Process for comprehensively recycling valuable metals from zinc-containing material

A technology for valuable metals and materials, applied in the field of metal recycling, can solve problems such as the inability to achieve comprehensive recovery of valuable metals, environmental pollution, etc., and achieve the effects of low overall operating costs, high quality, and small washing water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] This embodiment provides a process for comprehensive recovery and utilization of valuable metals from zinc-containing materials, including the following steps:

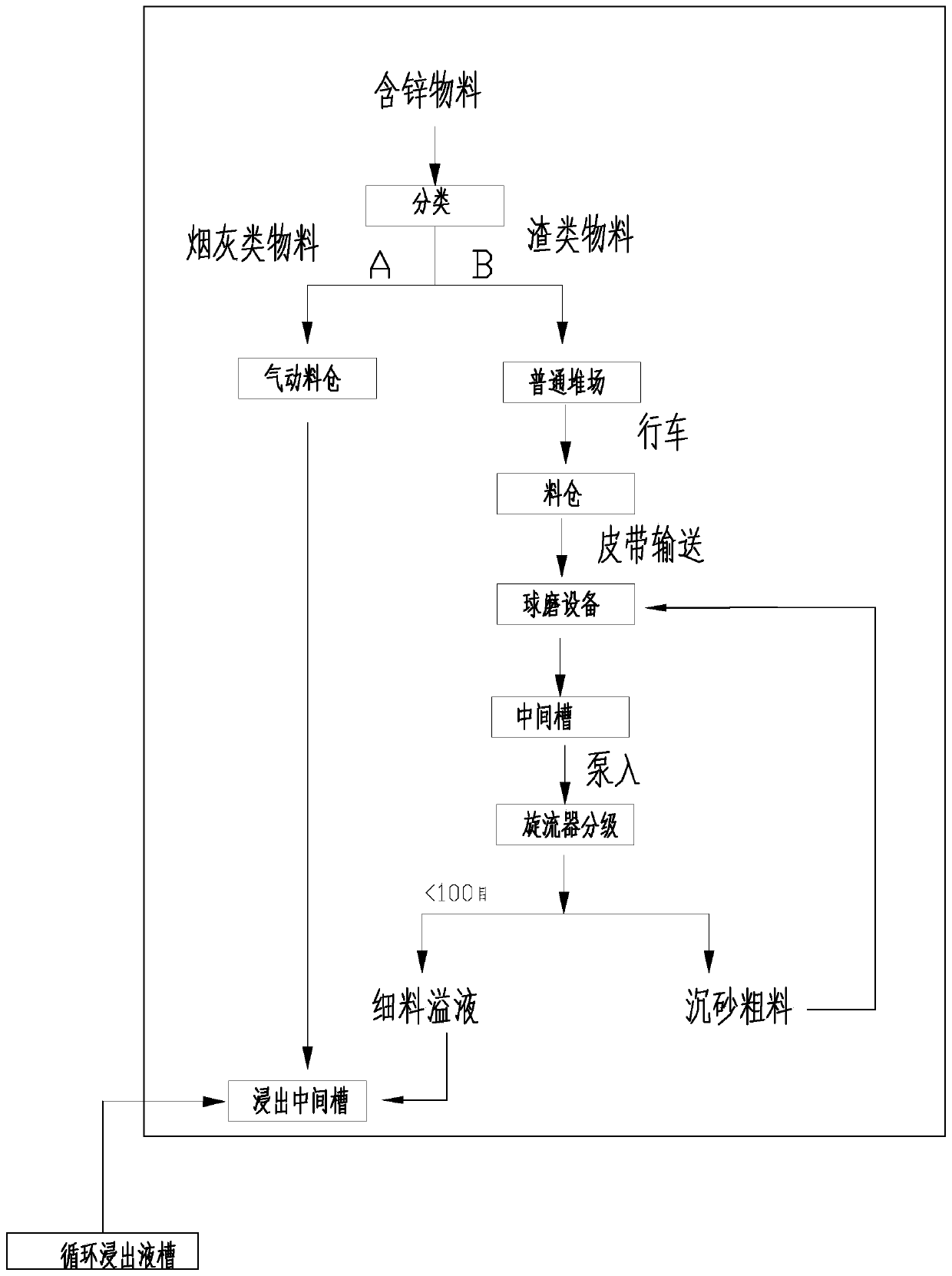

[0073] 1) Pretreatment section of zinc-containing materials

[0074] Zinc-containing materials are divided into two categories: soot materials and slag materials; taking zinc-containing materials with a mass of 20.80% of zinc and 15.19% of copper as an example:

[0075] A) Soot materials are sent to the leaching intermediate tank through the pneumatic silo;

