Patents

Literature

32results about How to "Reduce the chance of contamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

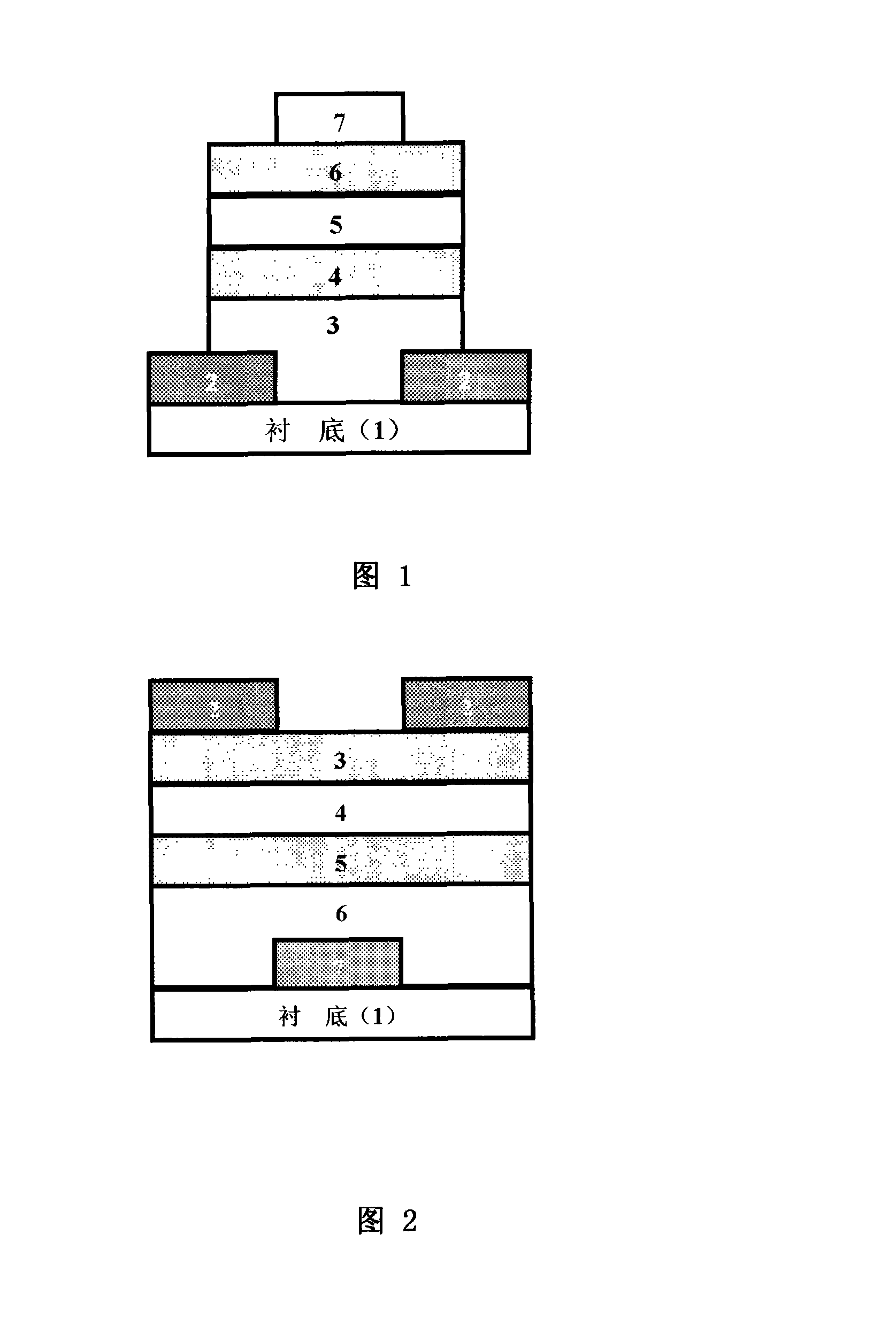

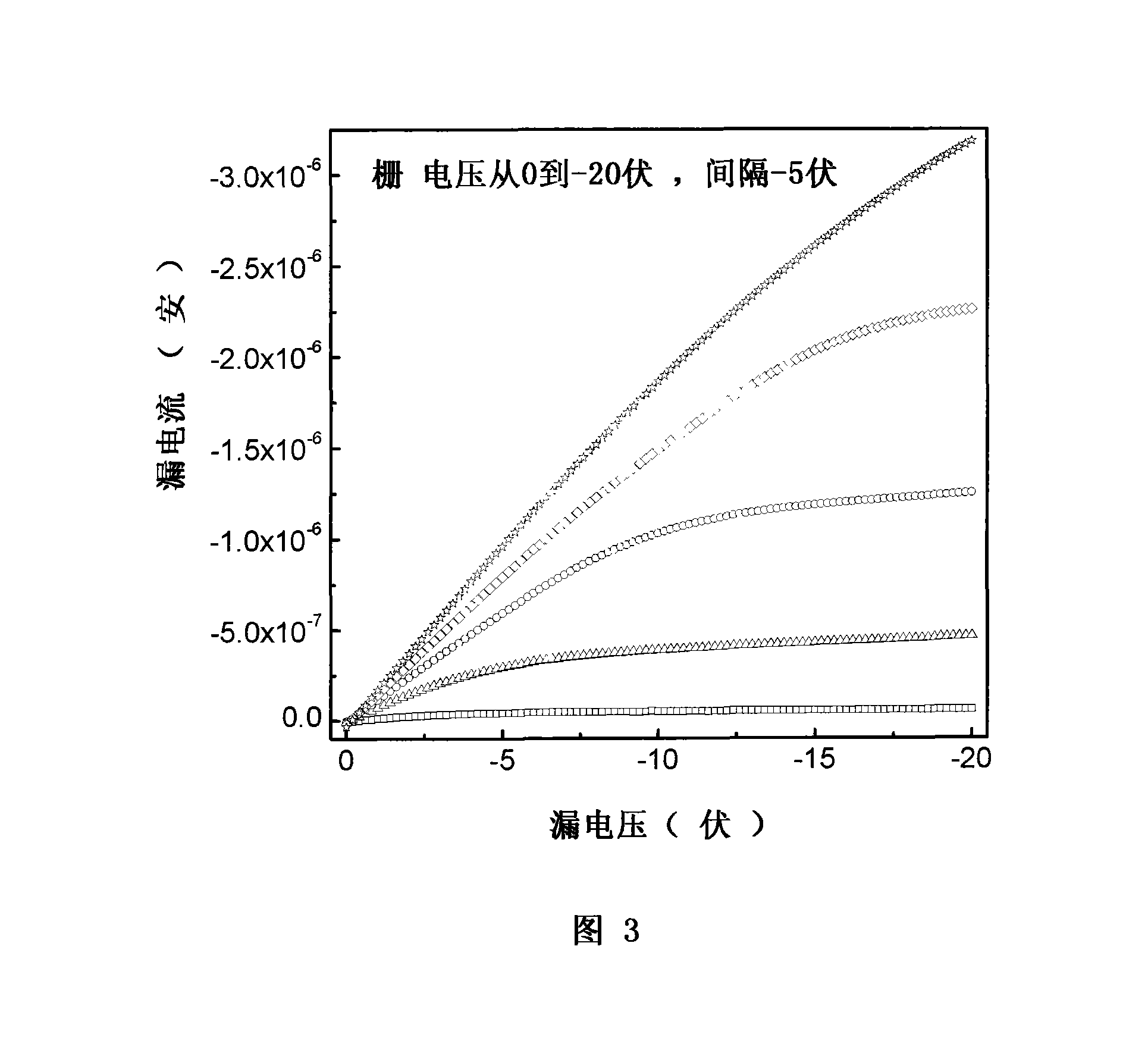

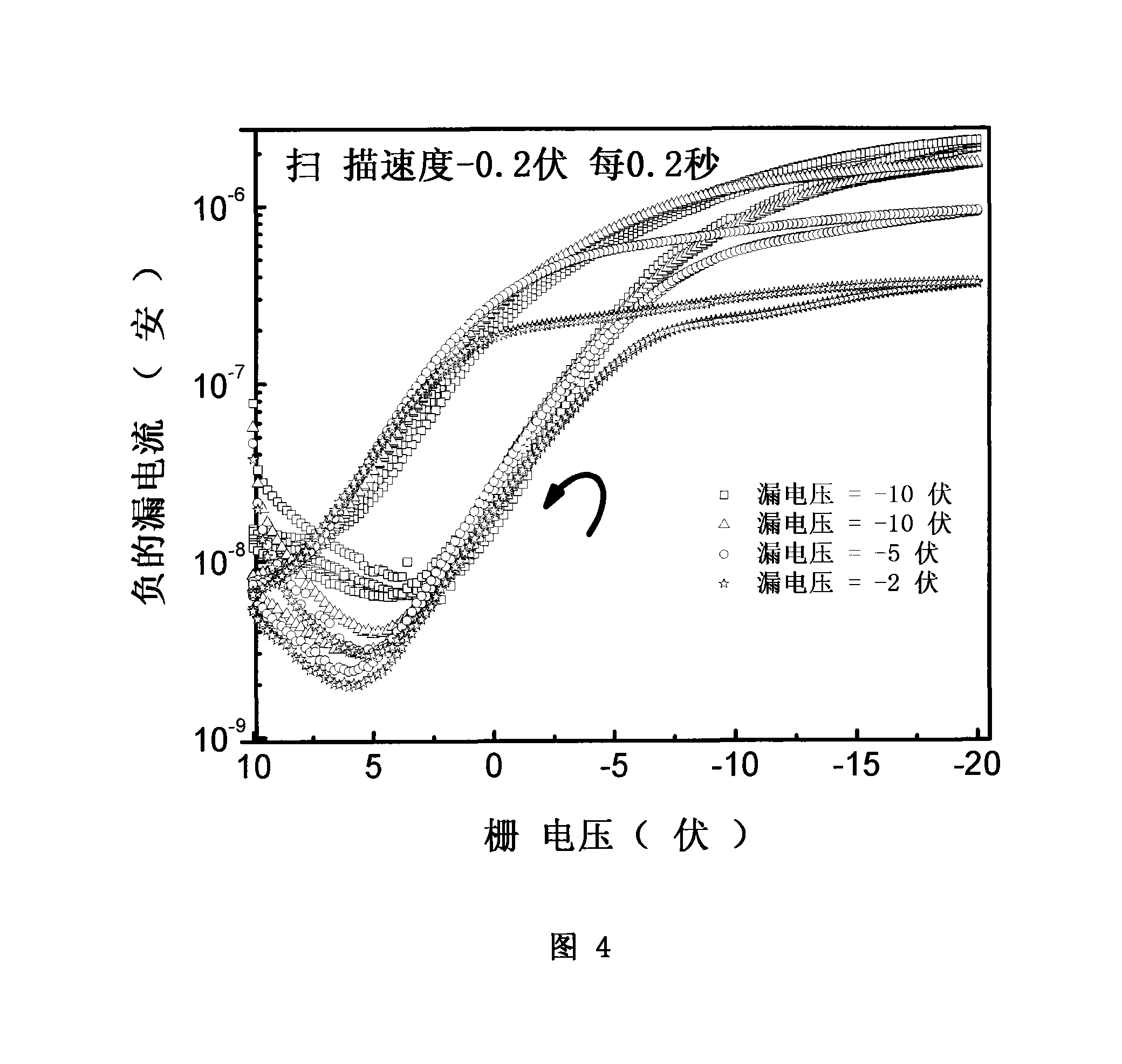

Non-volatile organic thin-film transistor memory based on floating gate structure and manufacturing method therefor

InactiveCN101179108AEasy to storeHigh Field Effect MobilitySolid-state devicesSemiconductor/solid-state device manufacturingBottom gateEngineering

The invention pertains to organic thin film transistorized memory based on floating gate structure. The manufacturing method adopts the top and bottom gate structures and the matched preparation process art respectively and introduces floating gate into medium layers between floating gate and control gate and realizes the nonvolatile memory of organic thin- film transistor. The invention has the advantages of simple process, low cost, small volume, low power dissipation and well stability.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

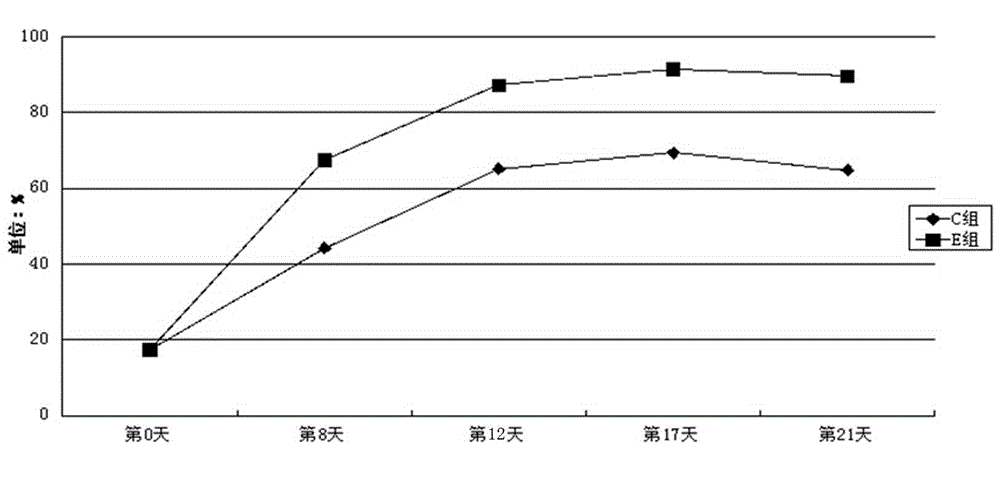

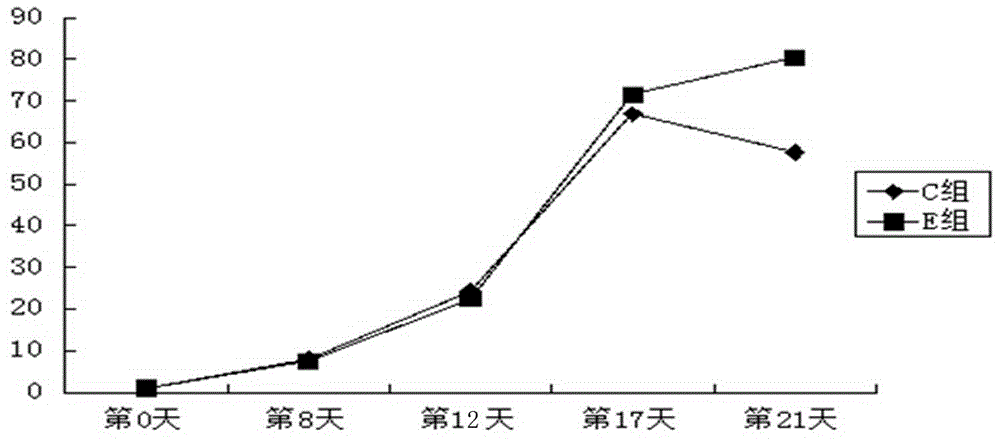

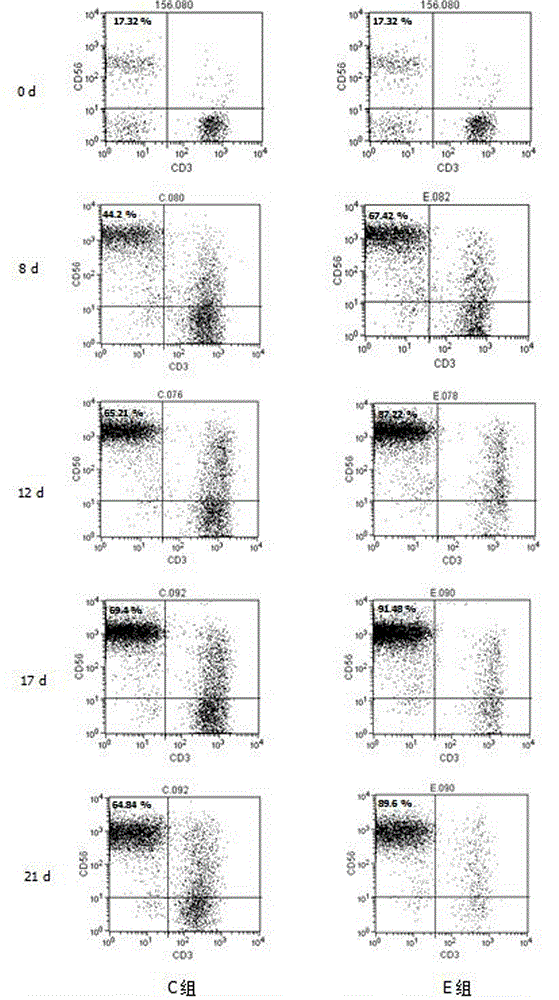

Solid tumor patient autologous NK cell separation, excitation, amplification and activity detection method

ActiveCN104928243ASimple and efficient operationReduce the chance of contaminationMicrobiological testing/measurementBlood/immune system cellsEffector cellCD3

The invention provides a solid tumor patient autologous NK cell separation, excitation, amplification and activity detection method. By the adoption of the NK cell separation, culturing and amplification method, highly active lymphocyte populations can be obtained through separation from peripheral blood, through stimulation of a series of in-vitro cell factors, NK cells (CD3-CD56+) are purified, activated and amplified greatly, and the NK cells can be applied to clinic treatment of tumors. Through the NK cell activity detection method, the kill rate of effector cells to target cells can be specifically analyzed in mixed cell sap of immune cells and tumor cells, interference from the effector cells in a detection result is avoided, and early apoptosis target cells and late apoptosis target cells can be analyzed. The method is easy and convenient to implement, the flexibility is high, the kill function of a cell can be detected at the single cell level, and the method has important significance in fundamental research conducted before clinical application of tumor adoptive cellular immunotherapy and quality control conducted in the clinical application process.

