Battery negative electrode, preparation method thereof and lithium ion battery

A negative electrode and preparation method technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor comprehensive electrochemical performance, unsatisfactory electrochemical performance, scrap rate, etc., and achieve stable electrochemical performance and excellent comprehensive Effect of electrochemical performance and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

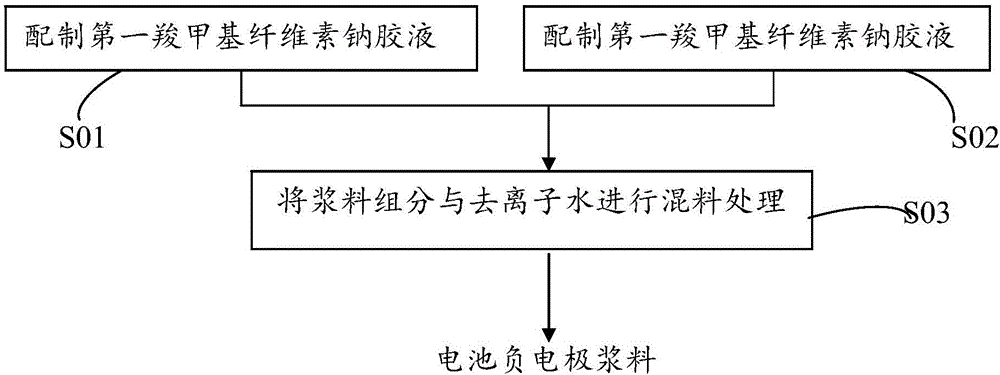

[0055] In yet another aspect, on the basis of the preparation method of the battery negative electrode slurry in the above embodiments of the invention, the embodiments of the present invention also provide a method for preparing a battery negative electrode. The method for preparing the negative electrode of the battery in the embodiment of the present invention includes the step of coating the slurry prepared by the method for preparing the negative electrode slurry of the battery in the embodiment of the present invention above on the surface of the current collector. Wherein, the current collector is a common current collector for electrodes as described above. Since the battery negative electrode preparation method of the present invention adopts the battery negative electrode slurry of the present invention as the electrode slurry, therefore, the prepared battery negative electrode does not stick to rolls in the roll-to-roll process, and the prepared battery negative elec...

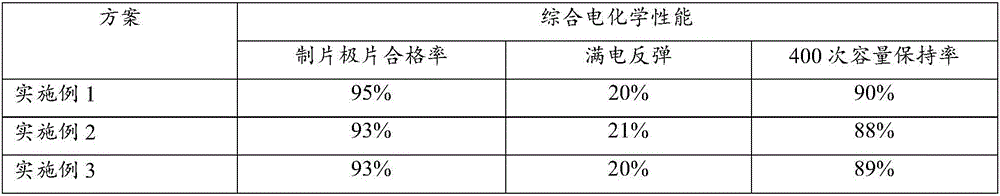

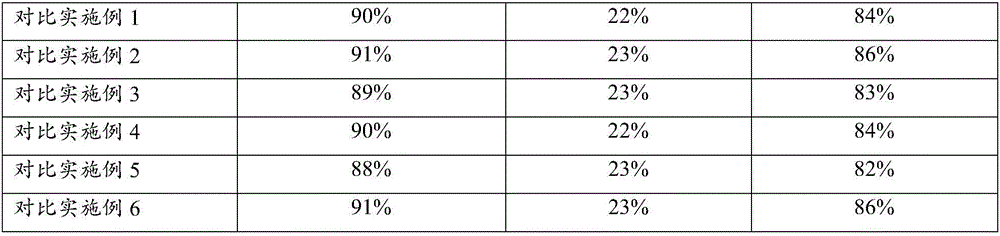

Embodiment 1

[0061] This embodiment provides a battery negative electrode and a preparation method thereof. The negative electrode of the battery in this embodiment includes a negative electrode current collector and a negative electrode active layer coated on the surface of the current collector, the negative electrode active layer includes a composite binder, and the binder includes LA133 and the first carboxymethyl cellulose Sodium and second sodium carboxymethylcellulose, the degree of substitution of the first sodium carboxymethylcellulose is 0.95, the degree of substitution of the second sodium carboxymethylcellulose is 0.85, and the first The mass ratio of sodium carboxymethylcellulose to the first sodium carboxymethylcellulose is 1:1.

[0062] The preparation method of the negative electrode of the battery in this embodiment is as follows:

[0063] Step S11. Preparation of the first sodium carboxymethylcellulose glue: select 2.0 parts by weight of CMC with a degree of substitution...

Embodiment 2

[0079] This embodiment provides a battery negative electrode and a preparation method thereof. The negative electrode of the battery in this embodiment includes a negative electrode current collector and a negative electrode active layer coated on the surface of the current collector, the negative electrode active layer includes a composite binder, and the binder includes LA133 and the first carboxymethyl cellulose Sodium and the second sodium carboxymethylcellulose, the degree of substitution of the first sodium carboxymethylcellulose is 0.98, the degree of substitution of the second sodium carboxymethylcellulose is 0.82, and the first The mass ratio of sodium carboxymethylcellulose to the first sodium carboxymethylcellulose is 1:1.

[0080] The preparation method of the negative electrode of the battery in this embodiment is as follows:

[0081] Step S21. Preparation of the first sodium carboxymethylcellulose glue: select 2.0 parts by weight of CMC with a degree of substitu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com