Preparation method for nail polish changing with temperature and nail polish changing with temperature

A technology of nail polish and temperature change, applied in manicure, pedicure, medicine formula, etc., to achieve the effects of simplified production process, scientific raw material ratio, and reasonable and ingenious process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: a kind of preparation method of temperature-changing nail oil, it comprises the following steps:

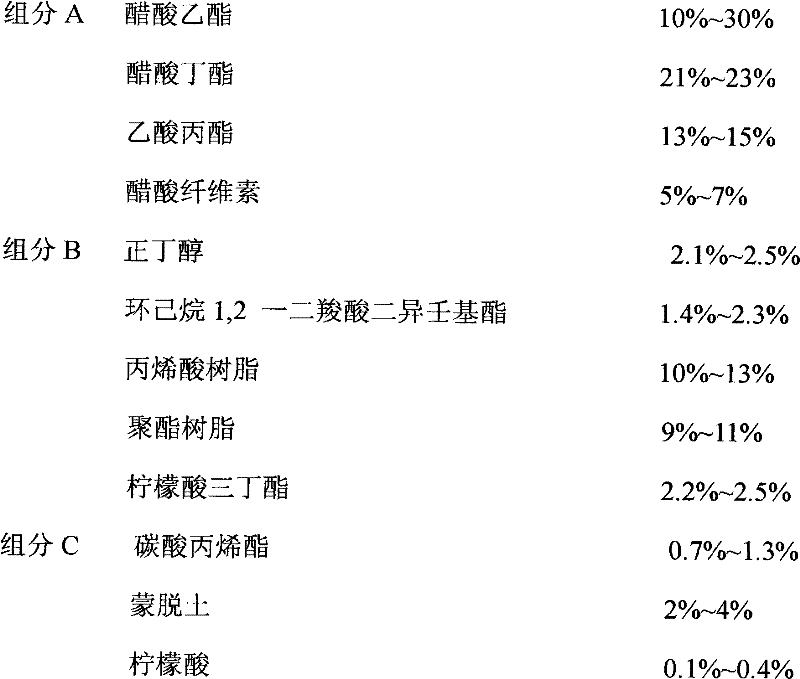

[0042] (1) Prepare a component A, the mass percentage is 10%~30% ethyl acetate, the mass percentage is 21%~23% butyl acetate, the mass percentage is 13%~15% propyl acetate and the mass percentage Mix the cellulose acetate with a percentage of 5% to 7%, and stir evenly at a high speed;

[0043] (2) Prepare a component B, the mass percentage is 2.1%~2.5% n-butanol, the mass percentage is 1.4%~2.3% cyclohexane 1,2-diisononyl dicarboxylate, mass percentage 10% to 13% of acrylic resin, 9% to 11% of polyester resin by mass percentage and 2.2% to 2.5% by mass of tributyl citrate are mixed and stirred evenly at high speed;

[0044] (3) Prepare a component C, the propylene carbonate of 0.7%~1.3% by mass percentage, the montmorillonite of 2%~4% by mass percentage, the citric acid and the citric acid of 0.1%~0.4% by mass percentage Mix 0.2% to 0.4% urea-modified polyu...

Embodiment 2

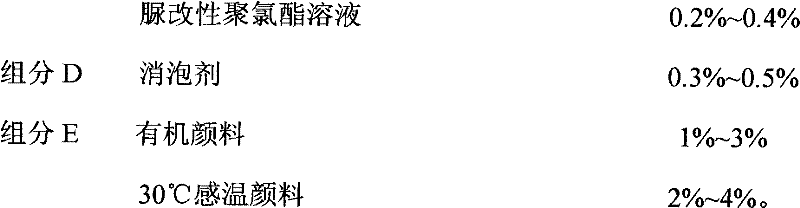

[0065] Embodiment 2: The preparation method of the temperature-changing nail polish of this embodiment and the temperature-changing nail polish are basically the same as in Example 1, the difference being that: specifically, the raw material composition and mass percentage of the temperature-changing nail polish are as follows:

[0066]

[0067]

Embodiment 3

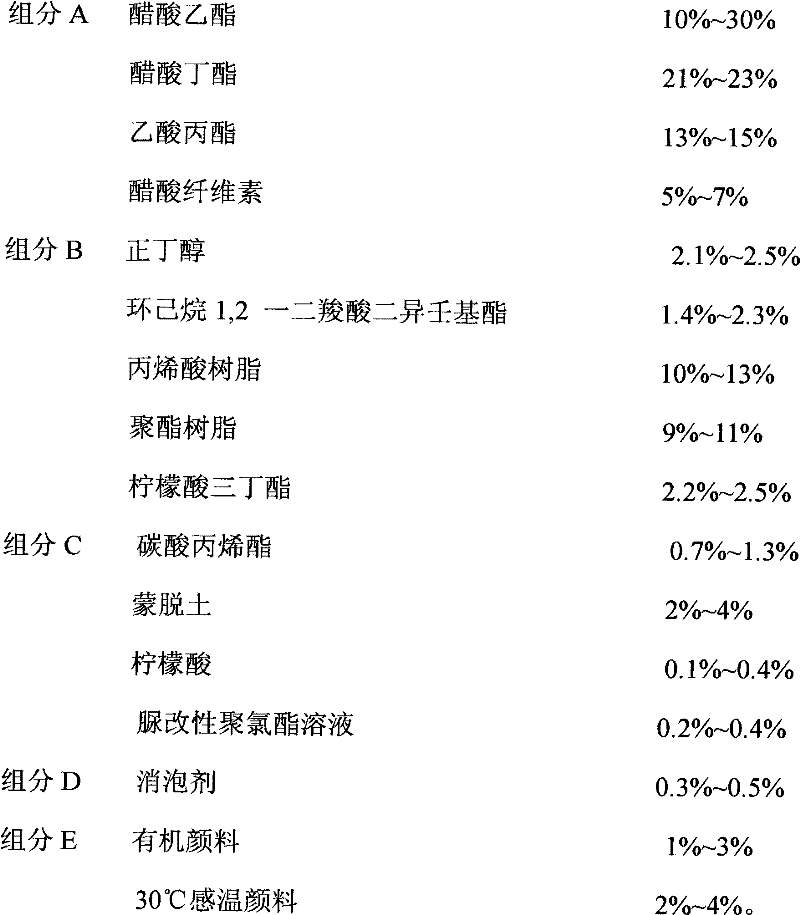

[0068] Example 3: The preparation method of the temperature-changing nail polish of this embodiment and the temperature-changing nail polish are basically the same as those in Examples 1 and 2, the difference being: specifically, the raw material composition and mass percentage of the temperature-changing nail polish as follows:

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com