Thermoplastic polyurethane elastomer of rolling-level and high temperature resistance as well as preparation method thereof

A technology of plastic polyurethane and elastomer, applied in the field of calendering plastic polyurethane elastomer and its preparation, can solve the problems of easy sticking, decomposition of additives, lowering of physical properties, etc., so as to reduce sticking phenomenon, reduce surface tension, improve The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the invention will be further described below through specific embodiments. The examples given are for the convenience of those skilled in the art to better understand the present invention, but do not limit the present invention in any form.

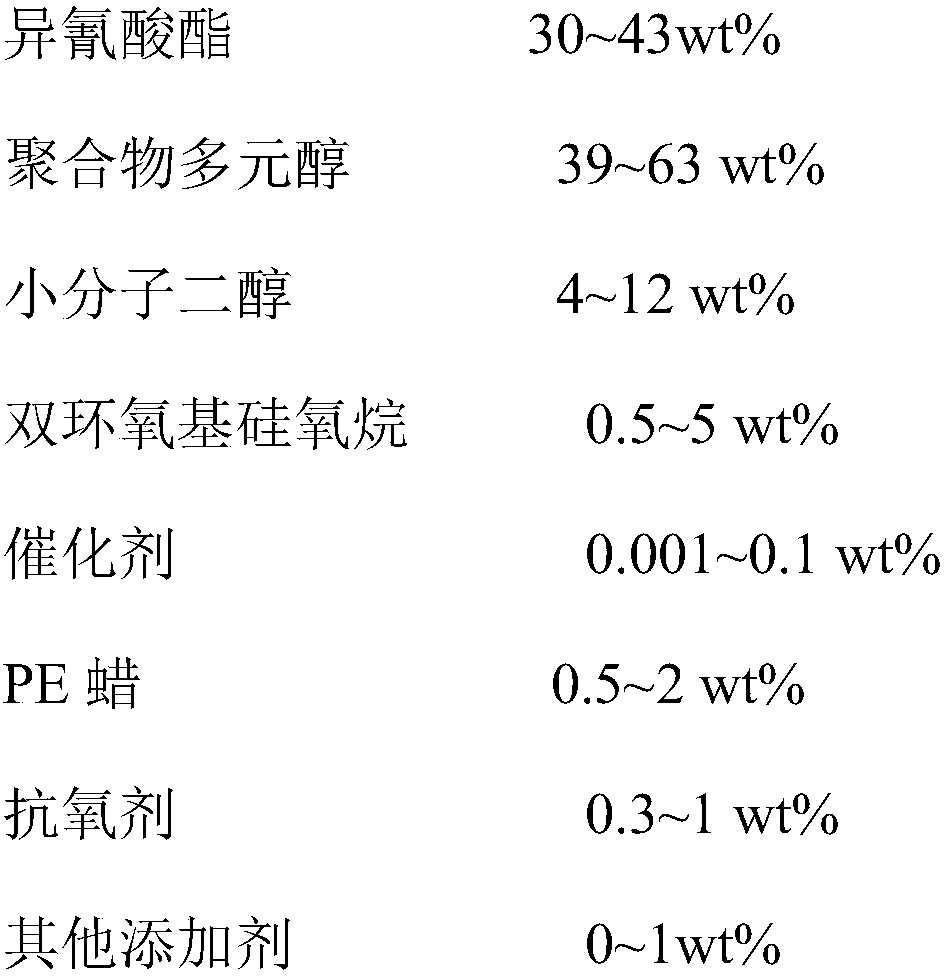

[0036] Embodiments 1-12, the raw materials involved in comparative examples 1-2 are as follows:

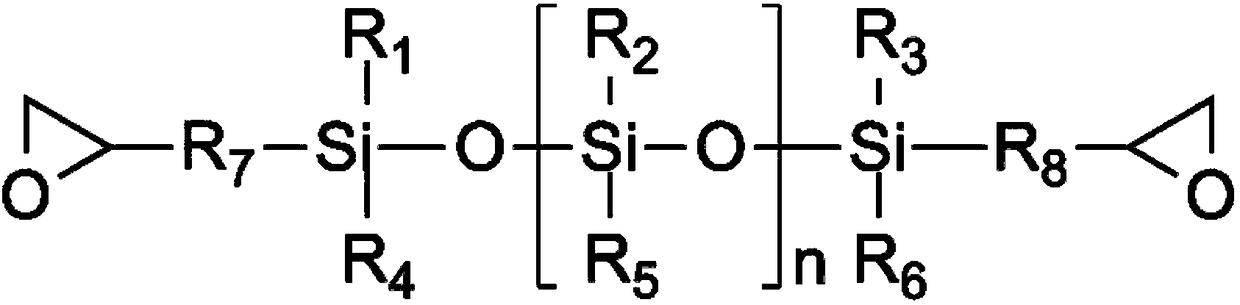

[0037] 1,3-bis(3-glycidyloxypropyl)tetramethyldisiloxane, the product of Foshan Xinhang Biotechnology Co., Ltd.;

[0038] 1,3-bis(oxiranyl)tetramethyldisiloxane, according to literature (Perry R J, Lewis L N, O'Brien MJ, et al.Carbon Dioxide Absorbent and Method of Using The Same:US,WO / 2011 / 014273[P].2011.) prepared by the synthetic method reported in;

[0039] 1,5-bis(oxiranyl)hexamethyltrisiloxane, references (Perry R J, Lewis L N, O'Brien MJ, et al.Carbon Dioxide Absorbent and Method of Using The Same:US,WO / 2011 / 014273[P].2011.) prepared by the synthetic method reported in;

[0040] 1,3-bis(oxirany...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com