Process for producing filled prestress steel strand of epoxy coating

A technology of prestressed steel strand and epoxy coating, which is applied in the direction of metal material coating process, coating, and liquid coating device on the surface, which can solve the problem of mechanical property degradation, low relaxation performance, and steel strand without Epoxy coating protection and other issues, to achieve the effect of scientific chemical resistance and scientific production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

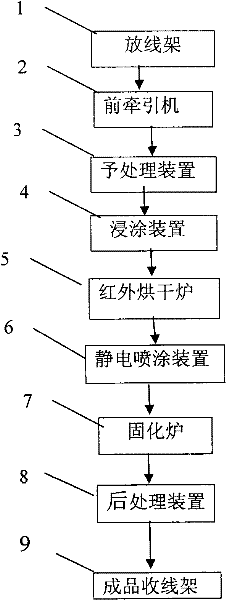

[0022] The process of producing epoxy coated filled prestressed steel strands of the present invention will be described with reference to the accompanying drawings and embodiments.

[0023] The process for producing epoxy coated filled prestressed steel strands of the present invention includes the following steps:

[0024] ① Pre-treatment process, degreasing the surface of the prestressed steel strand, after derusting, the prestressed steel strand must be activated, then washed and air-dried, so that the inner and outer metal layers of the prestressed steel strand are oil-free , No rust and activated conditions are ready to enter the next process.

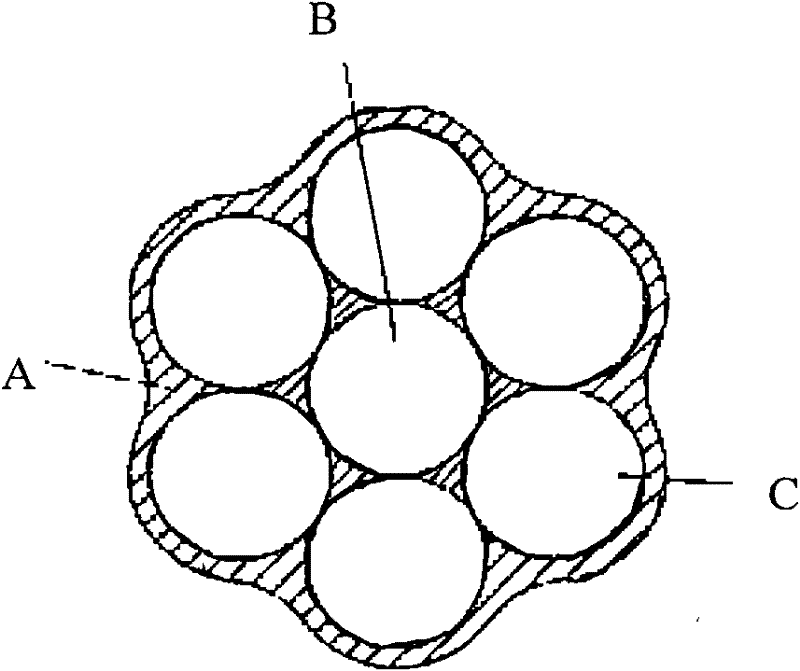

[0025] ②Dip coating process by chemical deposition method, the pre-treated steel strand enters the dip coating tank, which is filled with water-soluble acrylic epoxy resin solution, and the activated smooth steel strand is stranded when passing through the dip coating tank. The inside and outside of the wire are filled with water-solub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com