Self-emulsifying lactescence and its preparation method

An emulsion and self-emulsification technology, which is applied in the field of self-emulsification emulsion and its preparation, can solve the problems of unfavorable environmental protection, high cost, and long preparation cycle, and achieve the effects of environmental protection, low biological toxicity, and good self-emulsification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of self-emulsifying emulsion, comprising steps as follows:

[0027] Weigh 30ml of silane coupling agent A172 and add it to 70ml of biodiesel, stir evenly, as the oil phase. Weigh 3.333g of nano-silica sol (effective content 30wt%, wherein nano-silica particle size is 12nm) and add to 96.667g distilled water as the water phase, the concentration of silica in the water phase is 1.0wt%. Weigh 18ml of the water phase and add it to the sample bottle, then weigh 2ml of the oil phase and add it to the above sample bottle. Shake gently 10 times, from emulsifying emulsion. After standing at 20°C for 3h, 12h, and 24h, the emulsion still maintained good stability. After standing at 20°C for 24h, the particle size of the emulsion was measured with a winner2000 laser particle size analyzer, and the results are shown in the table below.

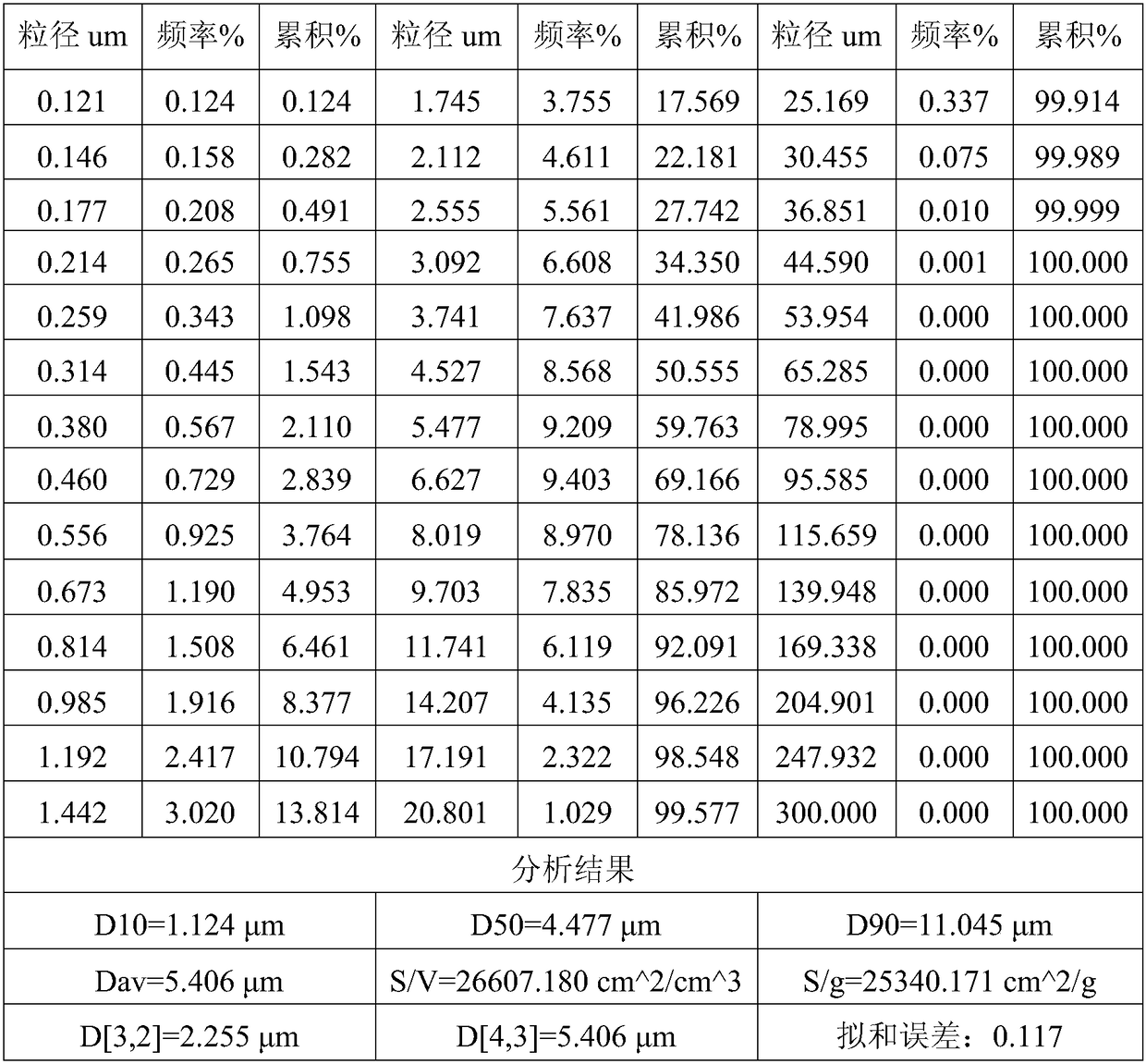

[0028] Table 1 Particle size of A172 self-emulsifying emulsion

[0029]

[0030] From the particle size analysis results...

