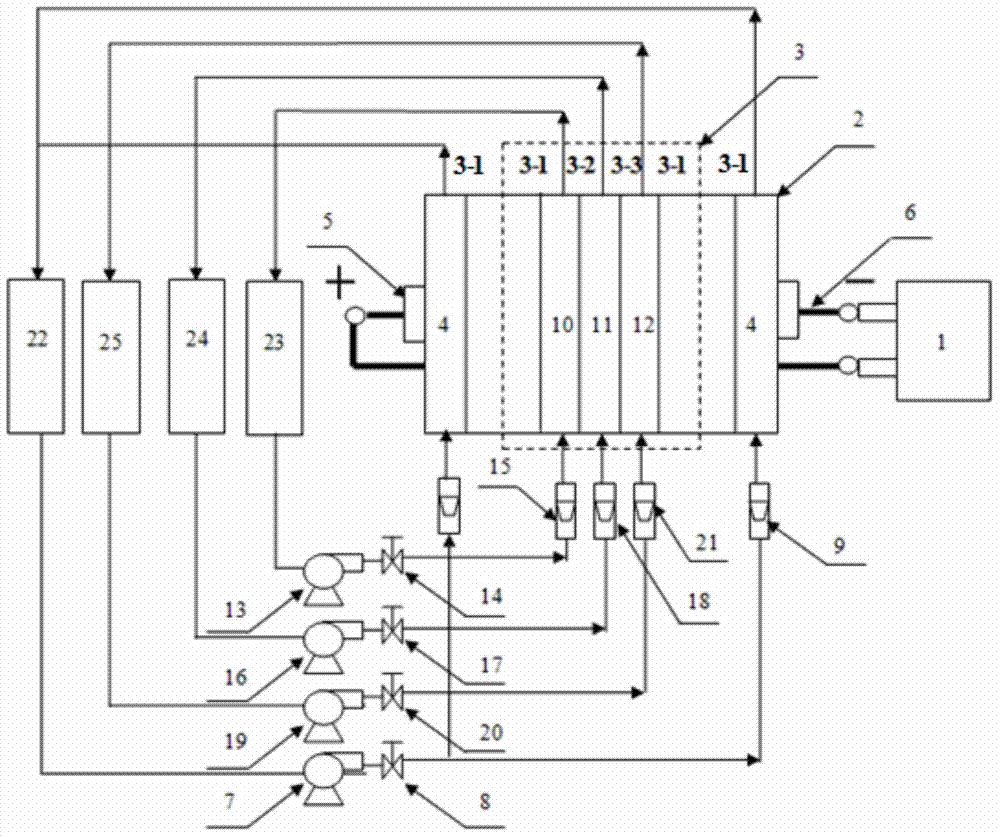

Device and method for processing sodium p-toluenesulfonate waste liquor

A technology of sodium p-toluenesulfonate and waste liquid, used in water/sludge/sewage treatment, water pollutants, dispersed particle separation, etc., can solve the problems of easy oxidation, corrosion resistance, etc. Longevity, the effect of reducing polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