Owner:山西大医院

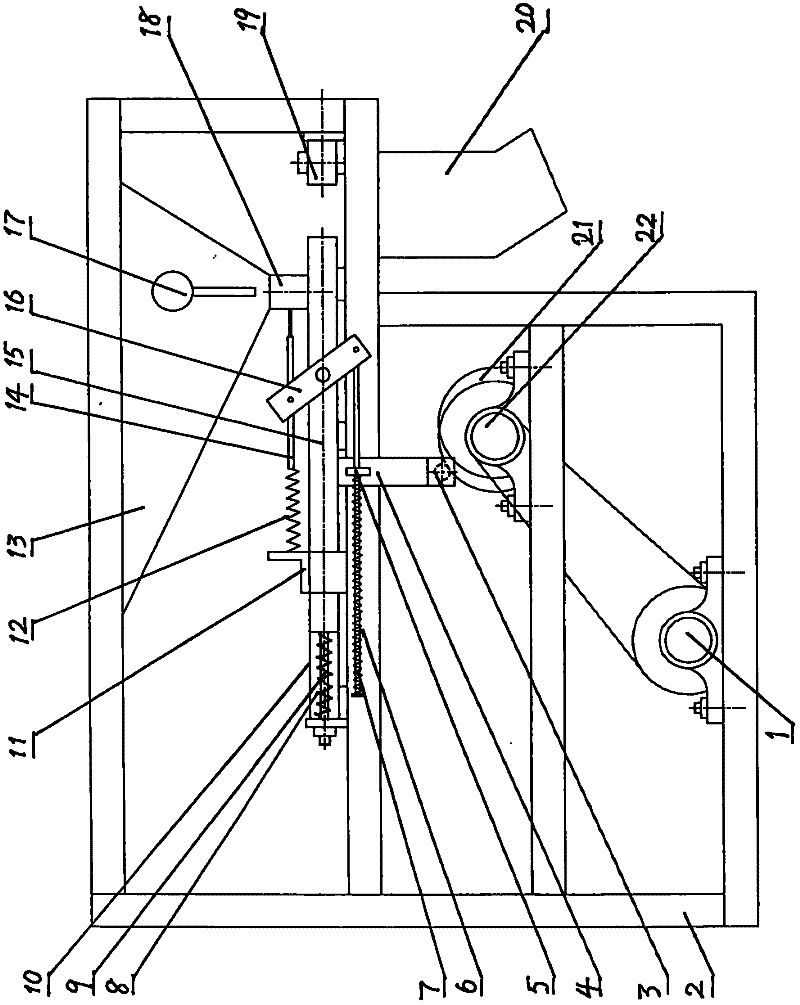

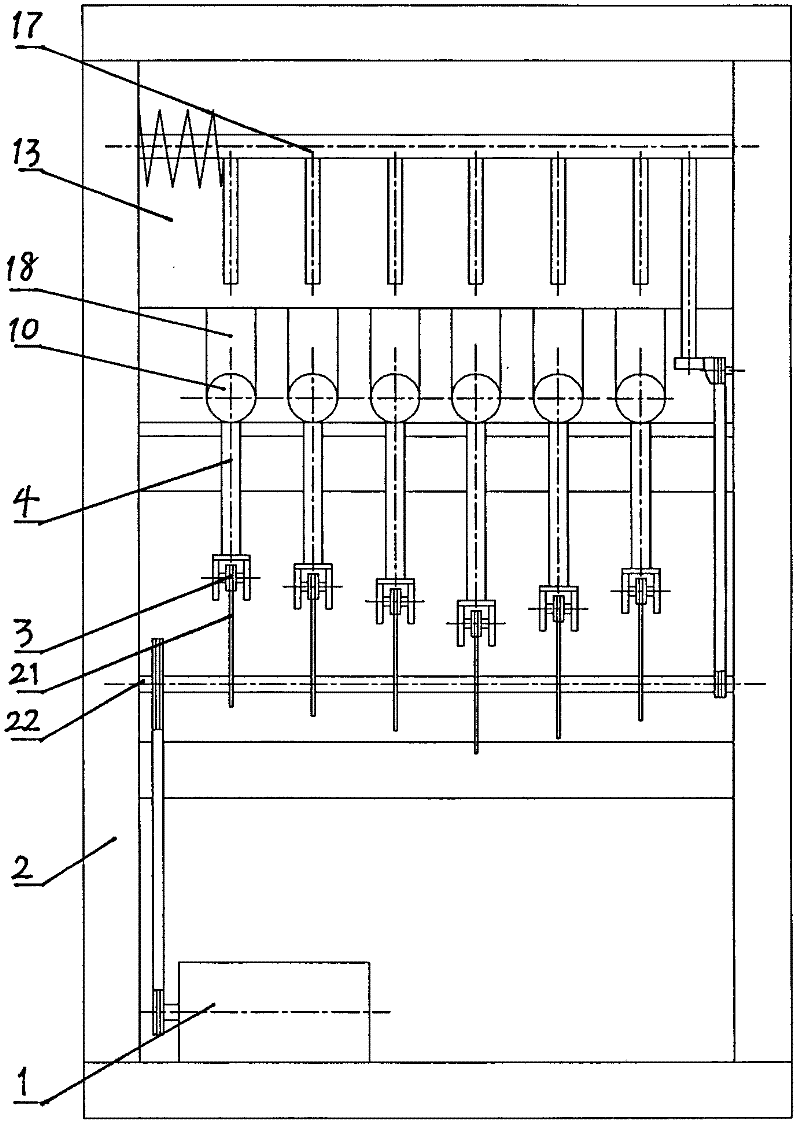

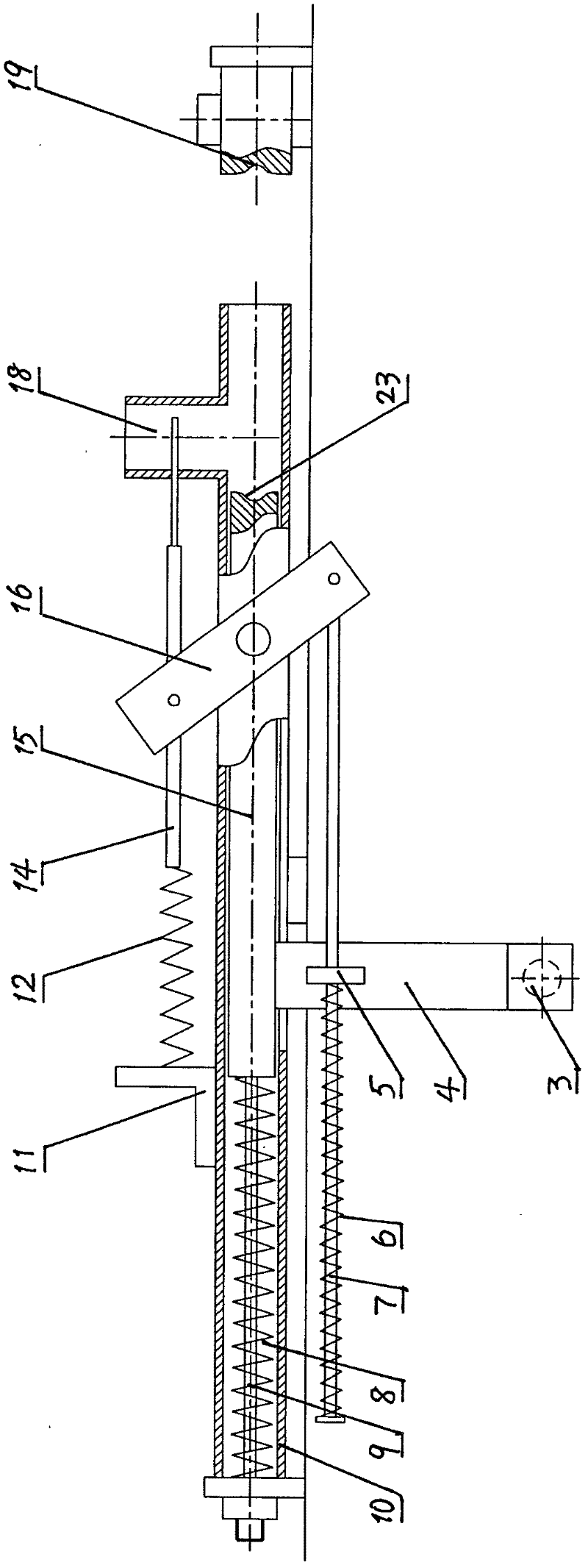

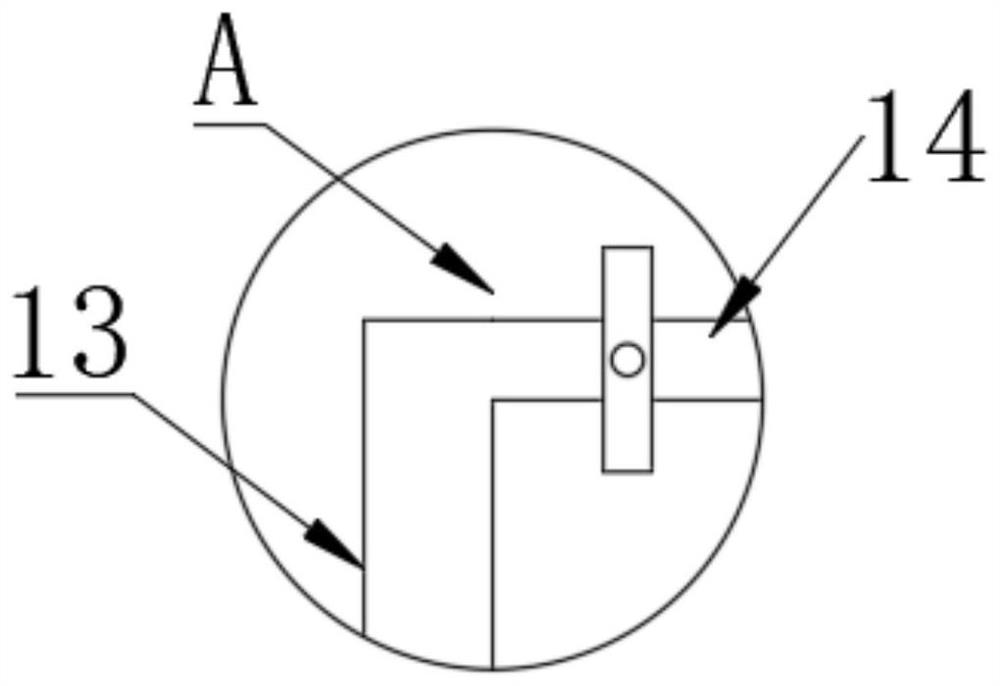

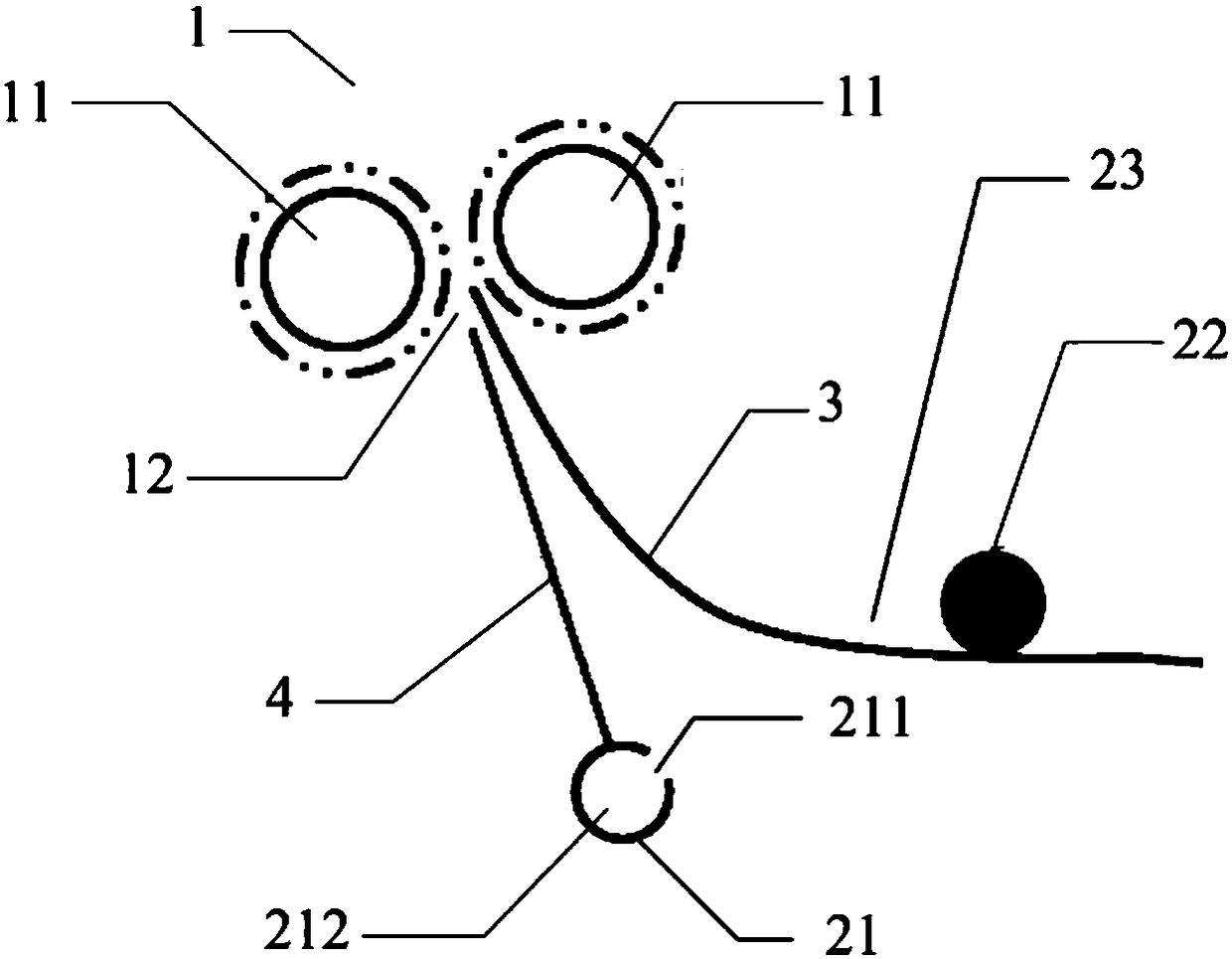

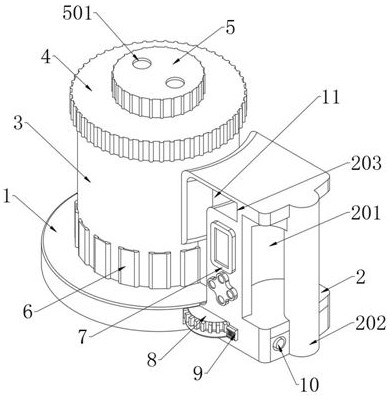

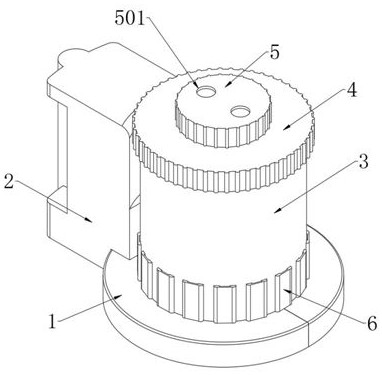

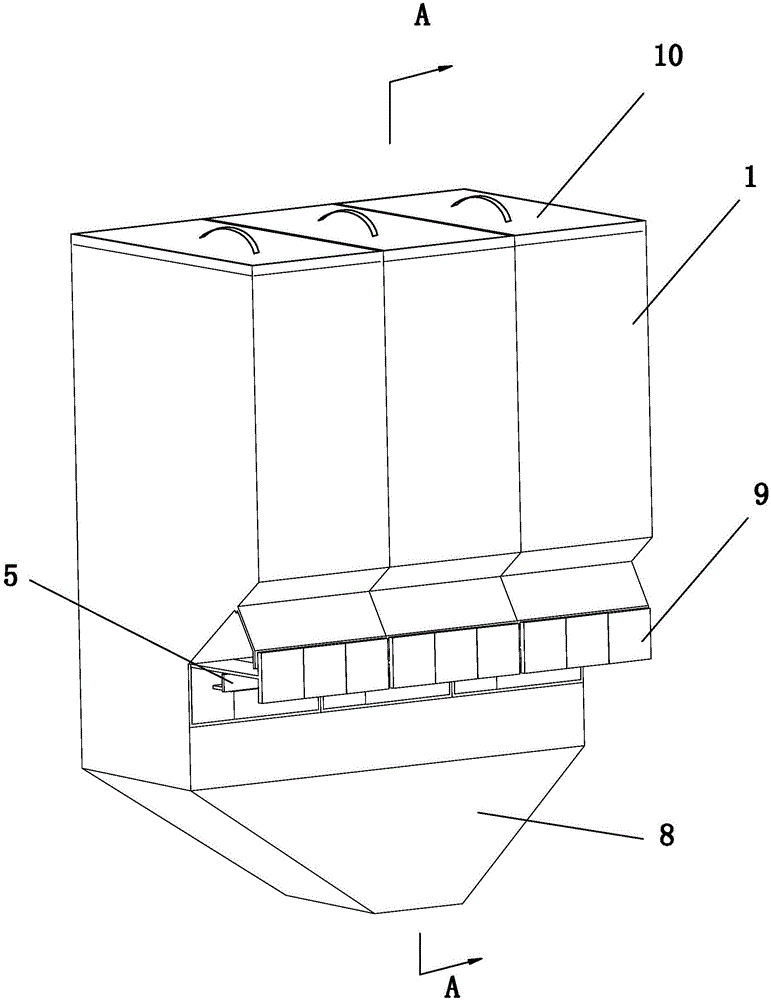

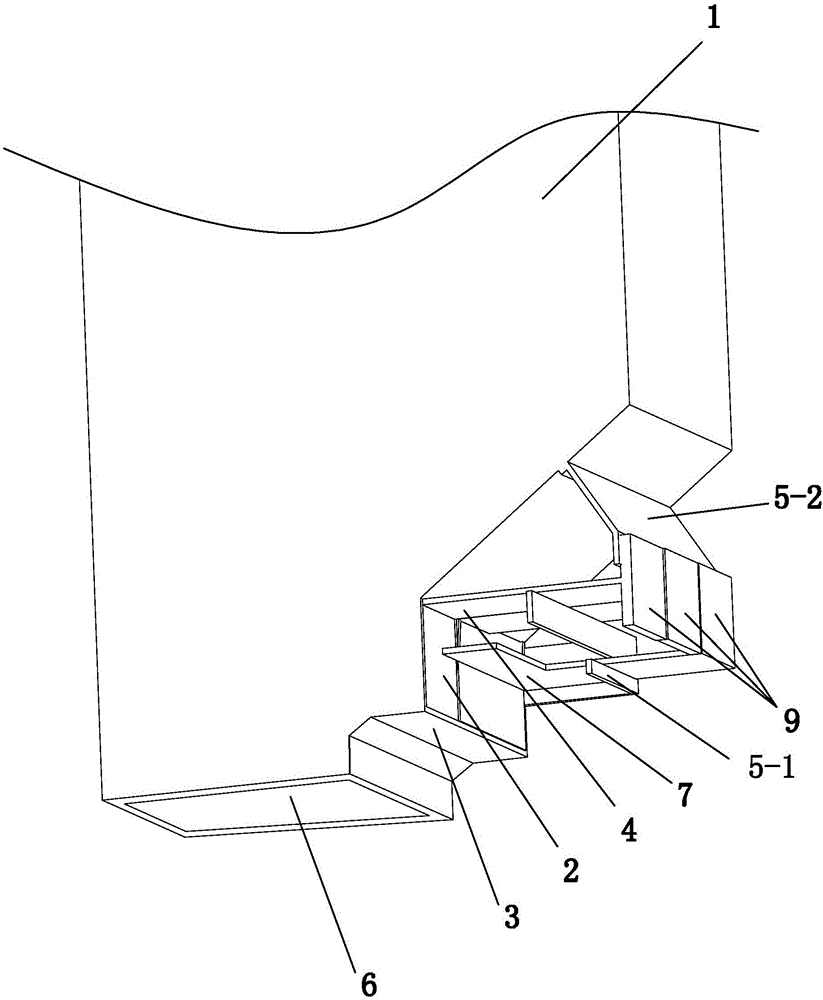

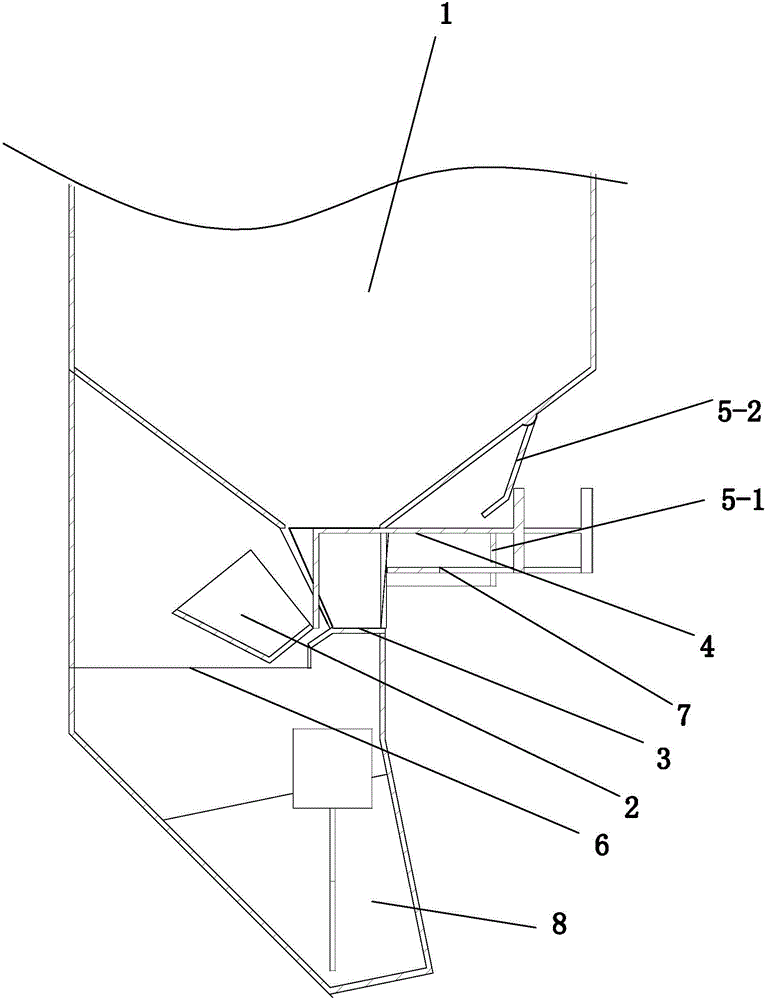

Pecan shelling machine

InactiveCN102283425AIncrease productivityReduce the chance of contaminationHuskingHullingEngineeringMechanical engineering

The invention discloses a shelling and integral kernel extracting machine for kiskatom, which comprises a stand (2), a feeding hopper (13), a discharging hopper (20), a motor (1) and a driving device of the motor (1). The shelling and integral kernel extracting machine is sequentially provided with the feeding hopper (13) from top to bottom; a kick-off grid (17) is arranged in the feeding hopper (17); a fruit falling pipe (18) is arranged at the bottom of the feeding hopper; an elastic impacting device and a fruit falling control device which are horizontally arranged are arranged below the feeding hopper (13); the discharging hopper (20), a transverse shaft (22) and a volute piece (21) on the transverse shaft are arranged below the elastic impacting device and the fruit falling control device; a gearbox of the motor (1) and a driving device are arranged at the lowermost part of the elastic impacting device and the fruit falling control device; and the elastic impacting device consists of a pressure spring (8), a socket spring rod (9), a guide sleeve (10), a sinking bar (15) and a fruit mortar (19). The invention relates to the shelling and kernel extracting machine and has high production efficiency and less pollution to the kernel compared with manual shell knocking and kernel extracting; and compared with a traditional shelling machine, the shelling and integral kernel extracting machine has high complete rate of integral kernel extraction of the kiskatom and improved selling price of the kernel.

