Method for manufacturing wind tunnel ultrahigh-pressure pipe fitting through high-nickel alloy structural steel

A technology of alloy structural steel and ultra-high pressure, applied in the direction of improving process efficiency, etc., can solve the problems of wear resistance and no adhesion of the joint surface, difficulty in meeting actual needs, difficulty in meeting needs in high grain size, etc., and achieve product quality Guaranteed, high production efficiency, and the effect of solving stress and deformation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

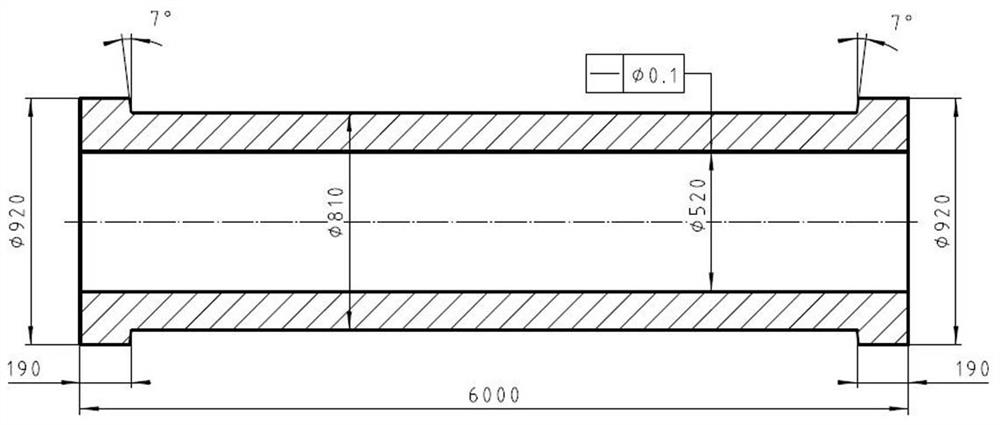

[0031] Example 1: Production of a batch of high-nickel alloy structural steel wind tunnel ultra-high pressure pipe fittings: Take the manufacture of pipe fittings with an inner diameter of φ520mm as an example, such as figure 1 As shown, the straightness of the inner hole is required to be no more than 0.1mm in length, the connecting surface is a 7° inclined plane, the length of the workpiece is 6000mm, and the material used is 35CrNi3MoV. The main requirements are that the grain size is not less than 6, the yield is not less than 960MPa, and the resistance Pull 1070-1230MPa.

[0032] Through comprehensive consideration, the actual production and manufacturing process of the pipe fittings is: electric arc furnace smelting + vacuum refining → electroslag remelting → double upsetting, elongation, forging and forming → annealing after forging → straightening → surface inspection, Cutting, physical and chemical testing (low magnification, ultrasonic flaw detection) → rough machini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com