Patents

Literature

68results about How to "Reduce sticking phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

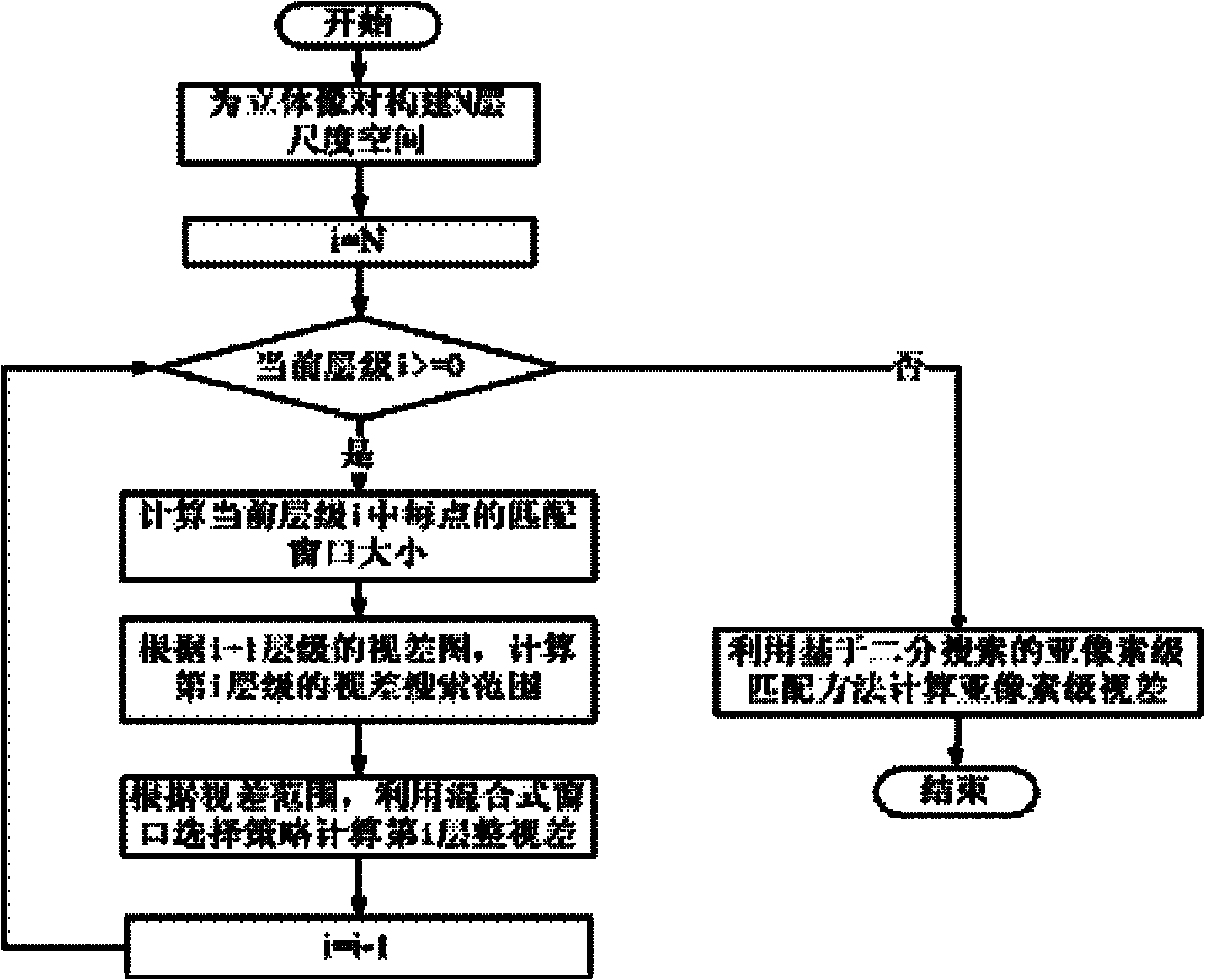

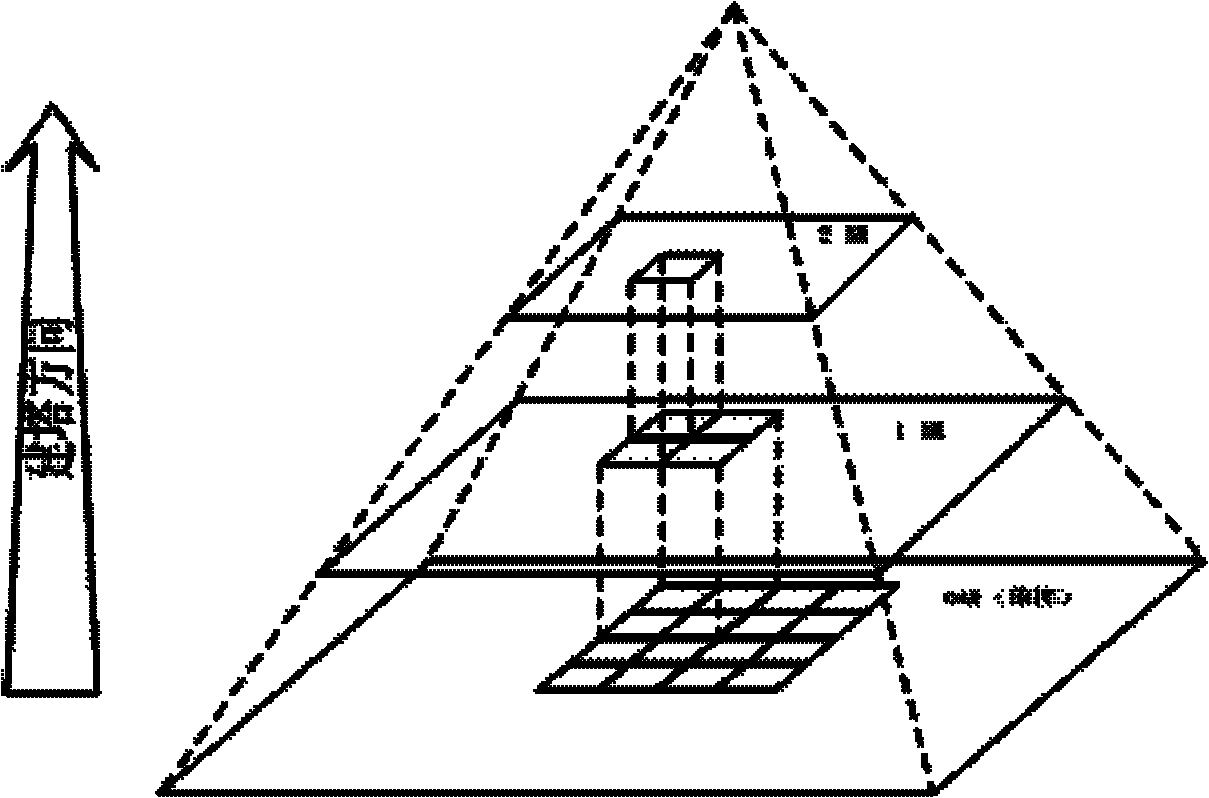

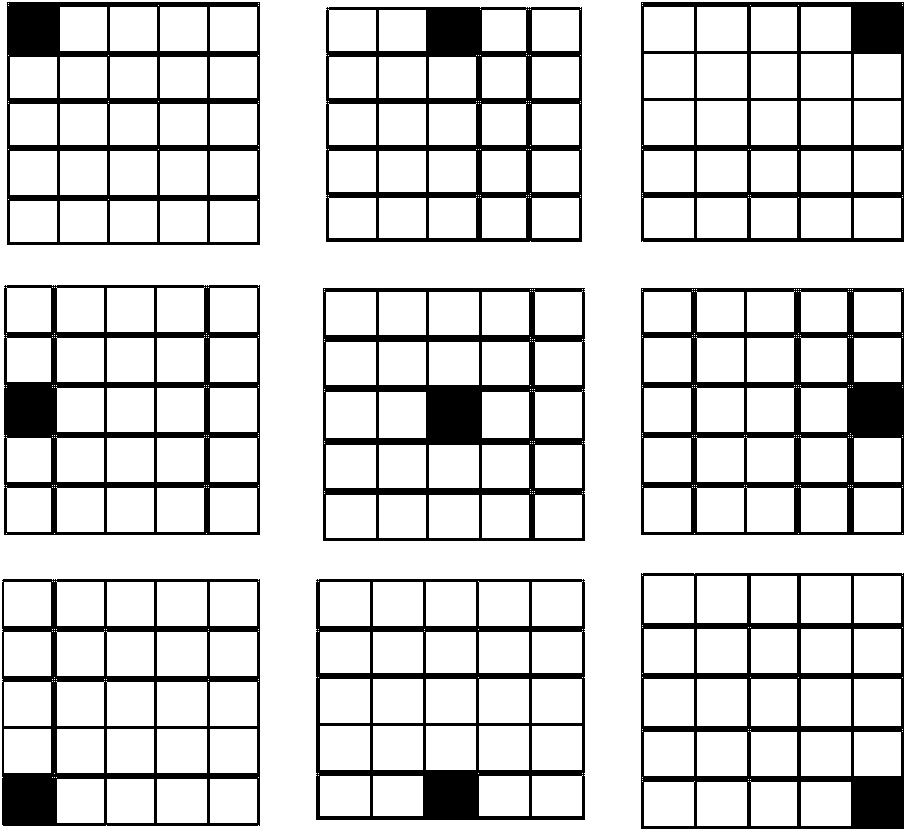

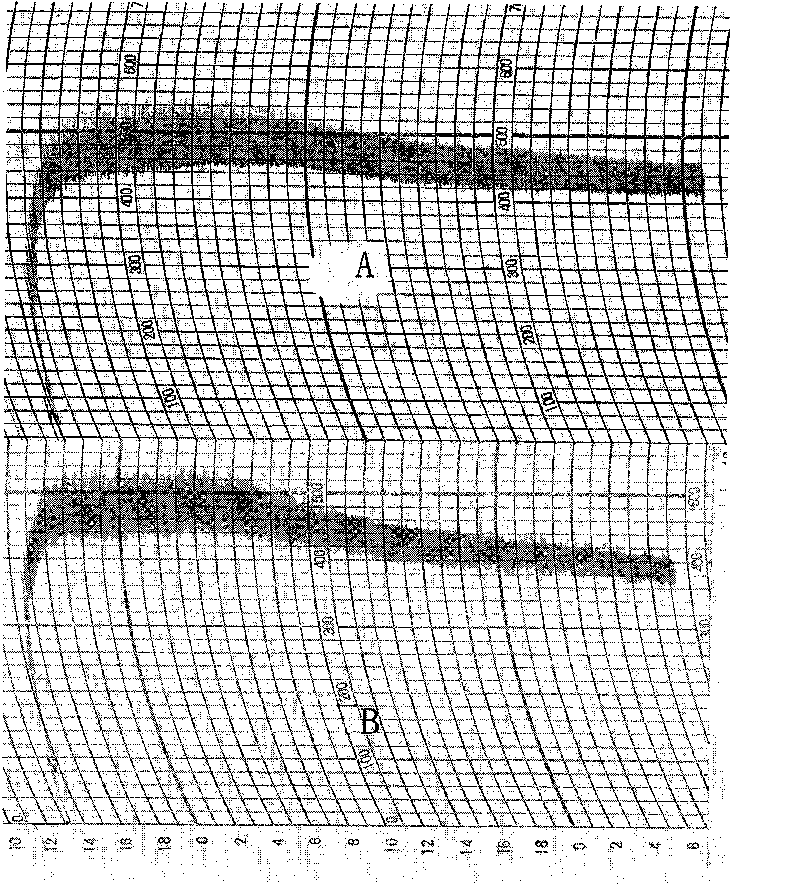

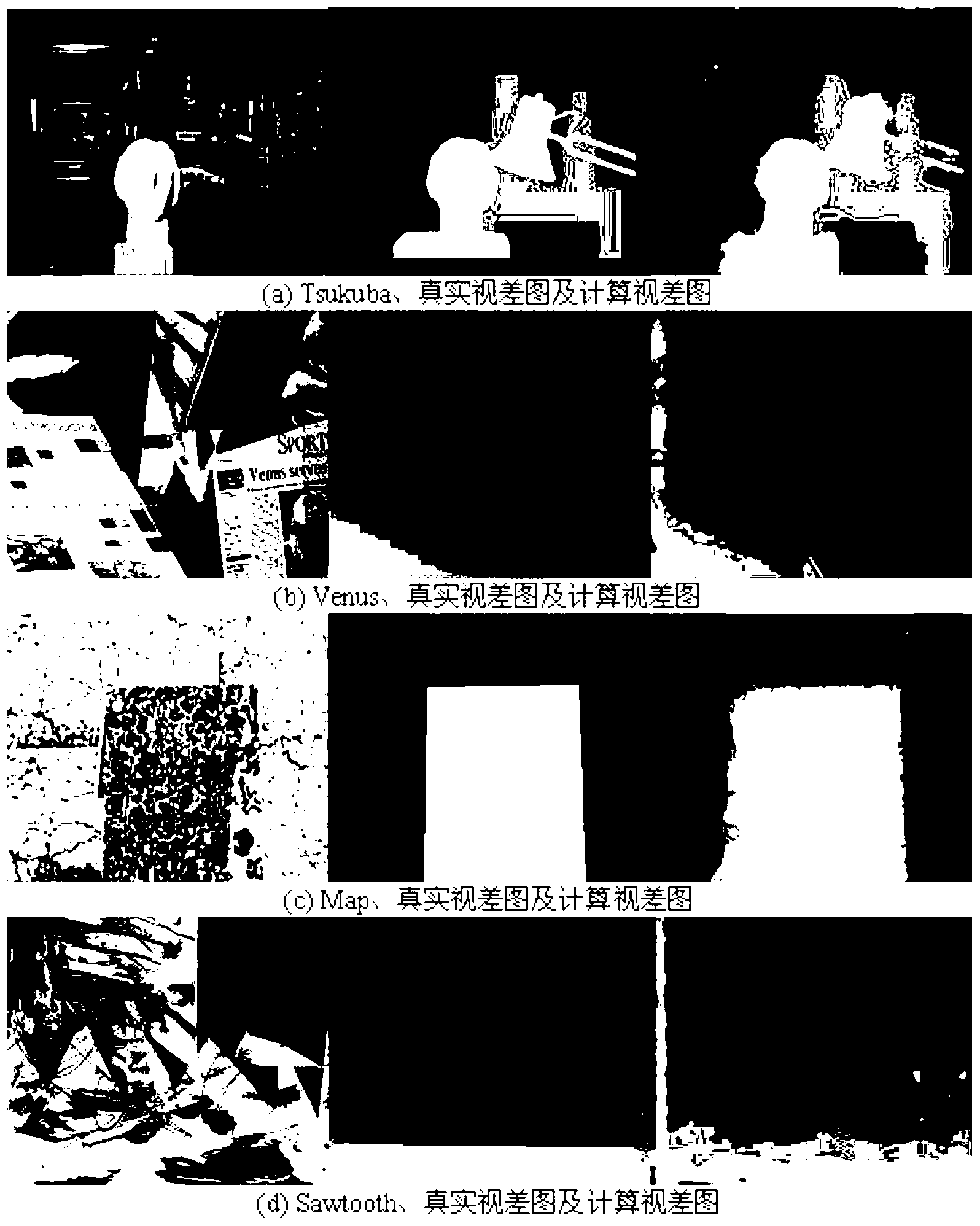

Sub-pixel level stereo matching method based on scale space

The invention provides a sub-pixel level stereo matching method based on a scale space. The method comprises the following steps of: (1) establishing the scale space for a stereopair; (2) determining the size of a matching window for each point of a current level reference image in the scale space; (3) calculating a parallax searching range for each point of the level reference image according tothe parallax of the former level; (4) calculating an integer-grade parallax of the current level in the scale space; and (5) calculating a sub-pixel level parallax through a sub-pixel level matching method based on binary search. The method of the invention uses the stereopair generated under the condition of small height ratio to match; a dispersed scale space is used in the matching process to improve the matching efficiency; a bonding phenomenon generated in the matching process is reduced by using a mixed window selecting strategy; and the sub-pixel level parallax is obtained by the sub-pixel level matching method based on the binary search so as to ensure high sub-pixel level precision, and greatly improve matching efficiency of the algorithm.

Owner:HARBIN ENG UNIV

Frozen dumpling modifying agent, preparation method thereof and application

InactiveCN101744021AImprove dough sticking rollerImprove sticking phenomenonDough treatmentPre-baking dough treatmentFreeze thawingEnzyme

The invention belongs to the technical field of frozen dumpling processing by additives, in particular to a frozen dumpling modifying agent, a preparation method thereof and application. The frozen dumpling modifying agent is prepared from the following components in percentage by weight via mixing: 35 to 42 parts of active soybean meal, 25 to 38 parts of konjaku flour, 5 parts of complex enzyme, 8 to 12 parts of carrageenin and 10 to 20 parts of modified starch. The modifying agent can adapt to the process requirements of the mechanized production of the frozen dumplings, improve the quality of finished products of the frozen dumplings, effectively improve the mechanical stirring resistance degree of the flour dough of the frozen dumplings, reduce the roll adhesion phenomenon of cheeks during the mechanized production, can simultaneously improve the boil resistance performance, the smooth performance and the freeze-thaw stability of the frozen dumplings, and improve the external appearance and the mouth feeling of the frozen dumplings.

