Preparation method of water dispersible alkyl/polyether amino silicone resin

A polyether amino and silicone resin technology, applied in the field of silicone resins, can solve the problems of restricting the application of silicone resins, and no patent report on water-dispersible alkyl/polyether amino silicone resins, etc., to improve water solubility, application Scope widening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

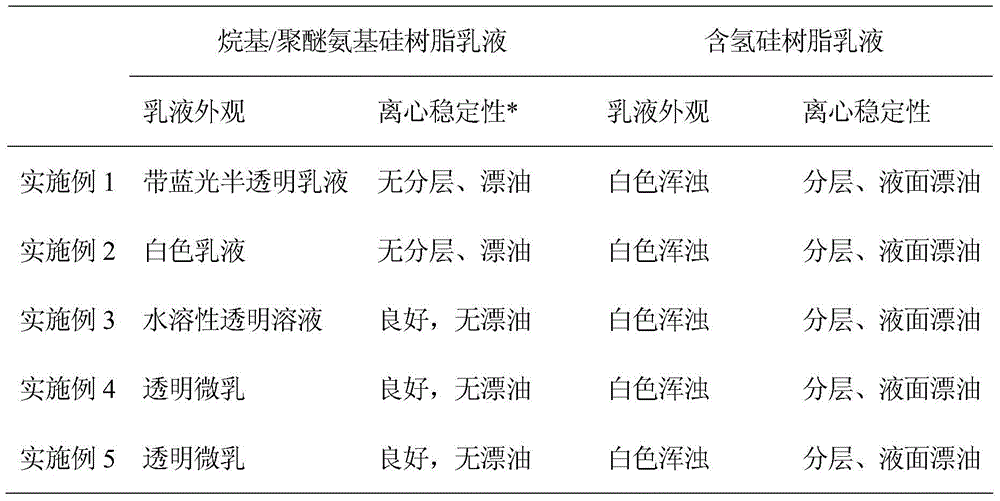

Examples

Embodiment 1

[0023] To a three-necked flask equipped with a thermometer, a reflux condenser, and an electric stirrer, 30 g of methyl hydrogen-containing silicone resin (containing 0.06 mol of Si-H bonds) with a viscosity of 2080 mPa·s and a Si-H bond content of 0.2% were sequentially added, 5.7g (0.05mol) allyl glycidyl ether and 1.14g (0.01mol) α-octene, then stir and pass N 2 Heat up to 70°C under protection, then add 20ppm catalyst chloroplatinic acid to the three-necked flask and keep it warm for 6h. After the reaction, cool down to room temperature to obtain a total of about 36.84g of colorless and transparent liquid, namely the intermediate octyl / 2,3-cyclo Oxypropoxypropyl silicone resin (referred to as octyl / epoxy silicone resin), containing about 0.05mol of epoxy group.

[0024] Continue to add 13.8g (0.06mol) polyetheramine D230 to the intermediate, stir and mix well, then heat up to 120°C for 1h reaction. After the reaction, the unreacted low boilers were evaporated under reduce...

Embodiment 2

[0026] Into a three-necked flask equipped with a thermometer, a reflux condenser, and an electric stirrer, 30 g of methyl hydrogen-containing silicone resin (containing 0.03 mol of Si-H bonds) with a viscosity of 5900 mPa s and a Si-H bond content of 0.1%, and 4.62g (0.0405mol) allyl glycidyl ether and 0.76g (0.0045mol) α-dodecene, then stir and pass N 2 Heat up to 100°C under protection, then add 50ppm catalyst chloroplatinic acid to the three-necked flask and keep it warm for 0.5h, then distill off excess allyl glycidyl ether under reduced pressure at a gauge pressure of 500mmHg and a temperature of 100°C, and cool down to room temperature A total of about 33.67 g of a colorless transparent viscous liquid, namely the intermediate dodecyl / epoxy silicone resin, containing about 0.0255 mol of epoxy groups was obtained.

[0027] Continue to add 7.04g (0.0306mol) of polyetheramine D230 to the intermediate, stir and mix well, then heat up to 45°C for 4h. After the reaction, the u...

Embodiment 3

[0029] Into a three-necked flask equipped with a thermometer, a reflux condenser, and an electric stirrer, 30 g of hydrogen-containing MQ silicone resin (containing 0.24 mol of Si-H bonds) with a viscosity of 130 mPa s and a Si-H bond content of 0.8%, 22.98 g (0.2016mol) allyl glycidyl ether, 12.7g (0.0504mol) α-octadecene and 60g isopropanol-toluene mixed solvent (mass ratio of isopropanol:toluene=1:1), and then Stir and pass N 2 Heated to 80°C under protection, then added 20ppm catalyst 1,3-divinyltetramethyldisiloxane platinum complex to the three-necked flask and kept it warm for 3 hours, then cooled down to room temperature to obtain a total of about 125.68g of Colorless transparent viscous liquid, namely the solution of intermediate octadecyl / epoxy silicone resin, containing about 0.2016mol of epoxy group.

[0030] Continue to add 80.64g (0.2016mol) polyetheramine D400 to the solution of the intermediate, stir and mix well, then heat up to 60°C for 2h reaction. After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com