Patents

Literature

58 results about "Textile effluents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

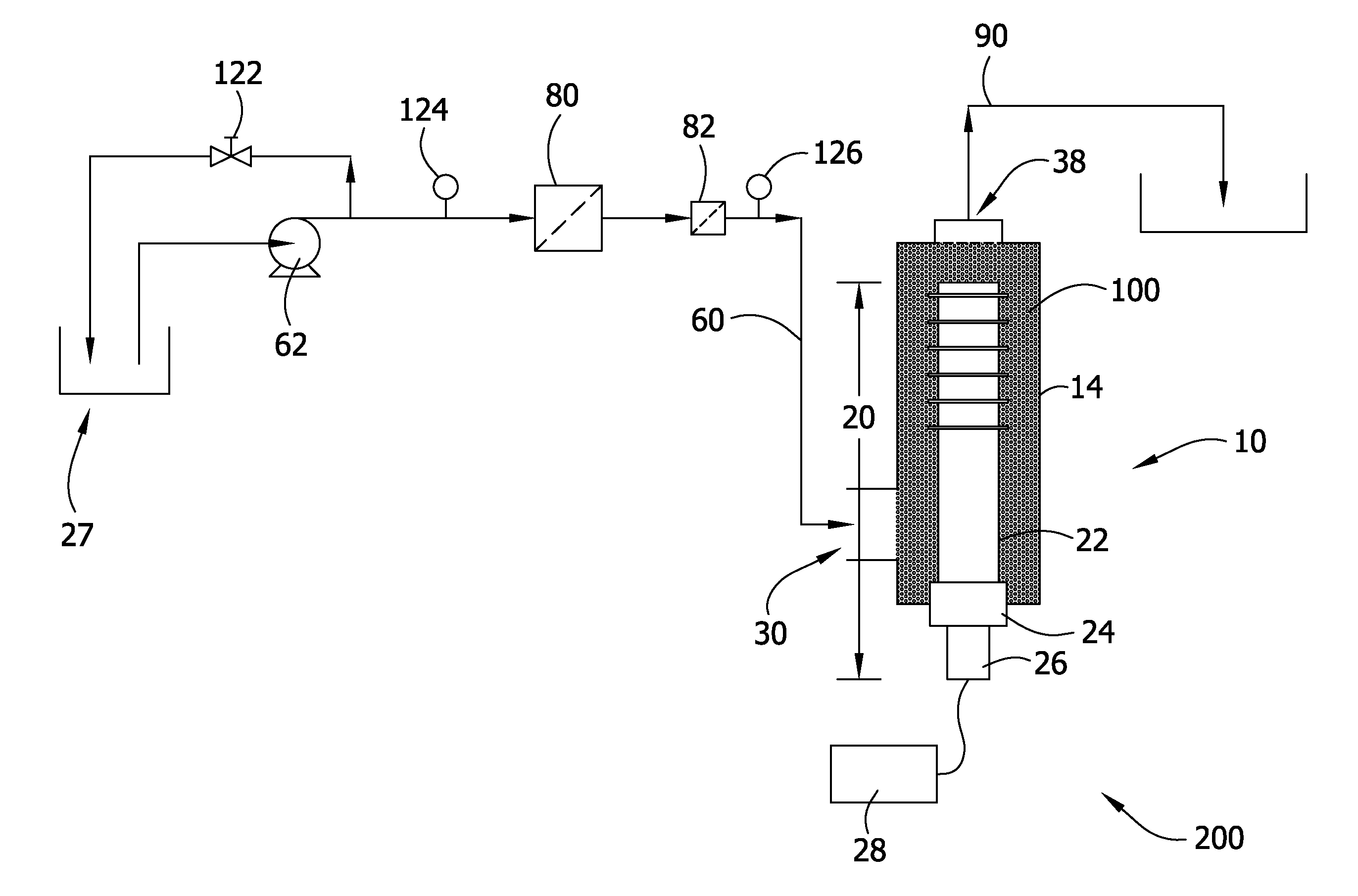

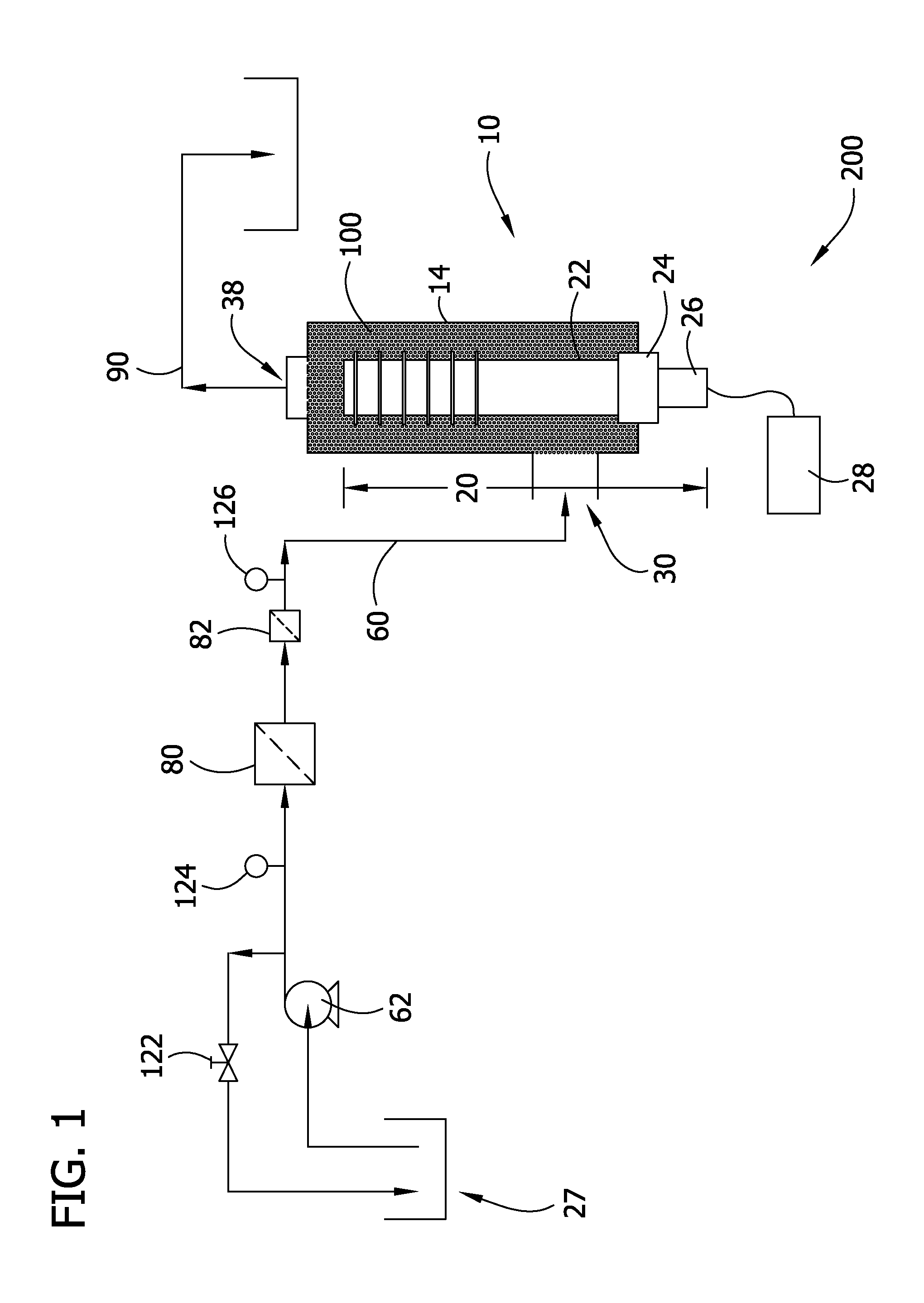

