Potato-rich fine dried noodles based on three-layer composite calendering and preparation method thereof

A production method and potato technology, which is applied in the field of noodle product processing, can solve the problems of poor tensile capacity of potato noodles, large cooking loss of noodles, and difficulty in rolling, etc., and achieve the goals of reducing cooking loss, good palatability, and improving tensile capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2、 3

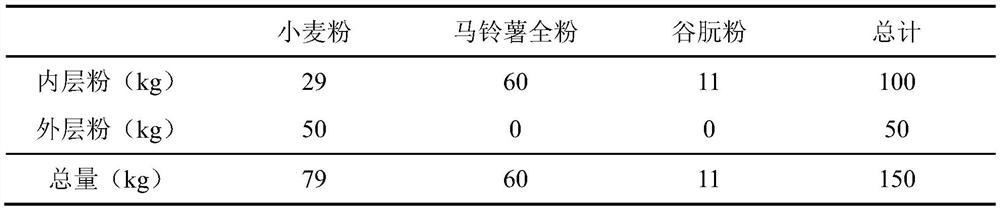

[0058] Embodiment 2, the making of three-layer composite potato noodles

[0059] (1) Noodle recipe

[0060]

[0061] (2) Raw material pre-mixing

[0062] Pour the weighed inner layer powder and outer layer powder into the mixer respectively, mix them evenly, and the mixing time is 15 minutes to obtain the inner layer mixed powder and the outer layer mixed powder.

[0063] (3) Kneading

[0064] Put the fully mixed inner layer flour and outer layer flour into different vacuum kneaders respectively, and add pre-dissolved 2% salt water, so that the moisture content of the inner dough reaches 44%, and the moisture content of the outer dough reaches 36%. , the water temperature is 20℃, and the dough mixing time is 12min;

[0065] (4) Maturation

[0066] Pour out the reconciled outer dough and inner dough from the vacuum dough mixer, and place them on the noodle conveyor belt for static curing, and the curing time is 20 minutes;

[0067] (5) Calendering

[0068] Put the cure...

Embodiment 3、 3

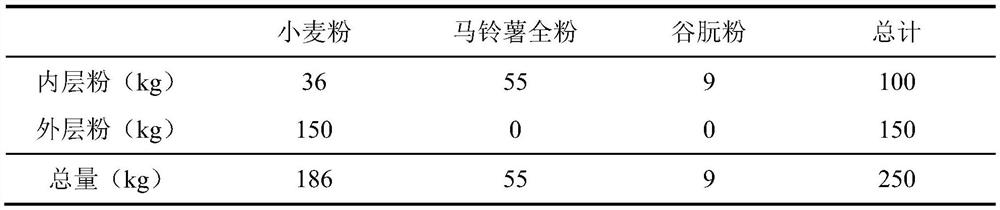

[0077] Embodiment 3, the making of three-layer composite potato noodles

[0078] (1) Noodle recipe

[0079]

[0080] (2) Raw material pre-mixing

[0081] Pour the weighed inner layer powder and outer layer powder into the mixer respectively, mix evenly, and the mixing time is 10 minutes to obtain the inner layer mixed powder and the outer layer mixed powder.

[0082] (3) Kneading

[0083] Put the fully mixed inner layer flour and outer layer flour into different vacuum kneaders respectively, and add pre-dissolved 2% salt water, so that the moisture content of the inner dough reaches 41%, and the moisture content of the outer dough reaches 37%. , the water temperature is 25℃, and the dough mixing time is 10min;

[0084] (4) Maturation

[0085] Pour out the reconciled outer layer dough and inner layer dough from the vacuum dough mixer, and place them on the noodle conveyor belt for static curing, and the curing time is 30 minutes;

[0086] (5) Calendering

[0087] Put t...

Embodiment 4

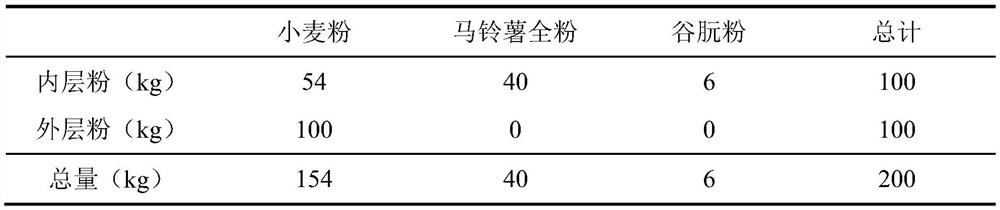

[0096] Embodiment 4, the making of conventional compound potato vermicelli

[0097] (1) Noodle recipe

[0098]

[0099] The total raw and auxiliary materials of embodiment 4 are identical with the total raw and auxiliary materials in embodiment 3;

[0100] (2) Raw material pre-mixing

[0101] Pour the weighed raw and auxiliary materials (except edible salt) into the mixer, mix evenly, and the mixing time is 10min.

[0102] (3) Kneading

[0103] Put the mixed powder into the vacuum dough mixer, add the pre-dissolved 2% salt water, make the dough moisture content reach 39%, the water temperature is 25 ℃, and the dough mixing time is 10min;

[0104] (4) Maturation

[0105] Pour out the reconciled outer layer dough and inner layer dough from the vacuum dough mixer, and place them on the noodle conveyor belt for static curing, and the curing time is 30 minutes;

[0106] (5) Calendering

[0107] Put the cured dough into the noodle press, and the thickness of the belt after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com