Method for preparing micro-capsule containing high light-effect rare earth compounding matter

A rare earth complex and microcapsule technology is applied in the field of preparation of microcapsules containing rare earth complexes with high optical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

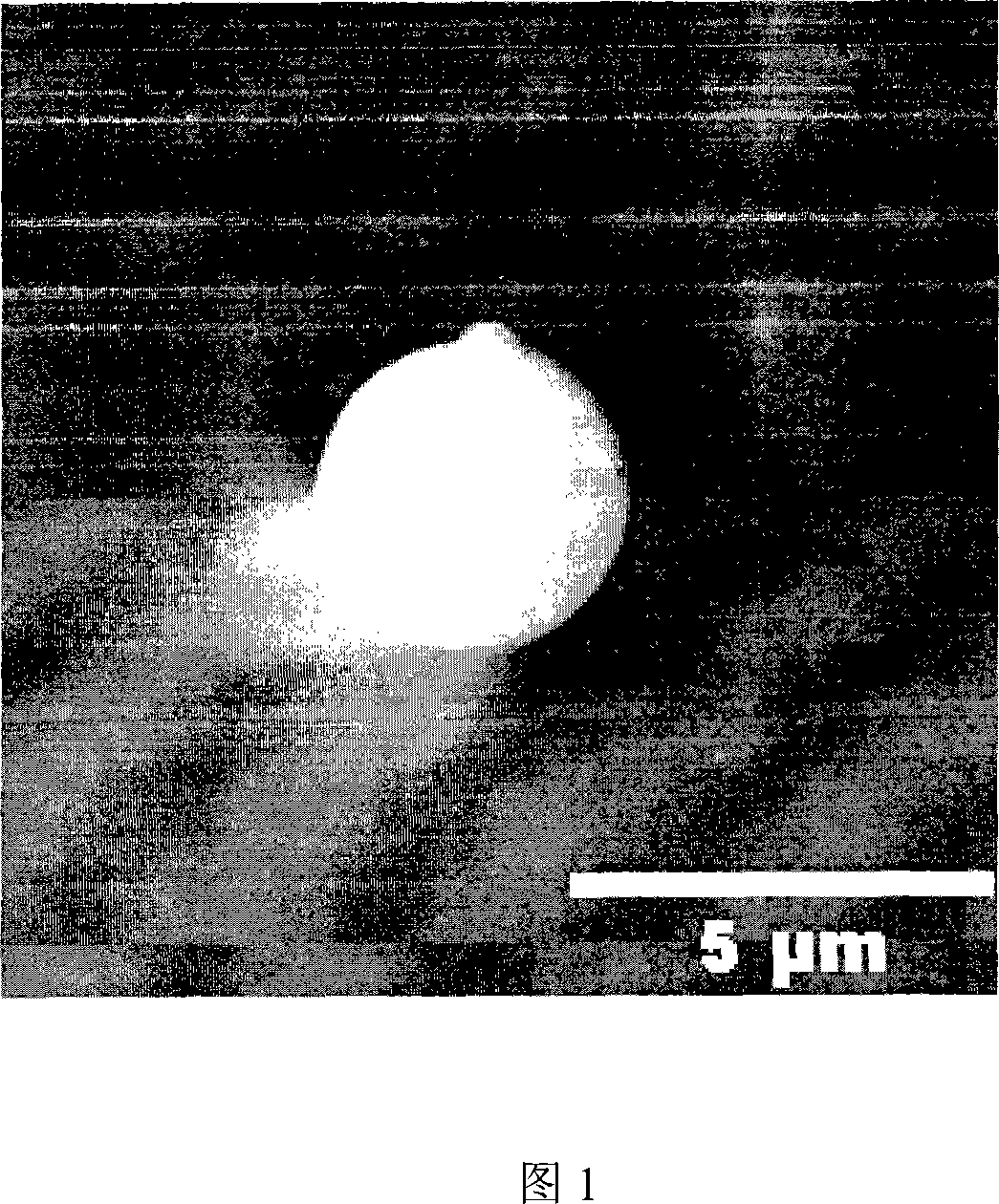

[0050] Embodiment 1. The preparation method of rare earth complex microcapsules containing high light efficiency, the steps are as follows:

[0051] (1) Select Europium(III) β-diketone complex Eu(DBM) 3 Phen;

[0052] (2) join the sodium chloride aqueous solution that concentration is 30mg / ml;