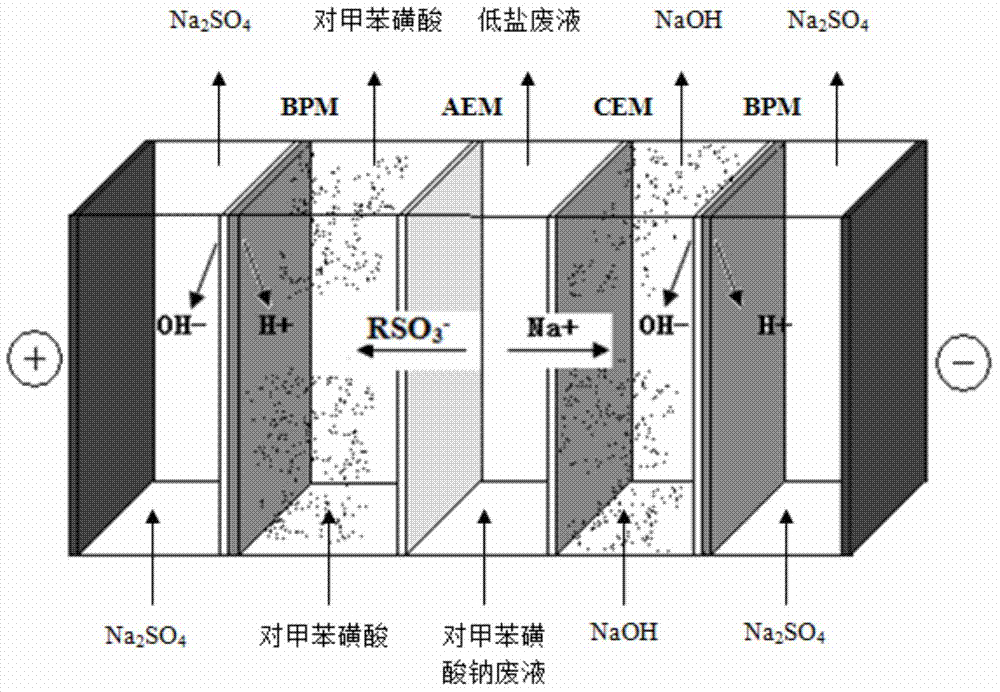

[0063] Filter the paint waste liquid containing sodium p-toluenesulfonate through a microporous membrane to remove suspended matter in the waste liquid. Acid chamber / salt chamber / alkali chamber (three-chamber) membrane unit composed of anion membrane-cation membrane-bipolar membrane, the salt chamber is not filled with ion exchange resin, and the alkali chamber is filled with quaternary ammonium-OH type anion exchange resin (201× 7 Strongly basic styrene-based heterogeneous anion exchange resin), the acid chamber is filled with sulfonic acid H-type cation-exchange resin (001×7 strongly acidic styrene-based heterogeneous cation-exchange resin). The initial influent of the salt chamber is the filtered sodium p-toluenesulfonate waste liquid with a concentration of 17g / L. In order to ensure a certain conductivity, the initial water intake of the alkali chamber is a sodium hydroxide solution with a pH of 8, the acid chamber is a p-toluenesulfonic acid solution with a pH of 5, and t...

Embodiment 2

[0065] The acid chamber / salt chamber / alkali chamber (three-chamber) membrane unit composed of anion membrane-cation membrane-bipolar membrane is adopted. The salt chamber is not filled with ion exchange resin, the alkali chamber is filled with anion exchange resin, and the acid chamber is filled with cation exchange resin. The initial water intake of the acid chamber is a p-toluenesulfonic acid solution with a pH of 6, the initial water intake of the alkali chamber is a sodium hydroxide solution with a pH of 9, and the remaining operating conditions are the same as in Example 1. The results are shown in Table 1.

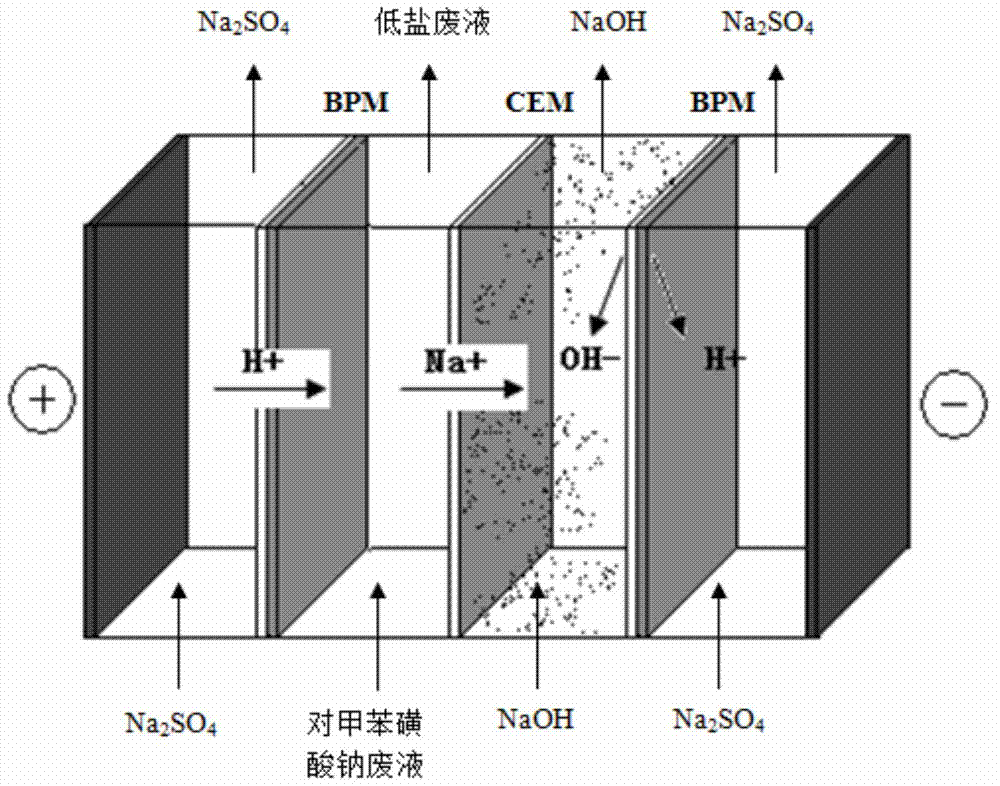

Embodiment 3

[0067] The acid chamber / salt chamber / alkali chamber (three-chamber) membrane unit composed of anion membrane-cation membrane-bipolar membrane is adopted. The salt chamber is filled with anion-cation mixed exchange resin, and the ratio of anion exchange resin to cation exchange resin is 7:3. The base compartment is filled with anion exchange resin and the acid compartment is filled with cation exchange resin. All the other operating conditions are the same as in Example 1. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com