Owner:河南兴泰科技实业有限公司

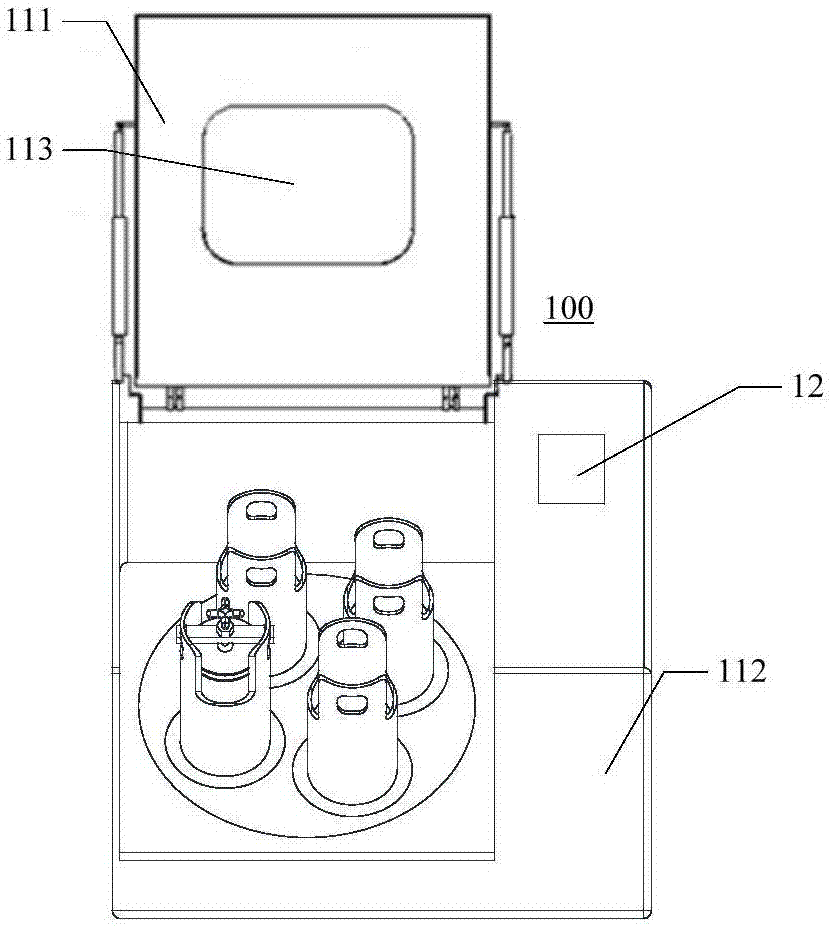

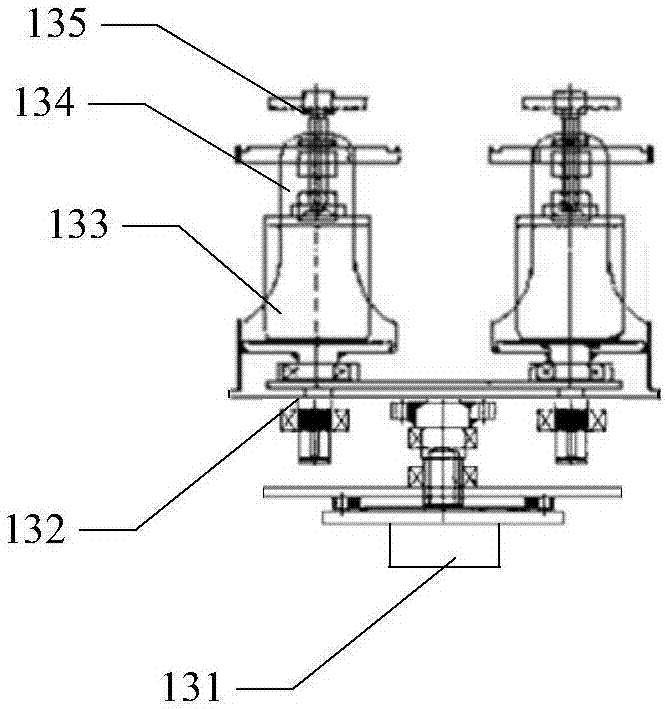

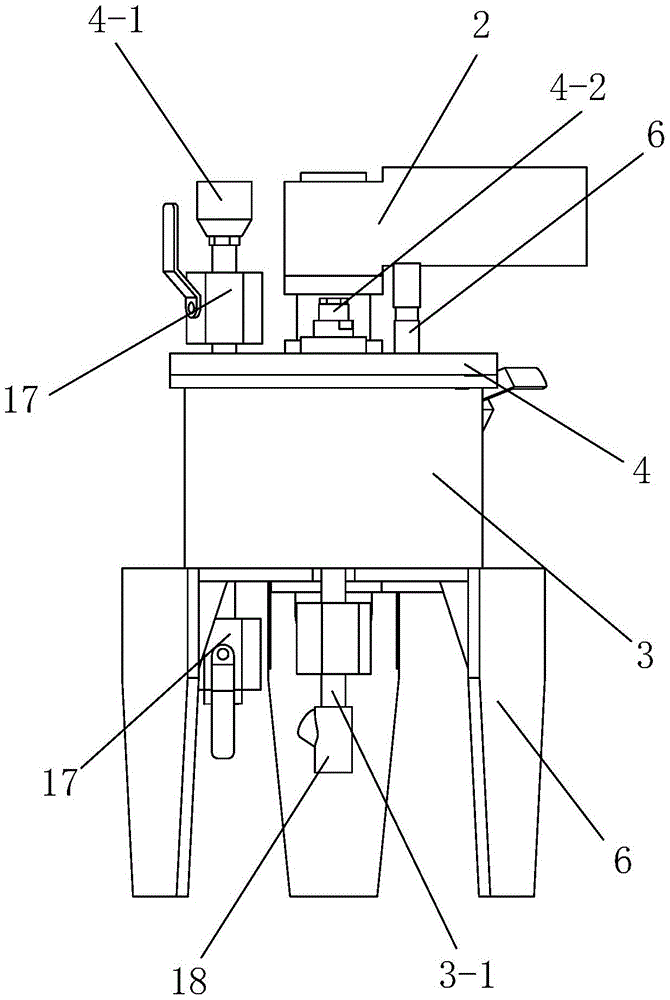

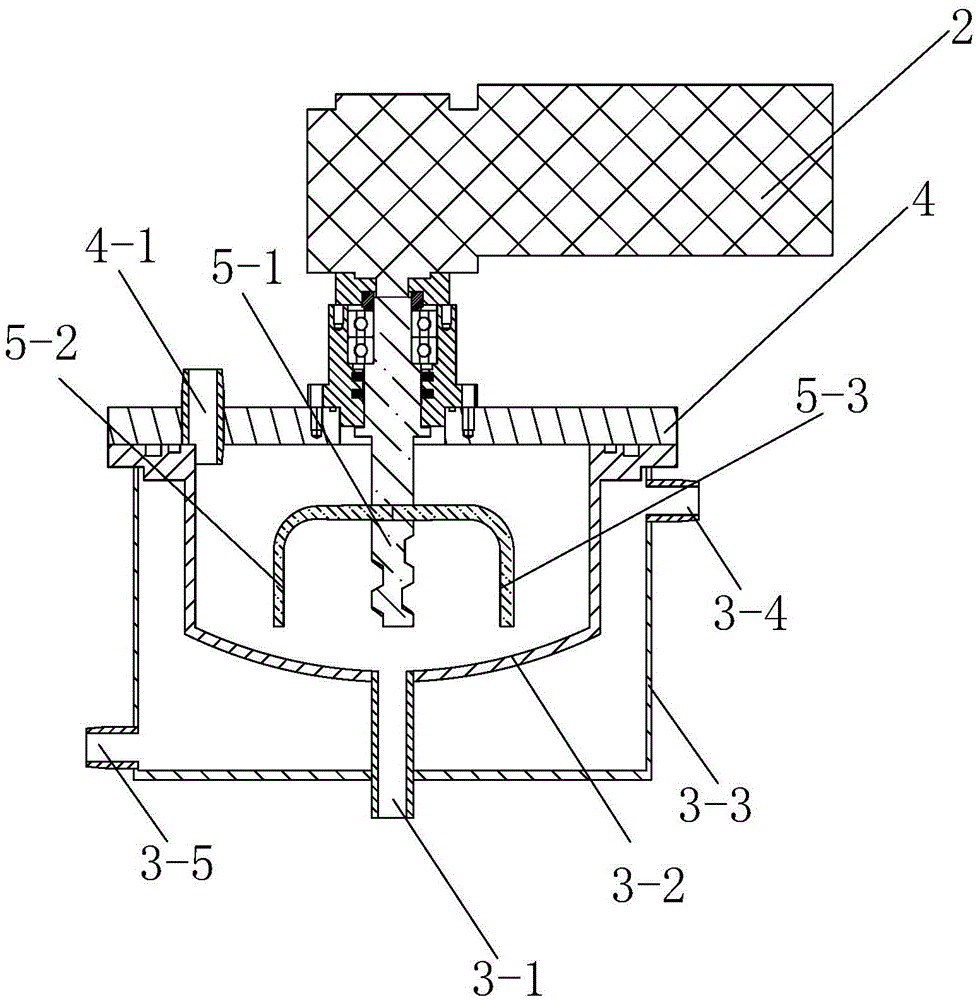

Obliquely vertical planetary ball mill and system

PendingCN106944199AAvoid blind spotsReduces deposits to the bottom of the grinding jarGrain treatmentsControl systemElectric machinery

The invention provides an obliquely vertical planetary ball mill and a system and relates to the technical field of powder grinding equipment. The obliquely vertical planetary ball mill comprises a shell, a rotary table part, grinding jar compressing parts and a control system, wherein the rotary table part comprises a speed reduction motor, a rotary table, grinding jar sleeves and grinding jars, the speed reduction motor is located below the rotary table, the grinding jar sleeves are mounted on the rotary table, the speed reduction motor drives the rotary table to revolve through a planetary bearing and simultaneously drives the grinding jars to rotate, and the grinding jars are fixed in the grinding jar sleeves through the grinding jar compressing parts; the bottom of each grinding jar is level, and the connecting part between the bottom and the jar wall of each grinding jar is arc; the rotary table is installed in the shell through a rotary table frame, and the rotary table frame enables the grinding jar sleeves to be oblique relative to the horizontal surface. The obliquely vertical planetary ball mill reduces the situation that grinded objects deposit to the bottoms of the grinding jars, reduces the occurrence probability of the jar adhesion phenomenon and improves the work efficiency of the equipment.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

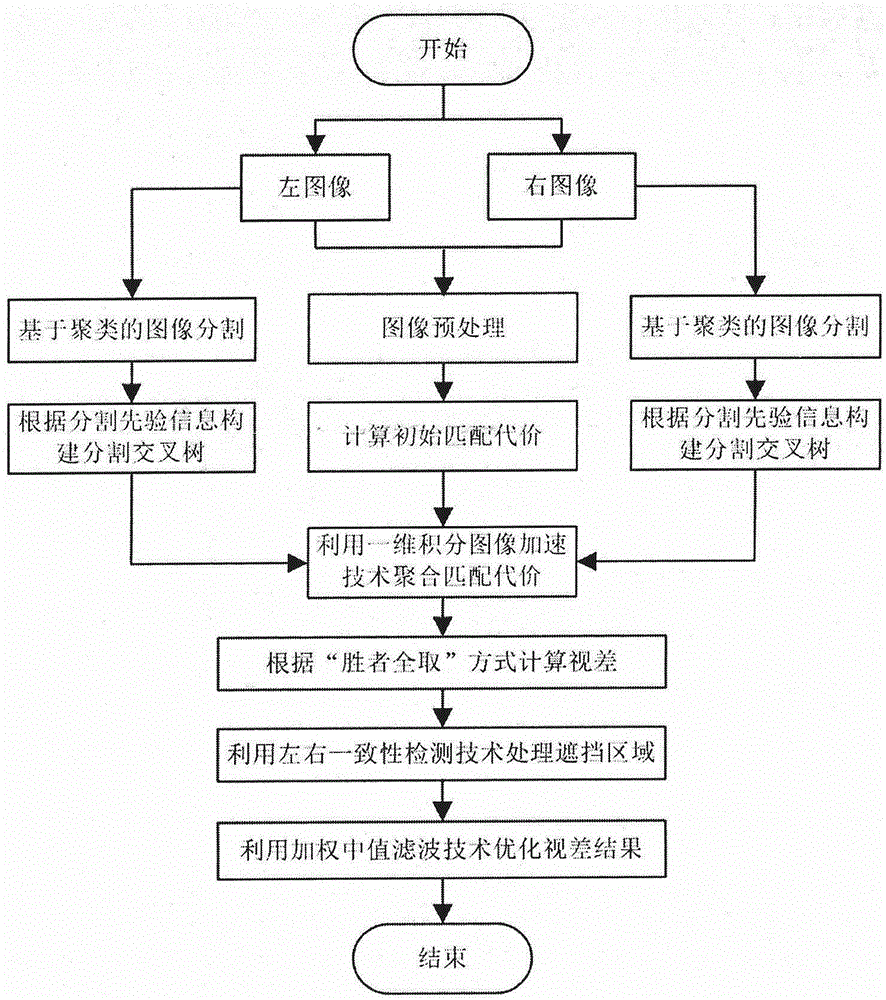

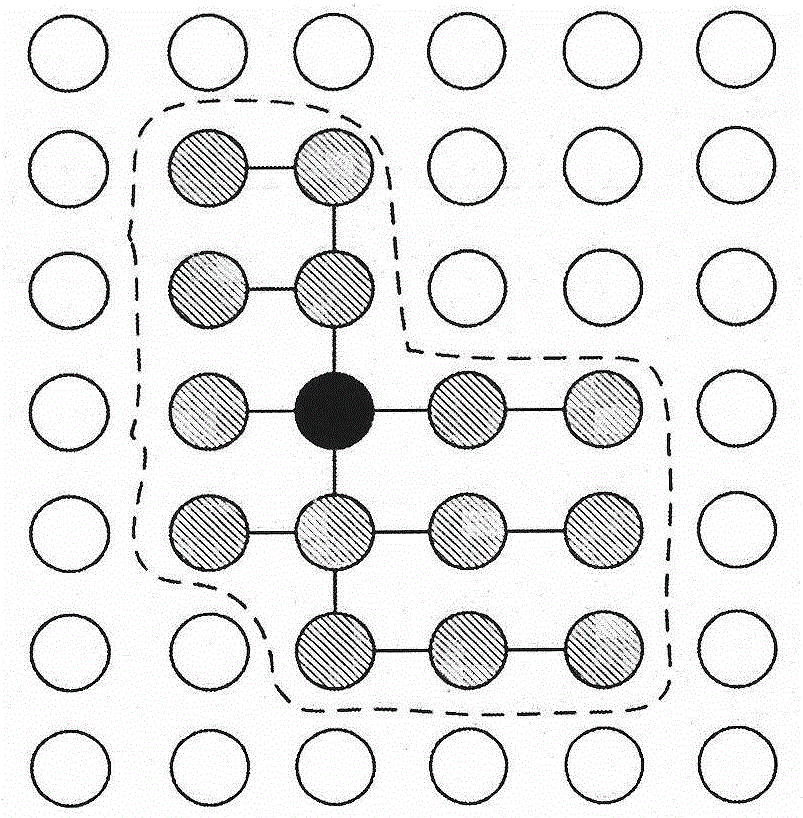

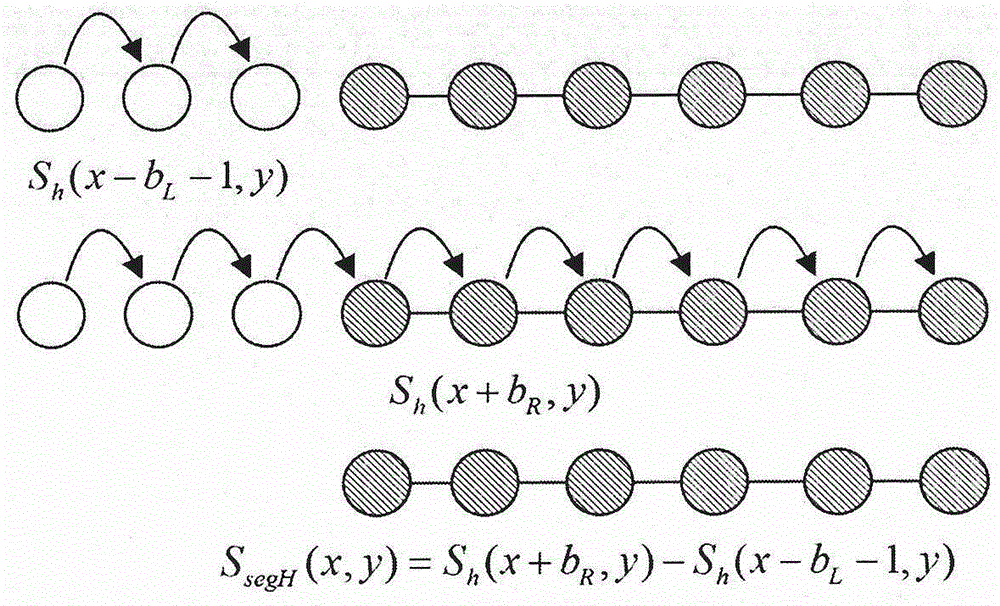

Stereo matching method based on segmentation cross trees

InactiveCN105787932AAddresses issues that do not accurately reflect matching constraintsSolve matching problemsImage enhancementImage analysisParallaxStereo matching

The invention relates to a stereo matching method based on segmentation cross trees, and discloses a stereo matching method based on segmentation cross trees. The method comprises the following six steps: step one, preprocessing left and right stereo images by use of a Gaussian filtering technology, step two, calculating initial matching cost, step three, constructing a segmentation cross tree for each pixel point to be matched of the left and right stereo images, step four, aggregating the initial matching cost in a segmentation cross tree support area by use of a one-dimensional integration image acceleration technology, step five, calculating parallax errors according to a "winner-take-all" method, and step six, according to the parallax error results of the left and right stereo images, correcting the parallax error results respectively by use of a left-right consistency detection technology and a weight median filtering technology. The method provided by the invention is applied to stereo matching based on the segmentation cross trees.