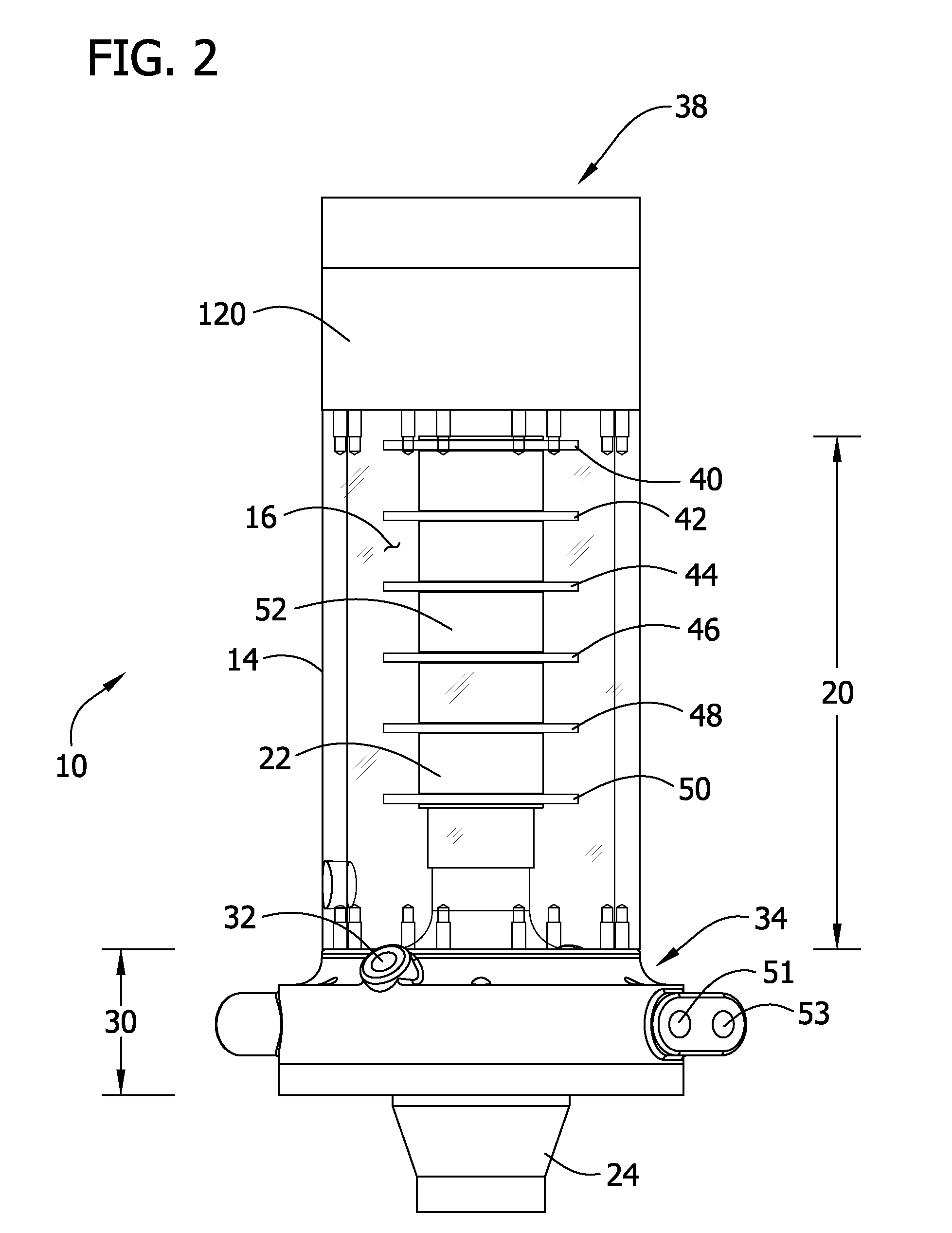