Owner:刘志光

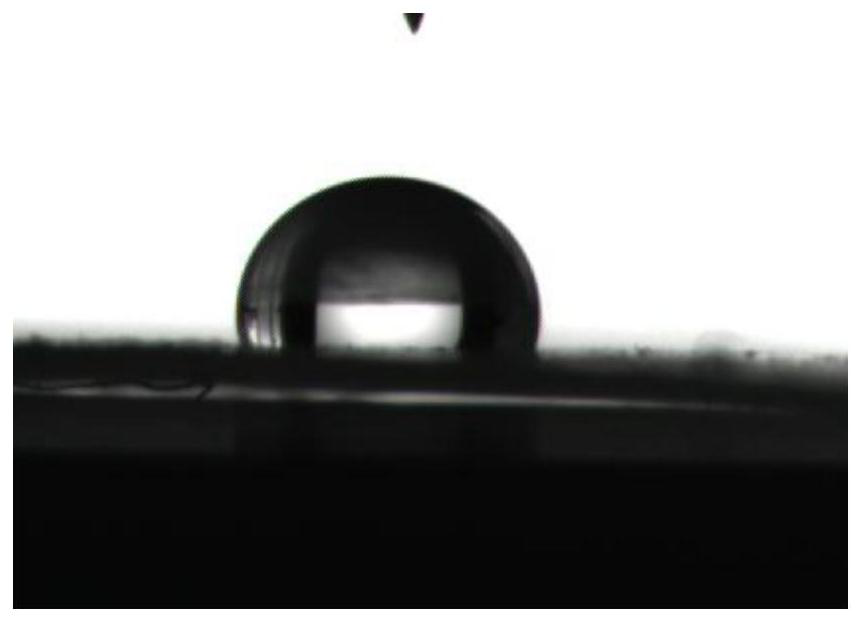

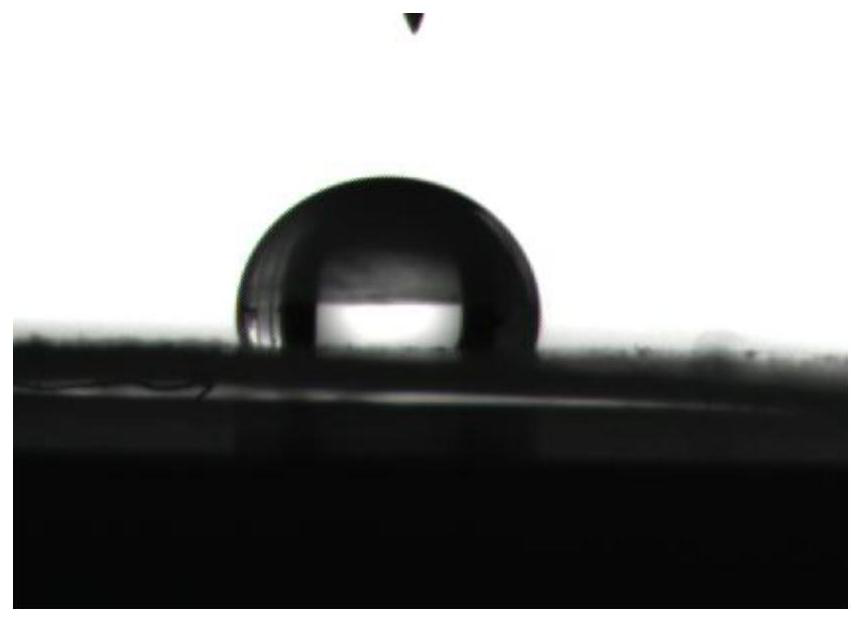

Long-lasting self-cleaned coating and preparation method thereof

InactiveCN107312407AReduce the chance of contaminationWash in timeAntifouling/underwater paintsPaints with biocidesSurface cleaningHigh surface

The invention provides a long-lasting self-cleaned coating which comprises the following components in parts by weight: 40-60 parts of a resin, 15-30 parts of a pigment filler, 1-5 parts of aids, 2-8 parts of active components, 20-40 parts of a solvent and 5-20 parts of a curing agent, wherein the aids comprise a dispersing agent, a defoaming agent and a leveling agent. The long-lasting self-cleaned coating provided by the invention has surface properties which are greatly different from those of a common coating, and has relatively high surface energy and humidity. If the coating is affected by external factors such as wind, frost, rain and snow, a relatively great amount of antifouling effective components can be slowly released from the coating continuously, and then surface cleaning of the coating is recovered. In different actual use environments, the long-lasting self-cleaned coating can last for 3-5 years or even longer, and can be applied to inner and outer coating of high-speed rains, vehicle stations and carriages, building aluminum profiles, aluminum veneers, metal curtain walls, glass curtain walls, automobiles, solar panels and decoration fields which require surface cleaning and cannot be frequently maintained or are barely maintained.

Owner:JIANGSU LEE & MAN CHEM +2

Anti-staining dyeing process for nylon-cotton blended fabric

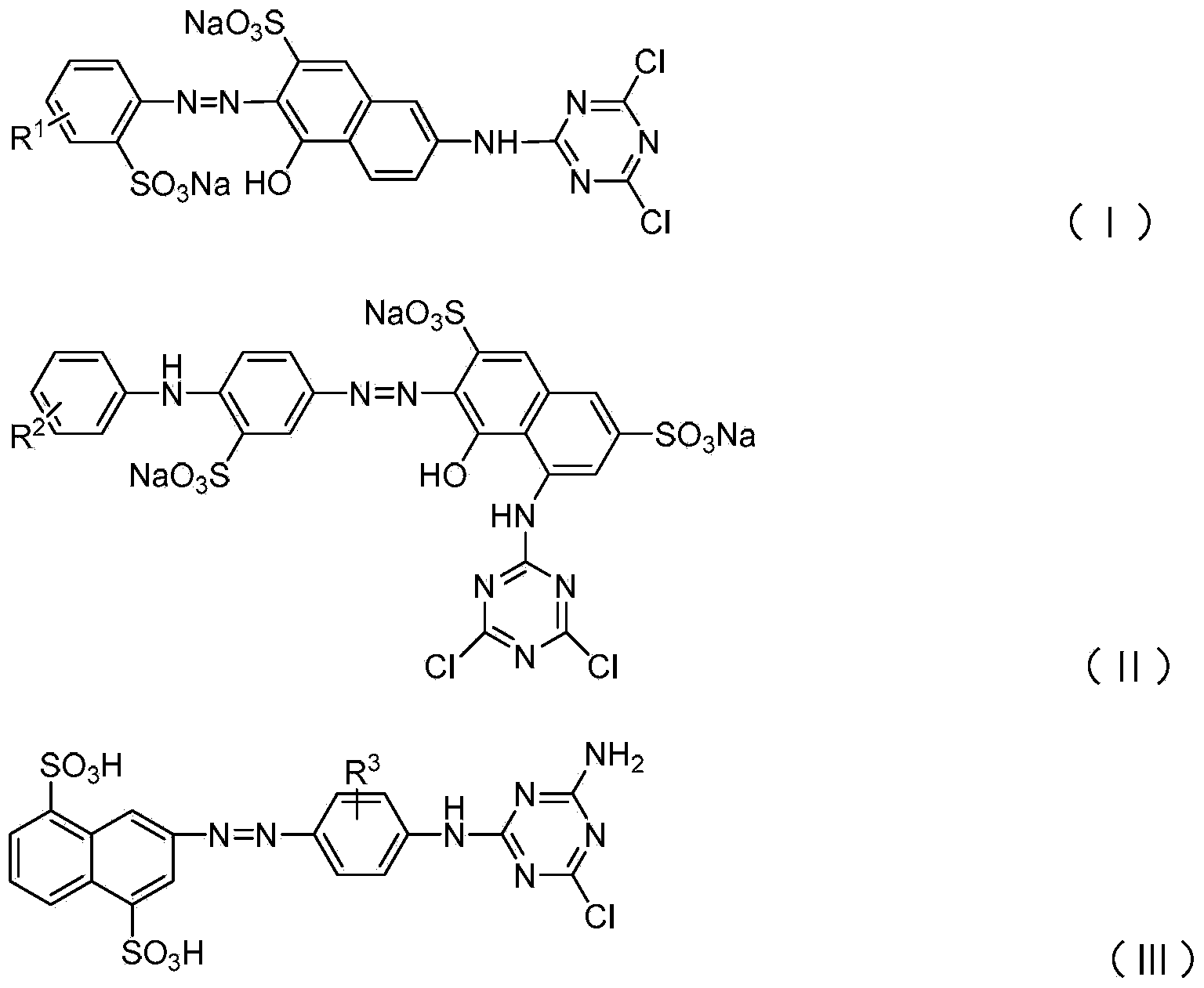

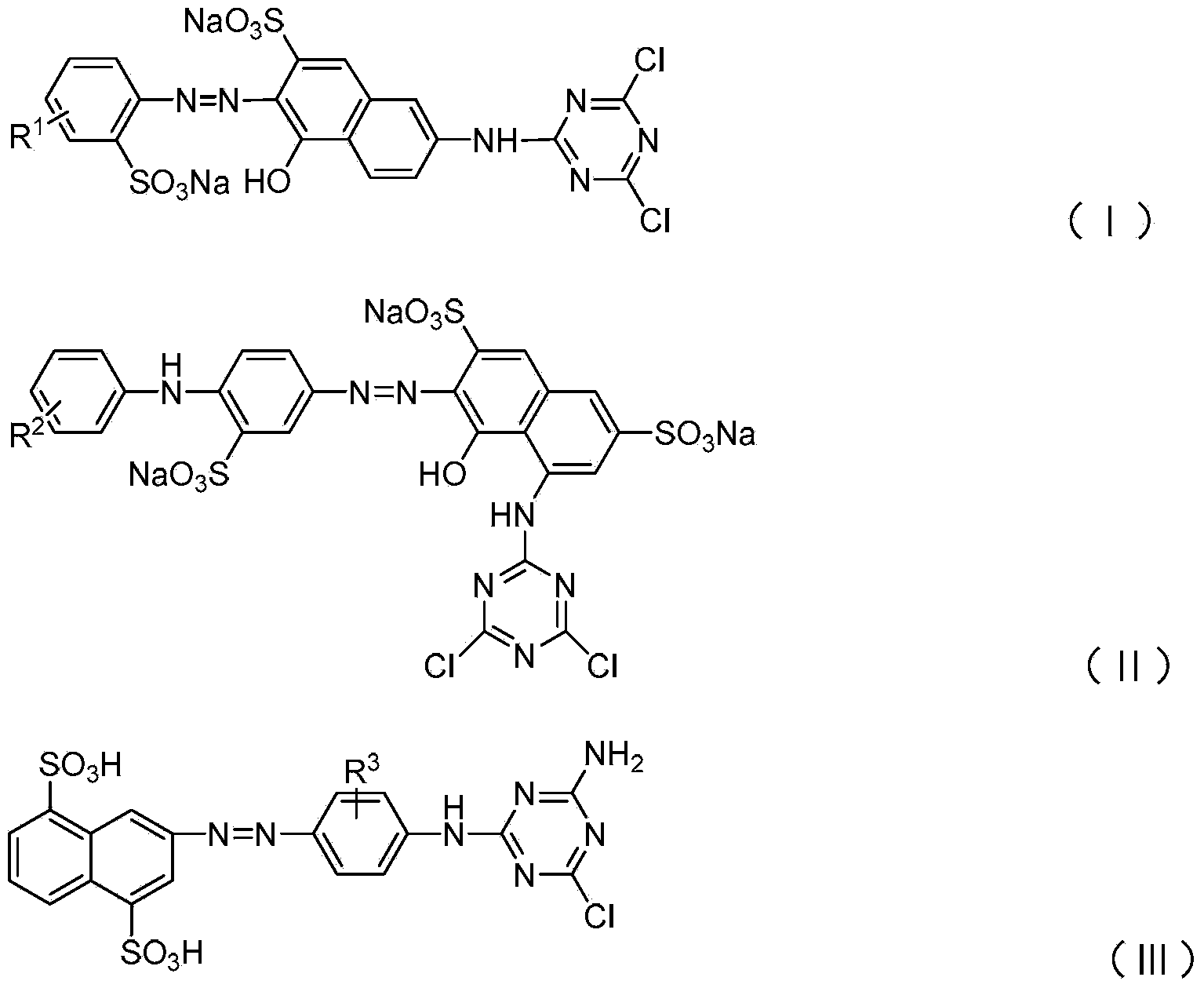

InactiveCN103669035AReduce the chance of contaminationReduce the binding forceDyeing processThermal insulationDyeing

The invention discloses an anti-staining dyeing process for a nylon-cotton blended fabric. The process comprises: adding a nylon-cotton blended fabric, a dye and an auxiliary agent to water, controlling a temperature at 20-30 DEG C, adding anhydrous sodium sulfate under a stirring condition, uniformly heating to achieve a temperature of 80-90 DEG C, carrying out thermal insulation for 0.5-1 h, adding an alkali to adjust the pH value to 9-11, continuously carrying out thermal insulation for 0.5-1 h, cooling to achieve a room temperature, removing the residue liquid, sequentially carrying out water washing, soaping and water washing, adopting glacial acetic acid to adjust the pH value to 5.0, and carrying out water washing and drying to obtain the dyed finished product, wherein the auxiliary agent is an anionic surfactant. According to the present invention, the used auxiliary agent anionic surfactant can be combined with NH<3+> on the nylon fibers in a salt type bond form, such that the reaction between the amino group on the nylon fibers and the active group of the active dye can be reduced, the combination of the nylon and the dye during the cotton dyeing process can be prevented, and the nylon staining grade is improved.

Owner:ZHEJIANG SHUNLONG CHEM

Preparation method of three-dimensional soft bracket

ActiveCN103120808AReduce the chance of contaminationAvoid exclusionProsthesisTomographic imageArtificial organ

The invention discloses a preparation method of an artificial organ soft bracket for replacing intracorporeal organs, and belongs to the technical field of bioengineering. The method comprises the steps of firstly, carrying out CT or MRI scanning on an individual organ of a patient, obtaining a group of N layers of faultage images related to organs and tissue parts from bottom to top; leading the obtained model data into a biological molding machine; then taking the organ tissue cells of the individual patient to cultivate, so as to obtain the tissue cell suspension solution with specific cell density; evenly mixing the cultivated tissue cell suspension with specific cell density and hydrogel according to a certain volume ratio; and finally printing the mixture of the tissue cell suspension solution and gel by a homemade biological molding machine, so as to finish preparation of the organ soft bracket. The soft bracket is prepared by a living tissue cell and the gel; meanwhile, the micro-structure and appearance prepared from the soft bracket are effectively controlled; and the requirements of individual difference of the patients and different parts on the organ soft bracket are met.

Owner:西安博恩生物科技有限公司

A kind of stage-by-stage solid culture method of Beauveria bassiana

InactiveCN102286385AReduce the chance of contaminationImprove ventilation performanceFungiMicroorganism based processesHyphomycetesFungal mycelium

The invention provides a method for carrying out solid culturing on beauveria bassiana by stages, which is characterized in that the beauveria bassiana solid culturing process is divided into two stages, i.e. a mycelium growing stage and a sporulating stage; in the mycelium growing stage, a closed fermenting mode is adopted and a liquid strain is inoculated with a solid culture material in a closed container to carry out culturing; and in the sporulating stage, the solid culture material on which mycelia full grow is taken out in a buckled mode and an open fermenting mode is adopted. The method for carrying out solid culture on the bassiana, which is provided by the invention, has simple process and does not need complex equipment. The fermenting period of the method is shortened to 6 to 7 d from 10 to 14 days in the prior art. The production efficiency is greatly improved. Meanwhile, the requirement on the environment humidity is low. The probability of the mixed fungi pollution is obviously reduced. The production cost is low. The method is easy to control and has high success rate. The product quality is stable. The method can be applied to laboratory production, can be used asthe preferred scheme of upgrading of technology of masses of small and medium bassiana manufacturers and has obvious social and economic benefits.

Owner:FUJIAN ACAD OF FORESTRY

Forming equipment of wavy noodles and process using same to manufacture noodles

ActiveCN104542785ACreate pollutionAvoid damageDough shaping and cutting apparatusDough processingManufactured formEngineering

The invention relates to forming equipment of wavy noodles and a process using the same to manufacture the noodles. The forming equipment comprises a shredding knife, a wave-manufacturing forming device and a steaming box, wherein the wave-manufacturing forming device comprises an air-blowing rod and a wavy adjusting rod; the outer wall surface of the air-blowing rod is provided with small holes facing to the wavy adjusting rod; the air-blowing rod is connected with an air-blowing pipeline, and air is provided for an inner cavity of the air-blowing rod and is blown out through the small holes; the downstream of the wave-manufacturing forming device is also provided with the steaming box which is connected with the wave-manufacturing forming device by a flour-conveying mesh belt; and the steaming box is connected with the wave-manufacturing forming device by the flour-conveying mesh belt, and the wavy noodles formed by the wave-manufacturing forming device fall onto the flour-conveying mesh belt and are conveyed into the steaming box for steaming by the flour-conveying mesh belt. The forming equipment and the manufacturing process have the advantages that the manufactured noodles are uniform-scattered-irregular wavy noodles, and the phenomenon of noodle sticking can be effectively reduced.