Owner:HARBIN NORMAL UNIVERSITY

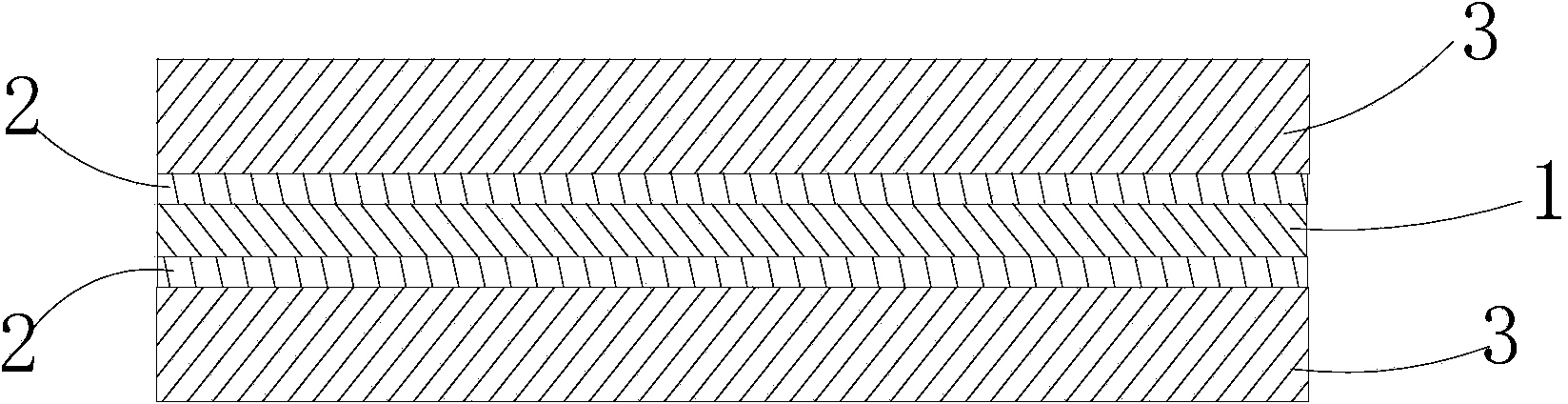

Copper-clad plate with two flexible surfaces and preparation method of copper-clad plate with two flexible surfaces

ActiveCN103612464APerformance impactReduce sticking phenomenonLamination ancillary operationsNon-macromolecular adhesive additivesEpoxyTemperature control

The invention belongs to the technical field of copper-clad plates and particularly relates to a preparation method of a copper-clad plate with two flexible surfaces. The preparation method comprises the following steps of preparing an adhesive; smearing the adhesive on one surface of a flexible insulated base film, then baking the adhesive by adopting a segmented temperature control method, then compositing the dried adhesive and a copper foil in a rolling manner; smearing the adhesive on the other surface of the flexible insulated base film, then baking the adhesive by adopting a segmented temperature control method, then compositing the dried adhesive and the other copper foil so as to obtain the copper clad plate with two flexible surfaces. Compared with the prior art, the copper-clad plate and the preparation method have the advantages that by segmented temperature control, the temperature is firstly increased to be higher than the volatilization temperature of a solvent slowly, so that the solvent can be fully volatilized; then the temperature is slowly increased to be more than the reaction temperature of epoxy resin, so that the linear epoxy resin is completely cured into a shaped high-molecular compound, further the curing of the adhesive is safe, the occurrence of the phenomenon of plate adhesion after a circuit is printed can be reduced and the quality of the product is improved.

Owner:SHANDONG JINDING ELECTRONICS MATERIALS CO LTD

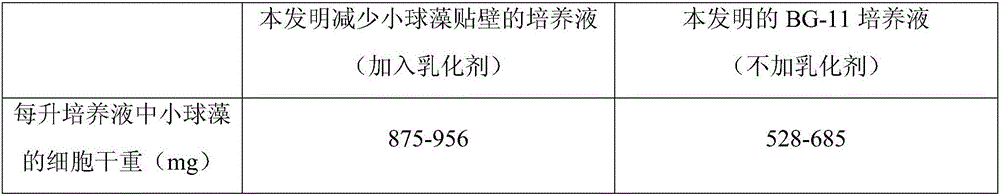

Culture method capable of reducing chlorella adherence

InactiveCN105754861AReduce sticking phenomenonAdverse effects on growthUnicellular algaeMicroorganism based processesFood additiveMicrobiology

The invention discloses a culture method capable of reducing chlorella adherence.The culture method includes preparing a BG-11 culture solution, and adding a 10-300 ppm emulsifying agent into the BG-11 culture solution to obtain a culture solution capable of reducing chlorella adherence.The culture method capable of reducing chlorella adherence means that the culture solution capable of reducing chlorella adherence is used for culturing chlorella.When cultured chlorella cells reach a stable phase, dry cell weight as high as 875-956 mg can be obtained from every L of culture solution and is increased by 40-66% than a BG-11 chlorella culture solution without the emulsifying agent.The culture solution capable of reducing chlorella adherence has no adverse effect on growth of the chlorella, and accordingly the cultured chlorella is safe and free of toxicity and is particularly suitable as raw materials of health products, feed, food additives, fine chemical products and medical preparations.

Owner:HAINAN GREEN ALGAE WORLD BIOTECHNOLOGY CO LTD

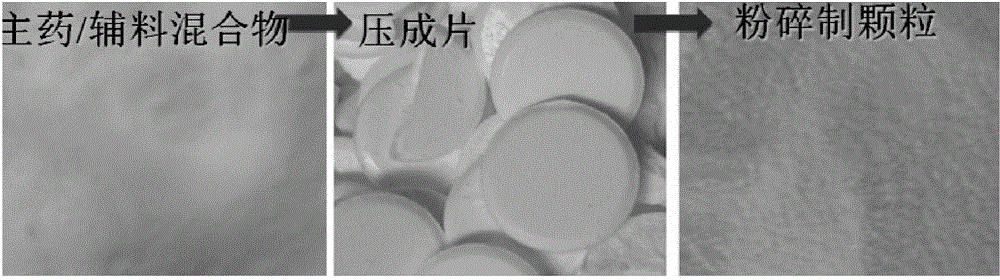

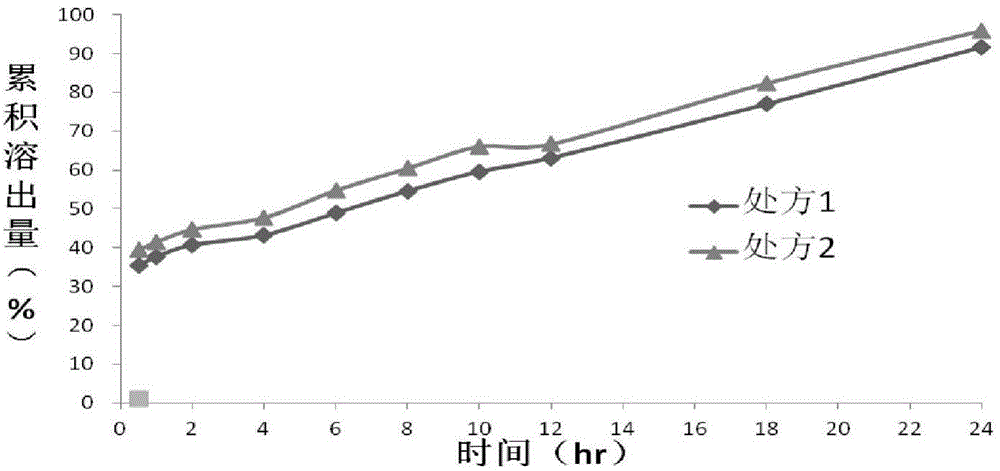

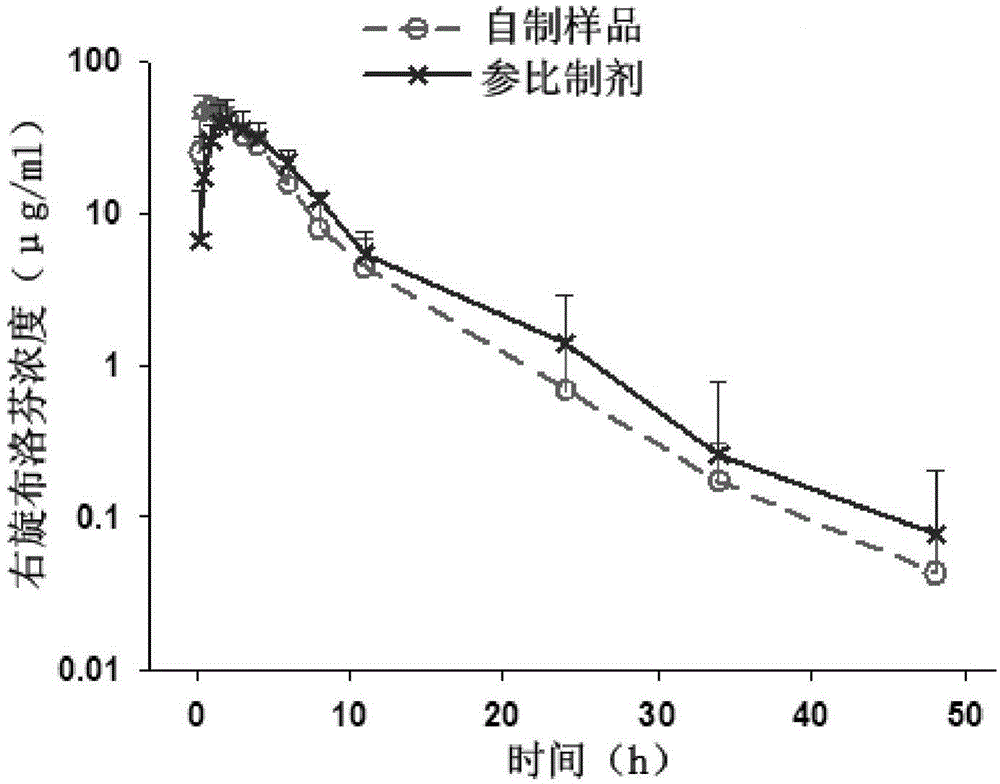

Dexibuprofen sustained-release tablet and preparation process thereof

InactiveCN104546732AHigh content of the main drugHigh particle yieldOrganic active ingredientsAntipyreticDexibuprofenTableting

The invention discloses a dexibuprofen sustained-release tablet and a preparation process thereof. According to the preparation process, colloidal silicon dioxide is used as an antiplastering aid, and dry granulation is carried out by using a high-speed rotary tablet press; the prepared dry granules are respectively mixed with auxiliaries in specific quick-release and sustained-release layers to press a dual-layer tablet which is the dexibuprofen sustained-release tablet. The preparation process can be used for effectively reducing the sticking phenomenon caused by temperature increase when tabletting is carried out for a long time, and has simple process and relatively high efficiency; and the prepared sustained-release tablet has high bioavailability and good stability.

Owner:BEIJING HANMI PHARMA CO LTD

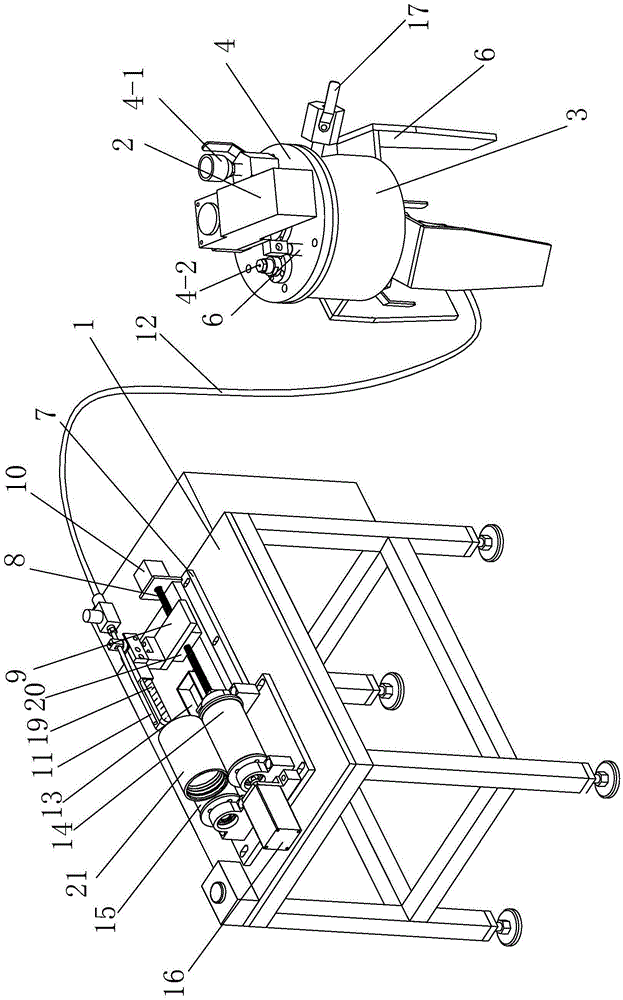

Device and method for coating inner wall of oil casing coupling with anti-friction nano coating

InactiveCN105583126ASimple structureNovel and reasonable designLiquid surface applicatorsCoatingsCouplingReciprocating motion

The invention discloses a device for coating the inner wall of an oil casing coupling with an anti-friction nano coating. The device for coating the inner wall of the oil casing coupling with the anti-friction nano coating comprises a storage mechanism, a feeding mechanism and a workpiece rotating mechanism. The storage mechanism comprises a stirring kettle and a first driving motor. The feeding mechanism comprises a base, a lead screw, a moving block and a second driving motor. A dripping pipe and a coating brush are arranged on the moving block. The workpiece rotating mechanism comprises a driving roller, a driven roller and a third driving motor. The invention further discloses a method for coating the inner wall of the oil casing coupling with the anti-friction nano coating. The method for coating the inner wall of the oil casing coupling with the anti-friction nano coating comprises the following steps that firstly, a workpiece is rotated; secondly, the anti-friction nano coating is evenly stirred; thirdly, the nano coating is brushed while the coating brush moves in a reciprocating mode; and fourthly, drying is conducted. According to the device and method for coating the inner wall of the oil casing coupling with the anti-friction nano coating, the design is novel and reasonable, the device can be obtained conveniently, and the method can be implement conveniently; the application range is wide, and the using effect is good; an oil casing coupling workpiece can be coated with the coating rapidly, and the purpose of improving the viscidity resistance of the oil casing coupling is achieved finally.