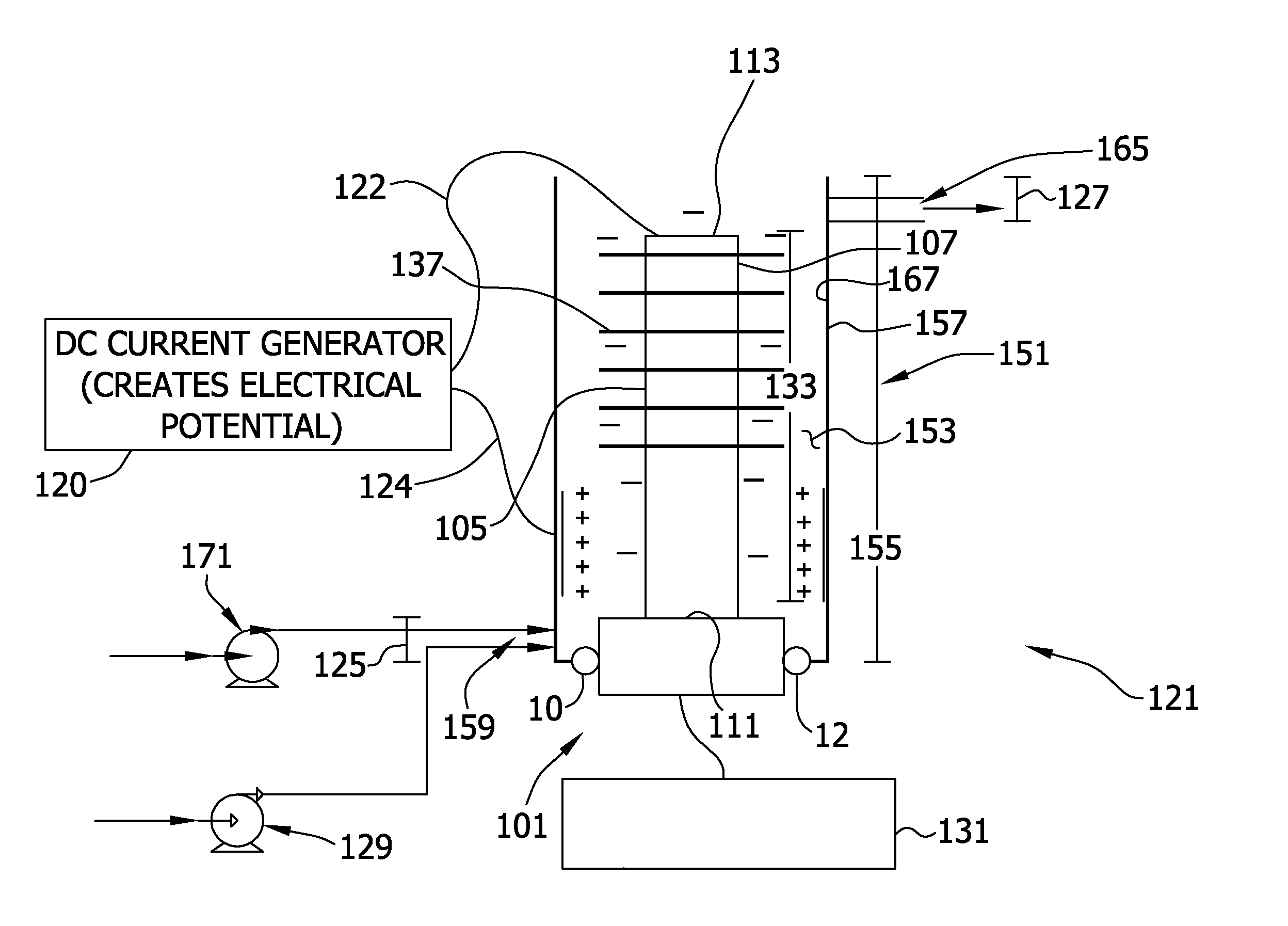

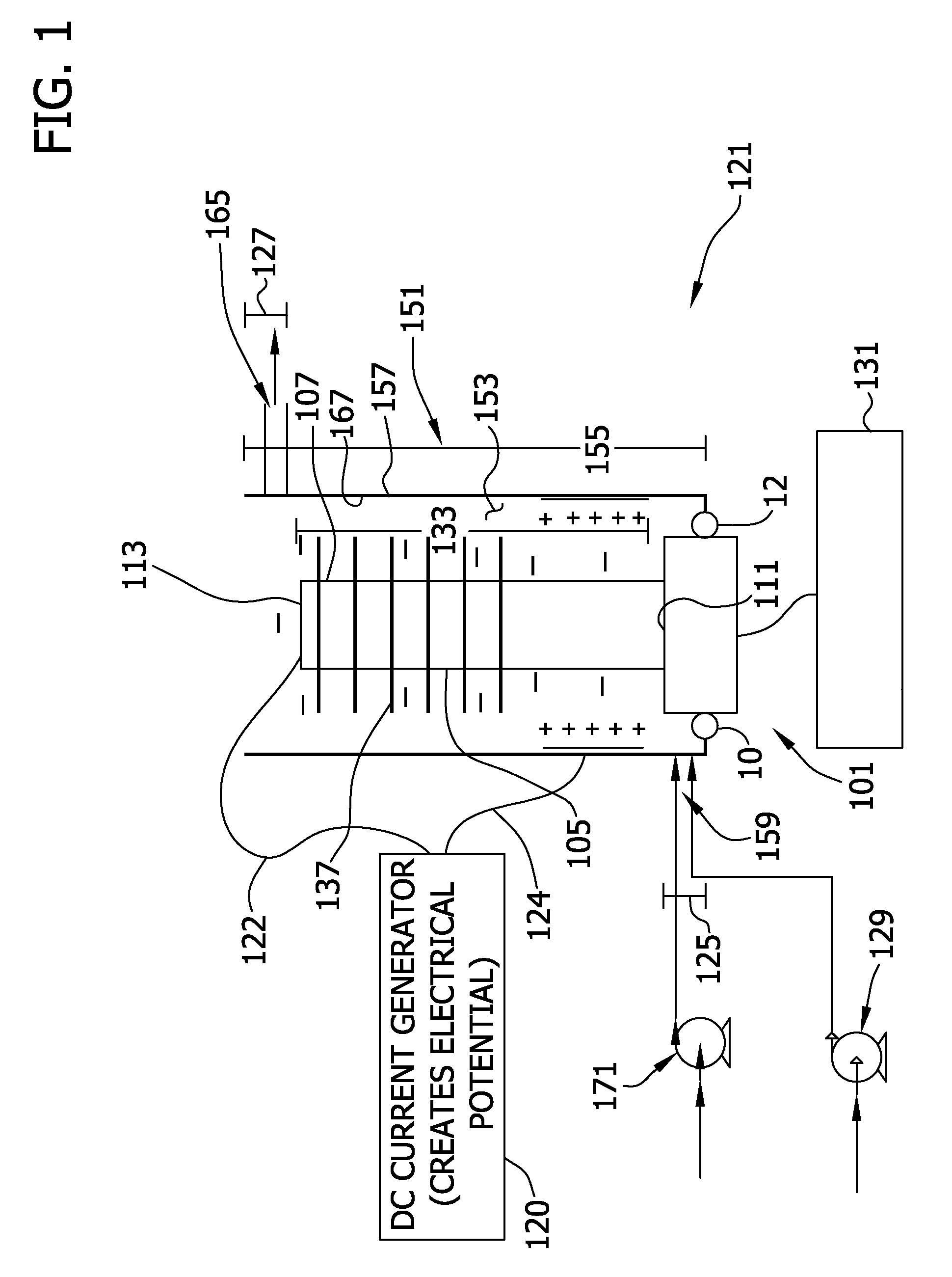