Owner:TINGYI (CAYMAN ISLANDS) HOLDING CORPORATION

Composite insulator cleaning composition with repairing function and preparation method thereof

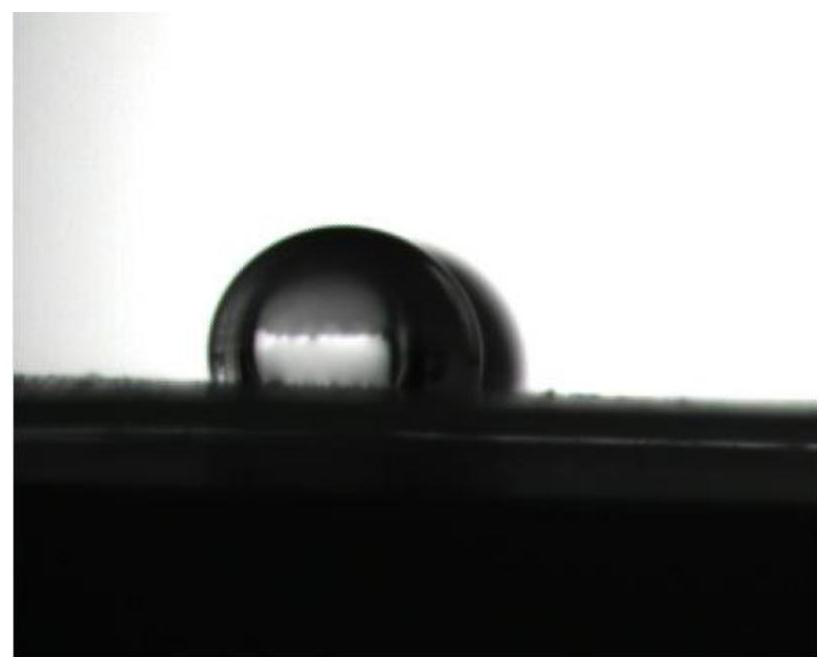

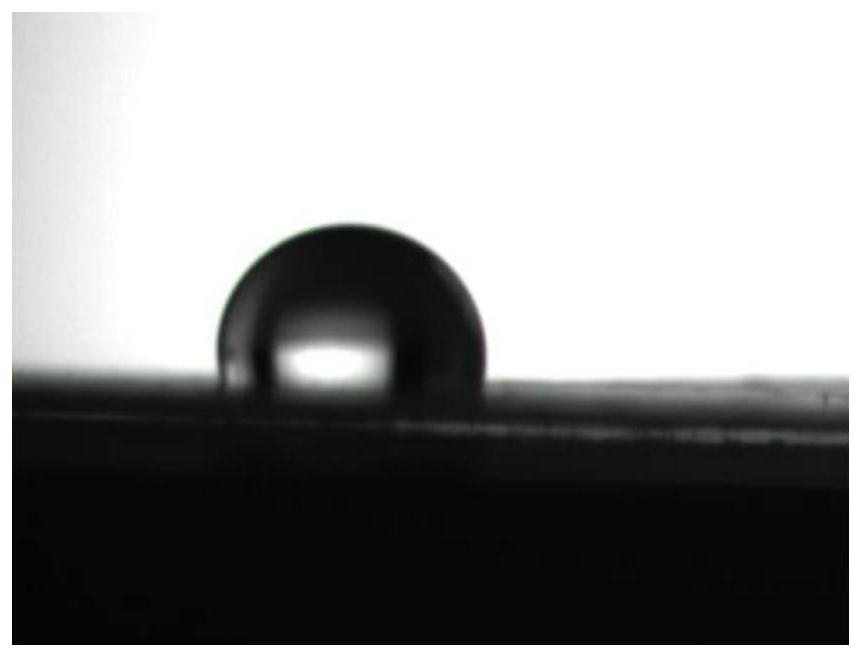

ActiveCN112812895AReduce the chance of contaminationExtended cleaning cycleOrganic detergent compounding agentsCoatingsActive agentSurface-active agents

The invention provides a composite insulator cleaning composition with repairing function, and a preparation method thereof, and belongs to the technical field of cleaning agents. The composite insulator cleaning composition comprises a dirt cleaning agent and an organic silicon rubber repairing agent, does not contain corrosive and forbidden and limited substances, and consists of a surfactant with relatively small surface tension, a permeation wetting agent, a washing assistant, a dust-proof agent, an insulating layer repairing agent and the like. According to the invention, a plurality of organic auxiliary agents cooperate to spontaneously soak and spread on the surface of the insulator with the dirt, so that the dirt falls off from the surface of the insulator, the dirt removing capability is ultrahigh, and the wetting and scrubbing time is obviously shortened; the contained functional organic silicon is deposited on the surface of the composite insulator to form a repairing layer of 2-5 microns, so that the corroded and uneven part of the surface layer is repaired, and the hydrophobicity and hydrophobic mobility of the surface are recovered; and the contained dust-proof agent can effectively reduce the follow-up dirt storage probability of the insulator and prolong the cleaning period.

Owner:苏州禾川化学技术服务有限公司

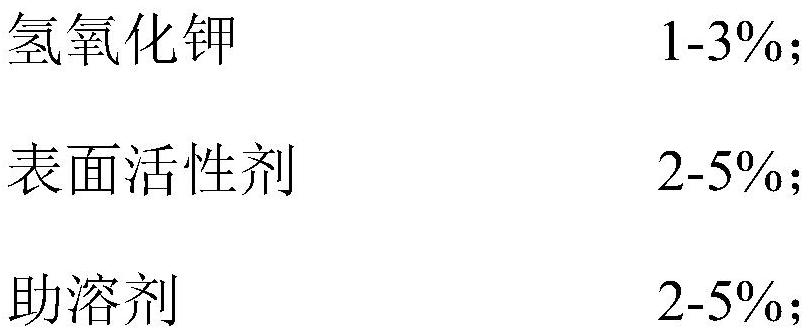

Two-component cleaning agent and preparation method and application thereof

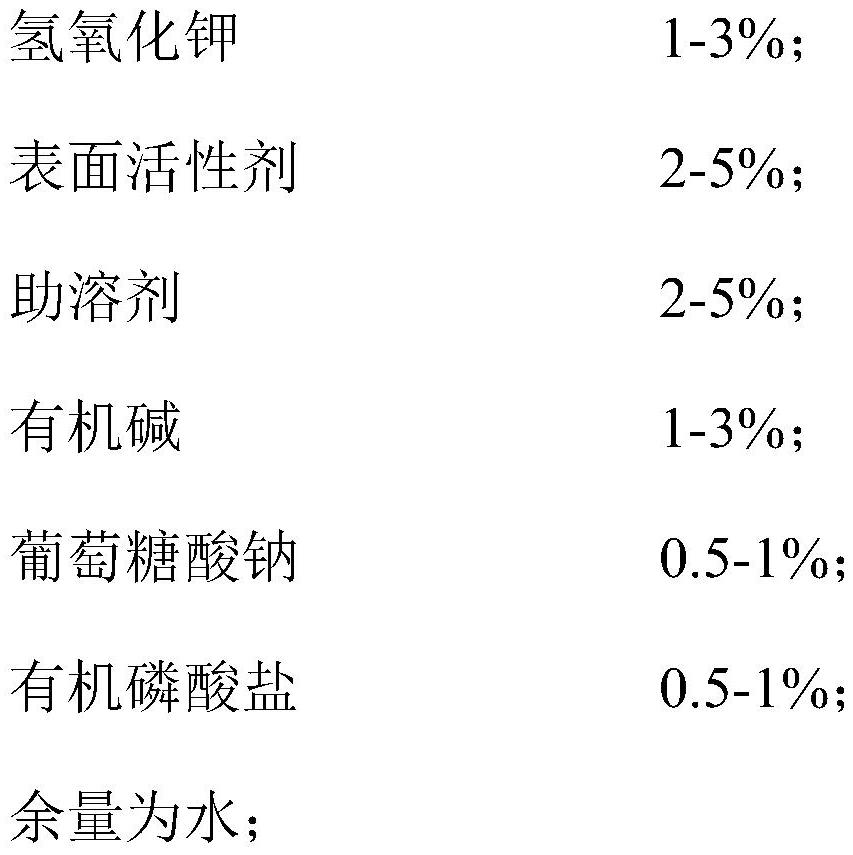

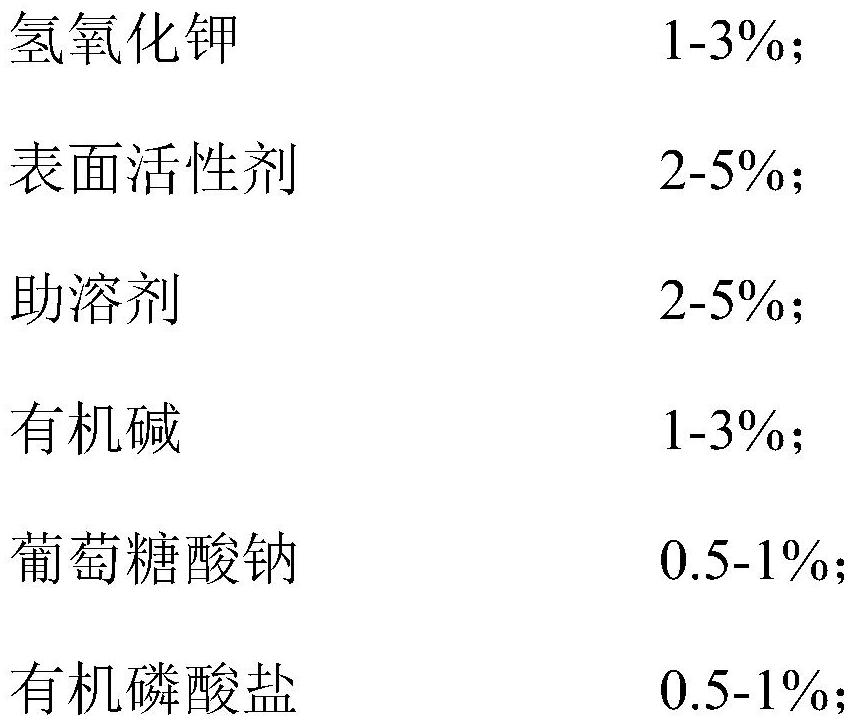

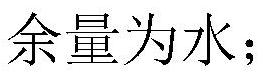

ActiveCN112745994AEfficient removalImprove photoelectric conversion efficiencyInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPhosphateOrganic base

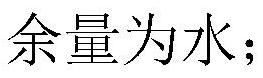

The invention provides a two-component cleaning agent and a preparation method and application thereof. The two-component cleaning agent comprises a component A and a component B, wherein based on the total mass of the component A being 100%, the component A comprises the following components: 1-3% of potassium hydroxide; 2-5% of a surfactant; 2-5% of a cosolvent; 1-3% of an organic base; 0.5-1% of sodium gluconate; 0.5-1% of an organic phosphate; and the balance of water. Based on the total mass of the component B being 100%, the component B comprises the following components: 3-18% of potassium hydroxide; 1-3% of a cosolvent; and the balance of water. The double-component cleaning agent provided by the invention has the cleaning capability equivalent to that of a commercially available cleaning agent, and has a relatively good removal effect on metal impurities.

Owner:LUOYANG CSI PHOTOVOLTAIC TECH CO LTD

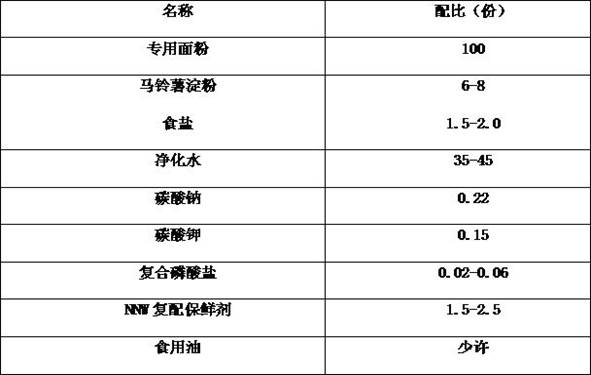

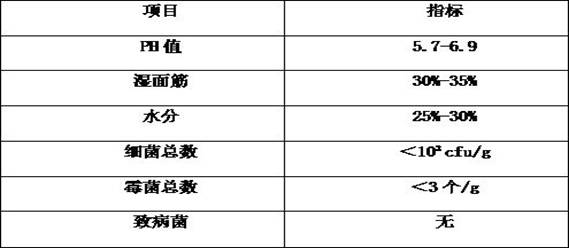

Novel processing method of fresh wet noodles

PendingCN112189790AReduce the amount of bacteriaImprove qualityFood preservationBiotechnologySterile water

The invention discloses a novel processing method of fresh wet noodles. The novel processing method comprises the following steps of sterilizing flour before use, and purifying production water; carrying out dough kneading work in a vacuum state on the fresh wet noodle processing raw materials in a vacuum horizontal double-shaft dough kneading machine; forming a dough band with the thickness of 20mm through preliminary calendering of dough, putting the dough band into a closed maturation machine for maturation, and repeatedly calendering the maturated dough band to form a dough band with the thickness of 20mm again; cutting the thinned dough band into strips by using a dough cutter machine, and segmenting the cut noodles at equal intervals; and washing the boiled noodles with cold water, and packaging the cooled noodles. According to the novel processing method of the fresh wet noodles, sterile water is used, the bacterium carrying amount of fresh wet noodle products can also be reduced, meanwhile, cooling work at different temperatures is conducted after boiling, the cooling work can be completed rapidly under the condition that it is guaranteed that the fresh wet noodles are morechewy, and the processing efficiency of the fresh wet noodles is improved.

Owner:江西省百约食品有限责任公司

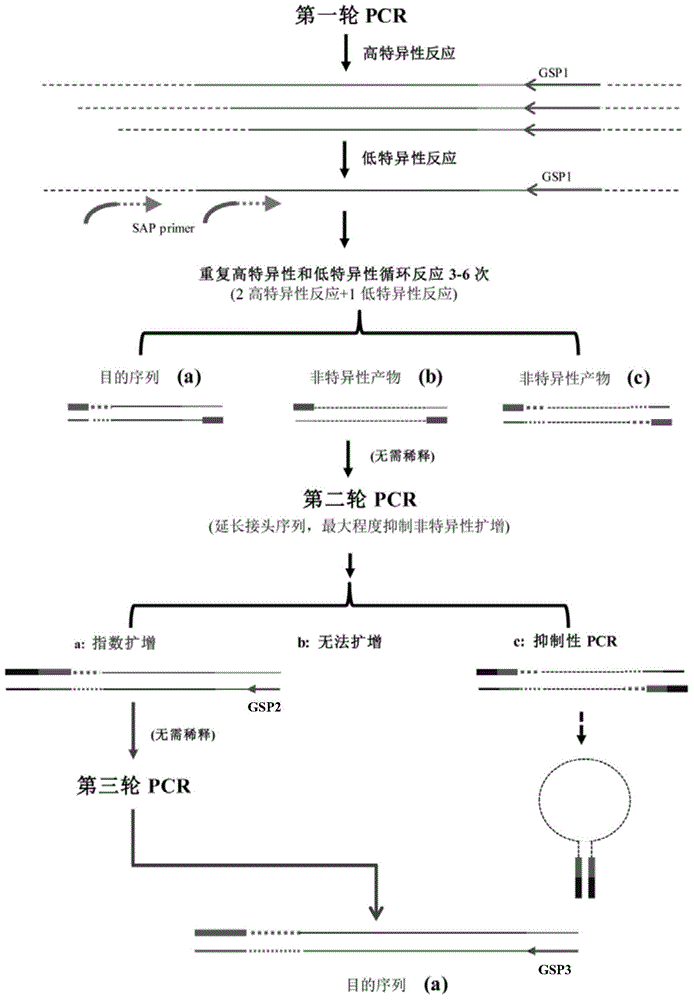

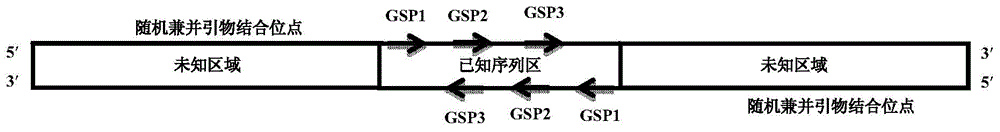

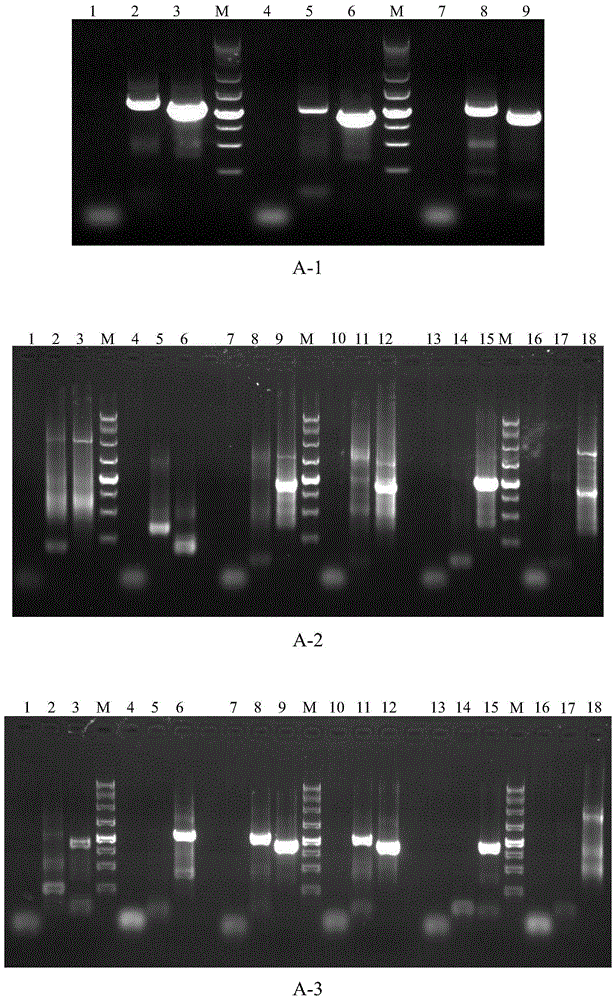

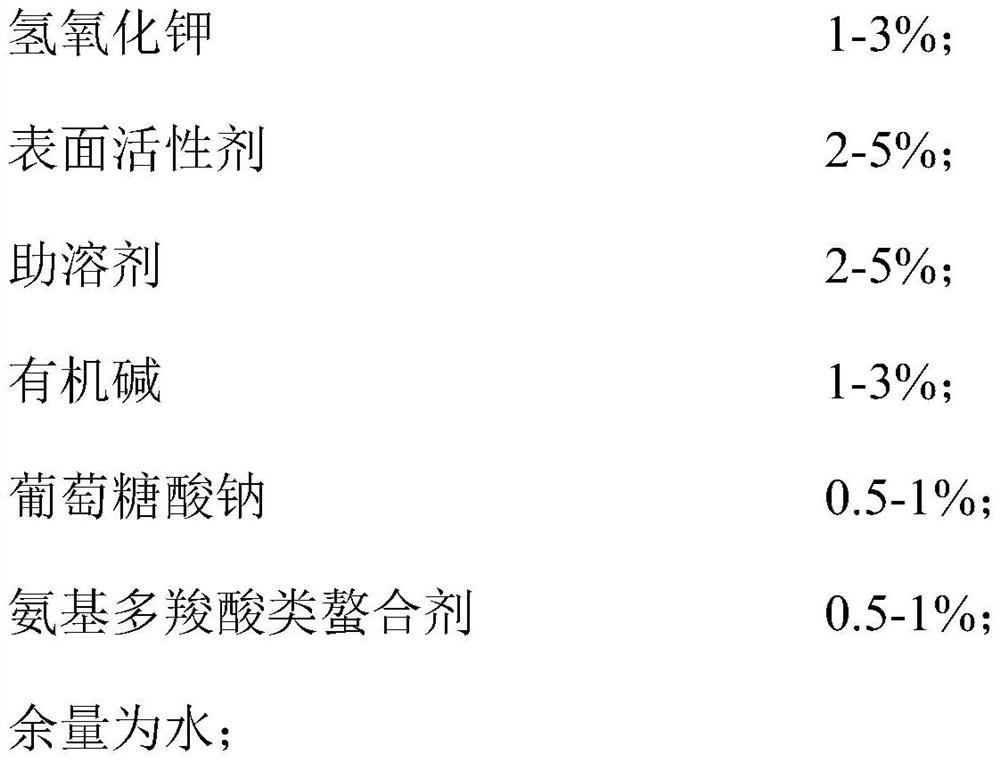

Method for acquiring flanking sequence from genome DNA

InactiveCN104450675AEasy to operateReduce the chance of contaminationDNA preparationAgricultural scienceLarge fragment

The invention discloses a method for acquiring a flanking sequence from genome DNA. The method comprises the following steps: 1) designing three specific primers having consistent directions and used for amplifying the flanking sequence according to a known sequence on the genome DNA, and sequentially marking the primers as GSP1, GSP2 and GSP3 according to the tapered distance between the primers and the flanking sequence; 2) performing first PCR (polymerase chain reaction) amplification by using the genome DNA as a template through a primer SAP (any of sequences 1-15) and the GSP1 to obtain a PCR product 1; 3) performing second PCR amplification by using the PCR product 1 as a template through primers SEP (sequences 16 and 17) and the GSP2 to obtain a PCR product 2; and 4) performing third PCR amplification by using the PCR product 2 as a template through a primer SNP (sequence 18) and the GSP3 to obtain a PCR product 3, thus acquiring the flanking sequence. The method has the following advantages of simplicity in operation, high specific amplification, high success rate, short time and the like; and large fragments are easily obtained.

