High strength modified polyester resin coating

A technology for modifying polyester and resin coatings, applied in polyester coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of limiting the application of high-performance coatings, large shrinkage, and low toughness, so as to reduce volume shrinkage and improve Reinforcing performance and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

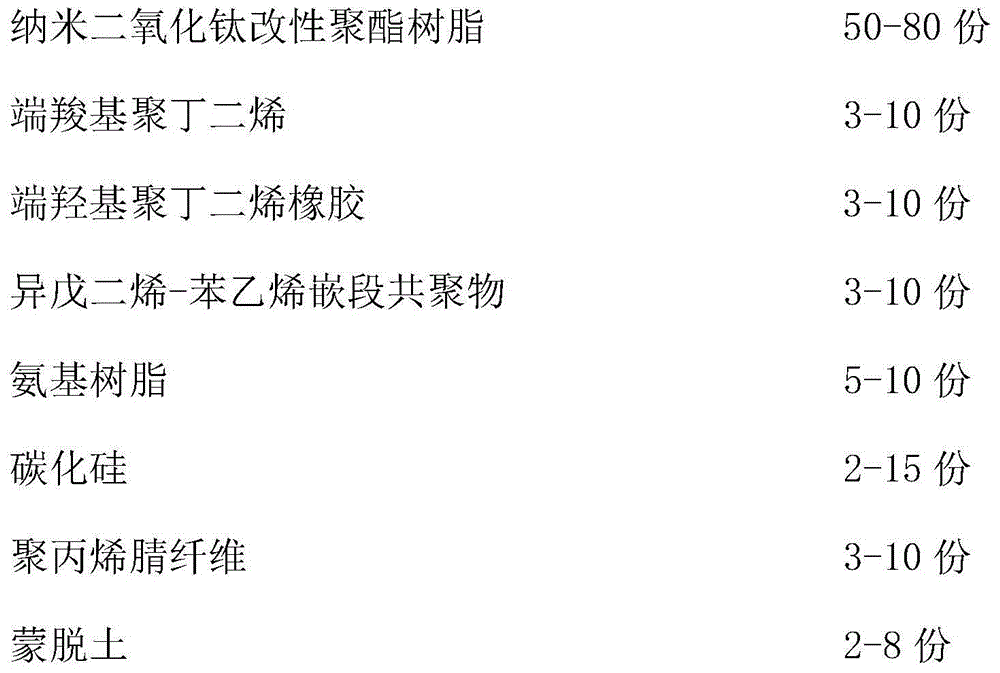

[0024] A kind of high-strength modified polyester resin paint that the present invention proposes, its raw material comprises the following components by weight:

[0025]

Embodiment 2

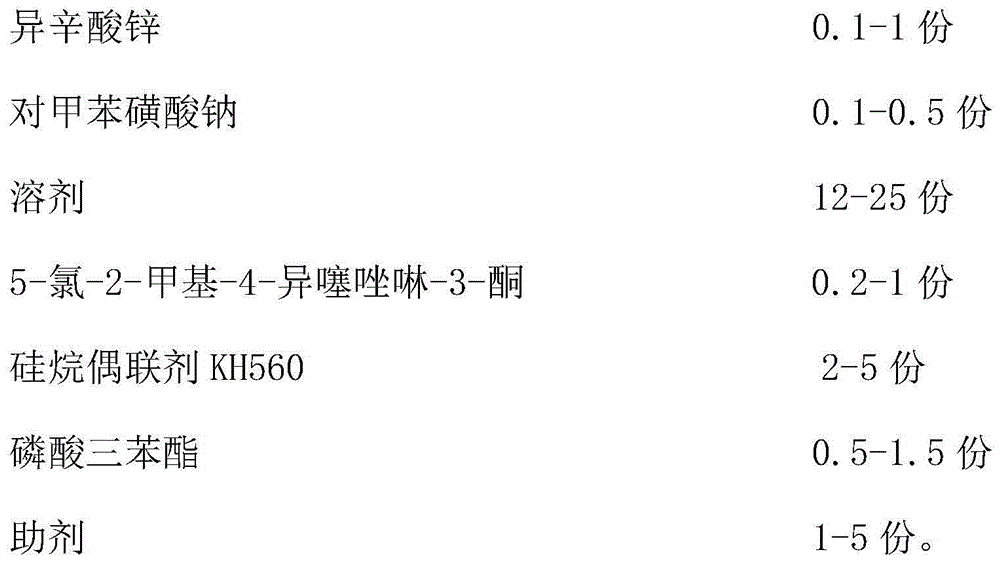

[0027] A kind of high-strength modified polyester resin paint that the present invention proposes, its raw material comprises the following components by weight:

