A cleaning composition for composite insulators with repair function and preparation method thereof

A technology of composite insulators and cleaning compositions, applied in the field of cleaning agents, can solve the problems of difficult removal of dirt, poor universality and functionality, and difficulty in cleaning, etc., and achieve the restoration of hydrophobicity and migration of hydrophobicity, and environmental damage Small, the effect of reducing the chance of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

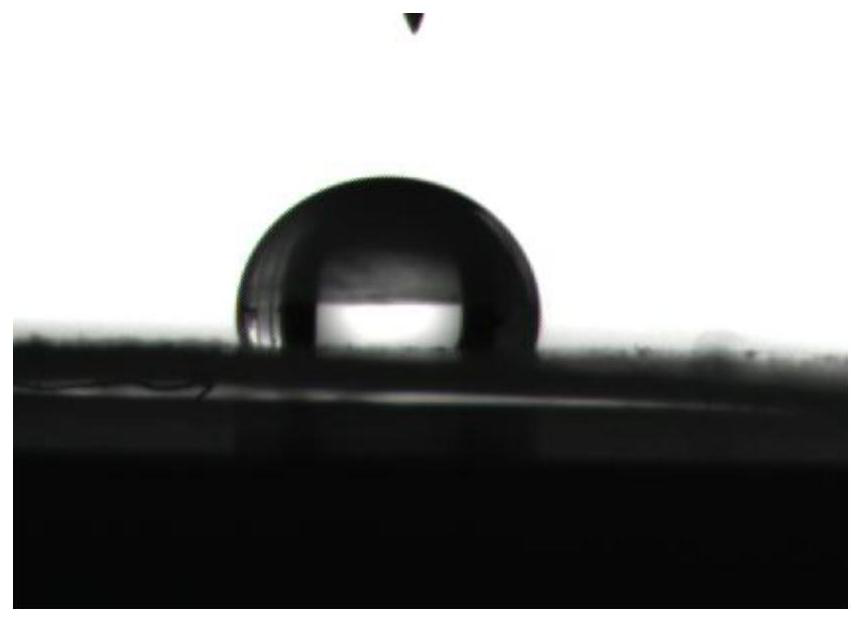

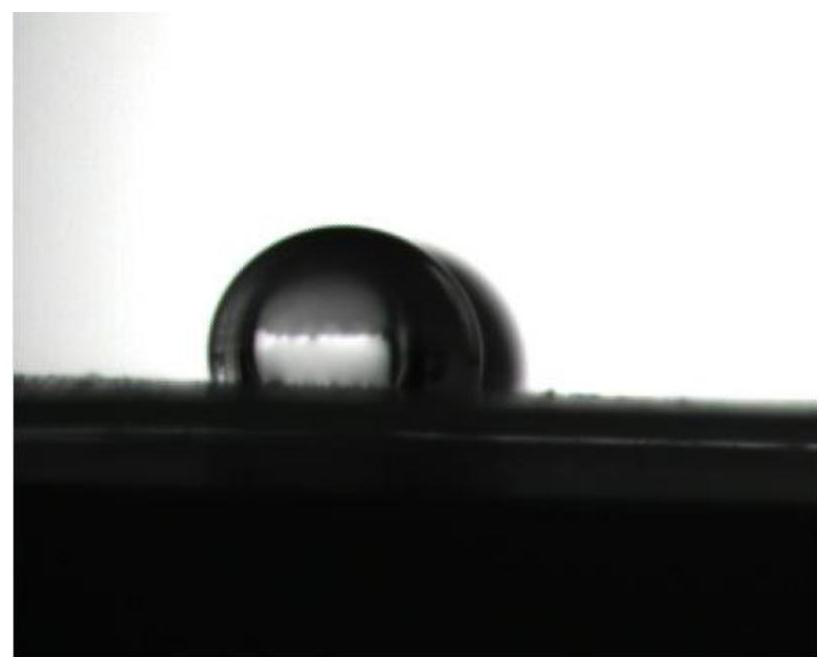

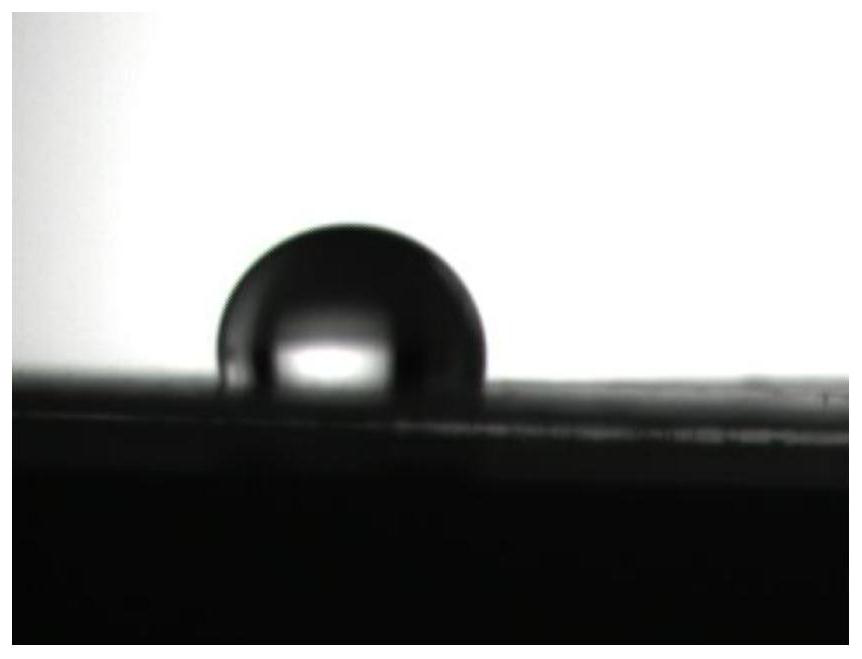

Image

Examples

preparation example Construction

[0059] The present invention also provides a preparation method for the above cleaning composition for composite insulators with repair function, comprising the following steps:

[0060] Based on the mass of organic acid, 5-10 parts of organic acid, 5-10 parts of alcohol ether solvent, 2-10 parts of ethoxylated polytrisiloxane, 1-5 parts of fluorine-containing surfactant, corrosion inhibitor 1 to 3 parts of antibacterial agent, 2 to 10 parts of bactericidal and antifungal agent, and 60 to 80 parts of water are mixed to obtain a dirt cleaning agent;

[0061] Based on the mass of polydimethylsiloxane containing denaturing groups, 25-35 parts of polydimethylsiloxane containing denaturing groups, 3-8 parts of compound emulsifier, 1-3 parts of dispersing agent The parts are mixed and then heated to obtain a denatured silicone oil mixture;

[0062] Mixing the denatured silicone oil mixture with 60 to 70 parts of water to obtain a denatured silicone oil emulsion;

[0063] The denat...

Embodiment 1

[0078] Prepare dirt cleaning agent and silicone rubber repair agent according to mass ratio:

[0079] The composition of the dirt cleaning agent is: 3 parts of citric acid, 4 parts of hydroxyethylidene diphosphoric acid, 6 parts of diethylene glycol monobutyl ether, ethoxylated polytrisiloxane (EO number is 7, HLB value is 8-9 ) 7 parts, 1 part of sodium perfluorooctane sulfonate, 1 part of 2-mercaptobenzothiazole, 1 part of 2-methyl-4-isothiazolin-3-one, 77 parts of water.

[0080] The composition of the silicone rubber repair agent is: 32 parts of hydroxyl-terminated polydimethylsiloxane, 32.5 parts of fatty alcohol polyoxyethylene ether, 92.5 parts of fatty alcohol polyoxyethylene ether, 1 part of sodium polyacrylate, γ-shrink 1 part of glyceryl ether oxypropyltrimethoxysilane, 62 parts of water

[0081] Take 12 parts of dirt cleaning agent, 5 parts of silicone rubber repair agent, and 83 parts of water, and mix them uniformly to obtain a cleaning composition for composite...

Embodiment 2

[0083] Prepare dirt cleaning agent and silicone rubber repairing agent respectively according to mass ratio:

[0084] The composition of the dirt cleaning agent is: 3 parts of glycolic acid, 5 parts of glycolic acid, 8 parts of dipropylene glycol methyl ether, 8 parts of ethoxylated polytrisiloxane (EO number 8, HLB value 9-10), perfluorinated 1 part of potassium hexyl ethylsulfonate, 1 part of benzotriazole, 1 part of 2-methyl-4-isothiazolin-3-one, 77 parts of water.

[0085] The composition of the silicone rubber repair agent is: 28 parts of hydroxyl-terminated silicone oil, 32.5 parts of isooctyl alcohol polyoxyethylene ether, 92.5 parts of nonylphenol polyoxyethylene ether, 1 part of sodium salt of acrylic acid-maleic acid copolymer, 1 part of γ-aminopropyltriethoxysilane, 65 parts of water.

[0086] Take 10 parts of dirt cleaning agent, 5 parts of silicone rubber repairing agent, and 85 parts of water, and mix them uniformly to obtain a cleaning composition for composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com