Owner:INST OF FORESTRY CHINESE ACAD OF FORESTRY

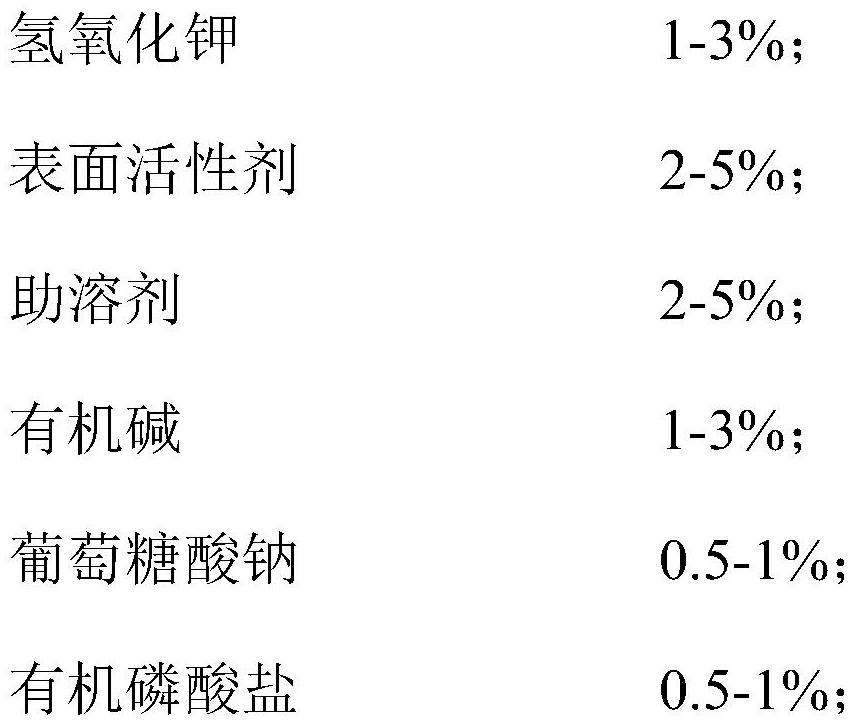

Phosphorus-free two-component cleaning agent as well as preparation method and application thereof

ActiveCN112745990AEfficient removalImprove photoelectric conversion efficiencyInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsOrganic baseActive agent

The invention provides a phosphorus-free two-component cleaning agent as well as a preparation method and an application thereof. The phosphorus-free two-component cleaning agent comprises a component A and a component B, wherein based on the total mass of the component A being 100%, the component A comprises the following components: 1-3% of potassium hydroxide; 2-5% of a surfactant; 2-5% of a cosolvent; 1-3% of an organic base; 0.5-1% of sodium gluconate; 0.5-1% of an amino polycarboxylic acid chelating agent; and the balance of water. Based on the total mass of the component B being 100%, the component B comprises the following components: 3-20% of potassium hydroxide; 1-3% of a cosolvent; and the balance of water. The double-component cleaning agent provided by the invention has the cleaning capability equivalent to that of a commercially available cleaning agent, and has a relatively good removal effect on metal impurities.

Owner:LUOYANG CSI PHOTOVOLTAIC TECH CO LTD

Silicon wafer cutting cooling liquid recycling method

InactiveCN111015988AReduce the chance of contaminationReduce disconnection rateWorking accessoriesFine working devicesEngineeringProcess engineering

The invention relates to a silicon wafer cutting cooling liquid recycling method. Recycled cooling liquid and newly-prepared cooling liquid are mixed according to the proportion of (3-1):1 to form recycling cooling liquid, sampling detection is conducted on the COD, the surface tension, the electrical conductivity and the pH value, the recycling cooling liquid can be applied to a cutting chamber after detection results reach the standards, and the line breakage rate and the silicon wafer fouling rate can be decreased.

Owner:无锡荣能半导体材料有限公司

Method for preparing single chromosome of peony

ActiveCN104357375AReduce overlapReduce the chance of contaminationPlant cellsMeiosisLaser micro dissection

The invention discloses a method for preparing single chromosome of peony, which is realized by virtue of micro-dissection technology. The method comprises the following steps: selecting peony cells in meiosis phase, and carrying out such steps as sample liquid preparation, microscopic examination, membrane transfer, and peony chromosome tabletting and dispersing to obtain a sample; and by adopting a high-end laser micro-dissection system, carrying out collection tube preparation, sample loading, seeking, target chromosome selection, laser parameter regulation, target chromosome lineation and laser cutting, thus successfully obtaining single complete chromosome in a peony pollen mother cell. The chromosomes are mutually free from pollution, thus laying a good foundation for downstream research.

Owner:SHANGHAI CHENSHAN BOTANICAL GARDEN

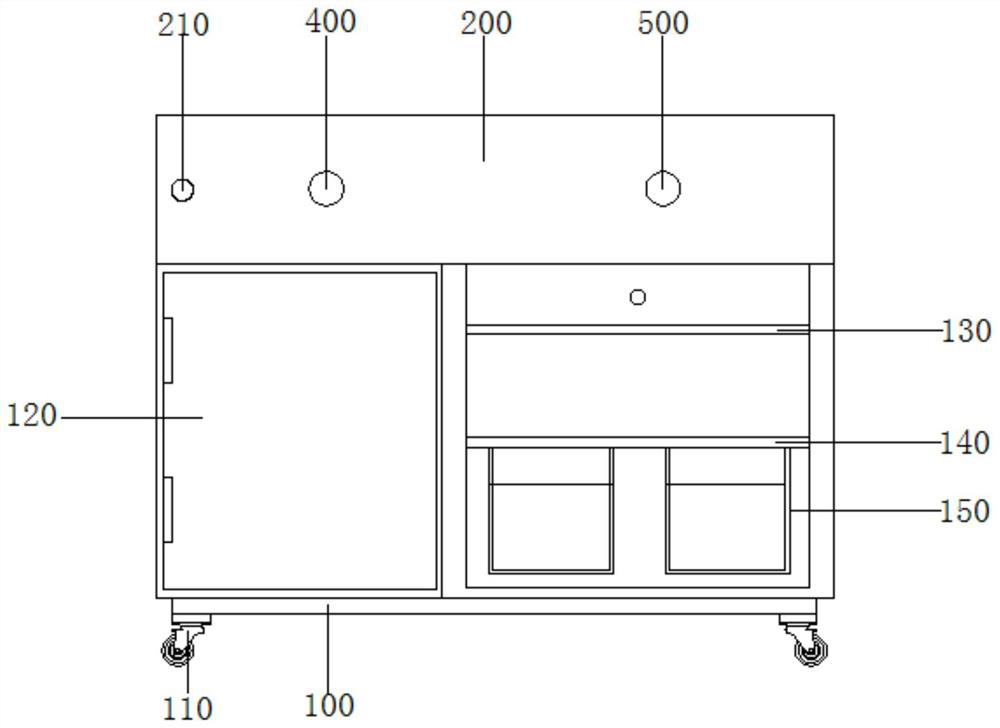

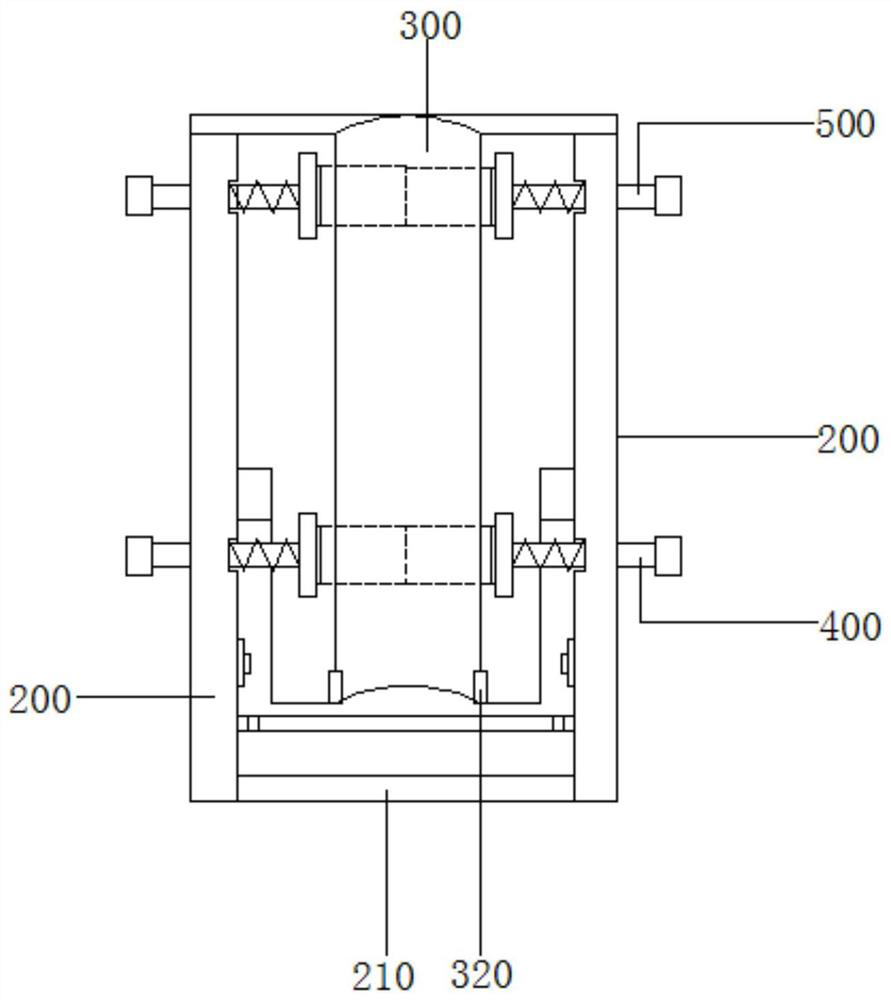

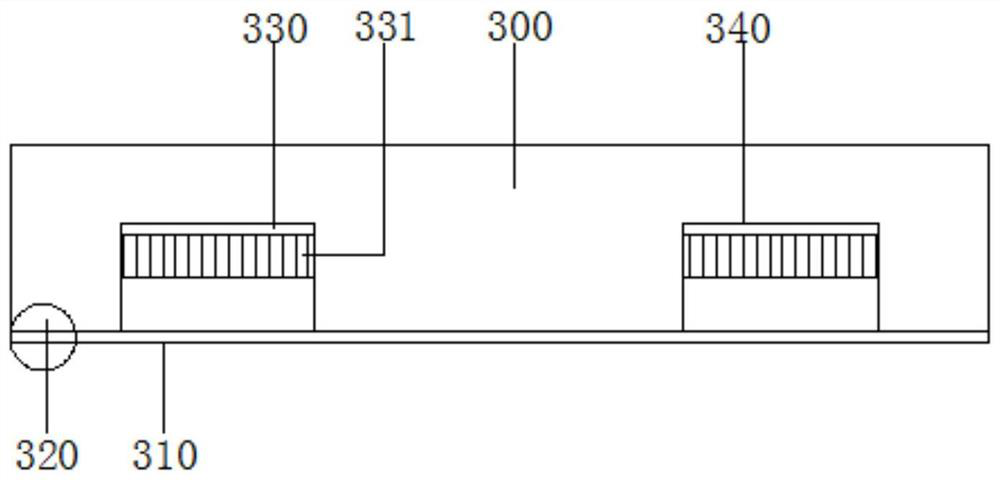

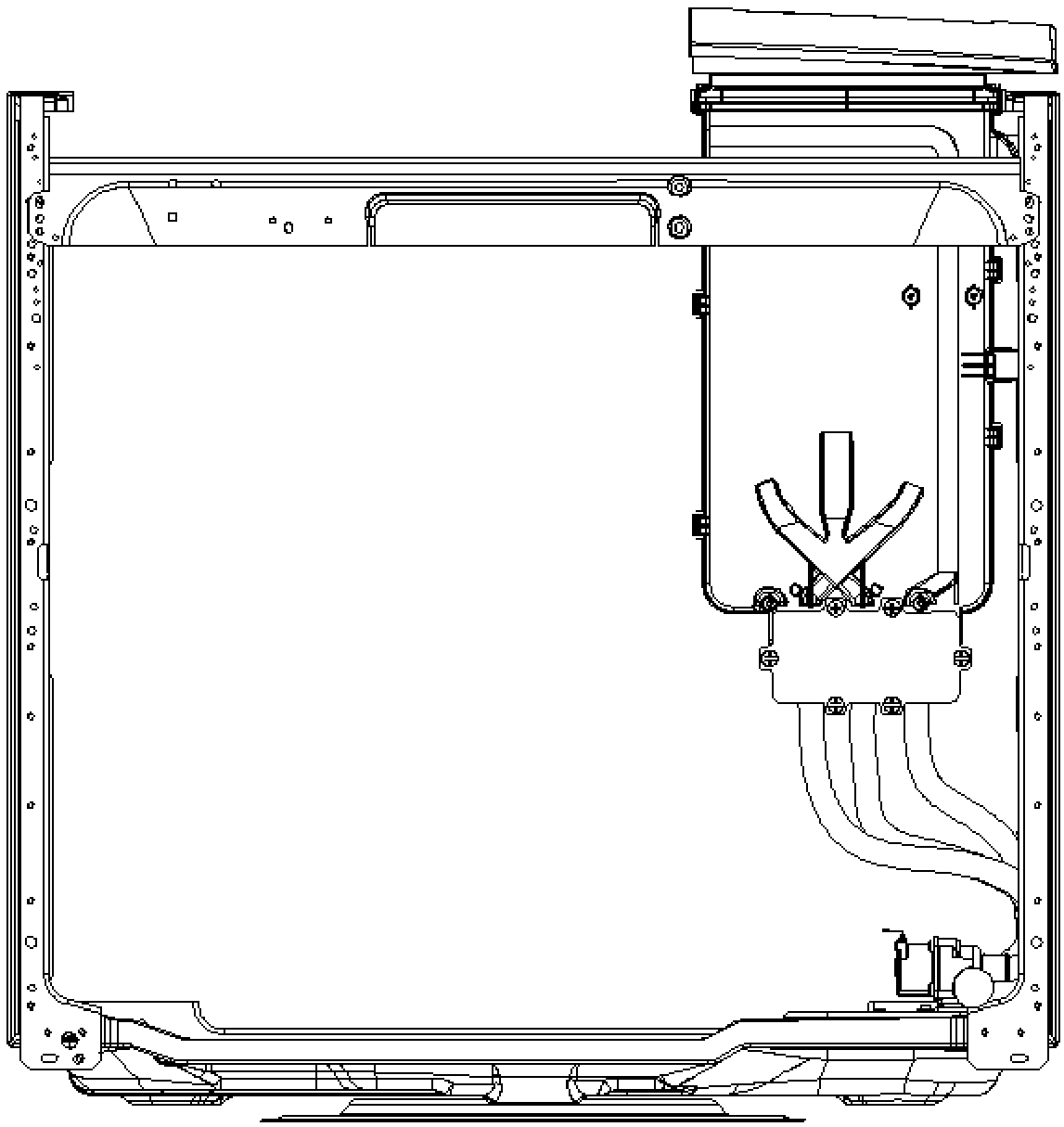

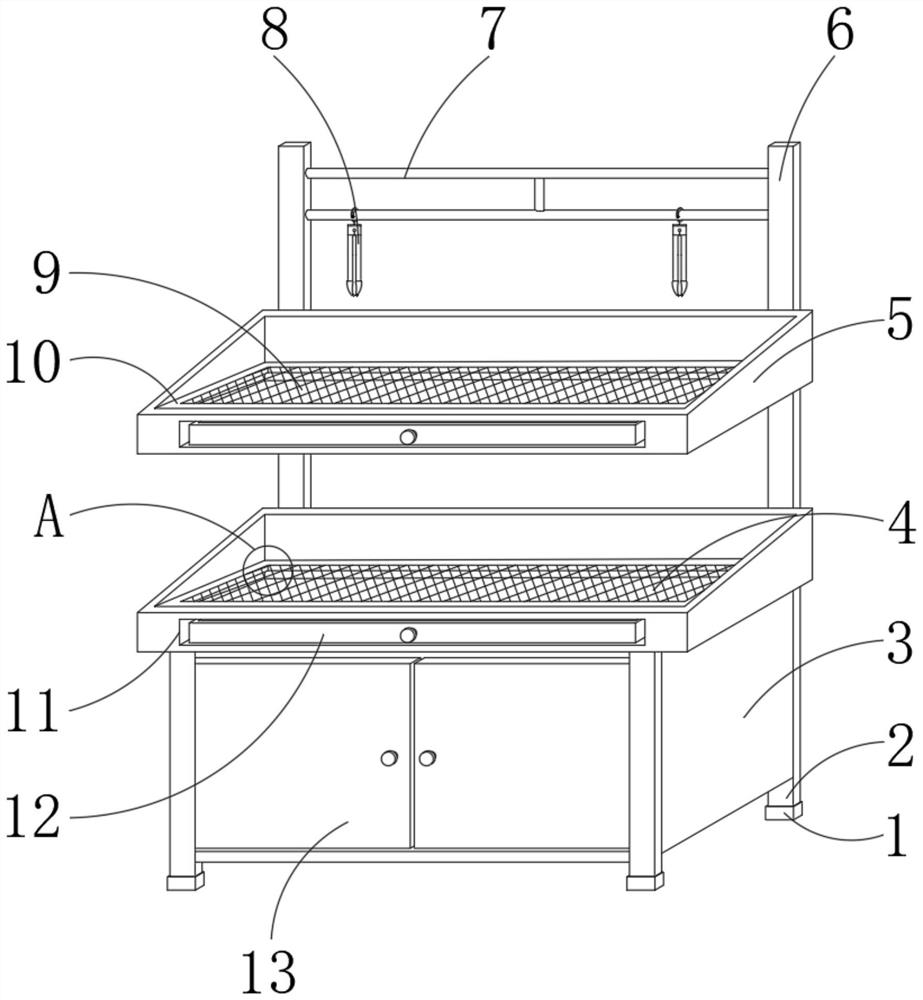

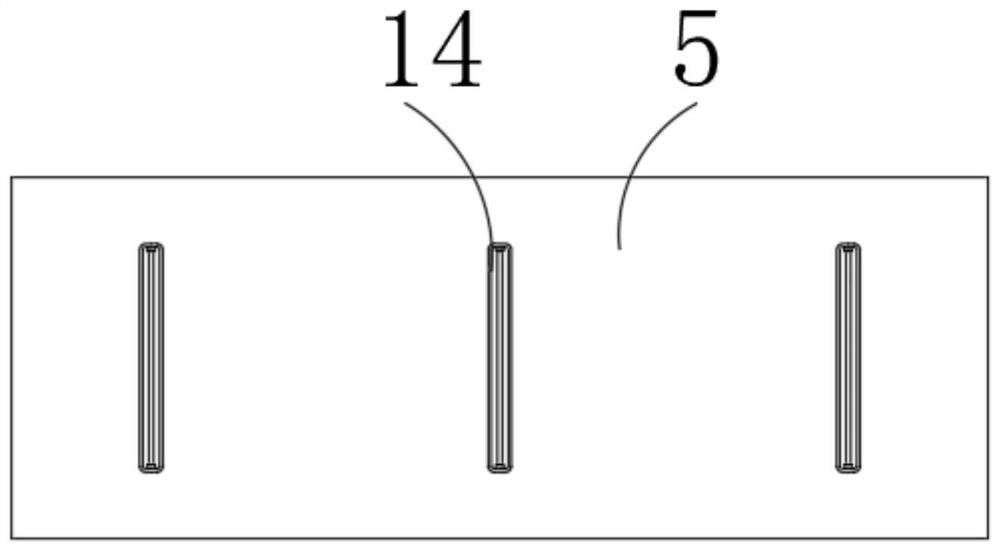

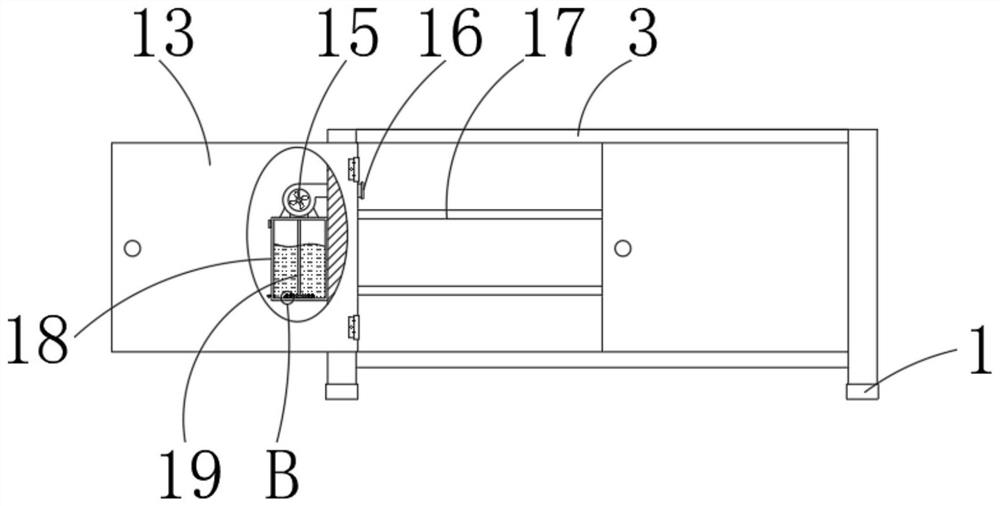

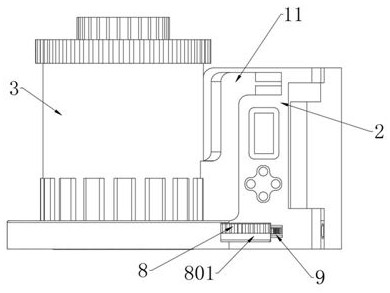

Medicine taking and distributing device for pharmacy

InactiveCN111955948AAvoid confusionReduce the chance of contaminationChestsDressing tablesEngineeringBiomedical engineering

The invention belongs to the technical field of medical devices. The invention especially relates to a medicine taking and distributing device for a pharmacy. The medicine taking and distributing device comprises a bottom frame, a top bin, a movable cover plate, a main medicine distribution frame and an auxiliary medicine distribution frame. The top of the bottom frame is fixedly connected with the top bin through bolts. The top of the top bin is movably connected with the movable cover plate; and the side wall of the movable cover plate is connected with the main medicine distribution frame and the auxiliary medicine distribution frame in an inserted mode. According to the medicine taking and distributing device for the pharmacy, the bottom frame convenient to move can be arranged, various storage structures are arranged on the side surface, a movable cover plate connected by a bearing in the top bin is matched, pharmacy medicine taking and transferring can be carried out, medicines are stored on the medicine distribution frame, shielding protection is achieved through the movable cover plate, confusion is avoided, the pollution probability is reduced, when the medicine distribution frame reaches the position where medicine distribution is needed, the medicine distribution plate on the limiting plate is separated from the movable cover plate through drawing of the medicine distribution frame and retraction of the spring, the movable cover plate can carry the medicines to be taken out, medicine distribution is completed after taking, and operation is simple.

