Preparation method of CsPb2Br5 nanosheet

A technology of nanosheets and oleic acid, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effect of stable light response and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 CsPb 2 Br 5 preparation of

[0030] Preparation of CsPb by hot injection method 2 Br 5 Nanosheets, the preparation steps are:

[0031] (1) Mix 625mg of cesium stearate, 10ml of octadecene and 0.5ml of oleic acid under the environment of feeding nitrogen and maintaining mechanical magnetic stirring, and heating to 140°C for 0.5h to obtain a cesium oleate solution;

[0032] (2) Mix 100mg of lead bromide, 7.5ml of octadecene, 0.5ml of octylamine and 0.5ml of oleic acid, heat to 100°C and mix and stir for 0.5h to obtain PbBr 2 Precursor solution;

[0033] (3) Add 0.375ml of cesium oleate solution to PbBr by hot injection method 2 Precursor solution, the two were mixed and stirred for 3 hours to obtain a crude product, which cannot be used directly because of the presence of ligands on the surface of the crude product, and must be purified. The purification method is to add the same amount of toluene as the crude product, centrifuge at 8000r for 5min, repeat...

Embodiment 2

[0034] Example 2 CsPb 2 Br 5 preparation of

[0035] Preparation of CsPb by hot injection method 2 Br 5 Nanosheets, the preparation steps are:

[0036] (1) Mix 625mg of cesium stearate, 10ml of octadecene and 0.5ml of oleic acid under the environment of feeding nitrogen and maintaining mechanical magnetic stirring, and heating to 140°C for 0.5h to obtain a cesium oleate solution;

[0037] (2) Mix 100mg of lead bromide, 7.5ml of octadecene, 0.5ml of octylamine and 0.5ml of oleic acid, heat to 120°C and mix and stir for 0.5h to obtain PbBr 2 Precursor solution;

[0038] (3) Add 0.375ml of cesium oleate solution to PbBr by hot injection method 2 Precursor solution, the two were mixed and stirred for 3h, and the crude product was purified to obtain CsPb 2 Br 5 Nanosheets.

Embodiment 3

[0039] Example 3 CsPb 2 Br 5 preparation of

[0040] Preparation of CsPb by hot injection method 2 Br 5 Nanosheets, the preparation steps are:

[0041] (1) Mix 625mg of cesium stearate, 10ml of octadecene and 0.5ml of oleic acid under the environment of feeding nitrogen and maintaining mechanical magnetic stirring, and heating to 140°C for 0.5h to obtain a cesium oleate solution;

[0042] (2) Mix 100mg of lead bromide, 7.5ml of octadecene, 0.5ml of octylamine and 0.5ml of oleic acid, heat to 140°C and mix and stir for 1h to obtain PbBr 2 Precursor solution;

[0043] (3) Add 0.375ml of cesium oleate solution to PbBr by hot injection method 2 Precursor solution, the two were mixed and stirred for 3h, and the crude product was purified to obtain CsPb 2 Br 5 Nanosheets.

[0044] The CsPb prepared by embodiment 1-3 2 Br 5 Nanosheets were dispersed in toluene for preservation.

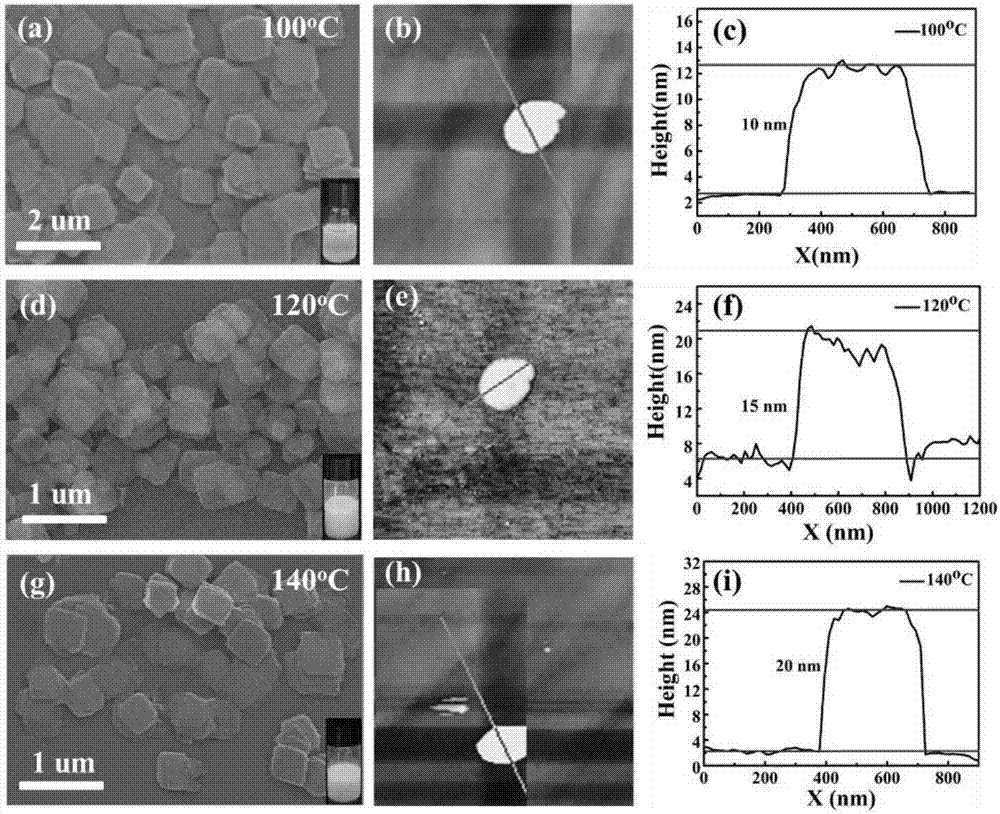

[0045] figure 1 Be the CsPb prepared under the different temperatures of embodiment 1-3 2 Br ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com