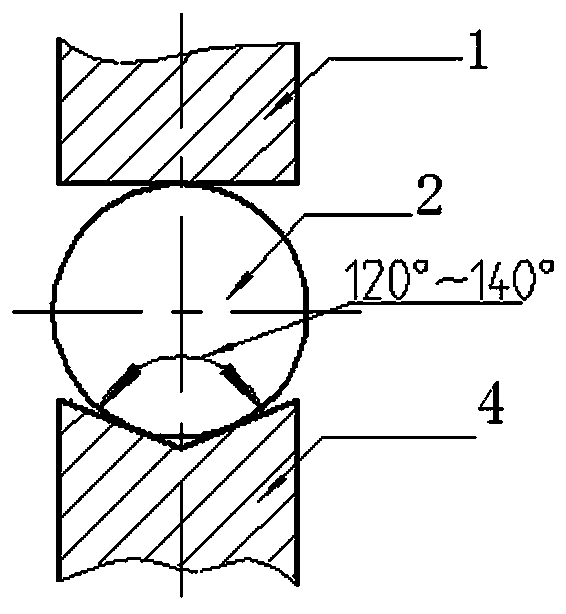

[0022] Such as Figure 4 As shown, in the traditional forging method using upper and lower flat anvils, for the φ800mm continuous casting billet 2, the 500mm wide upper flat anvil 1 and the lower flat anvil 3 are directly drawn and forged to φ500mm. The deformation diagram of the forging is shown in 4. by Figure 4 It can be seen that when the φ800mm continuous casting billet hydraulic press is deformed to φ500mm and forged with 500mm wide upper and lower flat anvils, the relative feed rate is relatively large (l i / h i >1), the deformation zone presents a single drum shape. This forging method has a large core deformation and can forge through, which is conducive to the compaction of the core. However, the side s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com