[0053] (3) With step (2) solution as solvent, select the anionic polyelectrolyte polystyrene sulfonate (PSS) that molecular weight is 70,000, mix its concentration and be the solution of 2.0mg / ml;

[0054] (4) select the cationic polyelectrolyte polyallyl ammonium chloride (PAH) that molecular weight is 70,000, take step (2) solution as solvent, mix its concentration and be the solution of 2.0mg / ml;

[0055] (5) by Eu(DBM) 3 Phen and PSS mass ratio are 1: 2 mixing the solution that step (1) obtains and the solution that step (3) obtains;

[0056] (6) by Eu(DBM) 3 Phen and PAH mass ratio are 1: 2 mixing the solution that step (1) obtains and the solution that step (4) obtains;

[...

Embodiment 2

[0066] Embodiment 2. The preparation method of rare earth complex microcapsules containing high light efficiency, the steps are as follows:

[0067] (1) Selection of rare earth complexes Eu(DBM) 3 Phen; with reference to embodiment 1 step (1)-(9) method, use MnCO 3 As template microspheres, make each milliliter solution contain 2.0×10 8 Microcapsules were deposited for 600 seconds, centrifuged at 3000rps for 600 seconds, and washed 3 times in ultrapure water to prepare Eu(DBM) 3 Solid Microcapsules of Phen {MnCO 3 [(Eu(DBM) 3 Phen / PAH)(Eu(DBM) 3 Phen / PSS)] 4} and hollow microcapsules [(Eu(DBM) 3 Phen / PAH)(Eu(DBM) 3 Phen / PSS)] 4 ;

