Instant fresh noodles and processing method thereof

A technology of fresh noodles and salt, applied in the fields of food science, food preservation, application, etc., can solve the problems of sour taste, restrict the market promotion of instant noodles, cannot inhibit the growth and reproduction of spoilage bacteria, etc., and achieve convenient consumption, sensory and quality. The effect of maintaining good structural quality, inhibiting growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

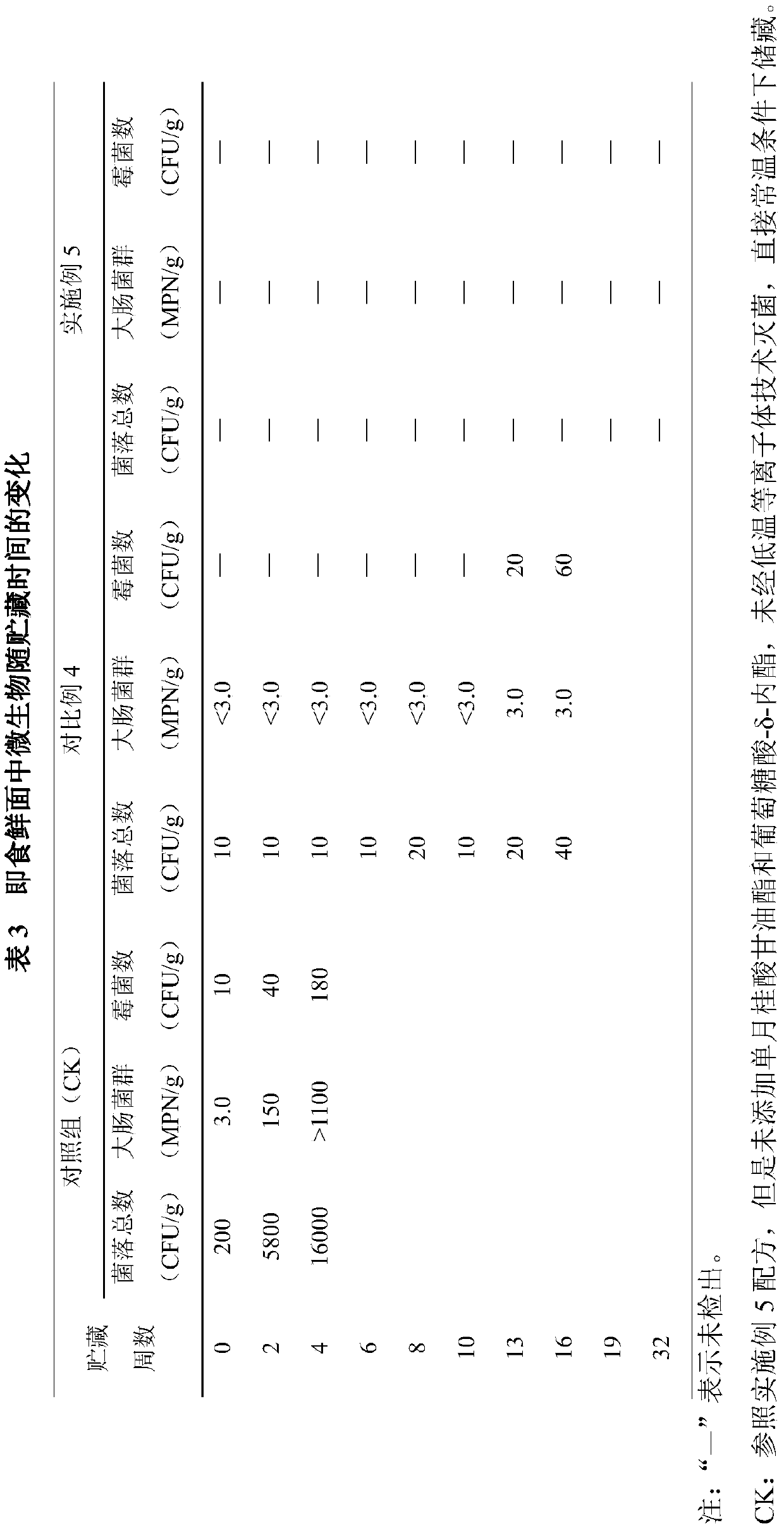

[0047] Instant noodle formula: 100kg of medium-gluten wheat flour, 40kg of water, 10kg of acetate starch, 3kg of gluten powder, 1.5kg of salt, compound phosphate (sodium tripolyphosphate, sodium pyrophosphate, sodium hexametaphosphate = 2:3:4 , the same below) 0.3kg, glyceryl monolaurate 0.2kg, sodium polyacrylate 0.05kg, glucono-δ-lactone 0.10kg. Wherein, the water mentioned is the active water obtained by low-temperature plasma treatment of pure water (the process parameters of low-temperature plasma treatment are still 42kV, 70Hz, 30s) (the same below).

[0048] Processing steps:

[0049] Combined ultraviolet and ozone sterilization for the operating environment before production; combined ultraviolet and ozone sterilization for 30min-50min according to the area of the operating environment before production, and the ozone concentration in the operating environment during the sterilization period is ≥5mg / m 3 , the equipment and countertops used are sprayed or wiped with ...

Embodiment 2

[0054] Instant noodle formula: 100kg of medium-gluten wheat flour, 42kg of water, 13kg of acetate starch, 4kg of gluten powder, 1.6kg of salt, 0.4kg of compound phosphate, 0.3kg of glyceryl monolaurate, 0.08kg of sodium polyacrylate, gluconic acid- δ-lactone 0.12kg.

[0055] Processing steps: Combined ultraviolet and ozone sterilization for the operating environment before production; combined ultraviolet and ozone sterilization for 30min-50min according to the area of the operating environment before production, and the ozone concentration in the operating environment during the sterilization period is ≥5mg / m 3 ; The equipment and countertops used are sprayed or wiped with 75% edible alcohol for disinfection to avoid bacterial contamination during the preparation process.

[0056] Weigh the raw materials in proportion to avoid external source pollution; dissolve table salt, compound phosphate, glyceryl monolaurate, sodium polyacrylate, glucono-δ-lactone in water and stir ev...

Embodiment 3

[0060] Instant noodle formula: 100kg of medium-gluten wheat flour, 42kg of water, 15kg of acetate starch, 5kg of gluten powder, 1.8kg of salt, 0.4kg of compound phosphate, 0.4kg of glyceryl monolaurate, 0.10kg of sodium polyacrylate, gluconic acid- δ-lactone 0.24kg.

[0061] Processing steps:

[0062] Combined ultraviolet and ozone sterilization for the operating environment before production; combined ultraviolet and ozone sterilization for 30min-50min according to the area of the operating environment before production, and the ozone concentration in the operating environment during the sterilization period is ≥5mg / m 3 ; The equipment and countertops used are sprayed or wiped with 75% edible alcohol for disinfection to avoid bacterial contamination during the preparation process.

[0063] Weigh the raw materials in proportion to avoid external source pollution; dissolve table salt, compound phosphate, glyceryl monolaurate, sodium polyacrylate, glucono-δ-lactone in water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com