Owner:卢鹏 +2

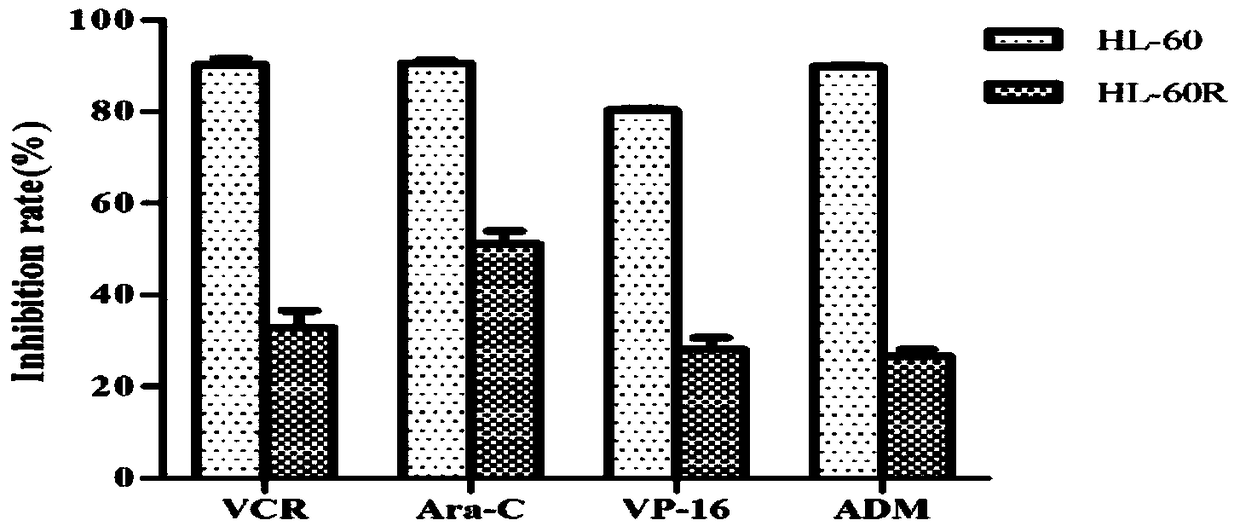

Polypeptide specifically binding to ATRA-resistant acute myeloid leukemia cells and preparation method and application thereof

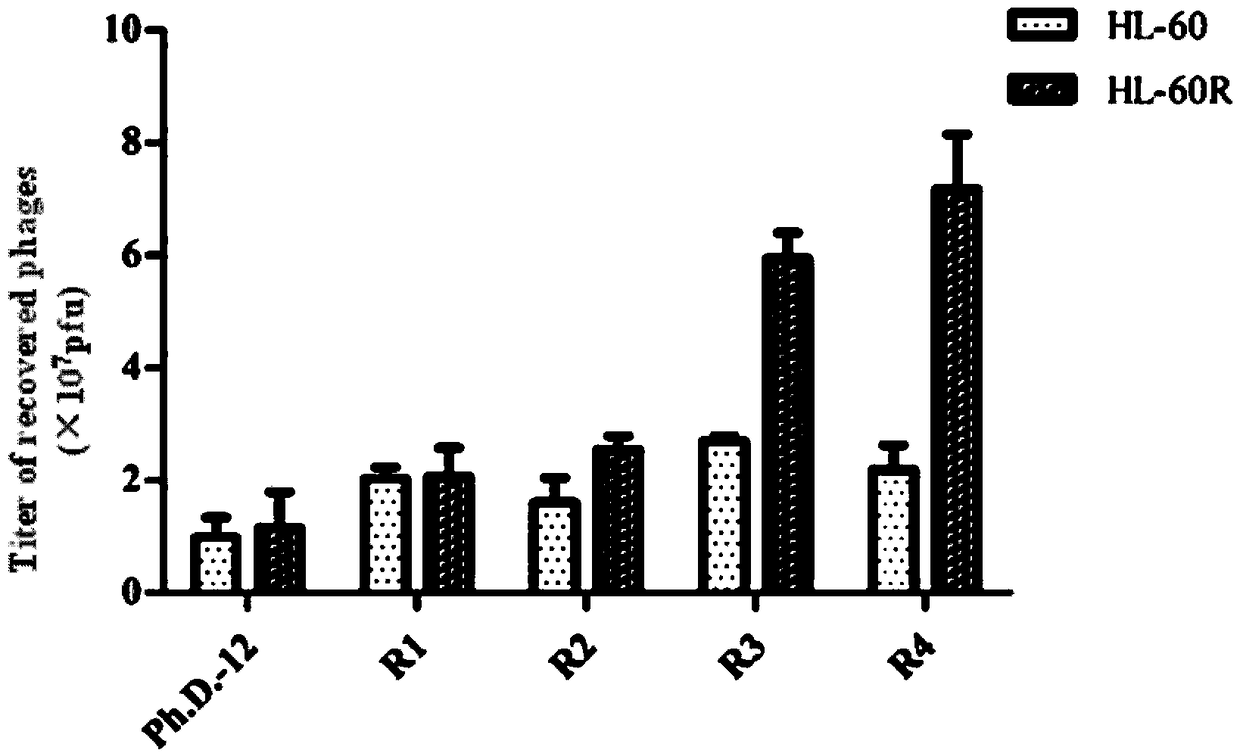

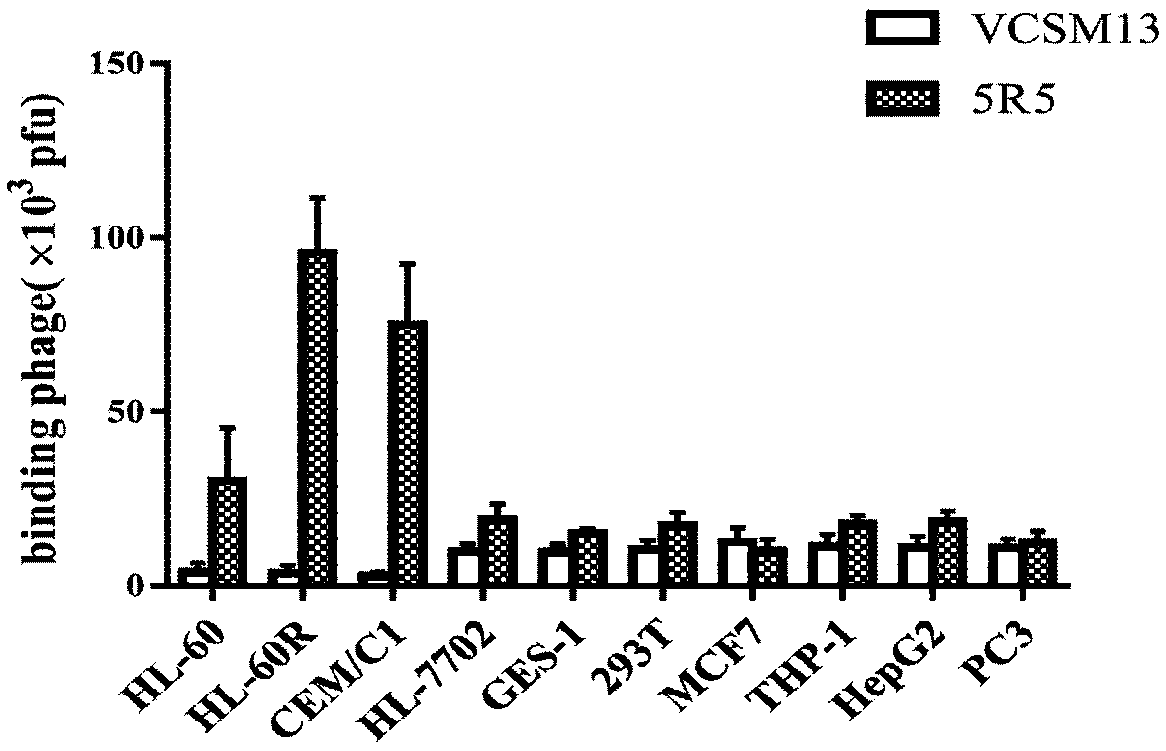

InactiveCN109021077AGood repeatabilityReduce the chance of contaminationPeptide/protein ingredientsPeptidesTumor targetHigh activity

The invention discloses a polypeptide specifically binding to ATRA-resistant acute myeloid leukemia cells and a preparation method and application thereof. The polypeptide specifically binding to ATRA-resistant acute myeloid leukemia cells is named as pepNo. 5R5 and has a base sequence shown in the formula of SEQ ID NO. 1 and an amino acid sequence shown in the formula of SEQ ID NO. 2. The polypeptide fills a gap in the current lack of polypeptides that bind to ATRA drug-resistant AML cells. The screened polypeptide is a small molecule polypeptide which can be synthesized by an artificial method, has small molecular weight, high activity, strong penetrating power, high affinity, high specificity and low toxicity, and is suitable as a carrier for targeted therapy. The polypeptide has good tumor targeting effects and lays a solid foundation for the preclinical deep research of the polypeptide.

