Preparation method of organic anion pillared rare earth hydroxide nanosheet sol

A rare earth hydroxide, organic anion technology, applied in rare earth metal compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of poor luminescence effect and complicated preparation process, and achieve rich research significance and application prospects, good Monochromatic, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

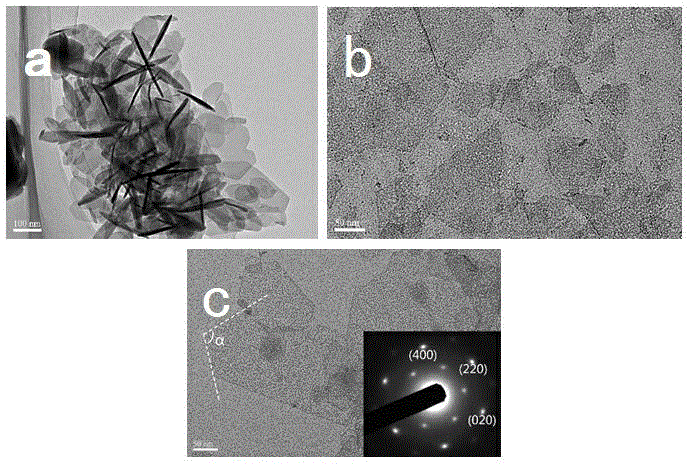

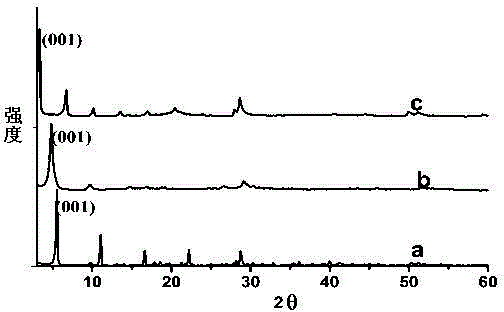

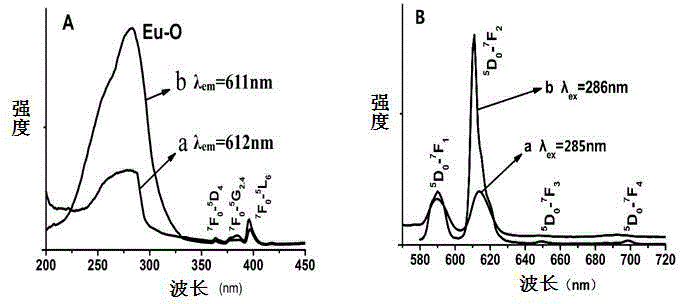

Embodiment 1

[0020] a. Get 1g of yttrium nitrate hexahydrate and dissolve it in 50ml of deionized water, add 0.061g europium nitrate hexahydrate; wherein Eu(NO 3 ) 3 ·6H 2 O and Y (NO 3 ) 3 ·6H 2 The ratio of the amount of substances between O is 1 to 19;

[0021] b, adjust step a with dilute ammonia to obtain the pH value of the solution, and adjust pH=7;

[0022] c, 0.475g sodium benzoate is dissolved in 10ml distilled water and then added in the solution of step b, wherein the ratio of the amount of Ln substance to the amount of sodium benzoate substance is 1 to 1.2, and the mixture is stirred for 30min and then transferred to polytetrafluoroethylene The substrate was reacted at 120°C for 24h in a reactor. After the reaction is finished, the product is filtered with suction, washed with water, washed with ethanol, and dried at 50°C for 1 hour to obtain the layered material Y of benzoate-supported rare earth hydroxide 1.9 Eu 0.1 (OH) 5 [C 6 h 5 COO]·2H 2 O;

[0023] d, tak...

Embodiment 2

[0026] a. Get 1g of yttrium nitrate hexahydrate and dissolve it in 50ml of dehydrated alcohol, add 0.061g europium nitrate hexahydrate; wherein Eu(NO 3 ) 3 ·6H 2 O and Y (NO 3 ) 3 ·6H 2 The ratio of the amount of substances between O is 1 to 19;

[0027] b, adjust step a with dilute ammonia to obtain the pH value of the solution, and adjust pH=8;

[0028] c, 0.568g of sodium p-toluenesulfonate is dissolved in 10ml of distilled water, and then added to the Ln(NO 3 ) 3In the solution, the ratio of the amount of Ln to the amount of sodium p-toluenesulfonate is 1 to 1.2, and the mixture is stirred for 30 minutes and then transferred to a reaction kettle with a polytetrafluoroethylene substrate at 120° C. for 24 hours. After the reaction is finished, filter the product with suction, wash with water, wash with ethanol, and dry at 50°C for 1 hour to obtain the rare earth hydroxide Y intercalated with sodium p-toluenesulfonate 1.9 Eu 0.1 (OH) 5 [C 7 h 7 COO]·2H 2 O;

...

Embodiment 3

[0032] a. Get 1g of yttrium nitrate hexahydrate and dissolve it in 50ml of dehydrated alcohol, add 0.061g europium nitrate hexahydrate; wherein Eu(NO 3 ) 3 ·6H 2 O and Y (NO 3 ) 3 ·6H 2 The ratio of the amount of substances between O is 1 to 19;

[0033] b, adjust step a with dilute ammonia to obtain the pH value of the solution, and adjust pH=6;

[0034] C, 0.952g sodium lauryl sulfate is dissolved in 10ml distilled water, then joins in the solution of step b, wherein the ratio of the amount of substance of Ln substance and sodium lauryl sulfate is 1 to 1.2, will The mixture was stirred for 30 min, then transferred to a polytetrafluoroethylene-lined autoclave at 120 °C for 24 h. After the reaction is completed, the product is subjected to suction filtration, washed with water, washed with ethanol, and dried at 50°C for 1 hour to obtain the dodecylsulfate-supported rare earth hydroxide Y 1.9 Eu 0.1 (OH) 5 [C 12 h 25 -OSO 3 ]·2H 2 O;

[0035] d, take 0.1g of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com