[0028]

[0029]

[0030] Wherein, the nano-titanium dioxide-modified polyester resin is prepared according to the following process: adding nano-titanium dioxide and vinyltriethoxysilane to ethanol, heating to 45°C, stirring for 3 hours, cooling, filtering, drying, and crushing to obtain the modified Nano-titanium dioxide; mix maleic anhydride, isophthalic acid, hexanediol and modified nano-titanium dioxide evenly, raise the temperature to 140°C, react for 2.5h, raise the temperature to 175°C, react for 3h, and then in a vacuum of 0.1MPa React under reduced pressure for 1 hour, add paraffin and dicyclopentadiene after cooling down to 160°C, add styrene and 2,4-toluene diisocyanate after cooling down to 110°C, stir for 100 minutes to obtain nano titanium dioxide modified polyester resin.

Embodiment 3

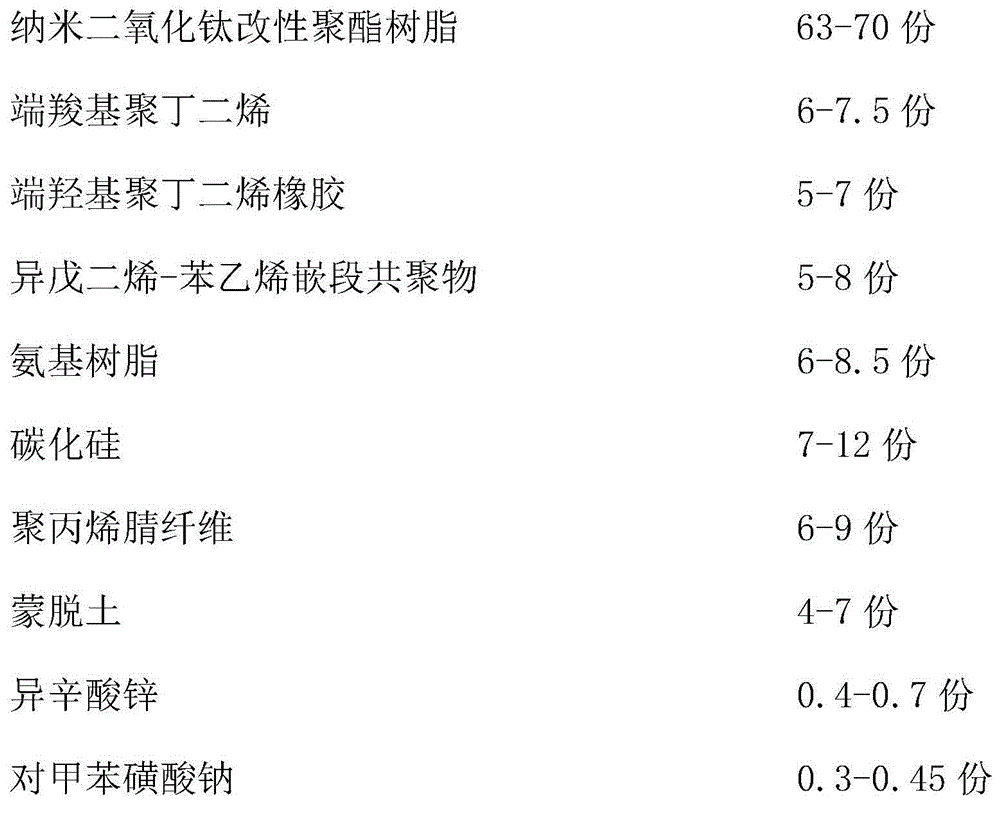

[0032] A kind of high-strength modified polyester resin paint that the present invention proposes, its raw material comprises the following components by weight:

[0033]

[0034] Wherein, the nano-titanium dioxide-modified polyester resin is prepared according to the following process: add 45 parts of nano-titanium dioxide and 0.8 part of vinyltriethoxysilane to 80 parts of ethanol in parts by weight, heat to 53 ° C and stir for 2.6 hours, After cooling down, filter, dry, and pulverize to obtain modified nano-titanium dioxide; mix 2.3 parts of maleic anhydride, 3.8 parts of isophthalic acid, 10 parts of hexanediol and 0.35 parts of modified nano-titanium dioxide in molar parts, and heat up to 150°C , react for 2.3 hours, heat up to 186°C, react for 2.5h, then react under reduced pressure for 2h under the condition of vacuum degree of 0.25MPa, add 0.15 parts of paraffin and 0.8 parts of dicyclopentadiene after cooling down to 158°C, and cool down to 126°C Then add 0.7 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com