Cast iron machine automatic iron-forging device

An iron casting machine and automatic technology, which is applied in the field of automatic iron striking devices of cast iron machines, can solve the problems of iron blocks sticking to the mold, unable to overcome the binding force, etc., and achieve the effect of improving the demoulding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Introduce embodiments of the present utility model below in conjunction with accompanying drawing.

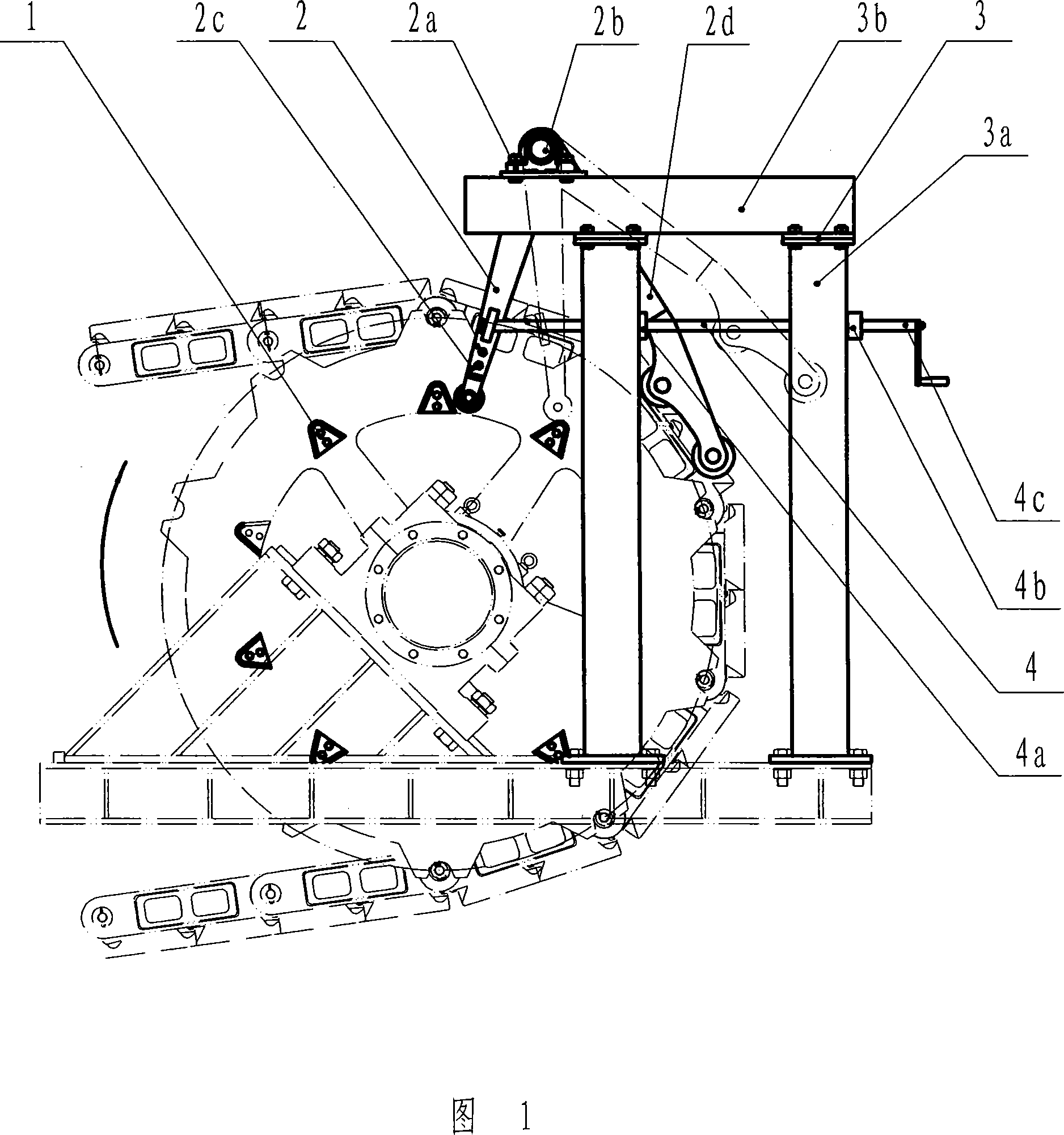

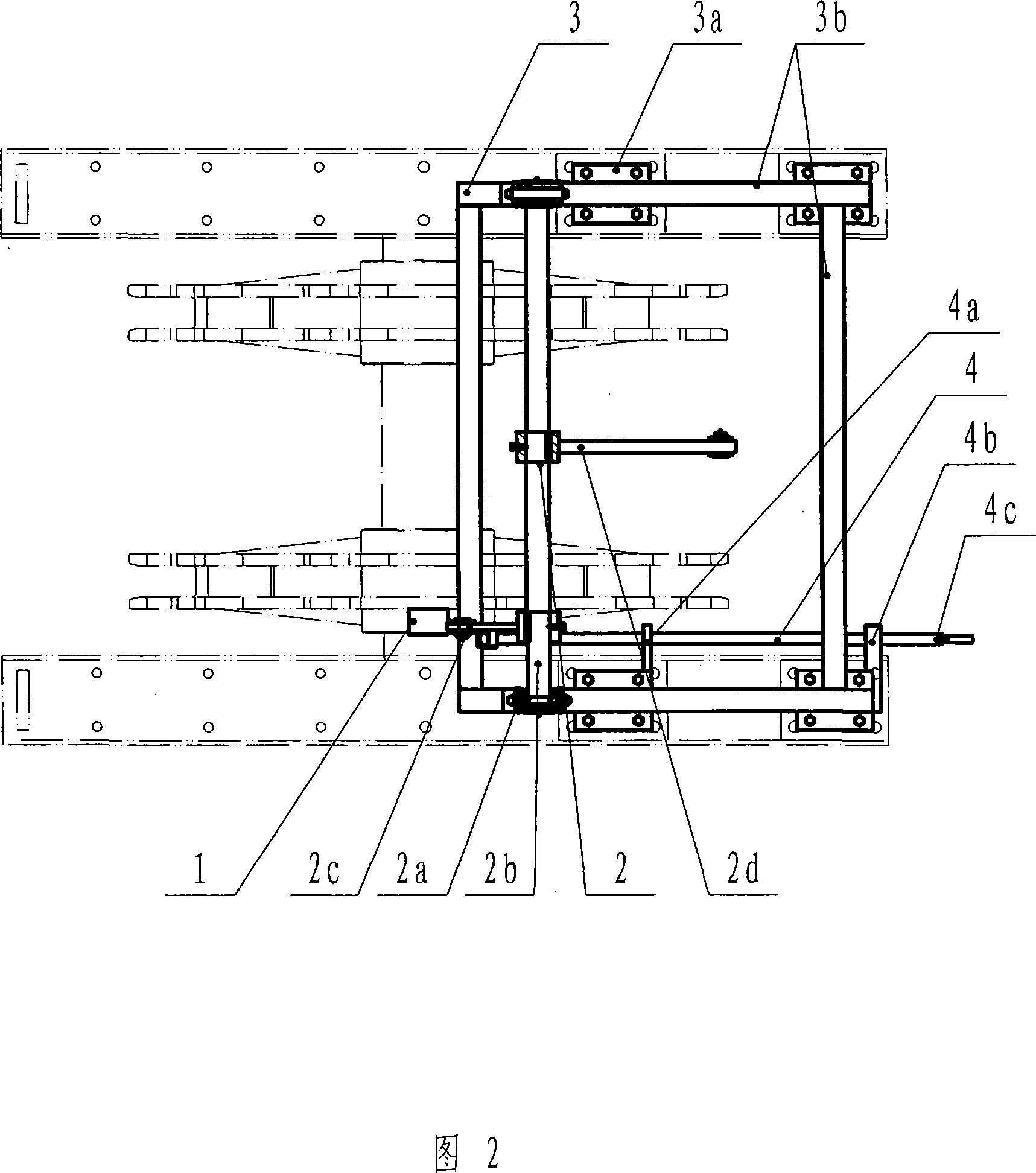

[0017] The automatic blacksmithing device of the cast iron machine is mainly composed of ten cam blocks 1, roller followers 2, supports 3 and lifting devices 4 and the like.