Owner:XIAN UNIV OF SCI & TECH

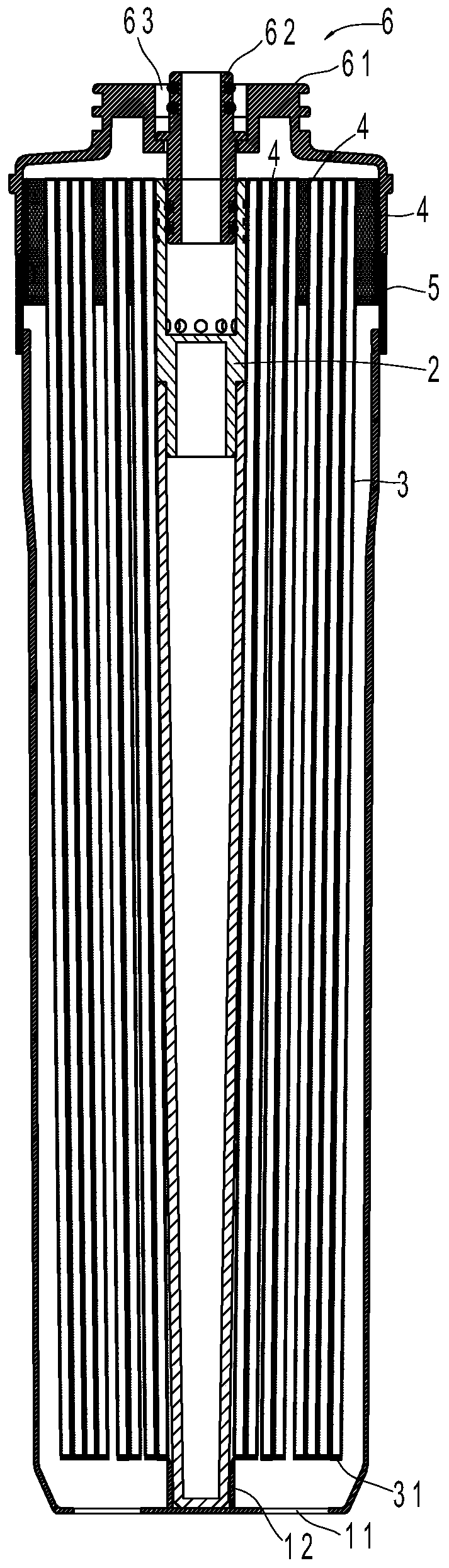

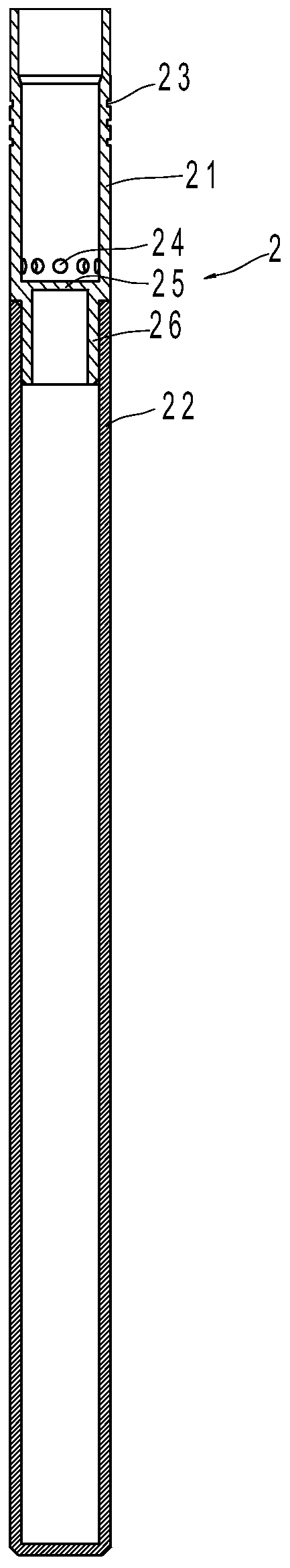

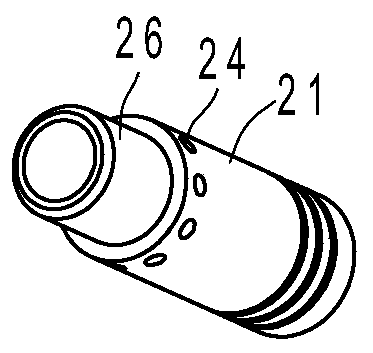

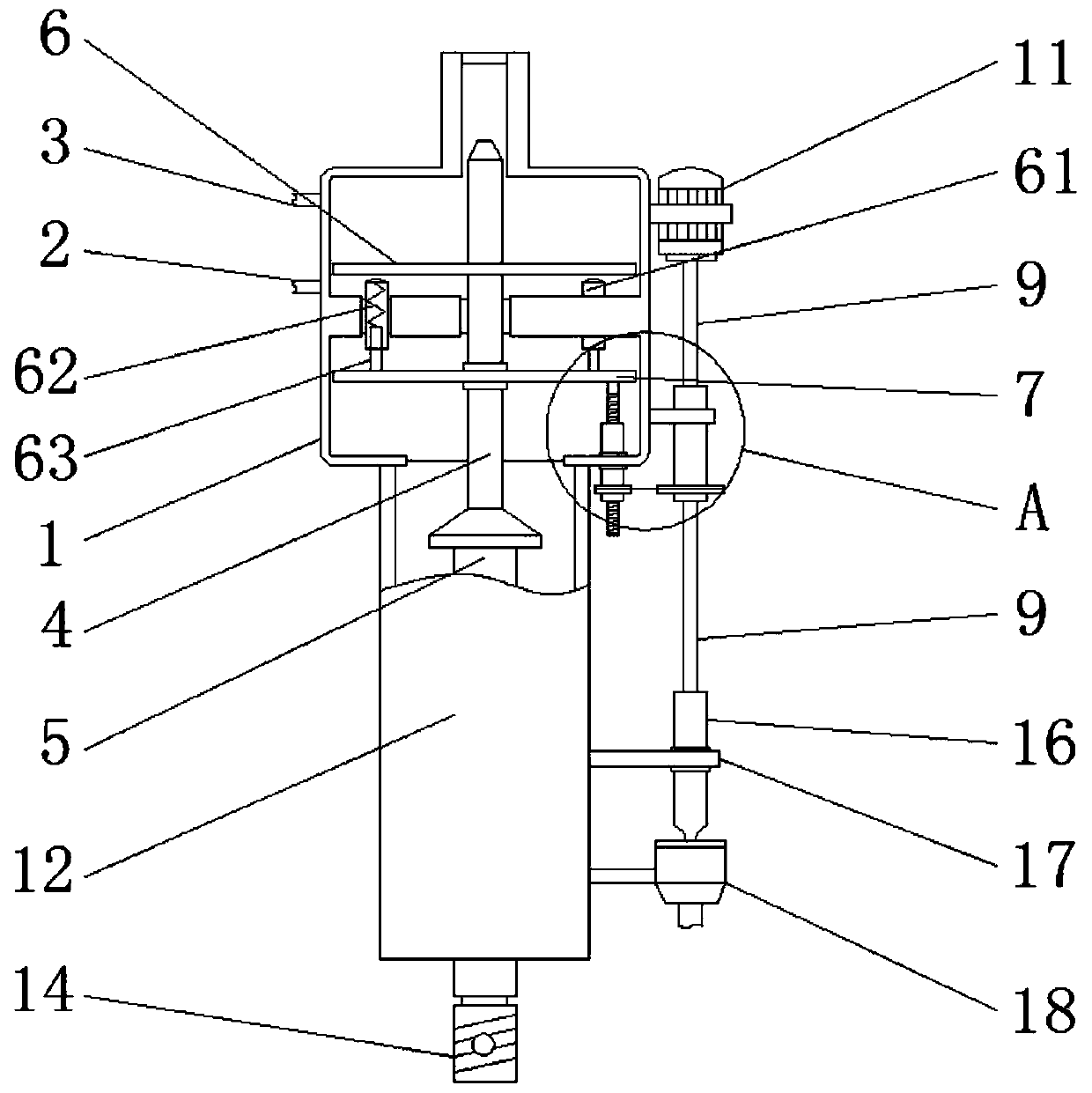

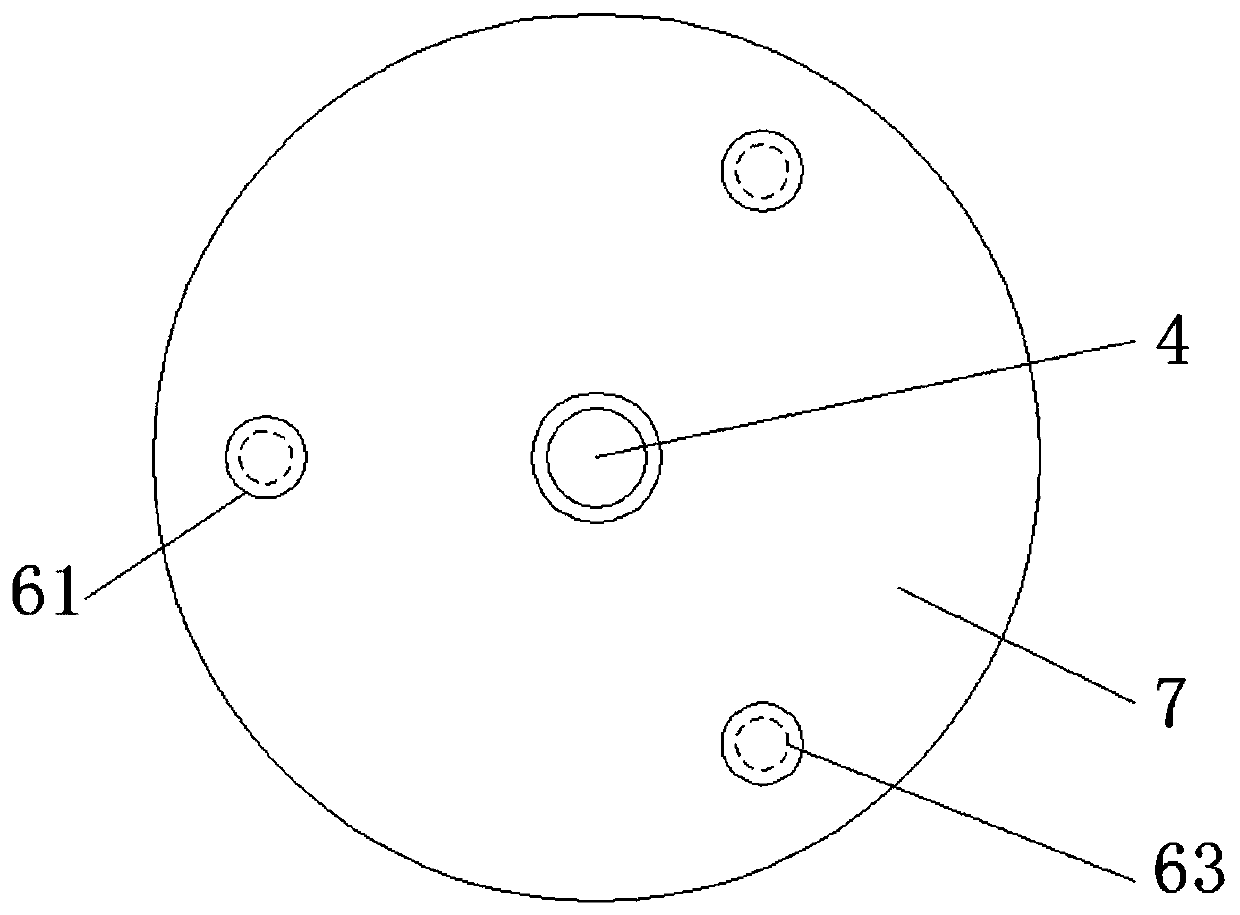

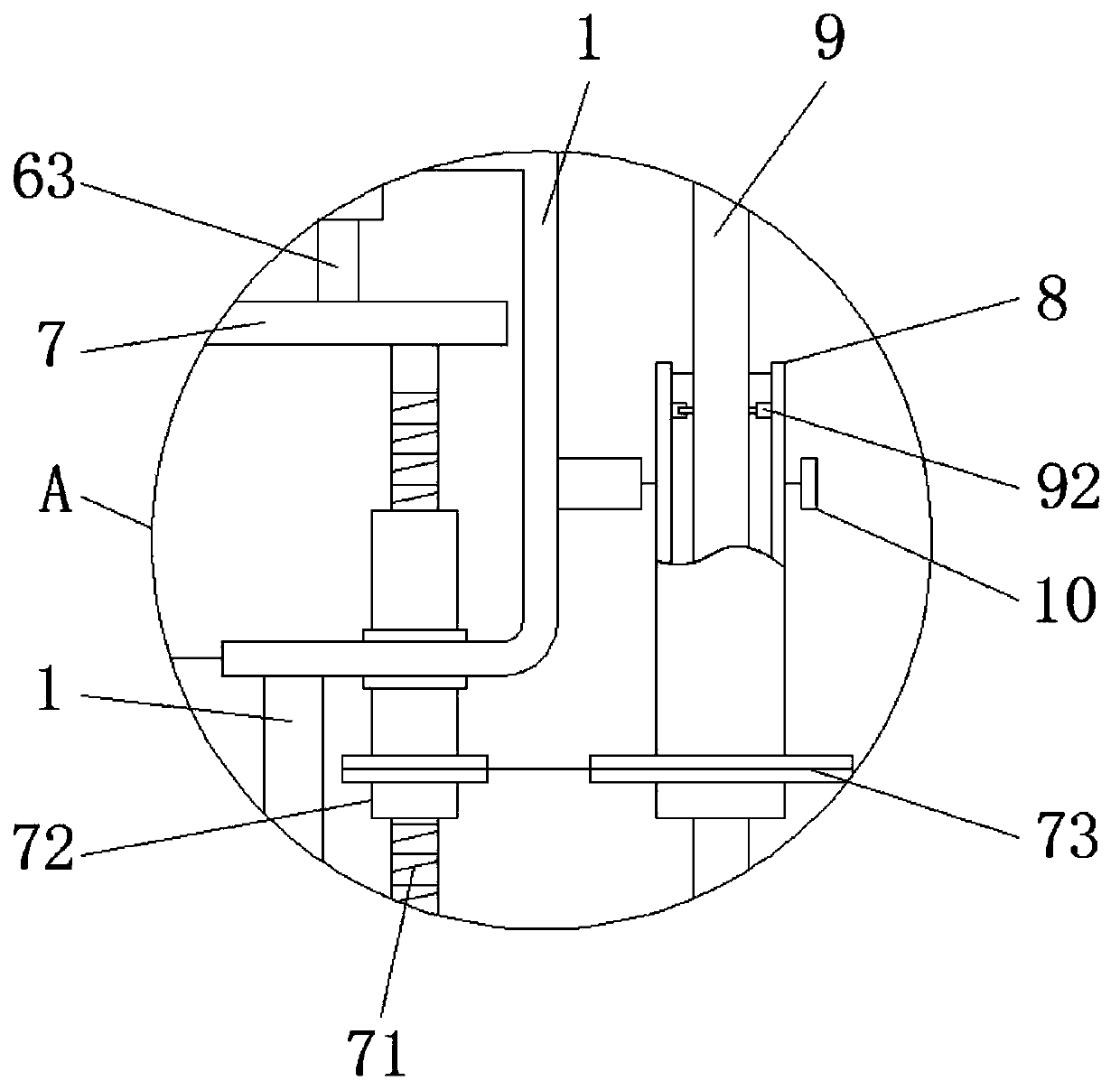

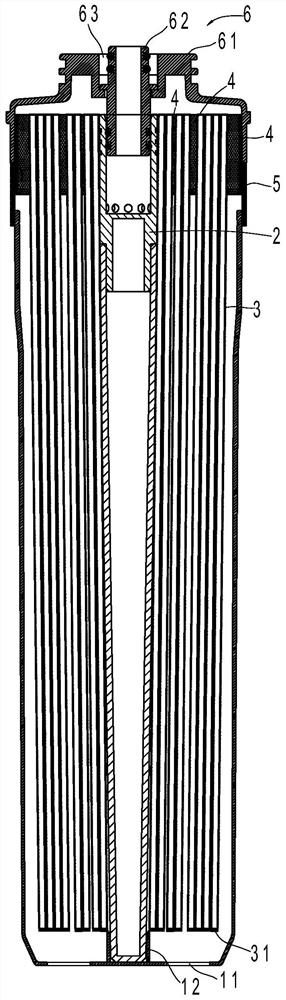

Hollow fiber membrane filter element and packaging method thereof

ActiveCN111389230AIncrease the lengthSame lengthSemi-permeable membranesEngineeringMechanical engineering

A hollow fiber membrane filter element is characterized in that the filter element comprises a filter shell, a central pipe, hollow fiber membranes, a glue sealing shell, glue sealing layers and a water collecting cover; an opening is formed in the upper end of the filter shell, and a dirty water outlet hole is formed in a bottom plate; the central pipe is arranged in the middle of the filter shell, one end is opened to form a water inlet port, and water distribution holes are formed in the side wall; the hollow fiber membranes are positioned in the filter shell, first ends of the hollow fibermembrane uniformly coat the periphery of the water inlet port of the central pipe, and second ends of the hollow fiber membranes are arranged in the length direction of the central pipe and close tothe bottom end of the central pipe; the glue sealing shell is arranged on the periphery of the opening of the filter shell; and the glue sealing layers are positioned between the inner wall of the glue sealing shell and the hollow fiber membranes, between the hollow fiber membranes and between the hollow fiber membranes and the outer wall of the central pipe. The invention further discloses a gluesealing method for the hollow fiber membrane filter element. The method has the advantages of more uniform inlet water distribution and reduction of membrane filament concentration polarization.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

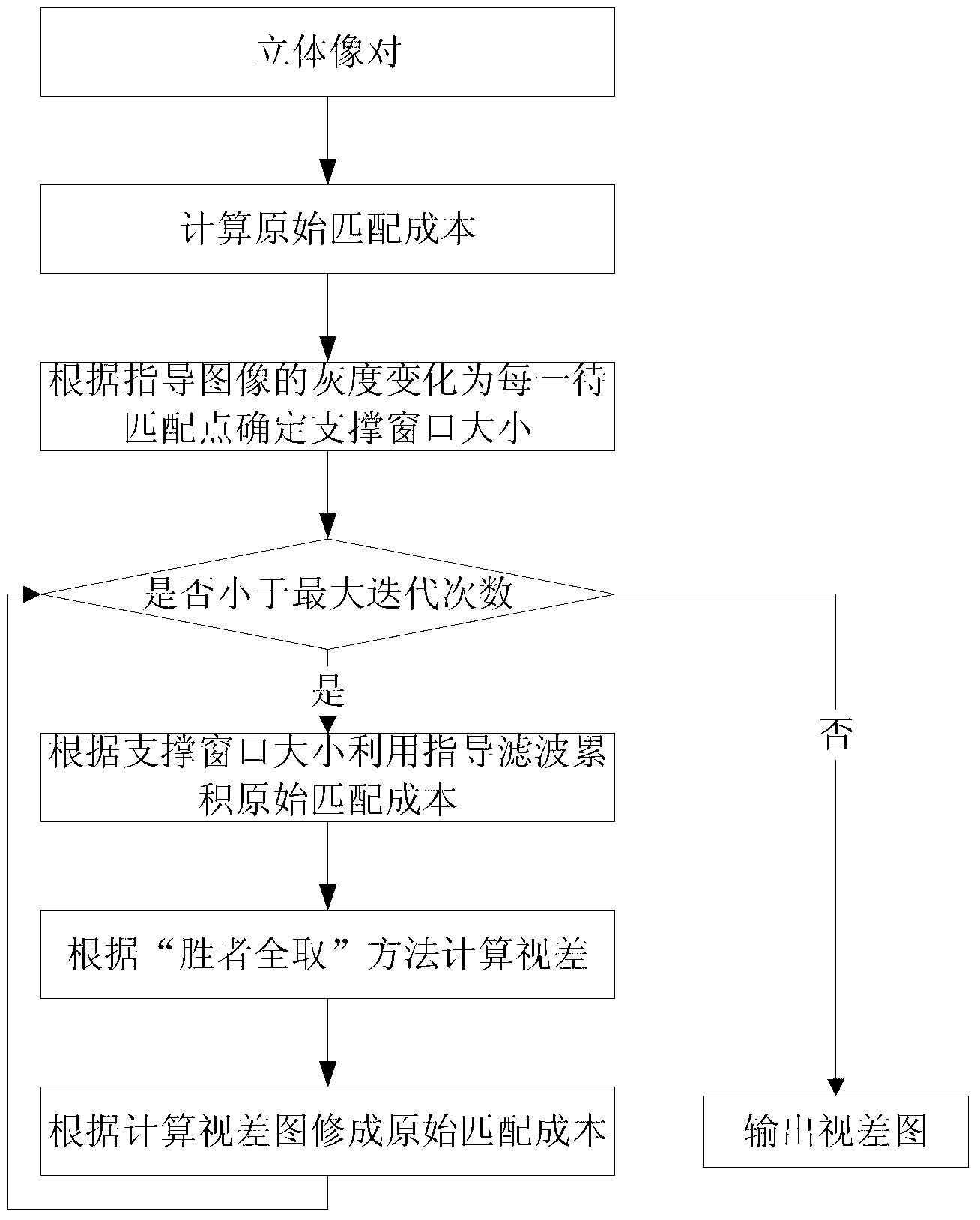

Stereo matching method based on iterative guidance filtering

The invention relates to fields of computer vision, aerial photography measurement and industrial automation, in particular to a stereo matching method based on iterative guidance filtering. The method includes computing original matching cost; determining size of a supporting window for each point to be matched according to gray changes of instruction images; accumulating original matching cost through utilizing guidance filtering according to the sizes of the supporting windows; computing parallax; correcting the original matching cost according to computed parallax images; repeating execute step (3) till the determined maximum number of iterations is reached. The integral image technology is utilized to compute adaptive windows and the guidance filtering, and matching efficiency of the stereo matching method is improved effectively. The computed parallax is utilized to correct the original matching cost and the guidance filtering is utilized to accumulate, robustness of matching cost to noise and radiation difference in enhanced, and accordingly accuracy of vision matching is improved.

