Novel processing method of fresh wet noodles

A processing method and technology of fresh and wet noodles, which are applied in the fields of food science, food preservation, and application, can solve the problems of easy deterioration during production and storage, the quality of fresh and wet noodles, and the influence of storage period, etc., so as to improve the preservation effect and reduce the The effect of bacterial contamination probability and improvement of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The invention provides a technical solution: a novel processing method for fresh wet noodles, comprising the following steps:

[0026] S1. Raw material pretreatment: Sterilize the flour before use and purify the production water. The sterilization methods for flour and production water are mainly ultraviolet mold, radiation sterilization, ozone sterilization and microwave sterilization;

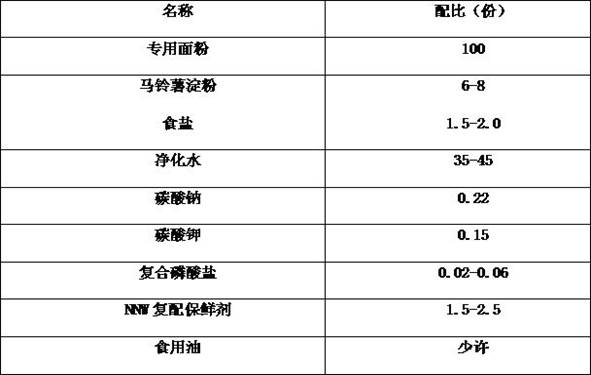

[0027] S2. Vacuum kneading: mix fresh wet noodle processing raw materials with flour evenly, add purified water, and knead dough in a vacuum state in a vacuum horizontal double-shaft kneading machine. The water is all salt water, the salt content is 0.05%, the amount of water added is 20% of the flour mass, and the water addition rate is 45% within the allowable range of the equipment;

[0028] S3. Continuous calendering and proofing and maturation: through the preliminary calendering of the dough, a 20mm thick noodle strip is formed, which will be placed in a closed aging machine for ...

Embodiment 2

[0034] The present invention provides another technical solution: a novel processing method for fresh wet noodles, comprising the following steps:

[0035] S1. Raw material pretreatment: Sterilize the flour before use and purify the production water. The sterilization methods for flour and production water are mainly ultraviolet mold, radiation sterilization, ozone sterilization and microwave sterilization;

[0036] S2. Vacuum kneading: mix fresh wet noodle processing raw materials with flour evenly, add purified water, and knead dough in a vacuum state in a vacuum horizontal double-shaft kneading machine. The water is all salt water, the salt content is 0.05%, the amount of water added is 27% of the flour mass, and the water addition rate is 45% within the allowable range of the equipment;

[0037] S3. Continuous calendering and proofing and maturation: through the preliminary calendering of the dough, a 20mm thick noodle strip is formed, which will be placed in a closed agin...

Embodiment 3

[0043] The present invention provides another technical solution: a novel processing method for fresh wet noodles, comprising the following steps:

[0044] S1. Raw material pretreatment: Sterilize the flour before use and purify the production water. The sterilization methods for flour and production water are mainly ultraviolet mold, radiation sterilization, ozone sterilization and microwave sterilization;

[0045] S2. Vacuum kneading: mix fresh wet noodle processing raw materials with flour evenly, add purified water, and knead dough in a vacuum state in a vacuum horizontal double-shaft kneading machine. The water is all salt water, the salt content is 0.05%, the amount of water added is 35% of the flour mass, and the water addition rate is 45% within the allowable range of the equipment;

[0046] S3. Continuous calendering and proofing and maturation: through the preliminary calendering of the dough, a 20mm thick noodle strip is formed, which will be placed in a closed agin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com