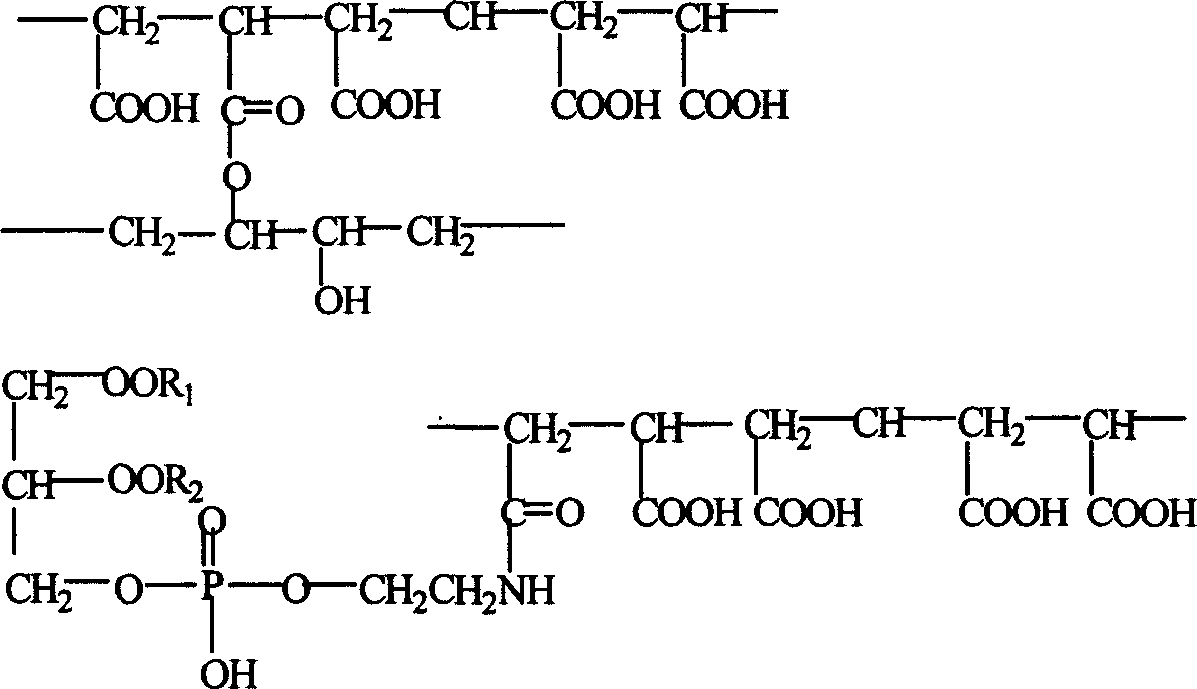

Method for preparing lecithoid retanning agent with lipide being added

A technology of retanning agent and phospholipid, which is applied in the field of preparation of phospholipid fatliquoring retanning agent, can solve the problems of no moisturizing effect, lack of moisturizing feeling of leather, and inconspicuous fatliquoring effect, etc., and achieve good emulsion stability and moisturizing feeling The effect of strengthening and increasing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0006] Example 1: First, 4 moles of acrylic acid and 6 moles of maleic anhydride are dissolved in 200% of its own mass in toluene as a mixed single solution, and 1% of its monomer mass in benzoyl peroxide is dissolved in 10 times its own mass in toluene As the initiator solution, add the initiator solution dropwise to the mixed monomer solution under stirring at 100°C, and the dropping time is controlled at 30 minutes. After 8 minutes after the dropwise addition, add 0.1% mercaptoacetic acid of the monomer mass, and keep warm React for 30 minutes to obtain acrylic acid-maleic anhydride copolymer; then heat the concentrated soybean lecithin containing more than 70% of phospholipid to 70°C, add dropwise 10% of concentrated phospholipid mass percentage concentration of 16% peracetic acid, add dropwise 40 minutes, oxidation reaction for 30 minutes, vacuum dehydration after the reaction to obtain milky white slurry hydroxylated phospholipids; finally, heat 100 parts of hydroxylated ...

Embodiment 2

[0008] Embodiment 2: at first 2 moles of acrylic acid and 8 moles of maleic anhydride are dissolved with 200% of its own mass in toluene as a mixed monomer solution, and 6% of its own mass of benzoyl peroxide is dissolved with 10 times of its own mass in toluene Dissolve as the initiator solution, add the initiator solution dropwise to the mixed monomer solution under stirring at 50°C, the dropping time is controlled at 60 minutes, after 15 minutes after the dropwise addition, add 0.5% mercaptoacetic acid of the monomer mass, Heat preservation reaction for 90 minutes to obtain acrylic acid-maleic anhydride copolymer; then heat the concentrated soybean lecithin containing more than 70% phospholipid to 65°C, add dropwise the peracetic acid with a mass percentage concentration of 7% of the concentrated lecithin mass is 16%, drop Add 20 minutes, oxidize for 40 minutes, remove water in vacuum after the reaction is over to obtain milky white slurry-like hydroxylated phospholipids; fi...

Embodiment 3

[0009] Embodiment 3: first 3 moles of acrylic acid and 9 moles of maleic anhydride are dissolved with 200% of its own mass in toluene as a mixed monomer solution, and 3% of its own mass of benzoyl peroxide is dissolved with 10 times its own mass of toluene Dissolve as the initiator solution, add the initiator solution dropwise to the mixed monomer solution under stirring at 80°C, the dropping time is controlled at 45 minutes, after 12 minutes after the dropwise addition, add 0.2% mercaptoacetic acid of the monomer mass, Insulation reaction for 82 minutes to obtain acrylic acid-maleic anhydride copolymer; then the concentrated soybean lecithin containing more than 70% of phospholipids was heated to 50°C, and the concentration of 5% of the concentrated lecithin mass was added dropwise with peracetic acid having a concentration of 16%. Add 35 minutes, oxidize for 60 minutes, remove water in vacuum after the reaction is over to obtain milky white slurry-like hydroxylated phospholip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com