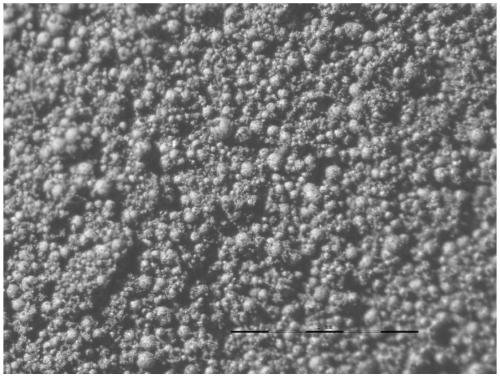

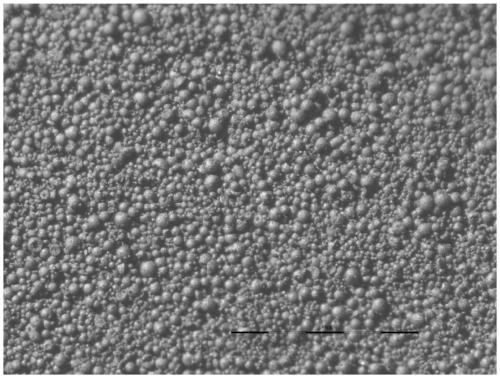

Method for improving fluidity of spray powder particles of hard alloy mixture

A technology of cemented carbide and mixed materials, which is applied in metal processing equipment, liquid separation into beads, granulation, transportation and packaging, etc. It can solve the problems of poor fluidity and rough surface of spray particles, so as to reduce fine particle spray powder and reduce The effect of incomplete spray drying and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Prepare the materials required for ball milling according to Table 1. and follow the steps below:

[0031] Table 1

[0032] material name weight and volume Specification Carbide Mixed Powder 500kg Fisherman's particle size 3μm alloy rod 1800kg Diameter 10mm, length 8mm paraffin 8.5kg 56# Refining fatty acid diethanolamide 0.3kg / Oleamide 0.7kg / industrial alcohol 130~150L 99.9% purity Cemented carbide ball mill jar 600L /

[0033] Put the alloy rod into the cemented carbide ball milling tank, then add cemented carbide mixed powder, paraffin and industrial alcohol in sequence, start the ball milling tank, stop after pre-grinding for 30 minutes and wait for the fatty acid diethanolamide and oleic acid amide mixture to be added;

[0034] Add fatty acid diethanolamide and oleic acid amide into industrial alcohol, stir with a stainless steel spoon until it is uniform and transparent without lumps,...

Embodiment 2

[0047] Prepare the materials required for ball milling according to Table 3. and follow the steps below:

[0048] table 3

[0049] material name weight and volume Specification Carbide Mixed Powder 500kg Fischer particle size 1~3μm alloy rod 1800kg Diameter 10mm, length 8mm paraffin 9kg 56# Refining fatty acid diethanolamide 0.5kg / Oleamide 0.5kg / industrial alcohol 140~150L 99.5% purity Cemented carbide ball mill jar 600L /

[0050] Put the alloy rod into the cemented carbide ball milling tank, then add cemented carbide mixed powder, paraffin and industrial alcohol in sequence, start the ball milling tank, stop after pre-grinding for 30 minutes and wait for the fatty acid diethanolamide and oleic acid amide mixture to be added;

[0051] Add fatty acid diethanolamide and oleic acid amide to an appropriate amount of industrial alcohol, and stir with a stainless steel spoon until it is uniform and tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com