Owner:HARBIN ENG UNIV

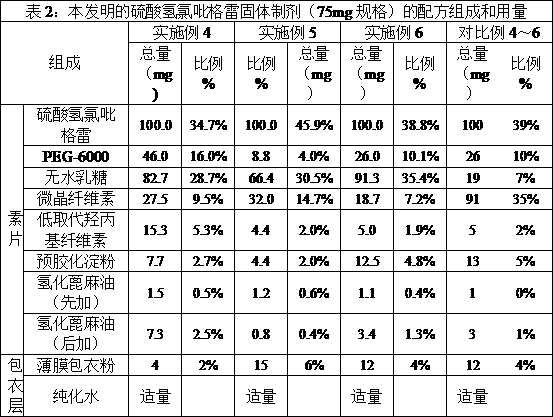

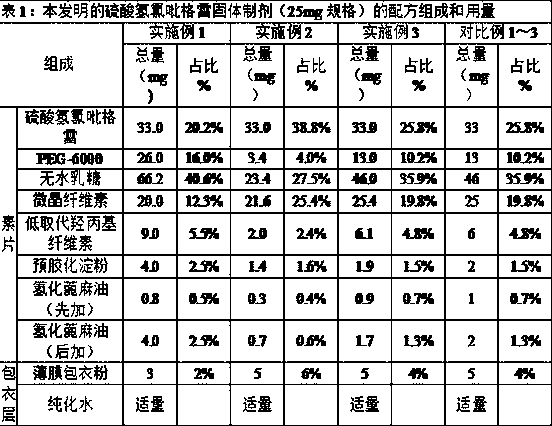

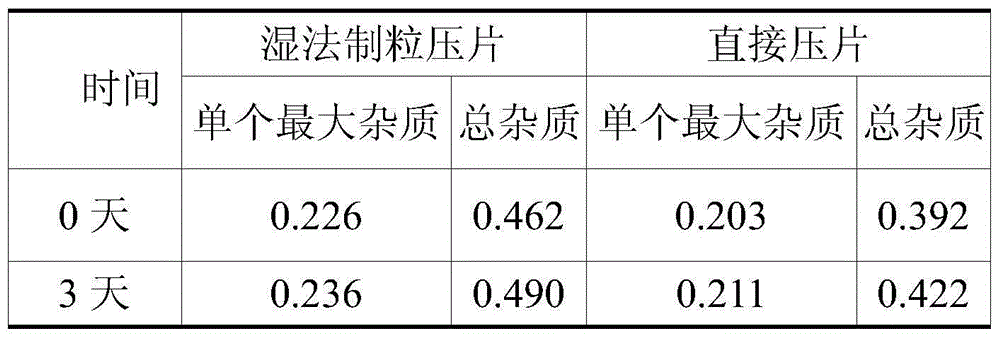

Preparation method of clopidogrel bisulfate solid preparation

ActiveCN110339178AReduce the probability of stickingIncrease dissolution rateOrganic active ingredientsDrageesSulfateDissolution

The invention relates to a preparation method of a clopidogrel bisulfate solid preparation. The method discloses a two-step granulation process of melt-granulating and then dry-pressing granulating for clopidogrel bisulfate, and the obtained granules have good compressibility and fluidity, and are not easy to stick to a die, so that the problems of tablet sticking, easy revealing or splitting which are common in the preparation of oral tablets of clopidogrel bisulfate is solved. The preparation method can ensure the rapid dissolution of the drug in the preparation, and the long-term retentionof the sample does not increase the impurities. The preparation process of the present invention is highly practical and can be used for large-scale preparation of clopidogrel sulfate bulk drugs withdifferent physical properties.

Owner:GUANGZHOU BAIYUSN TIANXIN PHARMA

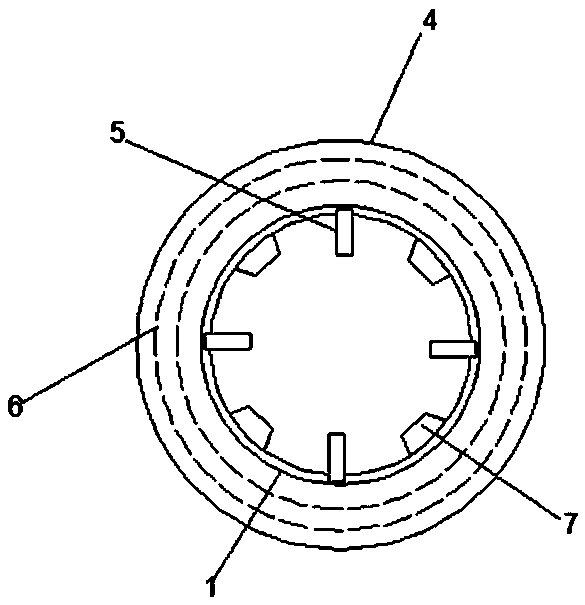

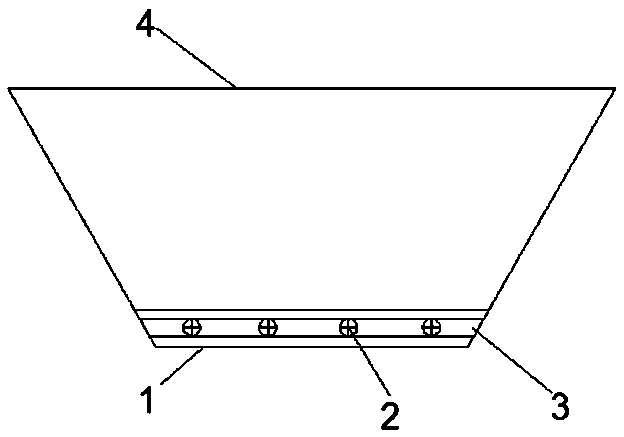

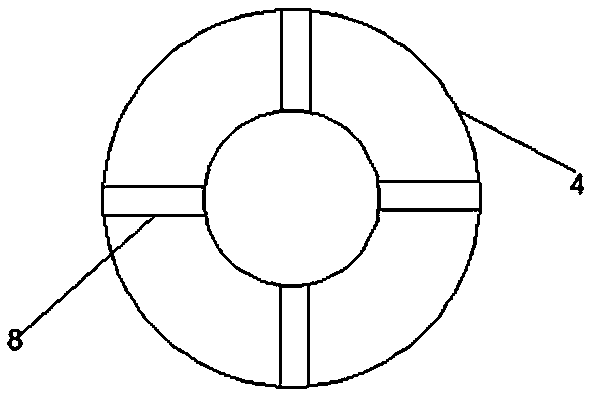

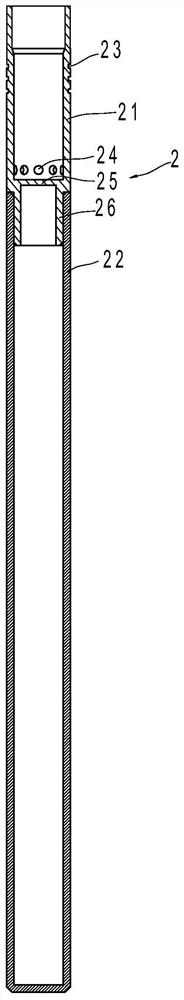

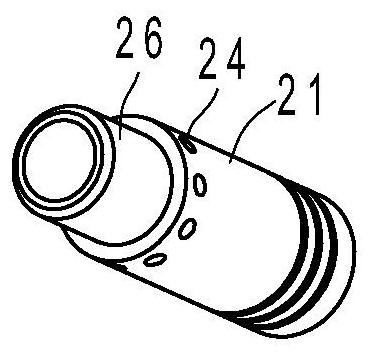

Press ring device for physical vapor deposition equipment

InactiveCN108179395AProtect normal alignmentNormal alignment apparentVacuum evaporation coatingSputtering coatingRing deviceWafer

The invention discloses a press ring device for physical vapor deposition equipment. The press ring device comprises an annular body, wherein a circular fixed table is connected to the top end of theannular body; the circular fixed table communicates with the annular body, a plurality of annularly-formed clamping grooves are formed in the bottom of the circular fixed table, and the area encircledbetween each two adjacent clamping grooves is equal; and stretching plates are fixedly connected to the edge position of the inner ring of the annular body. The press ring device has the following beneficial effects: components comprising a plurality of the stretching plates and a plurality of bulged tables are added to the inner ring of the annular body, and during working, only the bulged tables of the annular body make contact with a wafer, so that the contact area of the press ring device and the wafer is reduced. Through a locking disc arranged on the annular body, a strip-shaped plate on the annular body is enabled to relatively slide with a groove by virtue of the rotation of an adjustment hand wheel, so that the diameter of the annular body can be adjusted, and the dimensions of different wafers can be adapted.

Owner:张铭泽

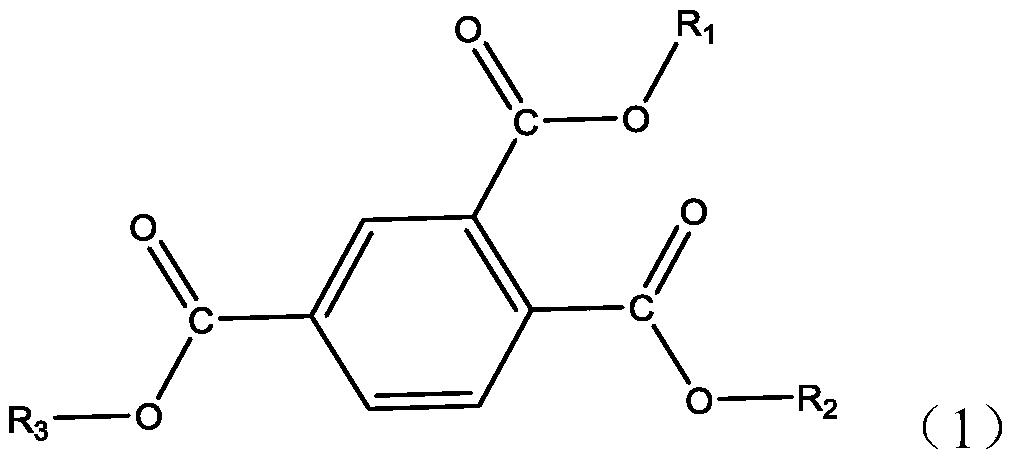

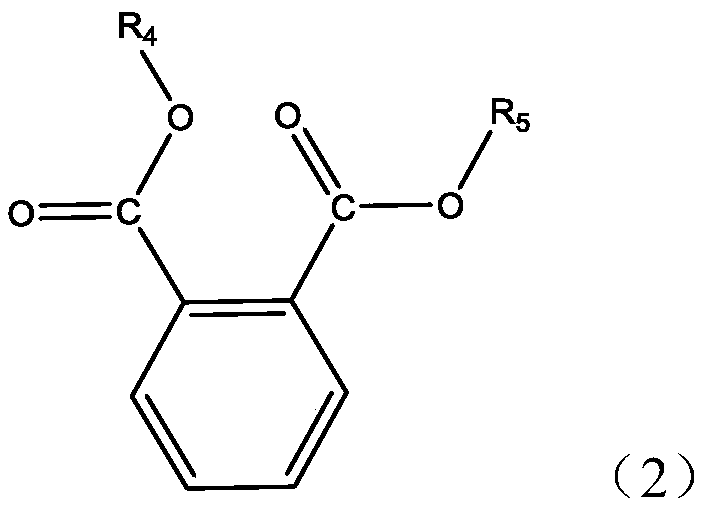

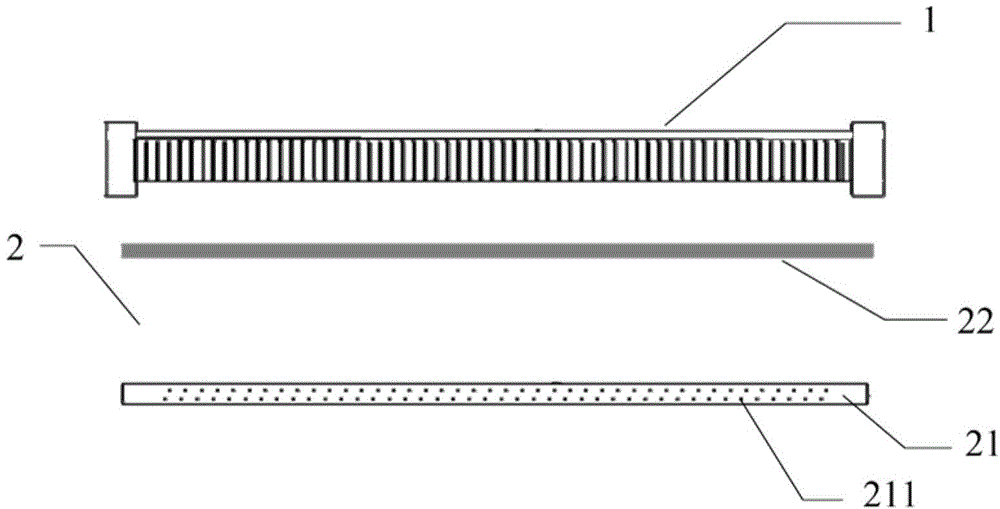

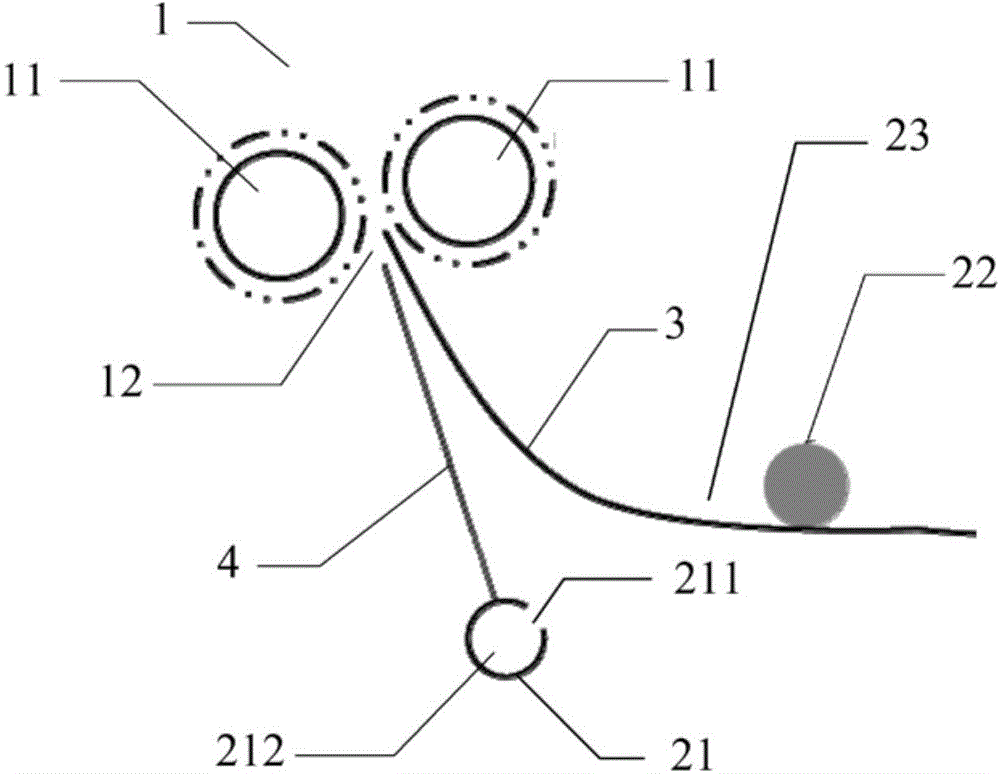

Silicon-free oiling agent for carbon fiber precursor

ActiveCN110670350AEnsure uniformity of qualityAvoid softeningFibre typesFibre chemical featuresBenzoic acidPolymer science

The invention discloses a silicon-free oiling agent for carbon fiber precursor. The silicon-free oiling agent comprises an aqueous emulsion prepared by dispersing aromatic ester compounds, aromatic polyoxyethylene ether and amine compounds, by the mass ratio of (50-80):(10-35):(1-5), in water; the aromatic ester compounds include one or more of benzene tricarboxylic acid esters, benzene dioctyl phthalate esters, hydroxy-benzoate esters and bisphenol ethoxide high-grade fatty acid esters; aromatic polyoxyethylene ether includes one or more of alkylphenol polyoxyethylene and bisphenol-A polyoxyethylene ether; the amine compounds include one or more of lauramide ethoxide, aliphatic long-chain quaternary ammonium; the survival rate of mass of the aromatic ester compounds is 80-98% at the temperature of 300 DEG C in the atmosphere of air, and the mass ratio of the aromatic ester compounds in involatile components of the oiling agent is 50-80%. Roll banding degree of the precursor in production can be reduced effectively, doubling and adhering of PAN filaments in the pre-oxidation process can be avoided, and the silicon-free oiling agent has certain hydrophilicity and heat resistance.