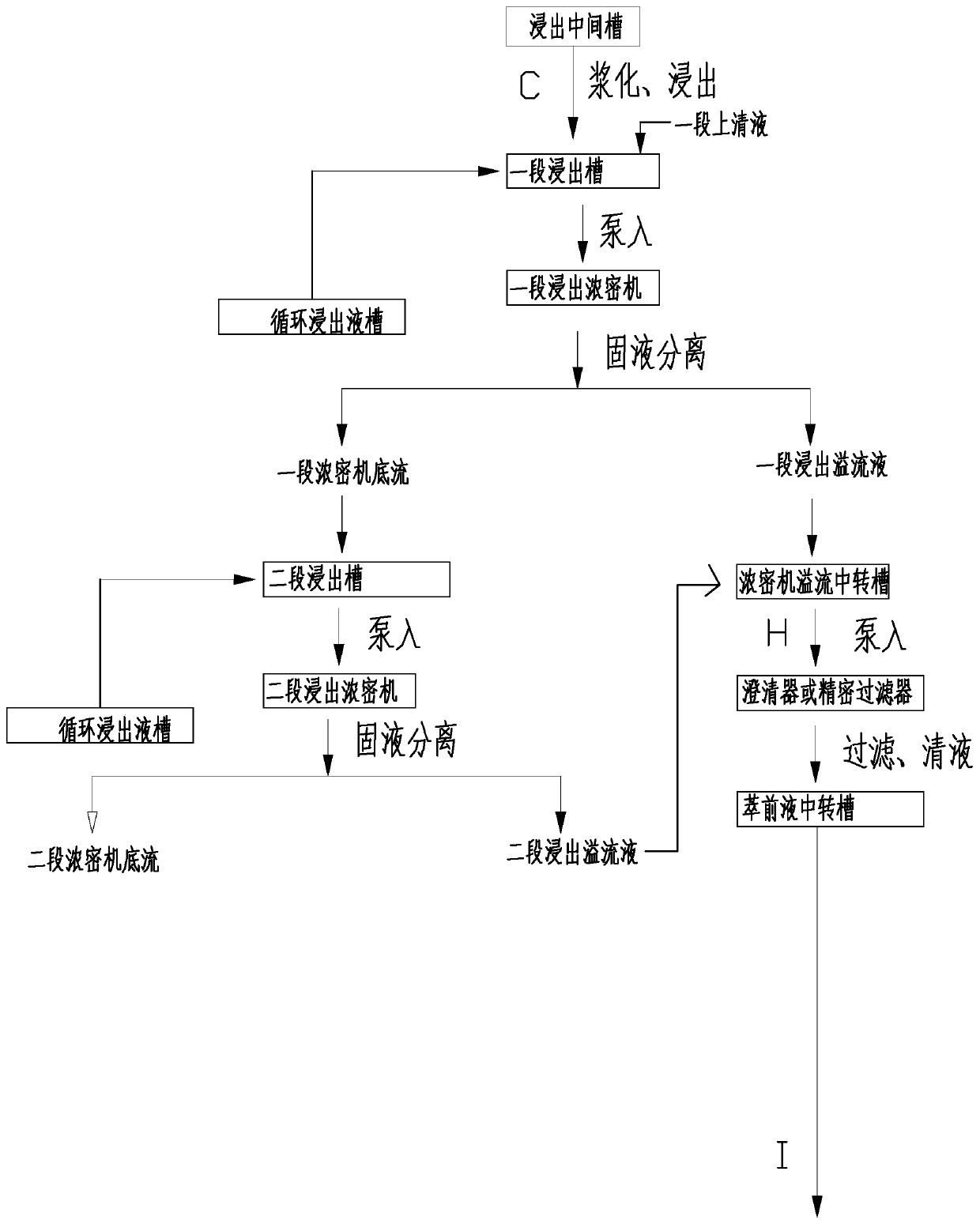

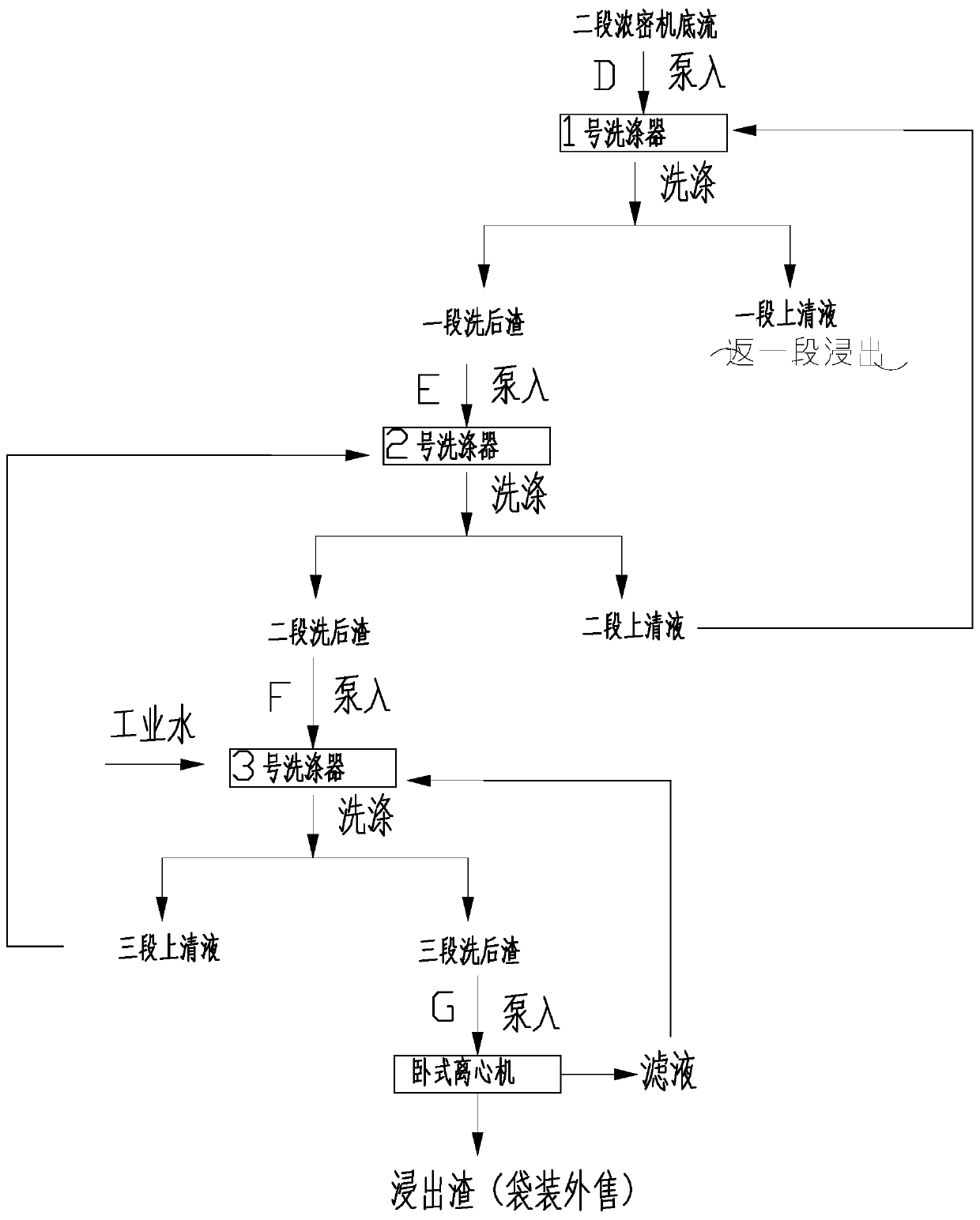

[0076] B) After the slag material is sent to the silo by driving, it is transported to the ball mill equipment through the belt. After the slag material is ball milled, it enters the transfer tank and is pumped into the cyclone for classification. The target fine material overflow is sent to the leaching intermediate tank, mixed with soot materials and a certain amount of circulating leaching solution obtained in the following step V), and then enters the...

Embodiment 2

[0103] Except for changes in some process control parameters, other operations in this implementation are the same as in Example 1:

[0104] The process control parameters of the first-stage leaching and the second-stage leaching in step C) are: leach solution temperature 55°C, pH 6.0, stirring 120r / min, leaching time 1.5h;

[0105] The flow ratio of the zinc-loaded organic flow rate to the cleaning liquid in step I) is 30:1; the flow rate ratio of the zinc-loaded organic flow rate to the chloride ion washing liquid flow rate is 30:1; the composition requirements of the two-stage zinc sulfate back-extraction pre-liquid in step I) : 200g / L;

[0106] Step K) adjusting the pH of the low-acid zinc sulfate rich solution to 5.0 with zinc oxide;

[0107] In step L), the mass of sulfuric acid added to the rich solution of zinc sulfate after degreasing is 100g / l, the crystallization temperature of zinc sulfate monohydrate is 60°C, and the crystallization time is 3h;

[0108] The copp...

Embodiment 3

[0110] Other operations in this implementation are the same as those in Embodiment 1, except for the following operations:

[0111] The process control parameters of the first-stage=leaching and second-stage leaching of step C) are: temperature 75°C, pH 6.2, stirring 190r / min, leaching time 3.0h;

[0112] The flow ratio of the zinc-loaded organic flow to the cleaning liquid in step I) is 10:1; the flow ratio of the zinc-loaded organic flow to the chloride ion washing liquid is 10:1; the composition requirements of the two-stage zinc sulfate back-extraction pre-liquid in step I) : 480g / L;

[0113] Step K) adjusting the pH of the low-acid zinc sulfate rich solution to 2.5 with zinc oxide;

[0114] In step L), the quality of sulfuric acid added to the zinc sulfate rich solution per liter of oil removal is 300g / l, the crystallization temperature range is 80°C, and the crystallization time is 5h;

[0115] In step P), the ratio of the copper extractant flow rate to the copper pre-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com