Polyvinylidene fluoride resin preparation method and reaction equipment

A polyvinylidene fluoride resin and reaction vessel technology, applied in the field of polyvinylidene fluoride resin preparation and reaction equipment, can solve the problems of reducing the heat transfer efficiency of the reactor, increasing the frequency of overhaul of reaction equipment, and increasing operating costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

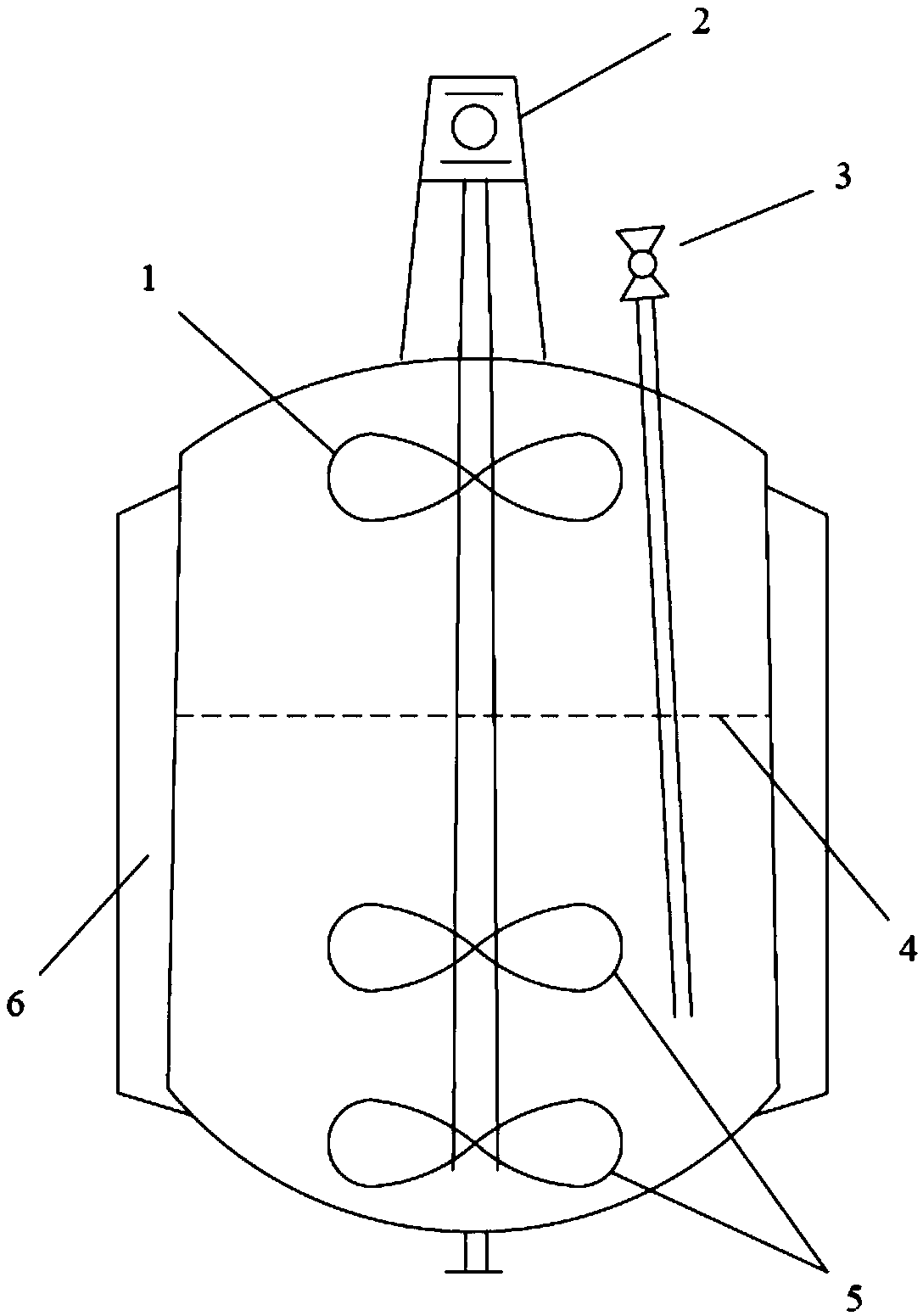

Image

Examples

Embodiment 1

[0060] Add 5kg deionized water, 5g hydroxypropyl methylcellulose and 10g diethyl malonate to a 10L autoclave equipped with a liquid phase stirrer, a gas phase stirrer and an initiator feeding tube, the liquid level of the liquid phase The material outlet that has not passed the initiator feeding pipe is degassed. At 50°C, 5.5MPa and the liquid phase and gas phase agitator are turned on, add 2g of diisopropyl peroxydicarbonate along the initiator feeding pipe through a metering pump to initiate a supercritical polymerization reaction, and continuously add VDF during the reaction process The pressure of the monomer is maintained at 5-7MPa, and the reaction is terminated after 5.5 hours of reaction.

[0061] After the polymerization, the polymer slurry was washed and dried at 105° C. to obtain polyvinylidene fluoride powder.

[0062] The sieve weight of the obtained polyvinylidene fluoride powder was measured, and the results are listed in Table 1 below.

Embodiment 2

[0064] Add 5kg deionized water, 5g hydroxypropyl methylcellulose and 10g diethyl malonate to a 10L autoclave equipped with a liquid phase stirrer, a gas phase stirrer and an initiator feeding tube, the liquid level of the liquid phase The material outlet that has not passed the initiator feeding pipe is degassed. At 50°C, 5.5MPa, and the gas phase and liquid phase agitator are turned on, add 2g of diisopropyl peroxydicarbonate along the gas phase from the top of the reactor through a metering pump to initiate a supercritical polymerization reaction. The VDF monomer maintains the pressure at 5-7MPa, and the reaction ends after 4-6 hours.

[0065] After the polymerization, the polymer slurry was washed and dried at 105° C. to obtain polyvinylidene fluoride powder.

[0066] The sieve weight of the obtained polyvinylidene fluoride powder was measured by the above method, and the results are listed in Table 1 below.

Embodiment 3

[0068] Add 5kg deionized water, 5g hydroxypropyl methylcellulose and 10g diethyl malonate to a 10L autoclave equipped with a liquid phase stirrer, a gas phase stirrer and an initiator feeding tube, the liquid level of the liquid phase The material outlet that has not passed the initiator feeding pipe is degassed. At 50°C, 5.5MPa and the liquid phase agitator is turned on but the gas phase agitator is not turned on, add 2g of diisopropyl peroxydicarbonate along the initiator feeding pipe through a metering pump to initiate supercritical polymerization reaction, during the reaction Constantly add VDF monomer to maintain the pressure at 5-7MPa, and stop the reaction after 4-6 hours.

[0069] After the polymerization, the polymer slurry was washed and dried at 105° C. to obtain polyvinylidene fluoride powder.

[0070] The sieve weight of the obtained polyvinylidene fluoride powder was measured by the above method, and the results are listed in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com