Owner:HENGSHEN

Famciclovir direct compressed tablet and preparation method thereof

ActiveCN104434852AAvoid wetAvoid the dry granulation stepPharmaceutical delivery mechanismAntiviralsColloidal silicaMedicine

The invention provides a famciclovir direct compressed tablet and a preparation method thereof. The direct compressed tablet comprises 70-80wt% of famciclovir, 10-20wt% of lactose, 5-15wt% of microcrystalline cellulose, 0.5-1wt% of colloidal silica and 0.5-1wt% of magnesium stearate.

Owner:BEIJING HANMI PHARMA CO LTD

Drilling tool joint thread anti-attrition lubricating treatment process

PendingCN113061834AGuaranteed lubrication effectImprove the lubrication effectLiquid surface applicatorsSolid state diffusion coatingOil canProcess engineering

The invention relates to the technical field of surface treatment, and discloses a drilling tool joint thread anti-attrition lubricating treatment process. The treatment process comprises the following steps of texturing a drilling tool joint, and then carrying out surface lubricating treatment to obtain a petroleum pipe joint with a composite lubricating structure. According to the drilling tool joint thread anti-attrition lubricating treatment process, the surface of the thread is subjected to texturing treatment, the texturing structure can store lubricating oil and maintain the lubricating effect of the joint, and abrasive dust can be stored after the surface of the thread is abraded and falls off, so that the surface is prevented from being repeatedly damaged by the abrasive dust, nitriding treatment is conducted on the thread surface, the surface hardness is improved, the surface abrasion resistance is improved, a compound on the surface of a nitriding connector is provided with a loose layer, lubricating oil can be stored, the anti-abrasion and lubricating effects are achieved, the continuity of lubricating of the drilling tool joint is guaranteed, the thread gluing phenomenon is effectively reduced, the surface of the joint is coated with the lubricating coating, the lubricating agent in the coating can reduce the friction coefficient of the surface of the joint, and the thread gluing failure of the joint is reduced.

Owner:SHANGHAI HILONG DRILL PIPE MATERIALS INST +2

Forming equipment of wavy noodles and process using same to manufacture noodles

ActiveCN104542785ACreate pollutionAvoid damageDough shaping and cutting apparatusDough processingManufactured formEngineering

The invention relates to forming equipment of wavy noodles and a process using the same to manufacture the noodles. The forming equipment comprises a shredding knife, a wave-manufacturing forming device and a steaming box, wherein the wave-manufacturing forming device comprises an air-blowing rod and a wavy adjusting rod; the outer wall surface of the air-blowing rod is provided with small holes facing to the wavy adjusting rod; the air-blowing rod is connected with an air-blowing pipeline, and air is provided for an inner cavity of the air-blowing rod and is blown out through the small holes; the downstream of the wave-manufacturing forming device is also provided with the steaming box which is connected with the wave-manufacturing forming device by a flour-conveying mesh belt; and the steaming box is connected with the wave-manufacturing forming device by the flour-conveying mesh belt, and the wavy noodles formed by the wave-manufacturing forming device fall onto the flour-conveying mesh belt and are conveyed into the steaming box for steaming by the flour-conveying mesh belt. The forming equipment and the manufacturing process have the advantages that the manufactured noodles are uniform-scattered-irregular wavy noodles, and the phenomenon of noodle sticking can be effectively reduced.

Owner:TINGYI (CAYMAN ISLANDS) HOLDING CORPORATION

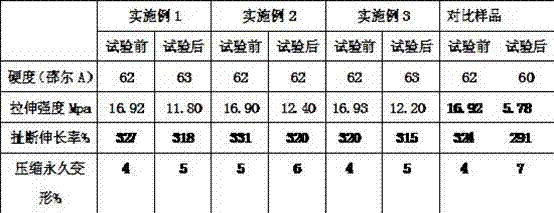

Thermoplastic polyurethane elastomer of rolling-level and high temperature resistance as well as preparation method thereof

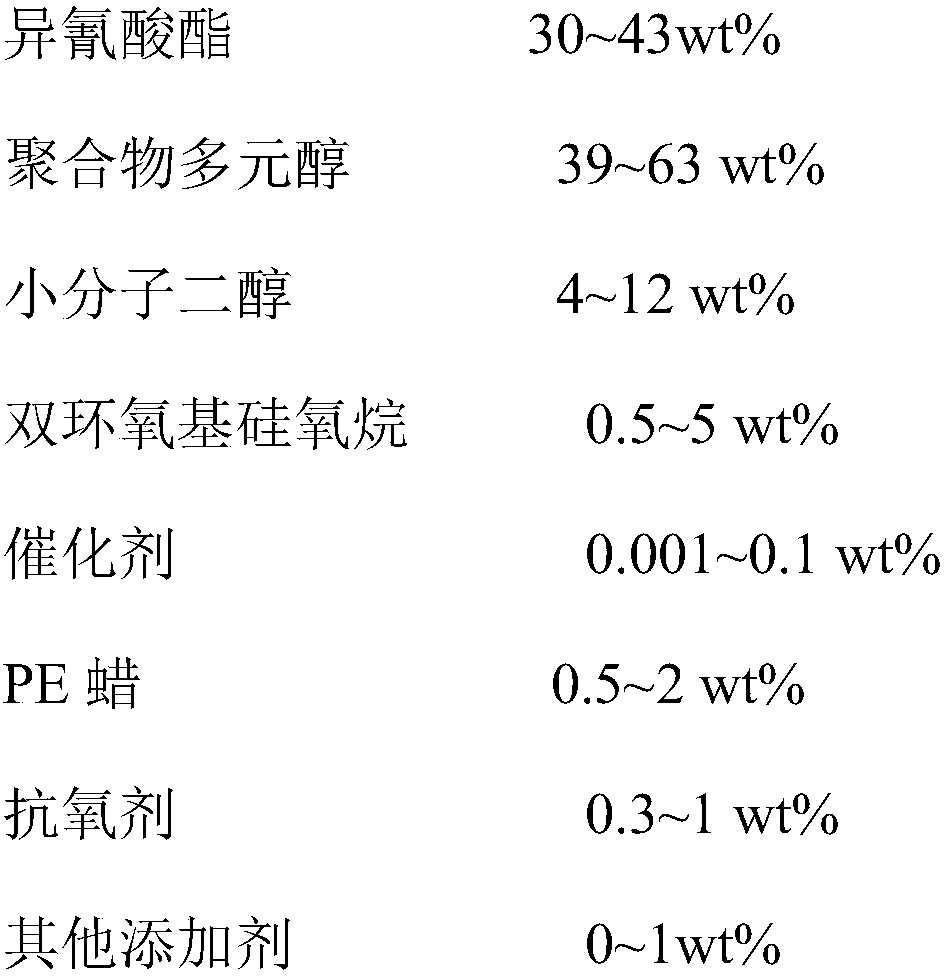

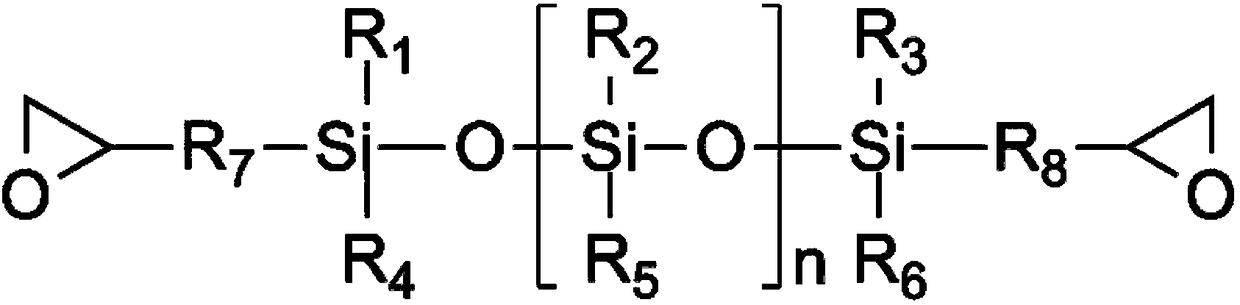

The invention discloses a thermoplastic polyurethane elastomer of rolling-level and high temperature resistance as well as a preparation method thereof. The thermoplastic polyurethane elastomer of rolling-level comprises components in percentage by weight as follows: 30wt%-43wt% of isocyanate, 39wt%-63wt% of polymer polyols, 4wt%-12wt% of small molecule glycol, 0.5wt%-5wt% of diepoxysiloxane, 0.001wt%-0.1wt% of a catalyst, 0.5wt%-2wt% of PE wax, 0.3wt%-1wt% of an antioxygen and 0wt%-1wt% of a other additive. According to the elastomer, the heat resistance of the TPU is effectively improved andcan be produced at higher operating temperatures, the phenomenon of decomposition and product sticking is not easy appeared.

Owner:ZHEJIANG HUAFENG THERMOPLASTIC POLYURETHANE

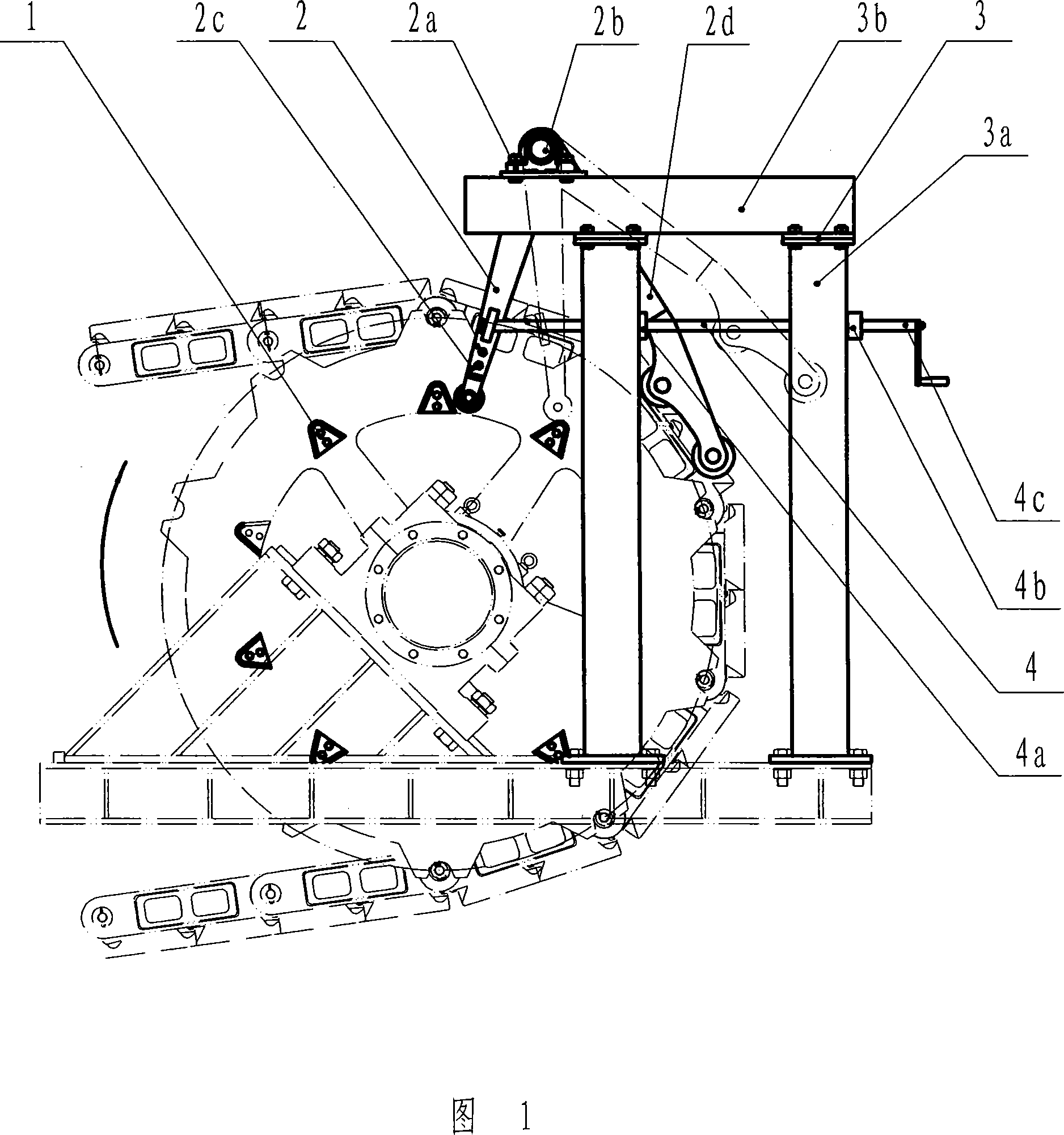

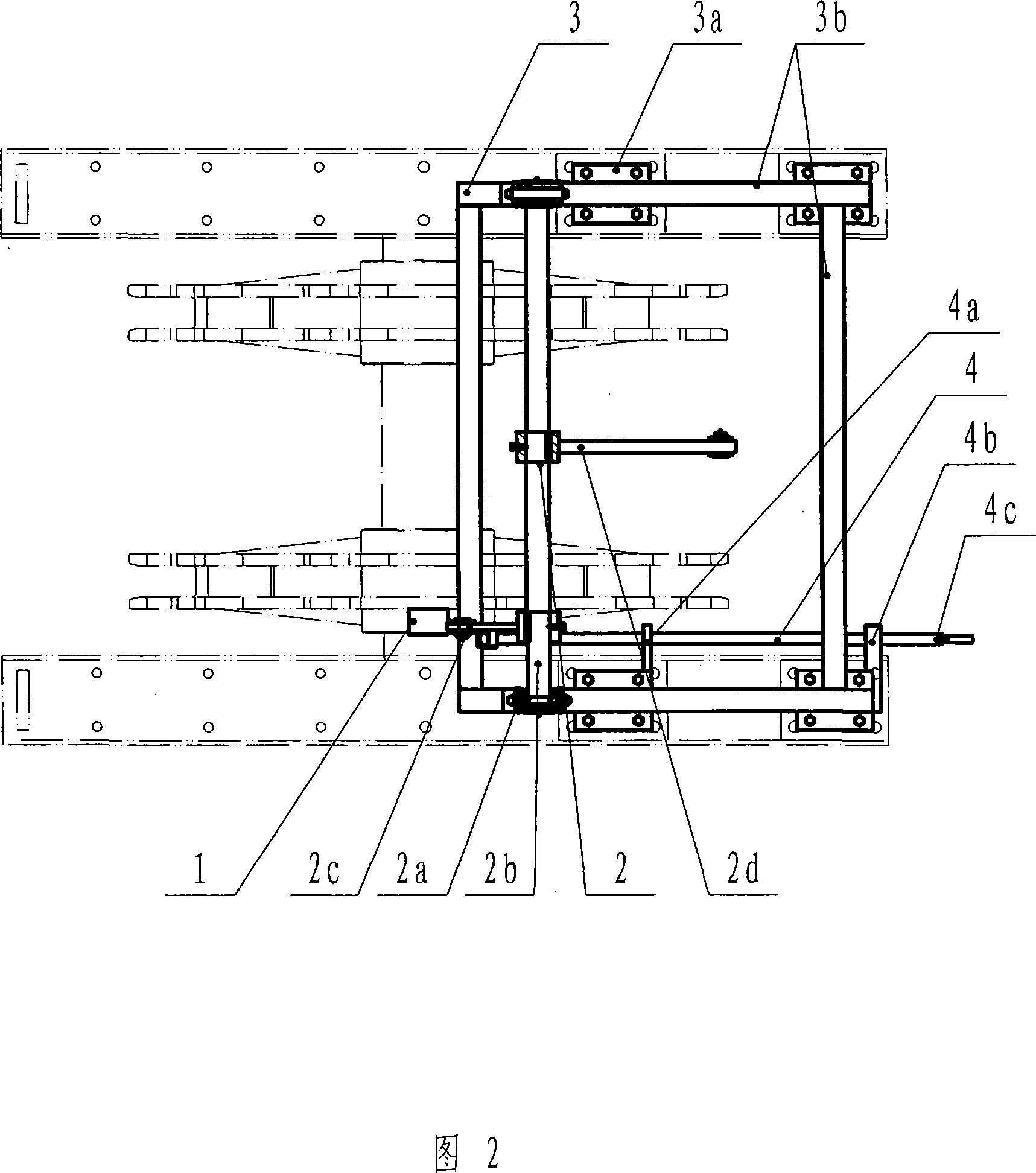

Cast iron machine automatic iron-forging device

The automatic forging device of pig-casting machine realizes automatic forging by means of the power the driving chain wheel provides and fluent demolding of the bloom. It includes cam blocks distributed on one side of the chain wheel; one roller driven assembly comprising bearing seat, forging shaft, roller arm and forging arm; one support for the forging shaft to be mounted on; and one raising unit for raising the roller driven assembly from the work site to the idle site. The automatic forging device with cam mechanism has easy demolding of the bloom and less stickness of iron to the mold.

