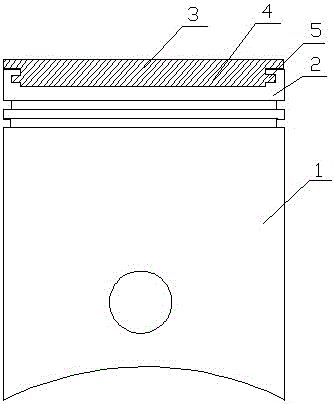

Preparation method for wear-resisting layer embedded at top of diesel engine piston

A wear-resistant layer, diesel engine technology, applied in pistons, mechanical equipment, clay products, etc., can solve the problems of difficult production and use of ceramic internal combustion engines, difficult to ensure reliability and stability, brittle and fragile assembly of ceramic materials, etc. The effect of small size, increased strength and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a wear-resistant layer inlaid on the top of a diesel engine piston described in this embodiment comprises the following steps:

[0028] (1) Preparation of raw materials: It consists of the following components in parts by mass: 3 parts of nano-zirconia, 11 parts of magnesium oxide, 14 parts of silicon nitride, 6 parts of hydroxypropyl methylcellulose, 33 parts of kaolin, wood fiber 4 parts, 5 parts of chromium oxide, 10 parts of manganese dioxide, 5 parts of grinding wheel fines, 6 parts of aluminum oxide, 2 parts of silicone resin, 1 part of acetic acid;

[0029] (2) Grind kaolin and grinding wheel fines to 200 mesh, and sieve;

[0030] (3) Mix the material after step (2) with nano zirconia, magnesium oxide, silicon nitride, hydroxypropyl methylcellulose, high wood fiber, chromium oxide, manganese dioxide and water for 1 hour, and keep the temperature at 78 ℃;

[0031] (4) Seal the mixture after step (3) for 9 days, spray acetic acid every 2 da...

Embodiment 2

[0049] A method for preparing a wear-resistant layer inlaid on the top of a diesel engine piston described in this embodiment comprises the following steps:

[0050](1) Preparation of raw materials: It consists of the following components in parts by mass: 3 parts of nano-zirconia, 10 parts of magnesium oxide, 12 parts of silicon nitride, 7 parts of hydroxypropyl methylcellulose, 30 parts of kaolin, wood fiber 5 parts, 4 parts of chromium oxide, 11 parts of manganese dioxide, 4 parts of grinding wheel fines, 10 parts of aluminum oxide, 2 parts of silicone resin, 2 parts of acetic acid;

[0051] (2) Grind kaolin and grinding wheel fines to 200 mesh, and sieve;

[0052] (3) Mix the material after step (2) with nano-zirconia, magnesium oxide, silicon nitride, hydroxypropyl methylcellulose, high wood fiber, chromium oxide, manganese dioxide and water for 2 hours, and keep the temperature at 75 ℃;

[0053] (4) Seal the mixture after step (3) for 10 days, spray acetic acid once ev...

Embodiment 3

[0071] A method for preparing a wear-resistant layer inlaid on the top of a diesel engine piston described in this embodiment comprises the following steps:

[0072] (1) Preparation of raw materials: It consists of the following components in parts by mass: 3 parts of nano-zirconia, 10 parts of magnesium oxide, 16 parts of silicon nitride, 5 parts of hydroxypropyl methylcellulose, 36 parts of kaolin, wood fiber 3 parts, 6 parts of chromium oxide, 8 parts of manganese dioxide, 8 parts of grinding wheel fines, 3 parts of aluminum oxide, 1 part of silicone resin, 1 part of acetic acid;

[0073] (2) Grind kaolin and grinding wheel fines to 250 mesh, and sieve;

[0074] (3) Mix the material after step (2) with nano zirconia, magnesium oxide, silicon nitride, hydroxypropyl methylcellulose, high wood fiber, chromium oxide, manganese dioxide and water for 1 hour, and keep the temperature at 80 ℃;

[0075] (4) Seal the mixture after step (3) for 8 days, spray acetic acid every 2 days...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com