Manufacturing process of wavy noodles

A manufacturing process and noodle technology, applied in the field of corrugated noodle forming equipment, can solve the problems of unstable consumer quality, uneven noodle corrugation, and inconspicuous effect, so as to reduce the probability of noodle contamination with impurities, reduce motor damage, reduce Effect of solid particle content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

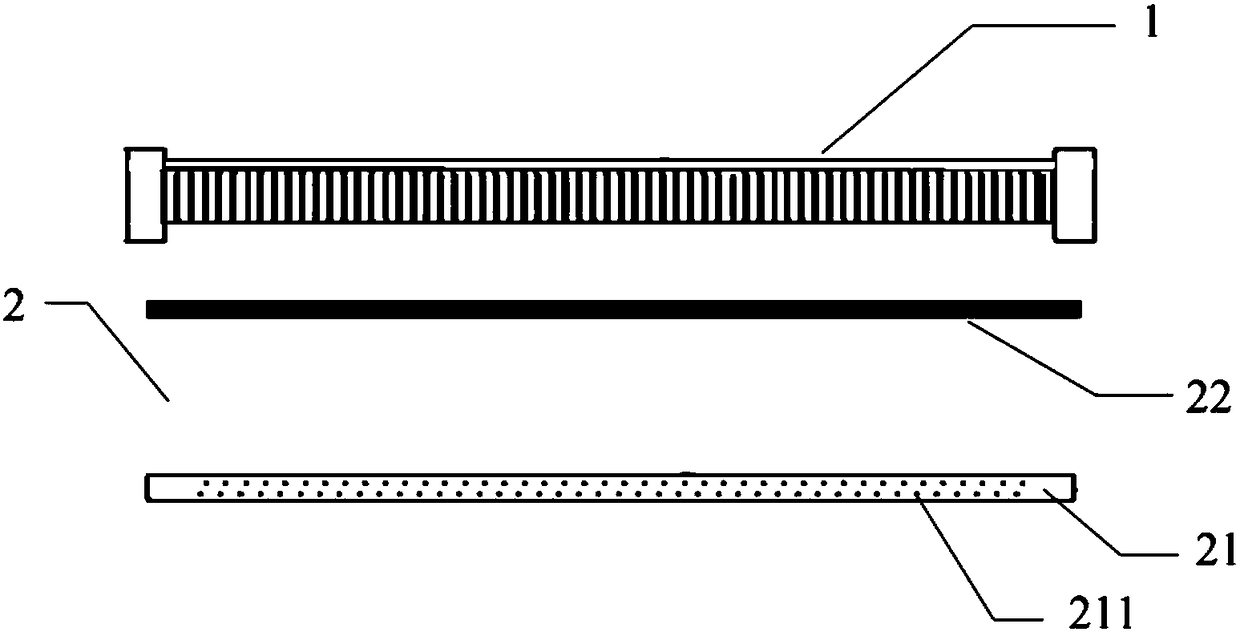

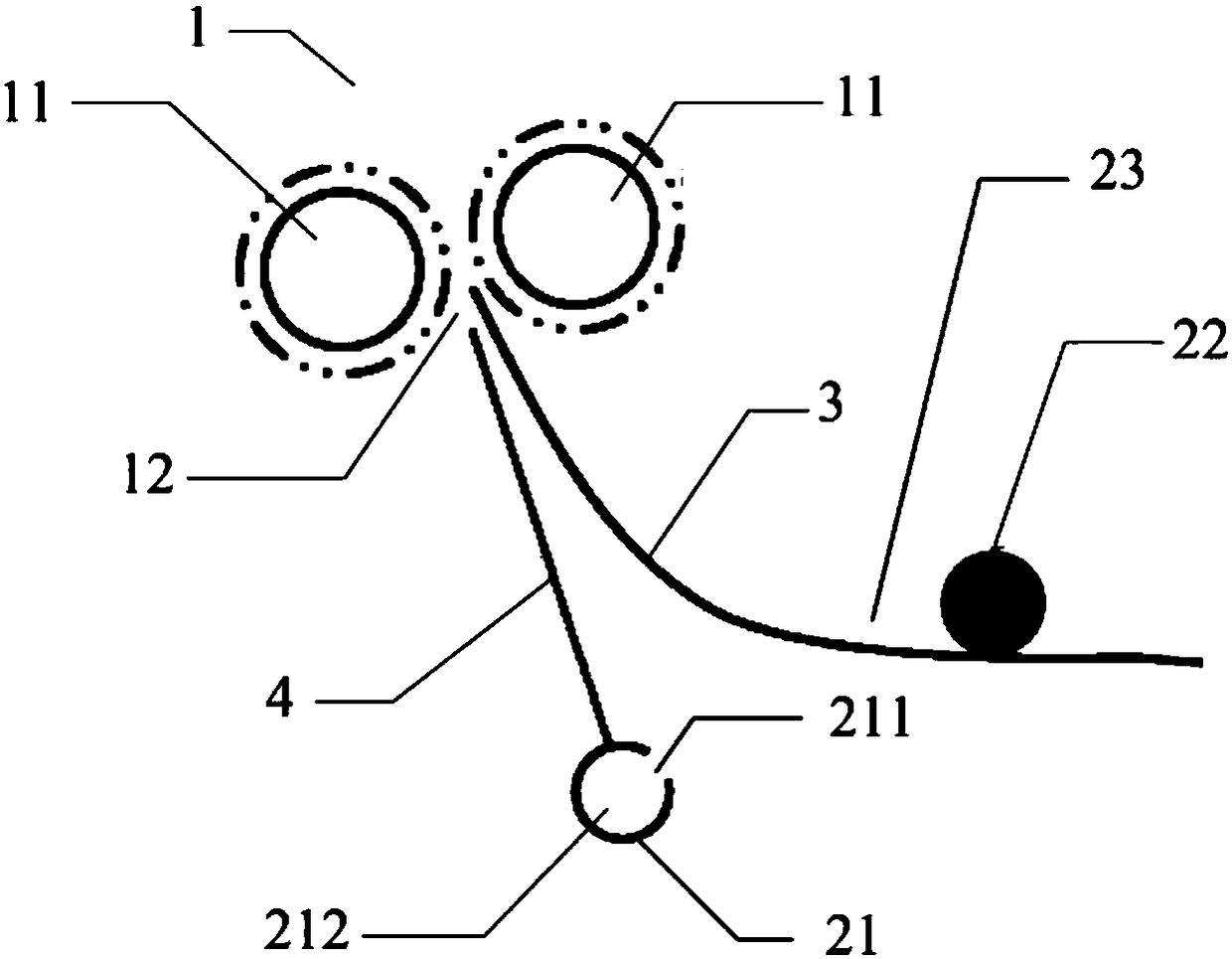

[0013] Below, the attached Figure 2-4 The wavy noodle forming equipment of the present invention and the manufacturing process of using the noodle forming equipment to produce wavy noodles will be described.

[0014] The corrugated noodle forming equipment includes a shred knife 1, a wave-making device 2 and a steam box (not shown), the shred knife includes two circular rollers 11 that rotate in opposite directions and mesh with each other, the shred knife 1 The wave-making and forming device 2 is provided downstream of the wave-making and forming device 2, and the wave-making and forming device 2 includes an air blowing rod 21 and a wave regulating rod 22 arranged in parallel, and a noodle channel is formed between the air blowing rod 21 and the wave regulating rod 22 23, wherein, the air blowing rod 21 is a hollow rod body, and one or more rows of small holes 211 facing the wave-shaped adjusting rod 22 are provided on the outer wall surface of the air blowing rod 21, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com