Owner:SHILIN LUOHE METALLURGY EQUIP

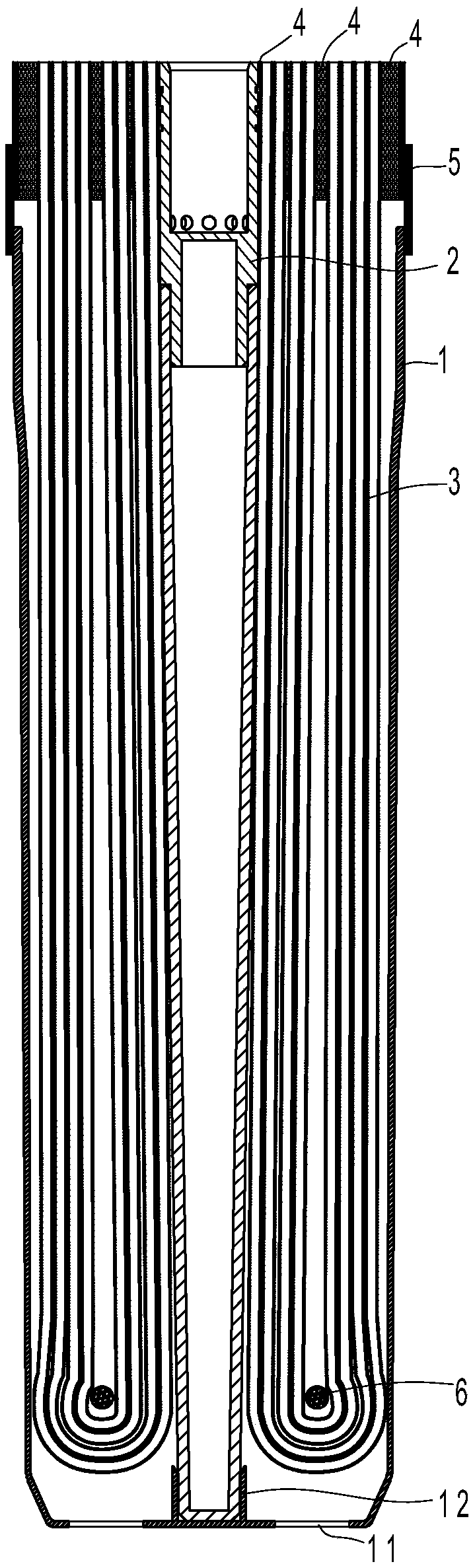

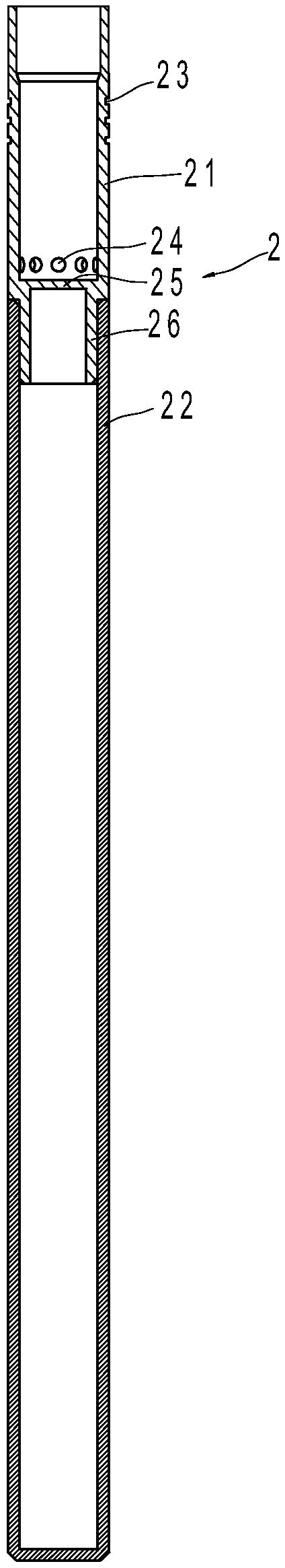

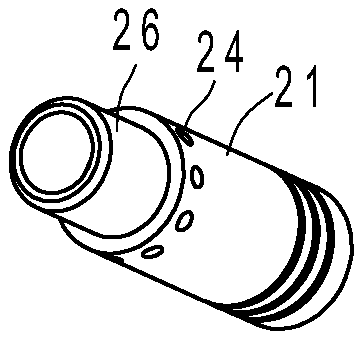

Hollow fiber membrane filter core and packaging method thereof

ActiveCN111359444AReduce sticking phenomenonReduce concentration polarizationSemi-permeable membranesEngineeringHollow fiber membrane

The invention discloses a hollow fiber membrane filter core, which comprises a filter shell, a central pipe, hollow fiber membranes, a glue sealing shell and glue sealing layers, wherein an opening isformed in the upper end of the filter shell, a dirty water outlet hole is formed in a bottom plate, the central pipe is arranged in the middle of the filter shell, one end is opened to form a water inlet port, water distribution holes are formed in the side wall, the hollow fiber membrane is positioned in the filter shell, the periphery of the water inlet port of the central pipe is uniformly coated with the first end of the hollow fiber membrane, the glue sealing shell is arranged on the periphery of the opening of the filter shell, and the sealing glue layers are positioned between the inner wall of the sealing glue shell and the hollow fiber membrane, between the hollow fiber membranes and between the hollow fiber membrane and the outer wall of the central pipe. The invention further discloses a glue sealing method of the hollow fiber membrane filter core. The hollow fiber membrane filter core has the advantages of uniform influent distribution and reduction of membrane filament concentration polarization.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

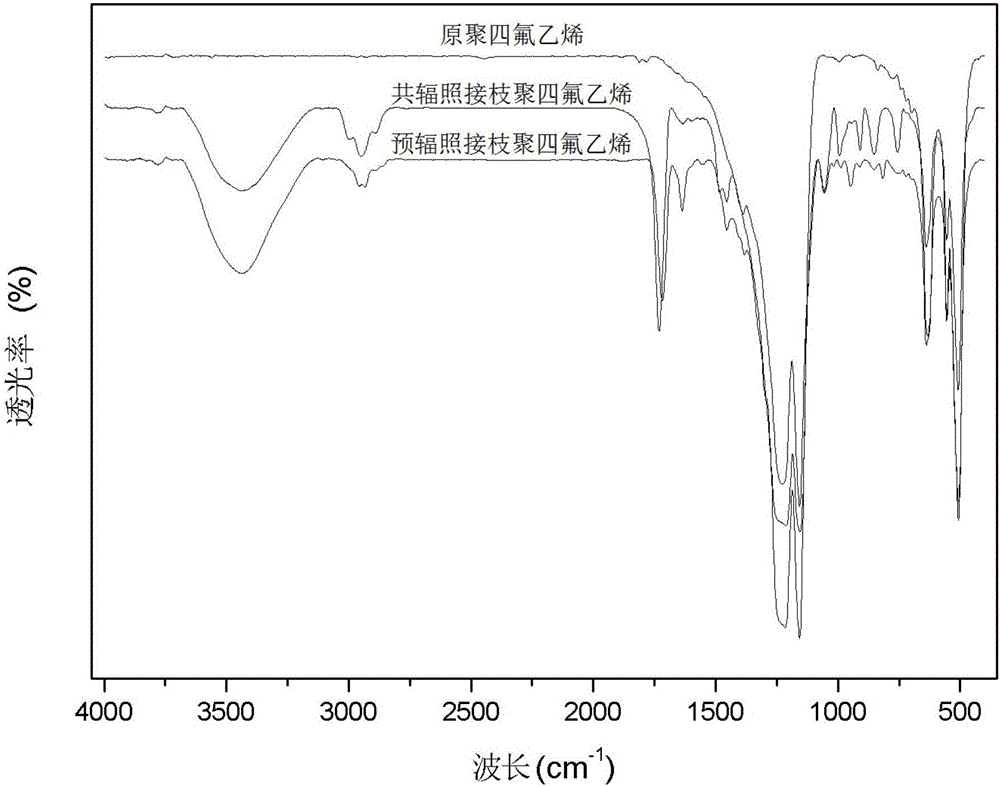

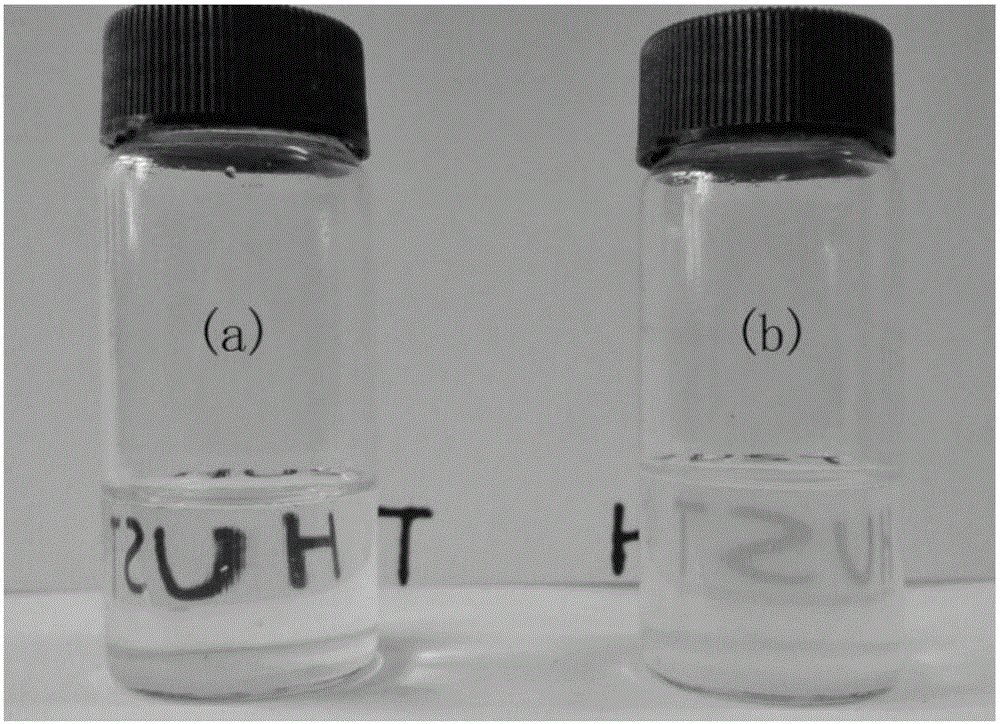

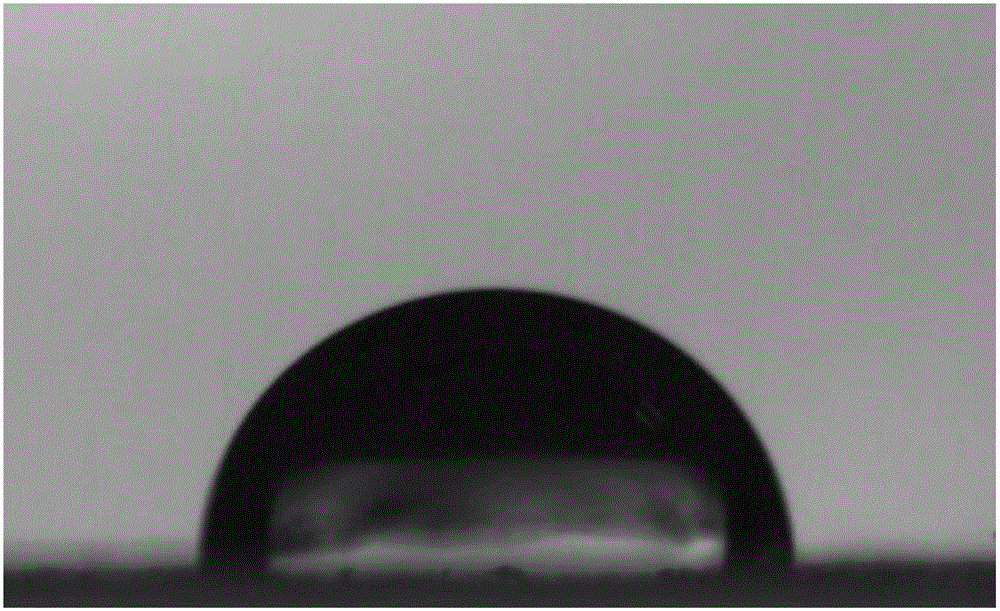

Laser embossed holography recording material and preparation method thereof

The invention discloses a laser embossed holography recording material and a preparation method thereof. The laser embossed holography recording material comprises imaging resin, and irradiation grafted modified polytetrafluoroethylene micro-powder used for compounding and modifying the imaging resin; and a mass ratio of the irradiation grafted modified polytetrafluoroethylene micro-powder to the imaging resin is 1 / 20 to 1 / 200. The laser embossed holography recording material with good internal uniformity and high stability is prepared through improving the microstructure composition and the structure of a key material and effectively solving the problems of easiness in sticking, point dropping and defects of resin used by present laser embossed holography recording layers in the molding process in the prior art.

Owner:HUAZHONG UNIV OF SCI & TECH

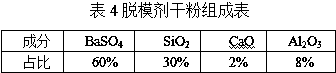

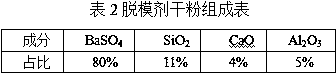

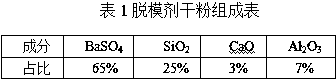

Use method of copper anode plate casting release agent

ActiveCN108356215AReduce sticking phenomenonAvoid large areas of agglomeration and slaggingMoulding toolsFoundry mouldsPolyvinyl alcoholSurface tension

The invention relates to a use method of a copper anode plate casting release agent, and belongs to the technical field of copper smelting and casting technique. A conventional barium sulfate releaseagent or a barium sulfate-based composite release agent is mixed with water to be prepared into suspension; then polycarboxylic acid is added into the suspension and spread uniformly; then polyvinyl alcohol is added in and spread uniformly to obtain release agent suspension; after mould temperature rises above 180 DEG C, the release agent suspension is sprayed for use, wherein the adding amount ofthe polycarboxylic acid is 0.3%-2.5% of the total mass of conventional barium sulfate release agent or barium sulfate composite release agent dry powder which needs to be prepared into suspension, and the adding amount of the polyvinyl alcohol is 0.2%-2% of the total mass of conventional barium sulfate release agent or barium sulfate composite release agent dry powder which needs to be prepared into suspension. According to the use method, for overcoming the use defects of a current release agent, other materials are added; the surface tension and of the release agent suspension is changed, and dispersity of release agent particles is improved; the release agent suspension is sprayed on a hot copper mould, and a condense film with high adhesive force is formed during a water evaporation process; agglomerated particles formed on a mould plate are reduced; and the appearance quality of an anode plate is improved.

Owner:KUNMING UNIV OF SCI & TECH +1

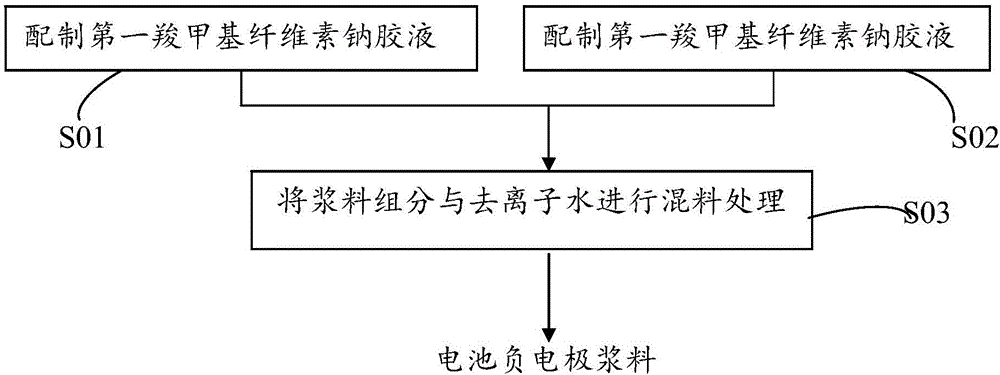

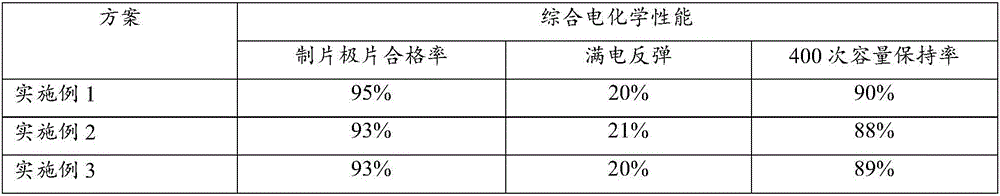

Battery negative electrode, preparation method thereof and lithium ion battery

InactiveCN106129417AImprove electrochemical performanceImprove thickness uniformityCell electrodesSecondary cellsAdhesiveMass ratio

The invention provides a battery negative electrode, a preparation method thereof and a lithium ion battery. The battery negative electrode comprises a current collector and a negative electrode active material layer arranged on the surface of the current collector in a coating manner, wherein the negative electrode active material layer comprises negative electrode active materials, conductive agents and an adhesive; the adhesive contains aqueous adhesives, first sodium carboxymethylcellulose and second sodium carboxymethylcellulose; the degree of substitution of first sodium carboxymethylcellulose is 0.95-1.0; the degree of substitution of second sodium carboxymethylcellulose is 0.8-0.85; the mass ratio of first sodium carboxymethylcellulose to second sodium carboxymethylcellulose is (0.5-0.75) to (0.5-0.75). The battery negative electrode has good active layer thickness uniformity, thus endowing the battery negative electrode with excellent comprehensive electrochemical properties.