Owner:SOUTHEAST UNIV

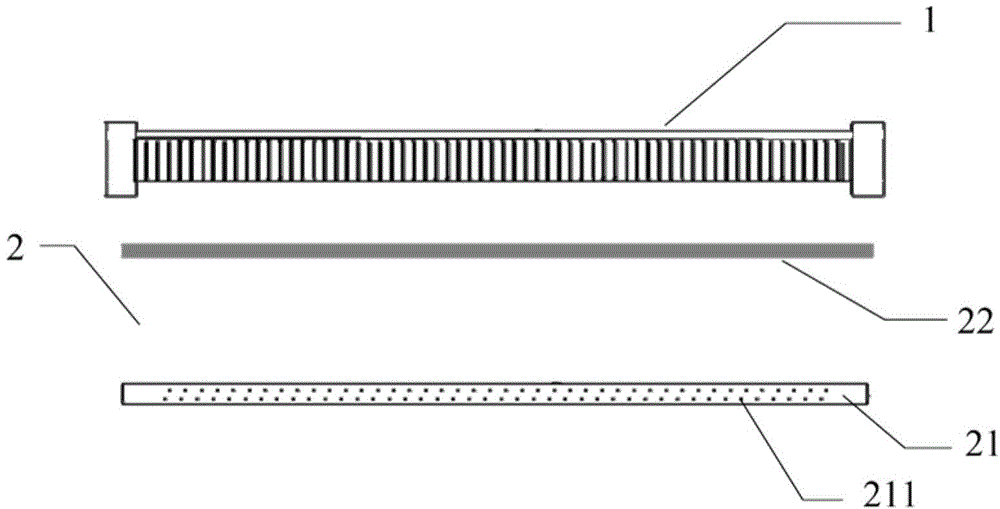

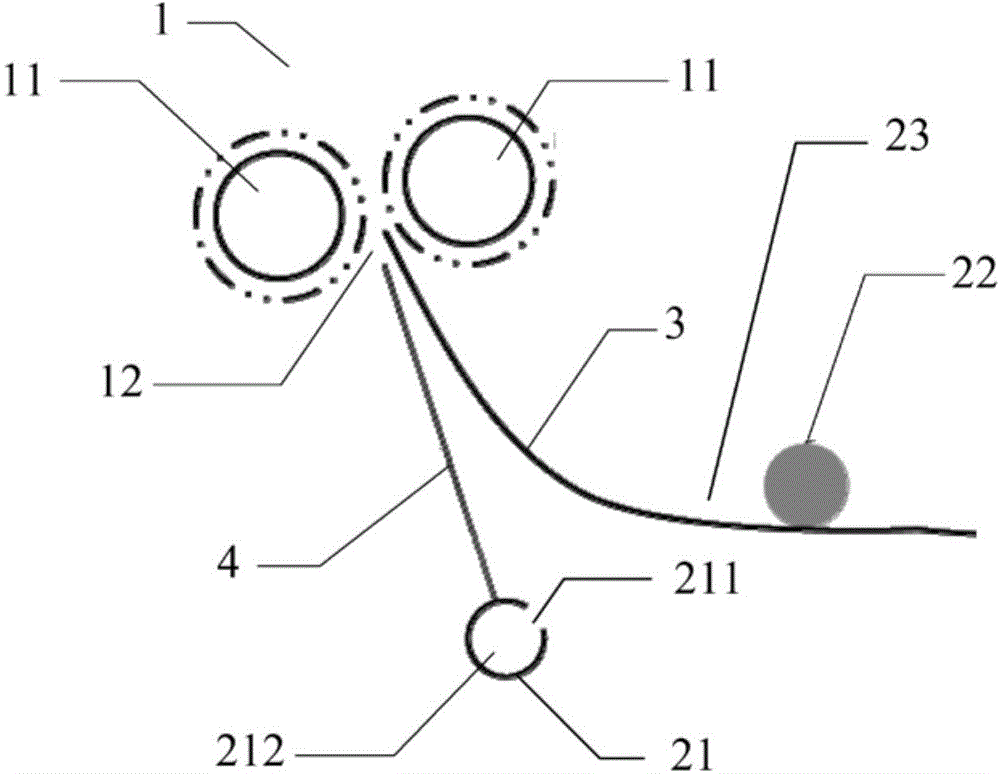

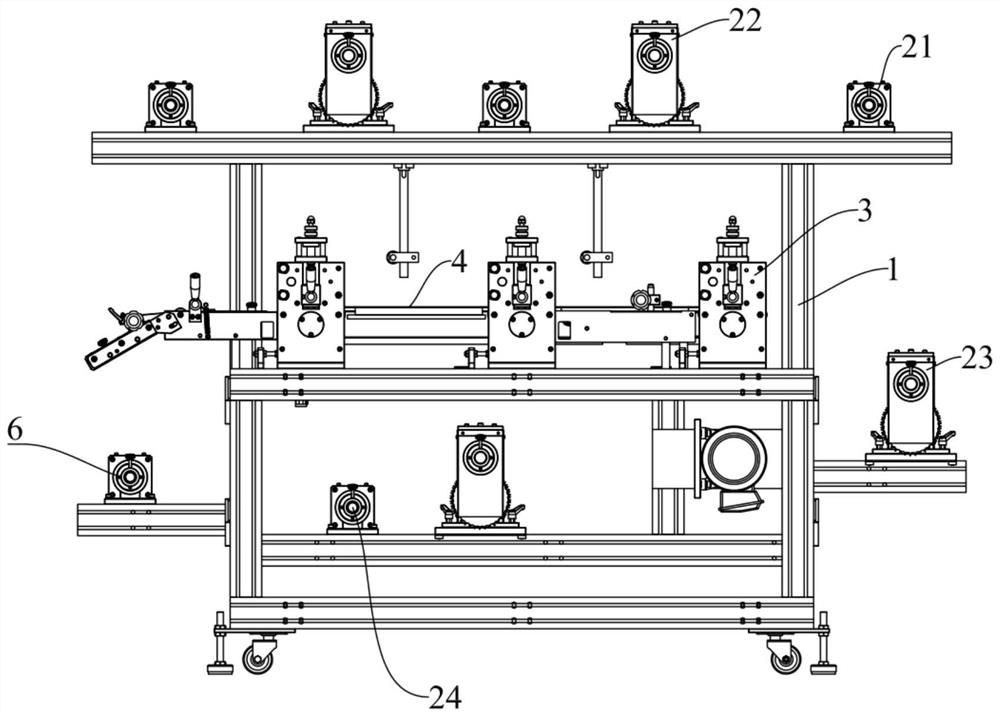

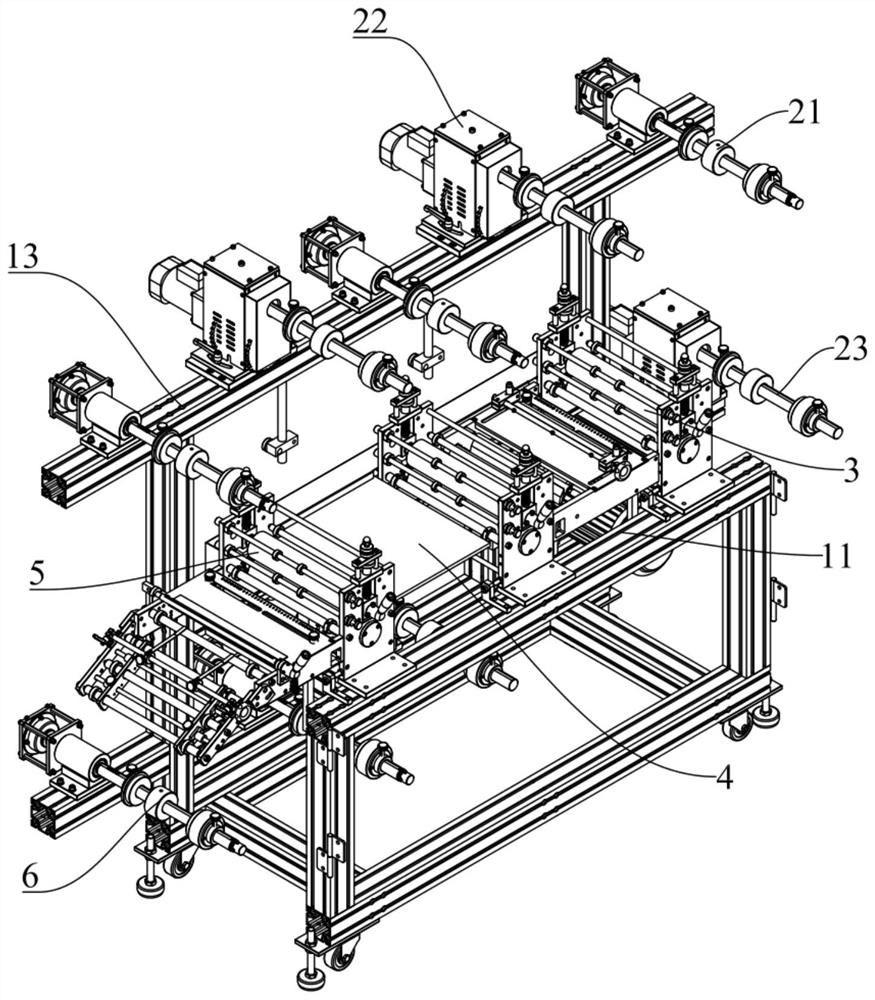

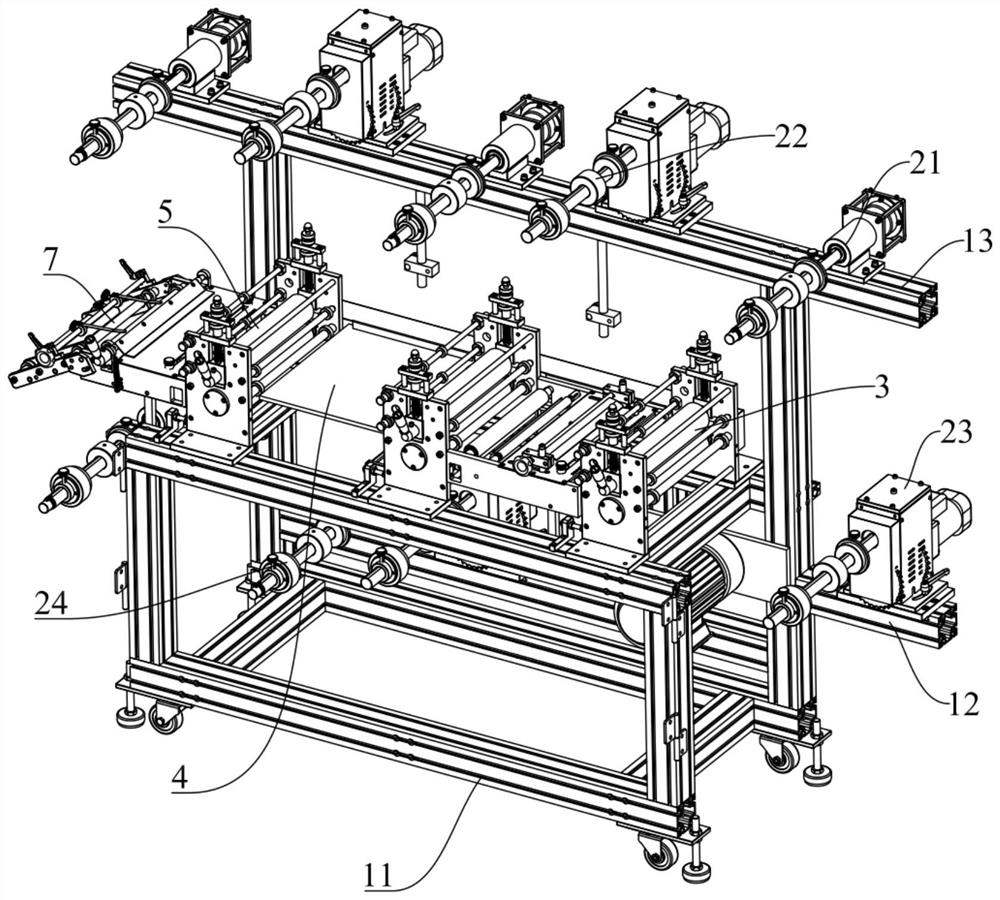

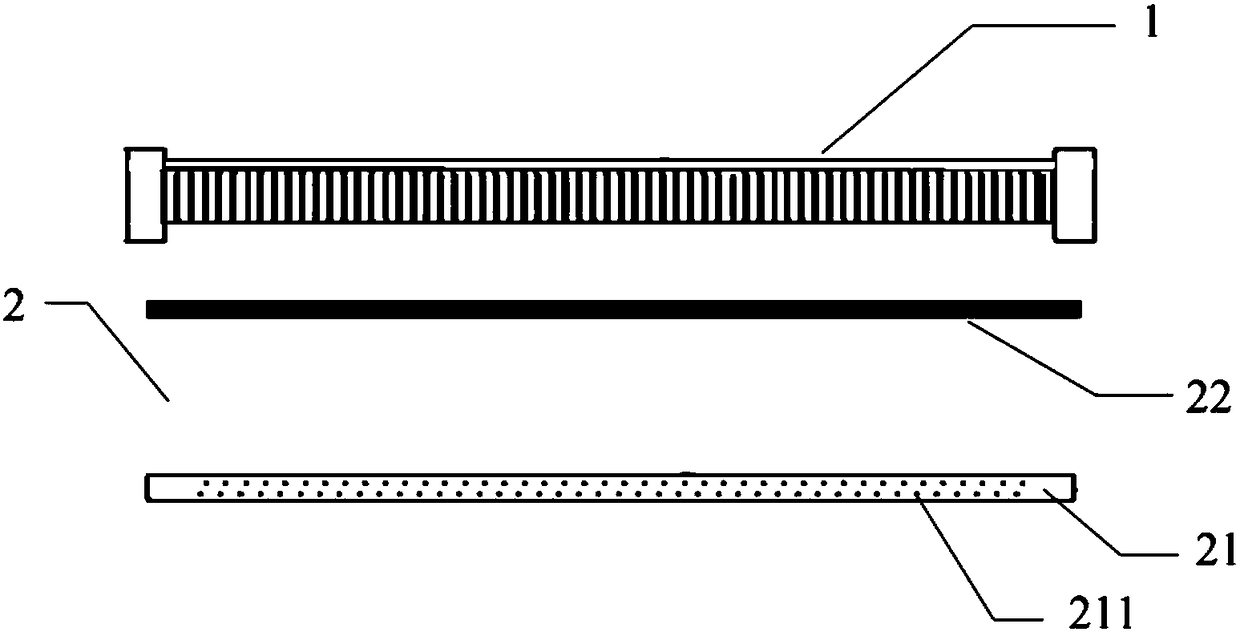

Hot laminating machine and hot laminating method

PendingCN113858628AImprove processing effectReduce the chance of contaminationDomestic articlesManufacturing engineeringIndustrial engineering

The invention discloses a hot laminating machine and a hot laminating method, and belongs to the technical field of electronic product decorating part machining. The hot laminating machine comprises a supporting component, a material receiving and discharging component, a flattening component and a heating component, the material receiving and discharging component comprises a first material discharging part, a first material receiving part and a second material discharging part, the first material discharging part is used for discharging a first material, the first material receiving part is used for winding a first protective film attached to the first material, and the second material discharging part is used for discharging a second material; the flattening component is arranged on the supporting component, and the flattening component is used for flattening the first material and the second material; and the heating component is arranged on the supporting component and located on the downstream of the flattening component, and the heating component is used for heating the flattened first material and the flattened second material and bonding the first material and the second material. The hot laminating machine and the hot laminating method provided by the invention have higher machining efficiency, need fewer operators, and reduce the probability that the first material or the second material is polluted.

Owner:KUNSHAN LIANTAO ELECTRONICS CO LTD

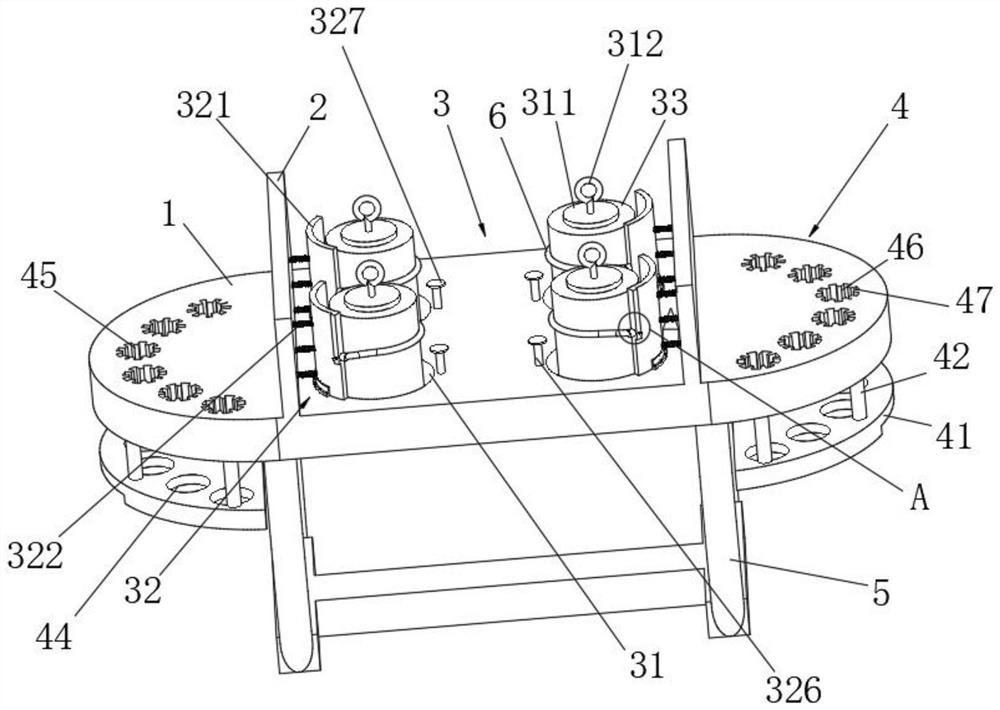

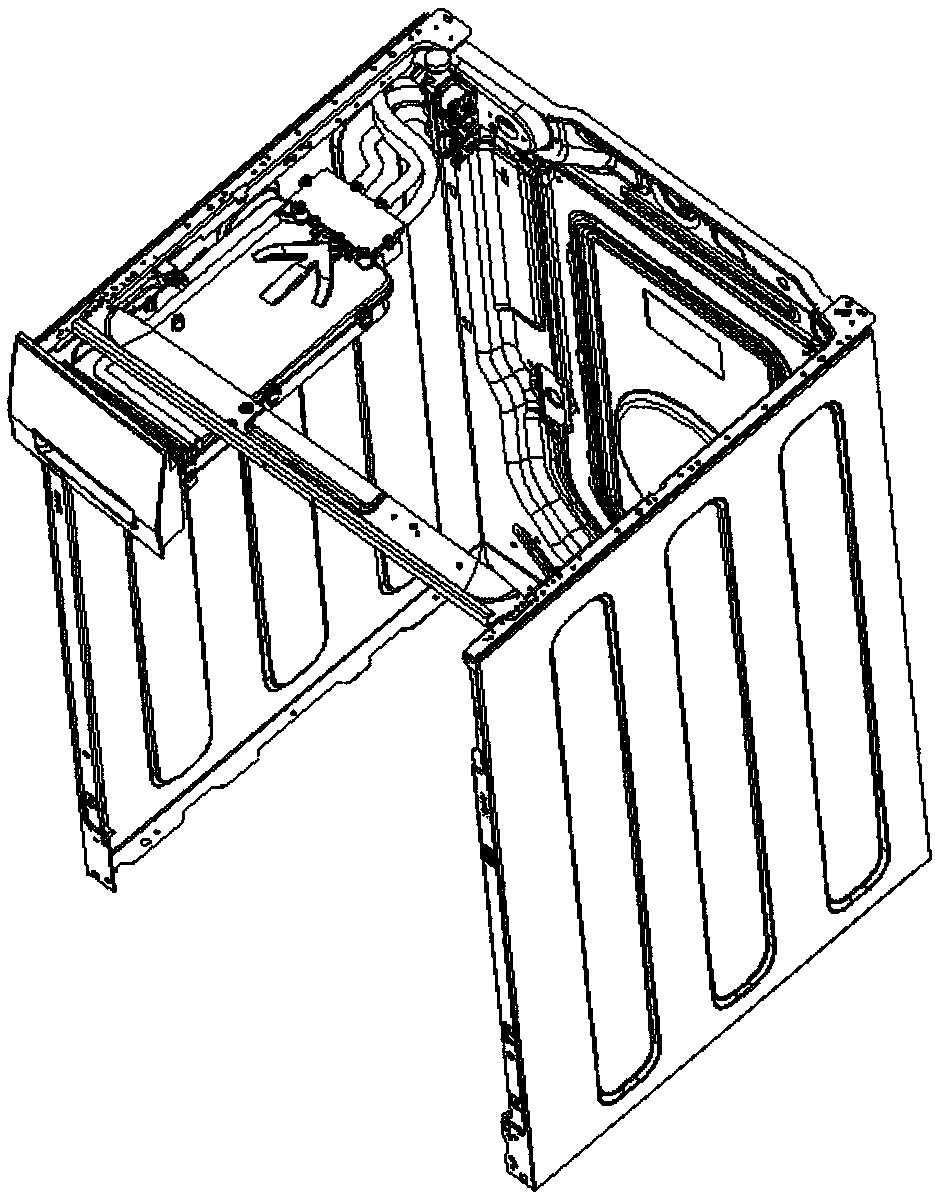

Urine stem cell preparation equipment

InactiveCN111925936AReduces the chance of humans touching the petri dishReduce the chance of contaminationBioreactor/fermenter combinationsBiological substance pretreatmentsStem like cellUrine

The invention discloses urine stem cell preparation equipment, and particularly relates to the field of stem cell preparation, the urine stem cell preparation equipment comprises a preparation workbench, two partition plates are arranged on the upper surface of the preparation workbench, a preparation mechanism is arranged between the two partition plates, two placement mechanisms are arranged onthe opposite sides of the two partition plates, and the number of the placement mechanisms is two. The preparation mechanism is arranged; a culture dish is placed in the culture barrel; a good preparation environment is provided for stem cell preparation by utilizing the leakproofness of the cavity; meanwhile, the culture dish can be conveniently taken out by pulling the limiting strips; the probability of artificial contact with the culture dish is reduced, the probability of contamination of the culture dish is further reduced, meanwhile, an inclination mechanism is arranged, a pressing threaded rod is rotated, a culture barrel is driven to incline according to the lever principle, a worker can conveniently transfer liquid to a culture medium, culture operation on urine stem cells is facilitated, and actual use is facilitated.

Owner:陈龙刚

A kind of two-component cleaning agent and its preparation method and application

ActiveCN112745994BEfficient removalImprove photoelectric conversion efficiencyInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPhosphateOrganic base

The invention provides a two-component cleaning agent and its preparation method and application, including A component and B component; wherein, based on the total mass of the A component as 100%, the A component includes the following components : Potassium hydroxide 1‑3%; surfactant 2‑5%; cosolvent 2‑5%; organic base 1‑3%; sodium gluconate 0.5‑1%; organic phosphate 0.5‑1%; Water; based on the total mass of the B component as 100%, the B component includes the following components: potassium hydroxide 3-18%; co-solvent 1-3%; the balance is water. The two-component cleaning agent provided by the invention has a cleaning ability equivalent to that of commercially available cleaning agents, and has a better effect on removing metal impurities.

Owner:LUOYANG CSI PHOTOVOLTAIC TECH CO LTD

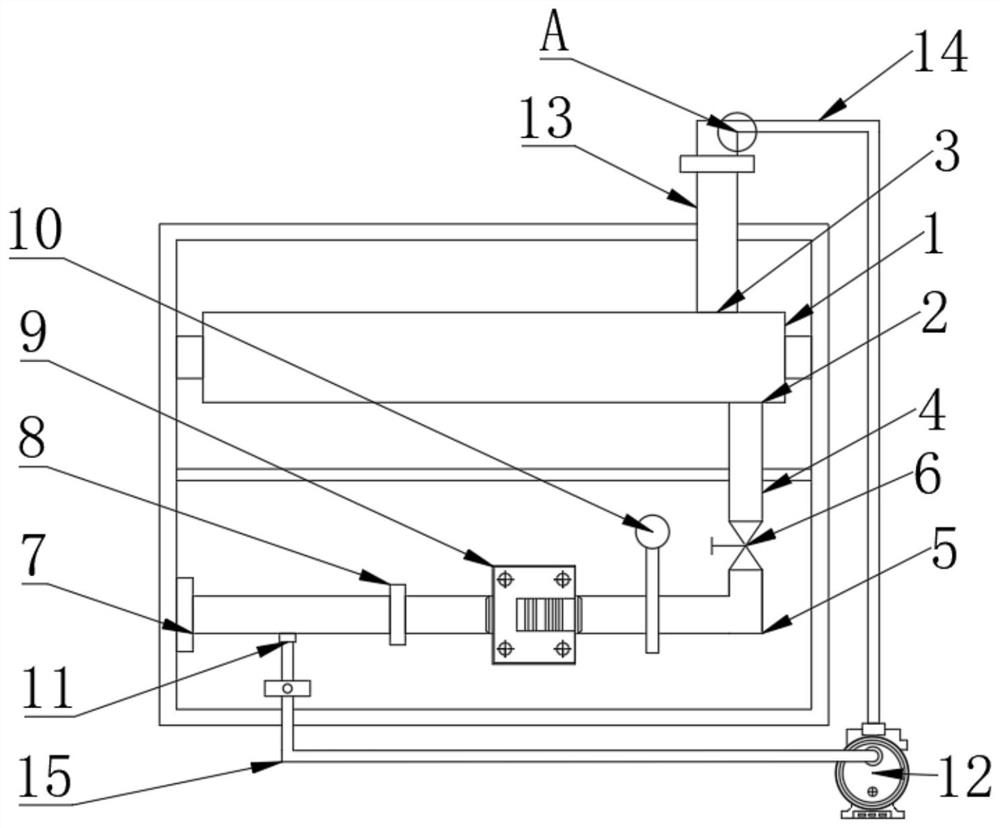

Heat-conduction oil heating device for heat-conduction oil furnace

PendingCN111895650AConvenient worker monitoringReduce the chance of contaminationStorage heatersPhysicsEngineering

The invention discloses a heat-conduction oil heating device for a heat-conduction oil furnace. The heat-conduction oil heating device comprises the heat-conduction oil furnace, a first interface is formed in the lower side of the heat-conduction oil furnace, a second interface is formed in the upper side of the heat-conduction oil furnace, a first heat-conduction oil pipe is arranged at the end,away from the heat-conduction oil furnace, of the first interface, the bottom end of the first heat-conduction oil pipe is fixedly connected with a second heat-conduction oil pipe, and a stop valve isarranged between the first heat-conduction oil pipe and the second heat-conduction oil pipe. A first oil injection hole is formed in the left side of the second heat-conduction oil pipe, an oil filter is arranged in the middle of the second heat-conduction oil pipe, and a graphite heat exchanger is arranged on the right side of the oil filter. By means of the heat-conduction oil heating device, hydrochloric acid is prevented from being plunged into the heat-conduction oil furnace after sealing of the graphite heat exchanger is damaged, it is convenient for a worker to monitor by arranging a PH meter, and the heat-conduction oil furnace is better protected. If an acid-connecting accident happens, only the heat-conduction oil in the second heat-conduction oil pipe is contaminated, the probability that the heat-conduction oil in the heat-conduction oil furnace is contaminated is reduced, and the cost loss is reduced.

