Phosphorus-free two-component cleaning agent as well as preparation method and application thereof

A two-component, cleaning agent technology, applied in the field of cleaning agents, can solve the problems of deterioration of ground water, poor removal of metal impurities, environmental pollution, etc., to achieve increased photoelectric conversion efficiency, improved photoelectric conversion efficiency, and excellent cleaning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A phosphorus-free two-component cleaning agent, consisting of A component and B component.

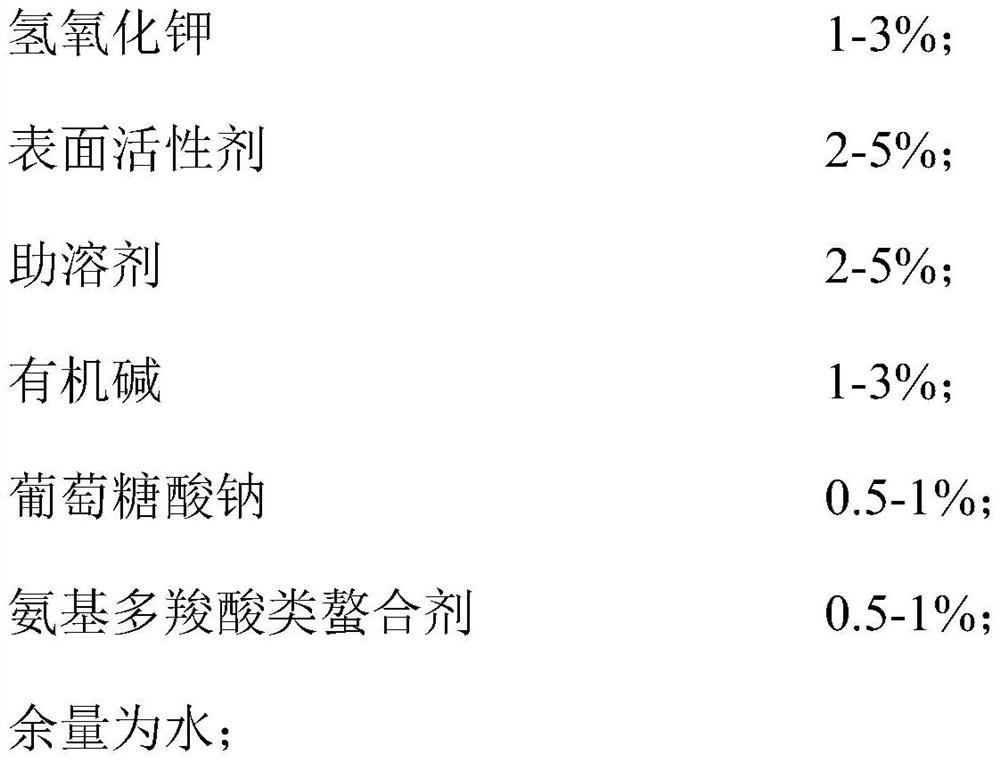

[0056] Wherein, taking the total mass of component A as 100%, component A consists of the following components:

[0057]

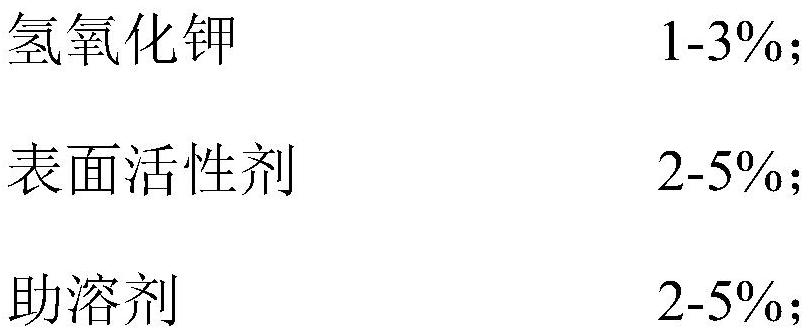

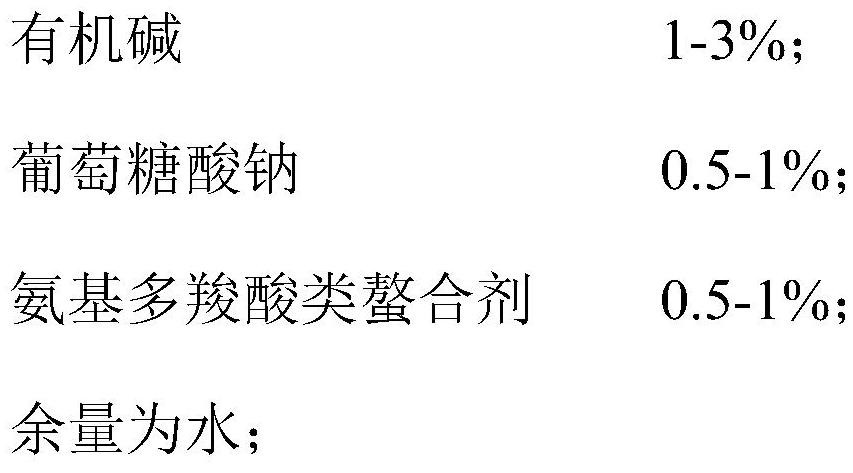

[0058] Based on the total mass of component B as 100%, component B consists of the following components:

[0059]

[0060] The preparation method is as follows: each component of component A and component B is mixed evenly.

Embodiment 2

[0062] The difference from Example 1 is that the nonylphenol polyoxyethylene ether (OP-9) in the A component is replaced by lauryl polyoxyethylene ether, the sodium iminosuccinate is replaced by ethylenediaminetetraacetic acid, the Sodium citrate in component B was replaced with sodium acetate.

Embodiment 3

[0064] The difference from Example 1 is that the sodium metasilicate pentahydrate in component A is removed, and the part of sodium metasilicate pentahydrate is supplemented by deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com