Owner:JIAN UTILITY TECH CO LTD

Potato-rich fine dried noodles based on three-layer composite calendering and preparation method thereof

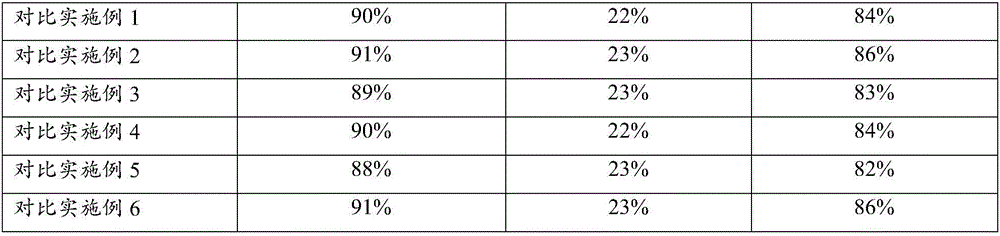

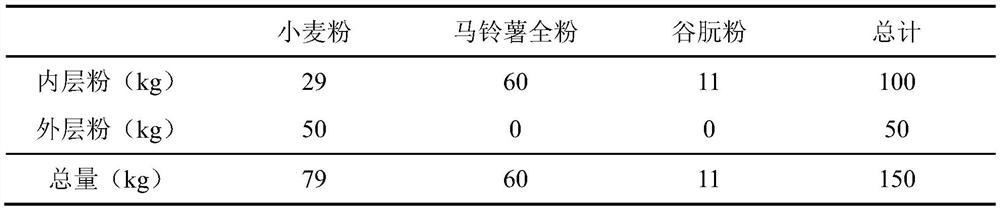

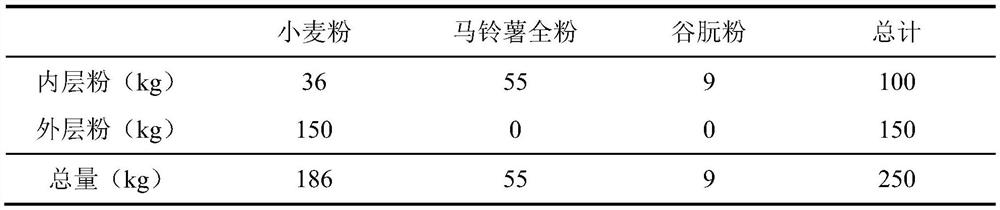

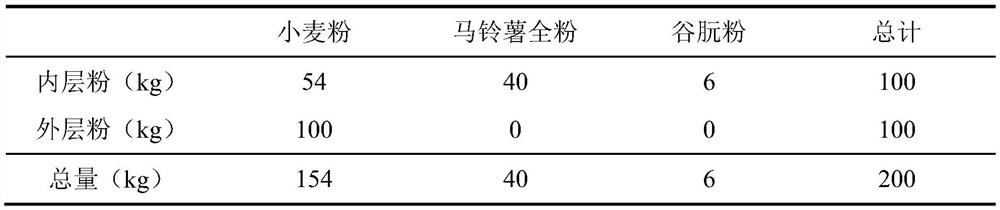

ActiveCN111920003AImprove processing qualityAdd lessClimate change adaptationFood scienceBiotechnologyGluten

The invention provides potato-rich fine dried noodles based on three-layer composite calendering and a preparation method thereof. The potato-rich fine dried noodles comprise the following raw materials in parts by weight: 20-40 parts of potato whole powder, 52.7-77 parts of wheat flour and 3-7.3 parts of vital gluten. The raw materials are premixed: the whole potato flour, the wheat flour and thevital gluten are divided into inner-layer flour and outer-layer flour, which are respectively and uniformly mixed; the inner-layer flour is mixed flour of whole potato flour, wheat flour and vital gluten, the outer-layer flour is wheat flour, and the mass ratio of the inner-layer flour to the outer-layer flour is 1: 0.5-1: 1.5; and the mass ratio of the whole potato flour to the wheat flour to the vital gluten in the inner-layer flour is (0.4-0.6): (0.29-0.54): (0.06-0.11). According to the potato-rich fine dried noodles, the technical problems that potato noodles are poor in tensile capacity, easy to stick to rollers, large in noodle cooking loss, easy to break, difficult in rolling and drying of inner-layer high-moisture sandwich noodles and the like are effectively solved, the potato-rich food fine dried noodles with excellent processing quality, eating quality and functional quality are produced, and the content of whole potato flour is 20%-40%.

Owner:KEMEN NOODLE MFG CO LTD

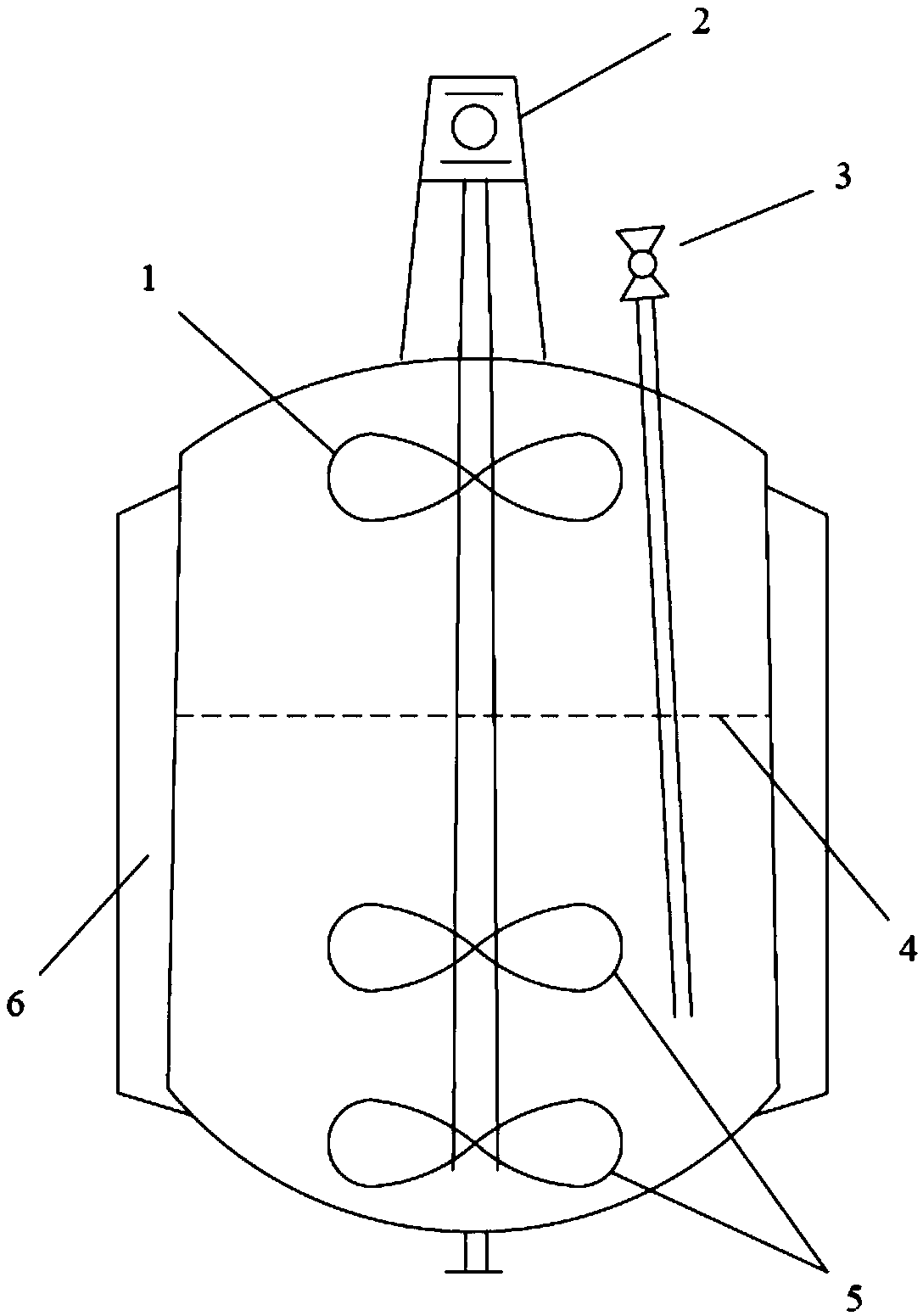

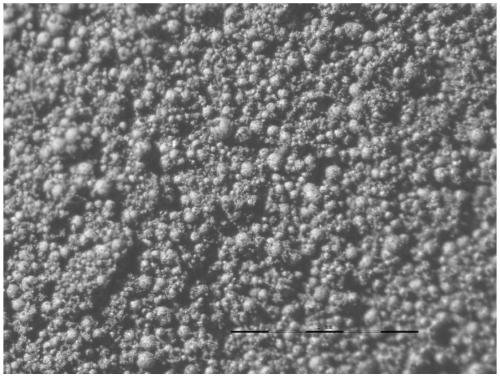

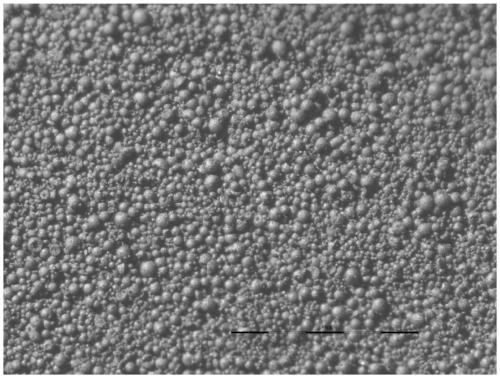

Polyvinylidene fluoride resin preparation method and reaction equipment

ActiveCN109456434AAvoid it happening againReduce sticking phenomenonChemical/physical/physico-chemical stationary reactorsBulk chemical productionGas phasePolyvinylidene difluoride

The invention discloses a polyvinylidene fluoride resin preparation method and reaction equipment. The method comprises the steps of adding a reaction medium, a dispersing agent and a chain transfer agent to a reaction vessel, performing degasification, and introducing an initiating agent and a vinylidene fluoride monomer so as to be subjected to polymerization reaction. In a reaction process, a gas phase and a liquid phase are stirred simultaneously. The reaction vessel comprises a stirrer for stirring the liquid phase, a stirrer for stirring the gas phase and an initiating agent charging pipeline connected with a fluid in the reaction vessel, wherein a discharging hole of the initiating agent charging pipeline is positioned below the liquid level of the reaction medium.

Owner:INNER MONGOLIA WANHAO FLUOROCHEM +1

Method for improving fluidity of spray powder particles of hard alloy mixture

InactiveCN111421140AReduce drynessReduce fine particle powder moreTransportation and packagingMetal-working apparatusAlcoholCrazing

The invention relates to a method for improving the fluidity of spray powder particles of a hard alloy mixture. Raw materials are prepared into the hard alloy mixture, a wet milling medium, an alloy bar and a forming agent are added for ball milling, and fatty acid diethanolamide and oleamide are added in the ball milling process; and mixture slurry obtained after wet milling is screened, spray-dried and pelletized, and the hard alloy spray particles smooth in surface and good in fluidity are prepared. The fatty acid diethanolamide and the oleamide are added, and in combination with ball milling and spray production processes matched with the fatty acid diethanolamide and the oleamide, the fatty acid diethanolamide can be fully fused with paraffin and ethyl alcohol; polar groups and non-polar groups in the fatty acid diethanolamide are combined with a ball milling medium and the paraffin correspondingly, and stable suspension is formed; the prepared mixture slurry is uniform and is notlikely to precipitate, the spraying efficiency is high, and the spray powder particles are good in uniformity; the spray powder particles are regular in morphology, smooth in surface and good in fluidity; and the prepared powder is good in pressing performance, and cracks and other defects are not likely to be generated.

Owner:SHAREATE TOOLS

High-temperature resistant rubber vulcanizing agent

InactiveCN107216487AImprove mechanical propertiesImprove high temperature resistanceVulcanizationPolymer science

The invention discloses the technical field of vulcanization compounding agents, particularly a high-temperature resistant rubber vulcanizing agent. The high-temperature resistant rubber vulcanizing agent is prepared from a vulcanizing agent component, a promoting agent component, an active agent component, an anti-scorching agent component and stearic acid. A trisulfide is used as the vulcanizing agent component to effectively improve the mechanical property, the high-temperature resistance and the ageing-resistant performance of high-temperature resistant rubber; zinc oxide is used as the active agent component and has a buffering effect on a vulcanization system, so that the high-temperature resistant rubber can be softened and plastified, the phenomenon that the high-temperature resistant rubber is stuck to a roller during mixing is effectively reduced, and meanwhile, compression long-lasting deformation of the high-temperature resistant rubber is reduced; o-hydroxybenzoic acid is used as the anti-scorching agent component and can prevent early vulcanization of the high-temperature resistant rubber during vulcanization so as to ensure that the high-temperature resistant rubber carry out vulcanization at appropriate vulcanization temperature, can prevent a scorching phenomenon of the high-temperature resistant rubber caused by a high-temperature effect during a processing process, and the storage life of the high-temperature resistant rubber is prolonged while the operation safety of the high-temperature resistant rubber is improved.

Owner:滨海县星光化工有限公司

Method for reducing isochrysis-galbana adherence and increasing growth amount

ActiveCN109355193AReduce adhesionIncrease biomassUnicellular algaeMicroorganism based processesIsochrysis galbanaBiology

The invention belongs to the technical field of algae, and discloses a method for reducing isochrysis-galbana adherence and increasing the growth amount. The method includes the following steps that an isochrysis-galbana seed solution is inoculated to a reaction pool containing a culture solution according to the inoculation amount of 5% to 10%, then 100 mg / L-200 mg / L amino acid is added, and themixture is cultured at the temperature of 20 DEG C to 22 DEG C, wherein the light-dark ratio is 12:12, and the ventilation rate is 0.4 vvm to 0.5 vvm; culturing is carried out for 48 h to 72 h, and algal cells are collected. By means of the method, the isochrysis-galbana adherence phenomenon can be obviously reduced, and the biomass of the algal cells is increased.

Owner:杭州园泰生物科技有限公司

Impact grade adjustable hydraulic jackdrill based on vibration impact

ActiveCN110005335ALow input costReal-time cleaningReciprocating drilling machinesConstructionsSlagEngineering

The invention discloses an impact grade adjustable hydraulic jackdrill based on vibration impact. The impact grade adjustable hydraulic jackdrill comprises a power box, a first oil inlet and a secondoil inlet, wherein the first oil inlet and the second oil inlet are formed in the side of the power box; and a connecting pipe is installed on the shell wall of the shell, a rotating drum is arrangedon the side of the connecting pipe, the rotating drum is rotatably connected with the shell through a second bearing seat, the bottom end of the rotating drum is installed on a slag discharging box, the top end of the rotating drum is connected with the bottom end of a rotating shaft, and the slag discharging box is fixedly connected with the shell. The impact grade adjustable hydraulic jackdrillbased on vibration impact can conveniently adjust the impact grade of a rock drill rod, use is more convenient, the jackdrill can rotate simultaneously by utilizing the linear movement of the rock drill rod, and thus the investment cost of equipment such as motor parts is saved; and broken rocks are cleaned in real time while rock drilling, and the stuck probability of a drill rod is reduced to the greatest extent.

Owner:HUNAN UNIV OF ARTS & SCI

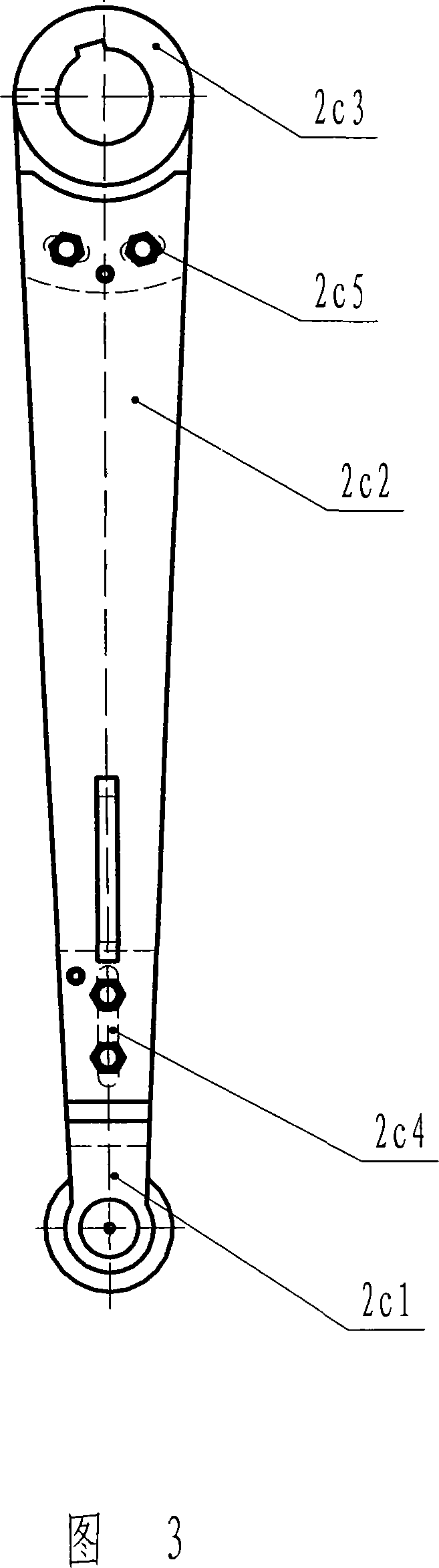

Drill rod and treatment process of threaded surfaces at joint thereof

InactiveCN111485069AGuaranteed continuityImprove wear resistanceDrilling rodsFurnace typesEngineeringScrew thread

The invention relates to a treatment process of a threaded surface at a joint in a drill rod. The treatment process comprises the following steps of quenching the drill rod with machined threads to obtain the drill rod with the hardness HV of 500-780. According to the treatment process of the threaded surface at the joint in the drill rod, after the drill rod is treated through the process, the abrasion resistance of the threaded surface at the joint in the drill rod is high, so that the use continuity of the drill rod is guaranteed, and the thread gluing phenomenon is effectively reduced.

Owner:中地装(无锡)钻探工具有限公司

Encapsulation method of hollow fiber membrane filter element

ActiveCN111389230BIncrease the lengthSame lengthSemi-permeable membranesMechanical engineeringHollow fiber membrane

A hollow fiber membrane filter element, characterized in that it includes a filter shell, a central tube, a hollow fiber membrane, a sealing shell, a sealing layer and a water collection cover, an opening is formed at the upper end of the filter shell, and a dirty water outlet hole is provided on the bottom plate; the central tube Located in the middle of the aforementioned filter housing, one end opens to form a water inlet port and the side wall is provided with a water distribution hole; the hollow fiber membrane is located in the aforementioned filter housing and the first end is evenly coated on the outer circumference of the water inlet port of the central tube, and the second end is along the Arranged along the length direction of the central tube, near the bottom end of the central tube; the sealing shell is arranged on the outer periphery of the opening of the aforementioned filter housing; the sealing layer is located between the inner wall of the aforementioned sealing shell and the hollow fiber membrane, and between the aforementioned hollow fiber membrane And between the aforementioned hollow fiber membrane and the outer wall of the central tube. The invention also discloses a glue sealing method for the hollow fiber membrane filter element. It has the advantages of more uniform water distribution and reduced concentration polarization of membrane filaments.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com