Owner:QINGYUAN JINGWANG ENVIRONMENTAL PROTECTION EQUIP

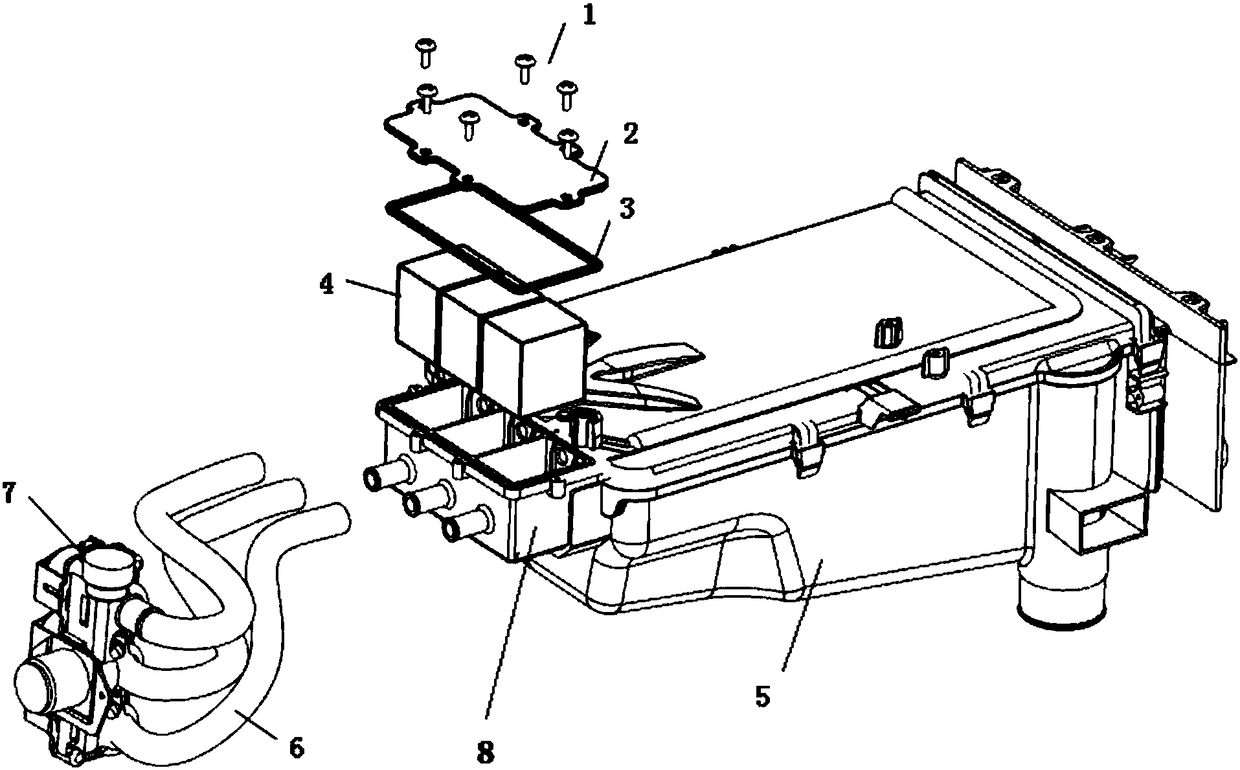

Water injection tank and washing machine

ActiveCN108570828AInhibition of reproductionReduce the chance of contaminationWater contaminantsOther washing machinesCalcium sulfiteResidual chlorine

The invention belongs to the technical field of washing machines, and particularly relates to a water injection tank and a washing machine. The water injection tank comprises a water injection tank body, a water purification chamber is formed in the water inlet side of the water injection tank body, a filter element composed of KDF and / or calcium sulfite is arranged in the water purification chamber, and a water inlet pipe of the water injection tank is directly communicated with the water purification chamber; the filter element composed of KDF and / or calcium sulfite can be taken out and replaced from the water purification chamber. The water injection tank has excellent purification effect, heavy metals and residual chlorine can be effectively removed, the growth of microorganisms can beinhibited, and the water injection tank has a simple structure and wide applicability.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +1

Sales rack for frozen food

InactiveCN112971464AImprove practicalityReduce the chance of contaminationShow cabinetsDispersed particle separationAgricultural engineeringAgricultural science

The invention discloses a sales rack for frozen food and relates to the field of food sales. The sales rack comprises a placement cabinet, wherein four corners of a lower surface of the placement cabinet are fixedly connected with supporting legs, a front end face of the placement cabinet is rotatably connected with two symmetrically distributed rotating doors, the interior of the placement cabinet is fixedly connected with a plurality of uniformly distributed layering plates, and one side of the placing cabinet is communicated with an air purifying mechanism. When the sales rack is used, frozen food is placed on the filter screen of the fixing frame, after blood on the surface of the frozen food is thawed, the blood drops into the drawing drawer along the filter screen, the situation that the blood slides down to pollute the surrounding ground is avoided, cleaning is convenient in the drawing drawer, and practicality is improved; a plurality of taking clamps are hung on the H-shaped connecting rod through hooks, so customers can select food conveniently, direct contact between the hands of the customers and the food is reduced, sanitation is achieved, and the probability that the food is polluted is reduced.

Owner:西安牛圈教育科技有限公司

A cleaning composition for composite insulators with repair function and preparation method thereof

ActiveCN112812895BReduce the chance of contaminationExtended cleaning cycleOrganic detergent compounding agentsCoatingsComposite insulatorsActive agent

The invention provides a cleaning composition for composite insulators with repairing function, belonging to the technical field of cleaning agents. The cleaning composition for composite insulators with repairing function provided by the present invention includes a dirt cleaning agent and an organic silicone rubber repairing agent, does not contain corrosive and prohibited substances, and is composed of surfactants with low surface tension, penetrating wetting agents. , builder, dust-proof agent, insulating layer repairing agent, etc. A variety of organic auxiliaries work together to spontaneously wet and spread on the surface of the insulator with contamination, so that the contamination will fall off the surface of the insulator, and it has a super high contamination removal ability. , significantly reducing wetting and brushing times. The functional silicone contained is deposited on the surface of the composite insulator to form a repair layer of 2 to 5 microns, repair the corroded and uneven parts of the surface layer, and restore the hydrophobicity and hydrophobicity of the surface. Effectively reduce the probability of subsequent contamination of the insulator and prolong the cleaning cycle.

Owner:苏州禾川化学技术服务有限公司

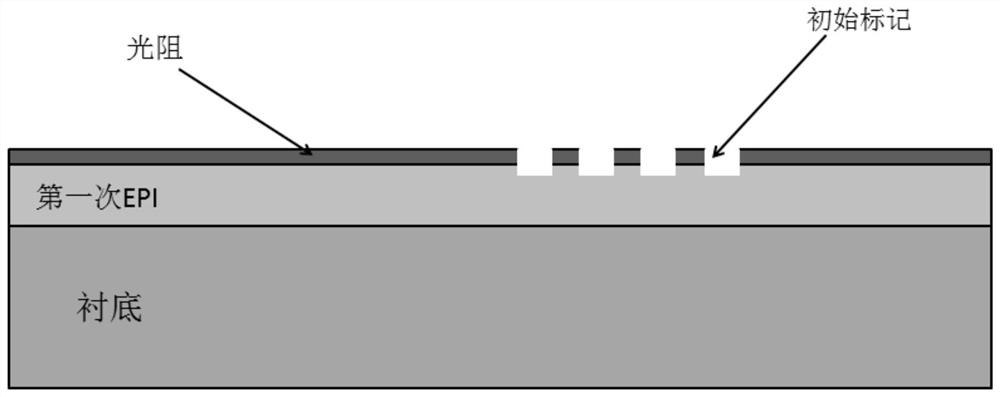

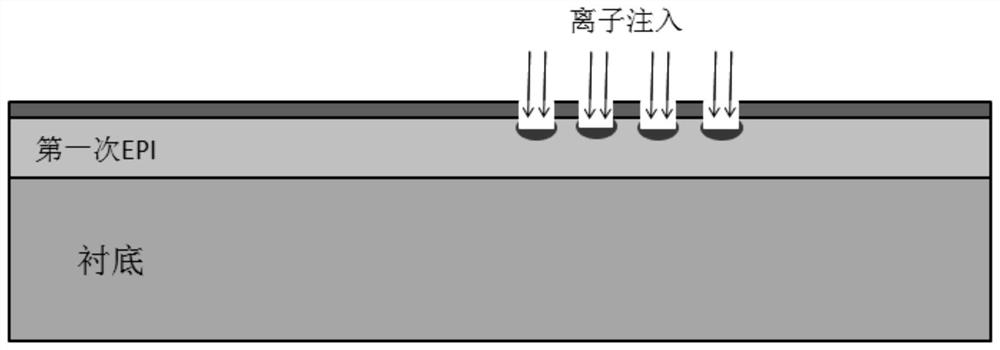

Method for improving alignment accuracy of lithographic marks, method for preparing superjunction products, and superjunction products

ActiveCN107706148BPreserve integritySolve pollutionSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringElectronic chip

The invention relates to the field of microelectronic chip production manufacturing, and specifically provides a method for improving the alignment accuracy of a photoetching mark, a preparation method of a superjunction product and the superjunction product. The method for improving the alignment accuracy of the photoetching mark comprises the following steps: (a) carrying out ion injection on anepitaxial wafer with an initial mark, wherein the position of ion injection is the bottom of the initial mark, and at least one of ion elements is injected; and the ion elements comprise inert elements and / or elements homogeneous with doping elements during second epitaxial growth; and (b) carrying out the steps of second epitaxial growth, third epitaxial growth, photoetching and etching in sequence, and forming a counterpoint mark outside the area of the initial mark during etching. According to the method, the alignment accuracy of the photoetching mark can be improved, the number of timesof photoetching is greatly reduced, the working procedures are simpler, the production efficiency is high, the production cost is low, and the chip quality is high.

Owner:JILIN SINO MICROELECTRONICS CO LTD

Manufacturing process of wavy noodles

ActiveCN104542785BCreate pollutionAvoid damageDough shaping and cutting apparatusDough processingManufactured formEngineering

Owner:TINGYI (CAYMAN ISLANDS) HOLDING CORPORATION

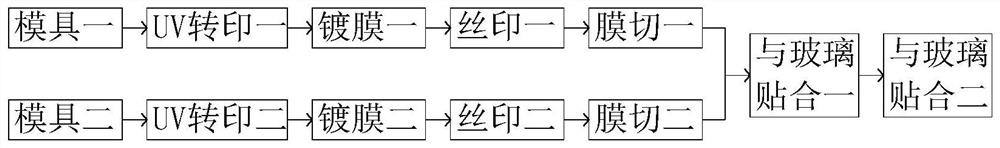

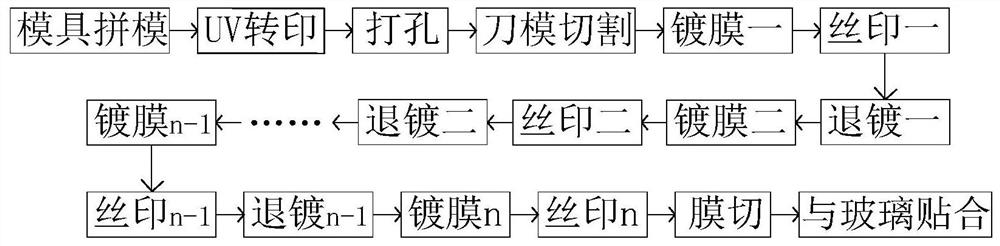

Preparation process of multiple textures for mobile phone camera

InactiveCN113733803ALow costReduce labor costsSpecial ornamental structuresLight effect designsColor effectFilm-coated tablet

The invention provides a preparation process of multiple textures for a mobile phone camera. The preparation process comprises the following steps of carrying out mold splicing, carrying out UV transfer printing, carrying out punching, carrying out cutting die cutting, carrying out first film coating, carrying out first silk printing, carrying out first deplating, carrying out second film coating, carrying out second silk printing, carrying out second deplating,... carrying out n-1 film coating, carrying out n-1 silk printing, carrying out n-1 deplating, carrying out n film coating, carrying out n silk printing, carrying out film cutting and carrying out laminating. According to the preparation process, various CD patterns are spliced and arranged on the same mold, and different glare and color effects are realized at different CD patterns by using corresponding processes, that is to say, the same PET explosion-proof film realizes the effect that various glare is matched with different colors, so that the material cost and the labor cost can be effectively reduced, and compared with two-time lamination, the single-time lamination has the advantages that the probability of smudginess of a binding surface is reduced, the yield of a single process is improved, and the yield of the whole finished product is further effectively improved.

Owner:JIANGXI CRYSTAL OPTECH +1

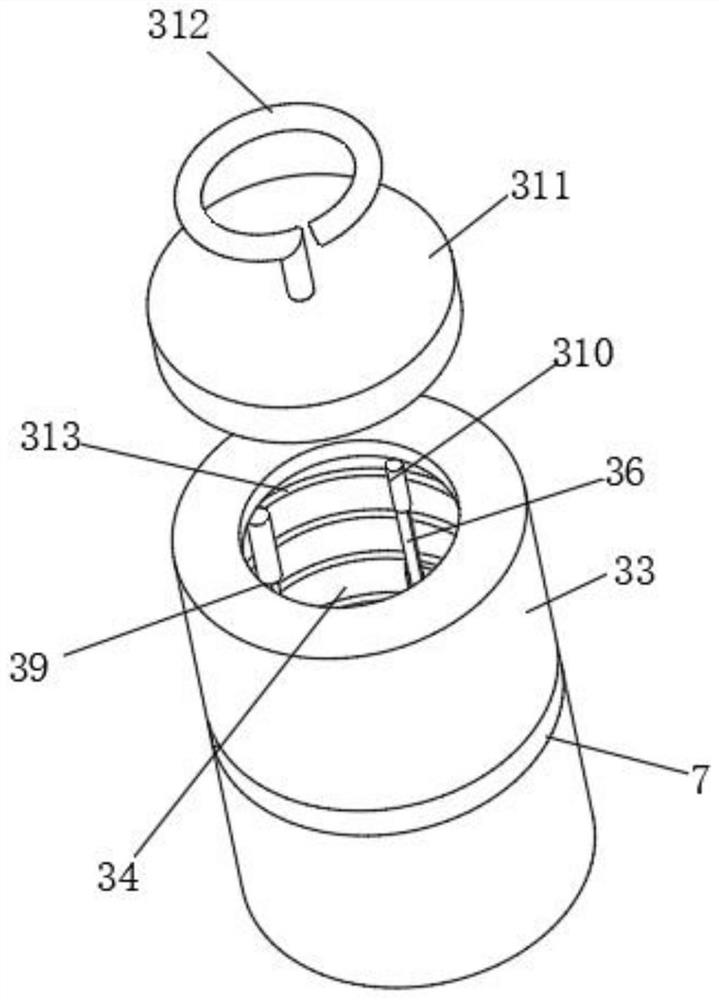

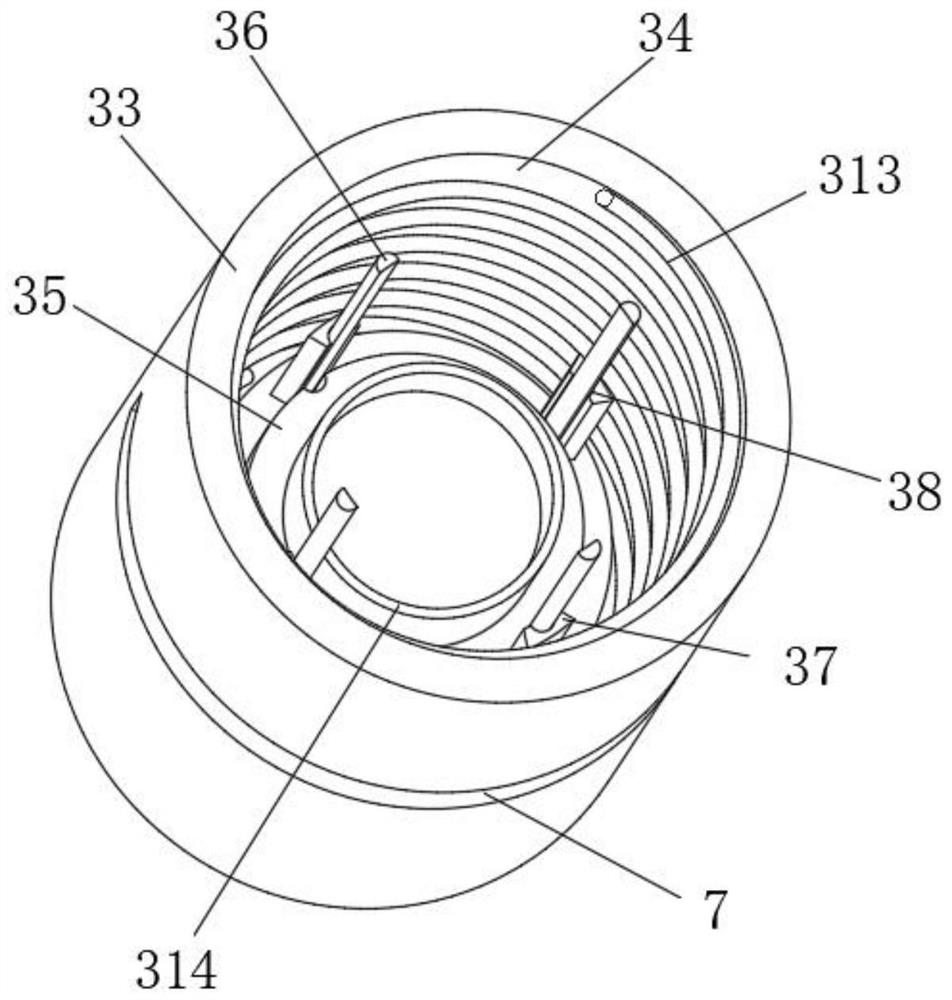

A nursing cup for self-care of postoperative patients

ActiveCN108814984BImprove sealingThere will be no repeated movement problemsFeeding-bottlesDomestic articlesCircular discPharmacy medicine

The invention provides a nursing cup for self-care of postoperative patients. The cup comprises a base, a driven gear disc and a battery, the disc-shaped battery is embedded in the bottom of the base,and the center of a groove of the base of the top of the battery is rotatably connected to the center of a bottom plane of the driven gear disc through a rotating shaft; the top of the driven gear disc is fixedly connected with a cylindrical cup body, and the diameter of the cup body and the diameter of the driven gear disc are consistent. According to the nursing cup, through mutual cooperationof the above various structures, the nursing cup can be automatically heated to adapt to the water temperature requirements of different drugs taken by the postoperative patients, the nursing cup is provided with decompression measures and insulation blocks to protect the postoperative patients from scald dangers, due to the poor immunity and physical condition of the postoperative patients, a water drinking pipe hidden in the base when not used can reduce the chance of bacterial contamination, a Z-shaped water drinking pipe arranged can prevent the patients from choking, and the most important advantage is that the nursing cup can be operated with one hand.

Owner:山西白求恩医院

Sauce dish seasoning machine

PendingCN106724992AAvoid open airReduce the chance of contaminationKitchen equipmentMechanical engineeringFood safety

The invention provides a sauce dish seasoning machine. The sauce dish seasoning machine comprises at least one seasoning storehouse of which the bottom is open, the bottom of each seasoning storehouse is provided with a supporting table which is used for placing tipping buckets, and at least two tipping buckets with different sizes are placed on the supporting table in a mode that the slope surfaces face backwards; the rear side of the supporting table is connected to a discharge hole, and a slope which is matched with the inclined angles of the tipping buckets is arranged between the discharge hole and the supporting table; the tail parts of the tipping buckets are connected to one end of a sliding blocking plate in a hinged mode, the other end of the sliding blocking plate is provided with a control button, and a reset device is arranged between the control button and a seasoning hopper. The tipping buckets with different volumes are utilized to load the seasoning, and the design of an auxiliary pushing plate makes it convenient to adjust the using amount of the seasoning; the form of the seasoning storehouses is utilized to load different seasoning respectively, and the situation that the seasoning is contaminated is avoided, which is beneficial to food safety. Through the improvement of the technology, the problems that the seasoning is prone to contamination in the process of adding the seasoning and the operation is inconvenient when the seasoning is added can be well overcome.

Owner:GUILIN NORMAL COLLEGE

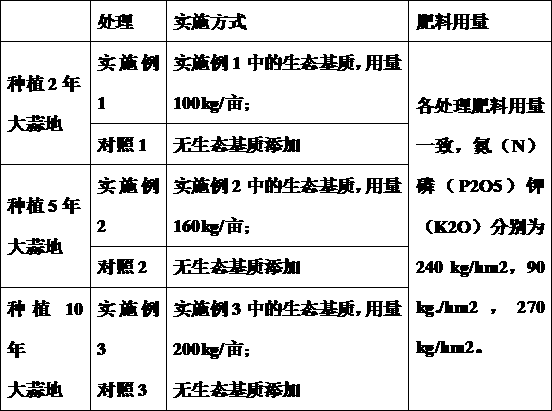

Ecological substrate for preventing and controlling nitrogen and phosphorus non-point source pollution in intensive garlic production area and preparation method thereof

InactiveCN109699435AIncrease productionReduce non-point source pollutionGrowth substratesCulture mediaPotassiumAlcohol sugars

The invention relates to an ecological substrate for preventing and controlling nitrogen and phosphorus non-point source pollution in an intensive garlic production area and a preparation method thereof, wherein the ecological substrate for preventing and controlling nitrogen and phosphorus non-point source pollution in the intensive garlic production area comprises the following components: magnesium sugar alcohol, potassium fulvic acid, cow dung, traditional Chinese medicine residue, tea residue, river snail shell powder and attapulgite powder. The ecological substrate comprises the following components in parts by weight: 3-6 parts of magnesium sugar alcohol, 5-10 parts of potassium fulvic acid, 30-60 parts of cow dung, 5-20 parts of traditional Chinese medicine residue, 5-10 parts of tea residue, 10-20 parts of river snail shell powder and 5-10 parts of attapulgite powder. The invention is used for the ecological substrate for preventing and controlling nitrogen and phosphorus non-point source pollution in the intensive garlic production area.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com