[0018] The roller follower 2 includes a bearing housing 2a, a blacksmith shaft 2b, a roller arm 2c and a blacksmith arm 2d. A certain angle is formed between the roller arm 2c and the blacksmith arm 2d, and they are respectively fixedly connected to the blacksmith shaft 2b. The blacksmith shaft 2b is supported and installed on the frame 3b of the support 3 by the bearing seat 2a.

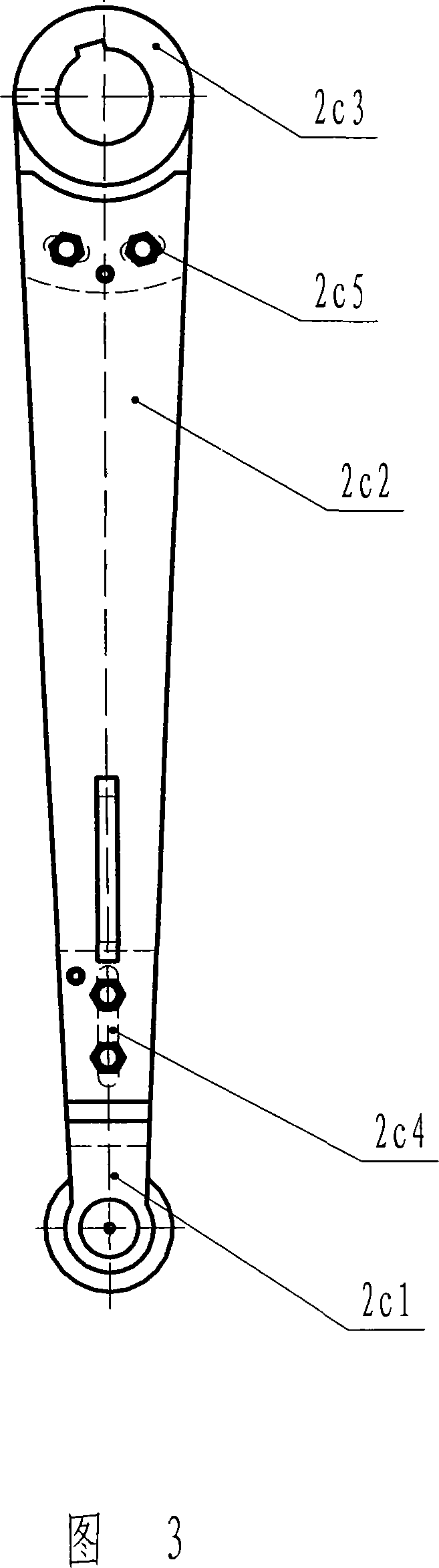

[0019] The roller arm 2c includes a roller member 2c1, a connecting plate 2c2 and a bushing 2c3. The roller part 2c1 is provided with a long bolt hole 2c4, which can be adjusted for a certain length in the connecting plate 2c2, so that the arm length of the roller arm 2c can be changed within a certain range; The plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com