Embodiment 2

[0034] A preparation method of self-emulsifying emulsion, comprising steps as follows:

[0035] Weigh 35ml of silane coupling agent A172 and add it to 65ml of biodiesel, stir evenly, as the oil phase. Weigh 2.667g of nano-silica sol (effective content 30wt%, nano-silica particle size 15nm) into 97.333g distilled water as the water phase, the concentration of silica in the water phase is 0.8wt%. Weigh 18.5ml of the water phase and add it to the sample bottle, then weigh 1.5ml of the oil phase and add it to the above sample bottle. Shake gently 10 times, from emulsifying emulsion. After standing at 20°C for 3h, 12h, and 24h, the emulsion still maintained good stability. After standing at 20°C for 24h, the particle size of the emulsion was measured with a winner2000 laser particle size analyzer, and the results are shown in the table below.

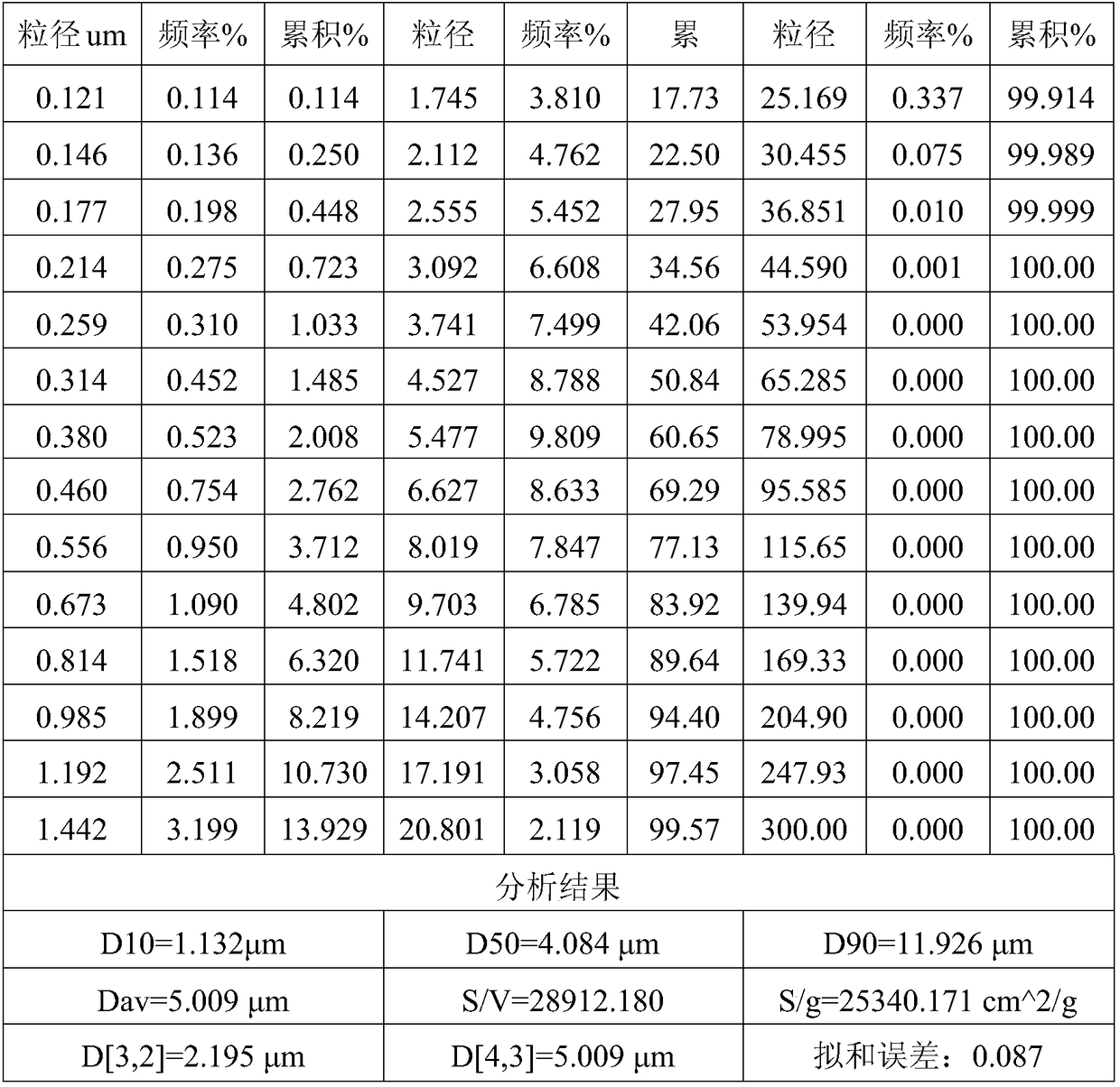

[0036] Table 2 Particle size of A172 self-emulsifying emulsion

[0037]

[0038] From the particle size analysis results in Table 2, ...

