Method using neutralizing wastewater in BHT (butylated hydroxytoluene) production to produce sodium p-toluenesulfonate

A technology of sodium p-toluenesulfonate and p-toluenesulfonic acid is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., and can solve problems such as increasing the difficulty and cost of wastewater treatment, increasing COD, and unfavorable environmental protection. , to achieve the effect of safe and reliable production process, mild reaction conditions and significant social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

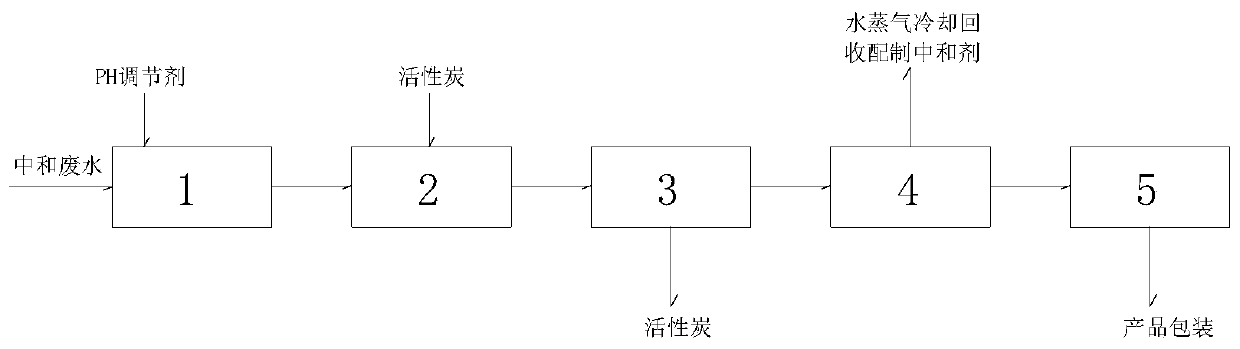

[0031] according to figure 1 The production process shown is a kind of BHT production neutralization wastewater, wherein the content of sodium p-toluenesulfonate is 19.8%, and the content of alkali neutralizer (alkali containing sodium ions) is 3.7%. The specific steps of using the neutralized wastewater to produce sodium p-toluenesulfonate include: adding an appropriate amount of pH regulator (p-toluenesulfonic acid) to the pH adjustment kettle to adjust the pH value of the neutralized wastewater to 6-7, and then the pump is turned into decolorization Add activated carbon to the decolorization kettle and raise the temperature to 80-90°C. After stirring for 1 hour to decolorize, the pump is transferred to the filter press to filter out the activated carbon. The liquid enters the evaporation and concentration kettle and is heated and evaporated to 120- At 125°C, enter the slicer to cool and slice to obtain the product sodium p-toluenesulfonate, and the evaporated water vapor is...

Embodiment 2

[0033] according to figure 1 The production process shown is a kind of BHT production neutralization wastewater, wherein the content of sodium p-toluenesulfonate is 11.2%, and the content of alkali neutralizer (alkali containing sodium ions) is 2.1%. The specific steps for producing sodium p-toluenesulfonate from the neutralized waste water include: adding an appropriate amount of pH regulator (p-toluenesulfonic acid) to the pH adjustment tank to adjust the pH value of the neutralized waste water to 6-7, and then transfer it to the decolorization tank , add activated carbon into the decolorization kettle and raise the temperature to 80-90°C, stir for 1 hour to decolorize, then transfer to a filter press, filter out the activated carbon, the liquid enters the evaporation and concentration kettle, heat and evaporate to 120-125°C under normal pressure, Enter the slicer to cool and slice to obtain the product sodium p-toluenesulfonate, and the evaporated water vapor is condensed a...

Embodiment 3

[0035] according to figure 1 The production process shown is a kind of BHT production neutralization wastewater, wherein the content of sodium p-toluenesulfonate is 26.8%, and the content of alkali neutralizer (alkali containing sodium ions) is 4.7%. The specific steps for producing sodium p-toluenesulfonate from the neutralized waste water include: adding an appropriate amount of pH regulator (p-toluenesulfonic acid) to the pH adjustment tank to adjust the pH value of the neutralized waste water to 6-7, and then transfer it to the decolorization tank , add activated carbon into the decolorization kettle and raise the temperature to 80-90°C, stir for 1 hour to decolorize, then transfer to a filter press, filter out the activated carbon, the liquid enters the evaporation and concentration kettle, heat and evaporate to 120-125°C under normal pressure, Enter the slicer to cool and slice to obtain the product sodium p-toluenesulfonate, and the evaporated water vapor is condensed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com