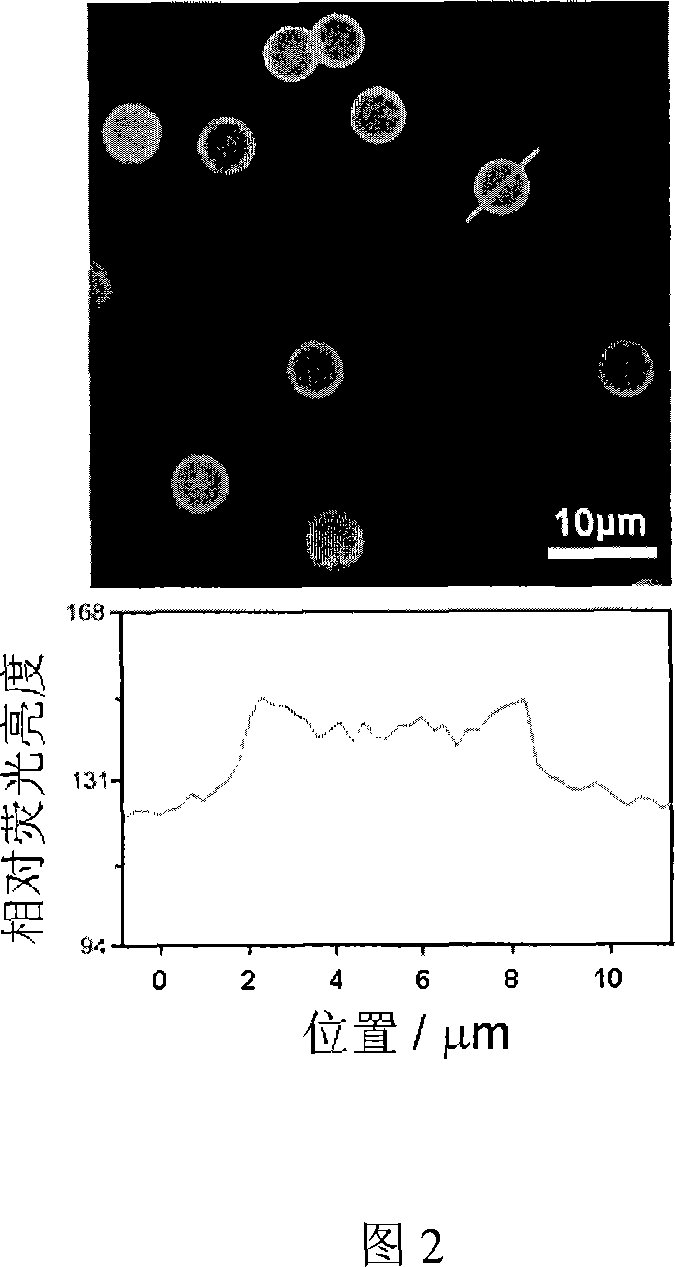

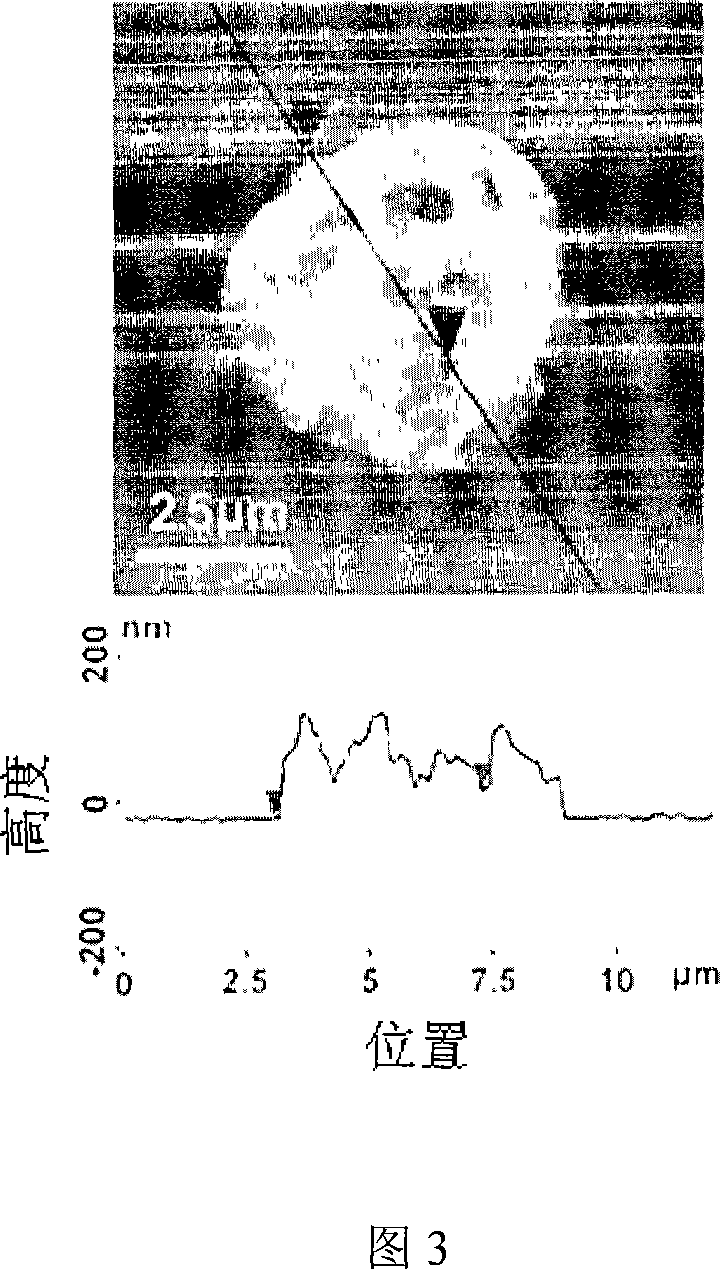

[0068] (2) Containing Eu(DBM) 3 The microcapsule film of Phen is complete and the structure is intact; the fluorescence performance of the microcapsule is excellent, and only one layer of Eu(DBM) is deposited in the shell 3 When Phen, the microcapsules emit light visible to the naked eye under the excitation of ultraviolet light; hollow E...

Embodiment 3

[0069] Example 3. The preparation method of microcapsules containing rare earth complexes with high light efficiency, the steps are as follows:

[0070] (1) Select the rare earth complex Eu(TTA) 3 Phen; with reference to embodiment 1 step (1)-(9) method, make every milliliter solution contain 5.0 * 10 7 Microcapsules were deposited for 600 seconds, centrifuged at 3000rps for 600 seconds, washed 3 times in ultrapure water, and prepared containing Eu(TTA) 3 Phen Solid Microcapsules {MF[(Eu(TTA) 3 Phen / PSS)(Eu(TTA) 3 Phen / PAH)] 4} and hollow microcapsules [(Eu(TTA) 3 Phen / PSS)(Eu(TTA) 3 Phen / PAH)] 4 ;

[0071] (2) Containing Eu(TTA) 3 The microcapsule film of Phen is complete and the structure is intact; the fluorescence performance of the microcapsule is excellent, and only one layer of Eu(TTA) is deposited in the shell 3 When Phen, the microcapsules emit light visible to the naked eye under the excitation of ultraviolet light; the hollow Eu(TTA) 3 The fluorescent emis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com