Embodiment 3

[0042] A preparation method of self-emulsifying emulsion, comprising steps as follows:

[0043] Weigh 40ml of silane coupling agent KH702 and add it to 60ml of biodiesel, stir evenly, as the oil phase. Weigh 1.667g of nano-silica sol (effective content 30wt%, nano-silica particle size 15nm) and add to 98.333g distilled water as the water phase, the concentration of silica in the water phase is 0.5wt%. Weigh 19ml of the water phase and add it to the sample bottle, then weigh 1ml of the oil phase and add it to the above sample bottle. Shake gently 10 times, from emulsifying emulsion. After standing at 20°C for 3h, 12h, and 24h, the emulsion still maintained good stability. After standing at 20°C for 24h, the particle size of the emulsion was measured with a winner2000 laser particle size analyzer, and the results are shown in the table below.

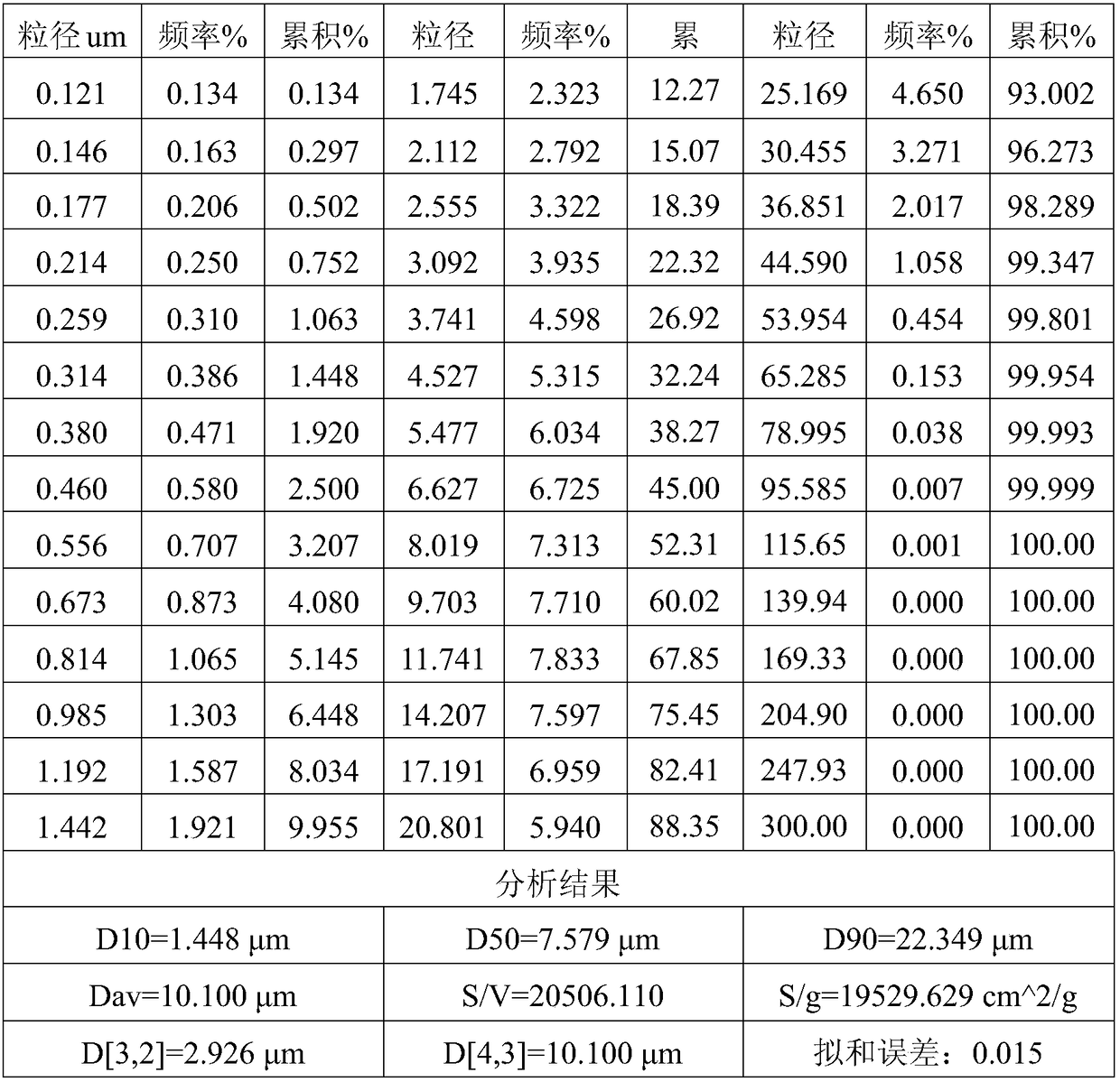

[0044] Table 3 KH702 self-emulsifying emulsion particle size table

[0045]

[0046] From the particle size analysis results in Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com