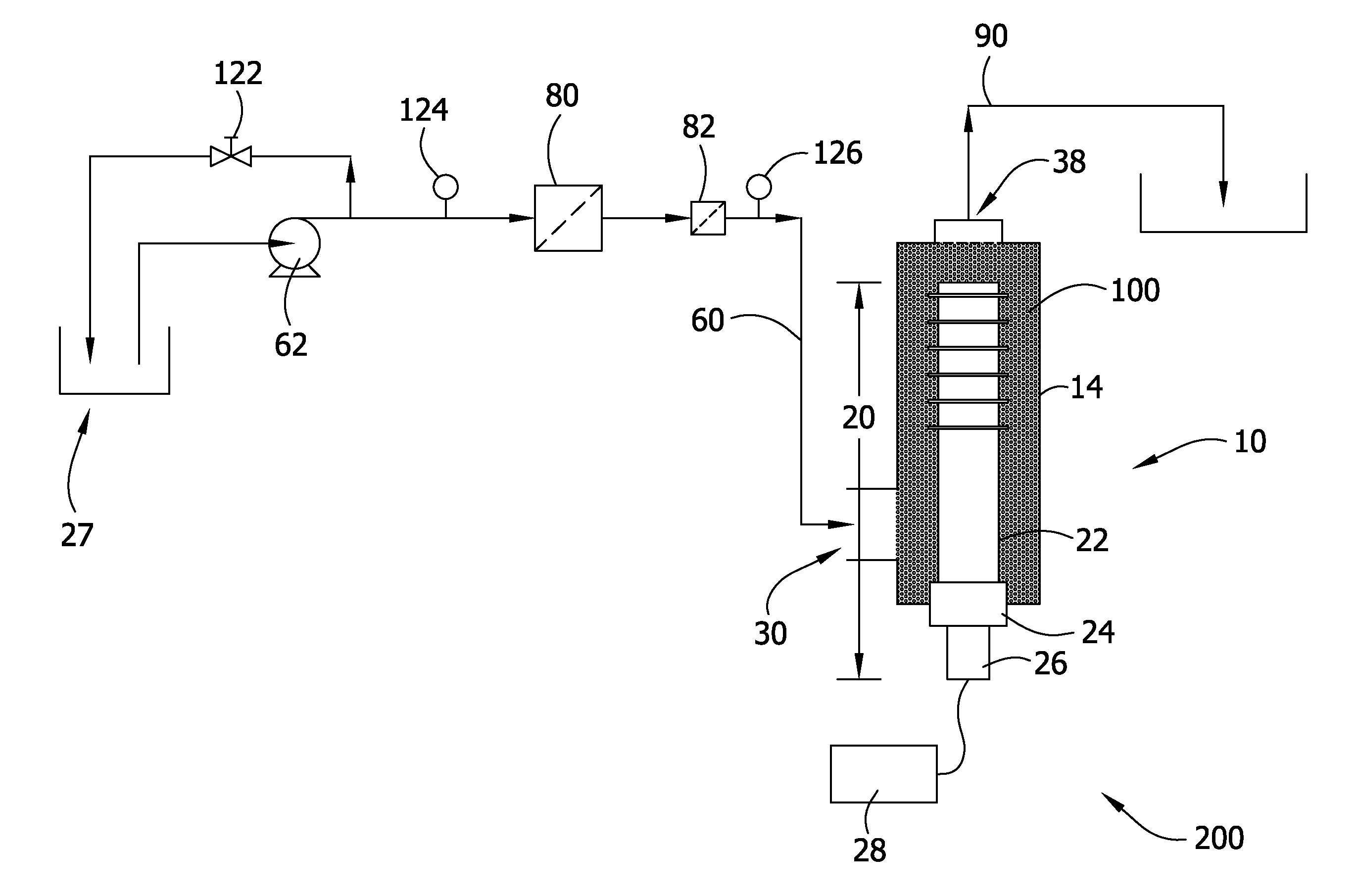

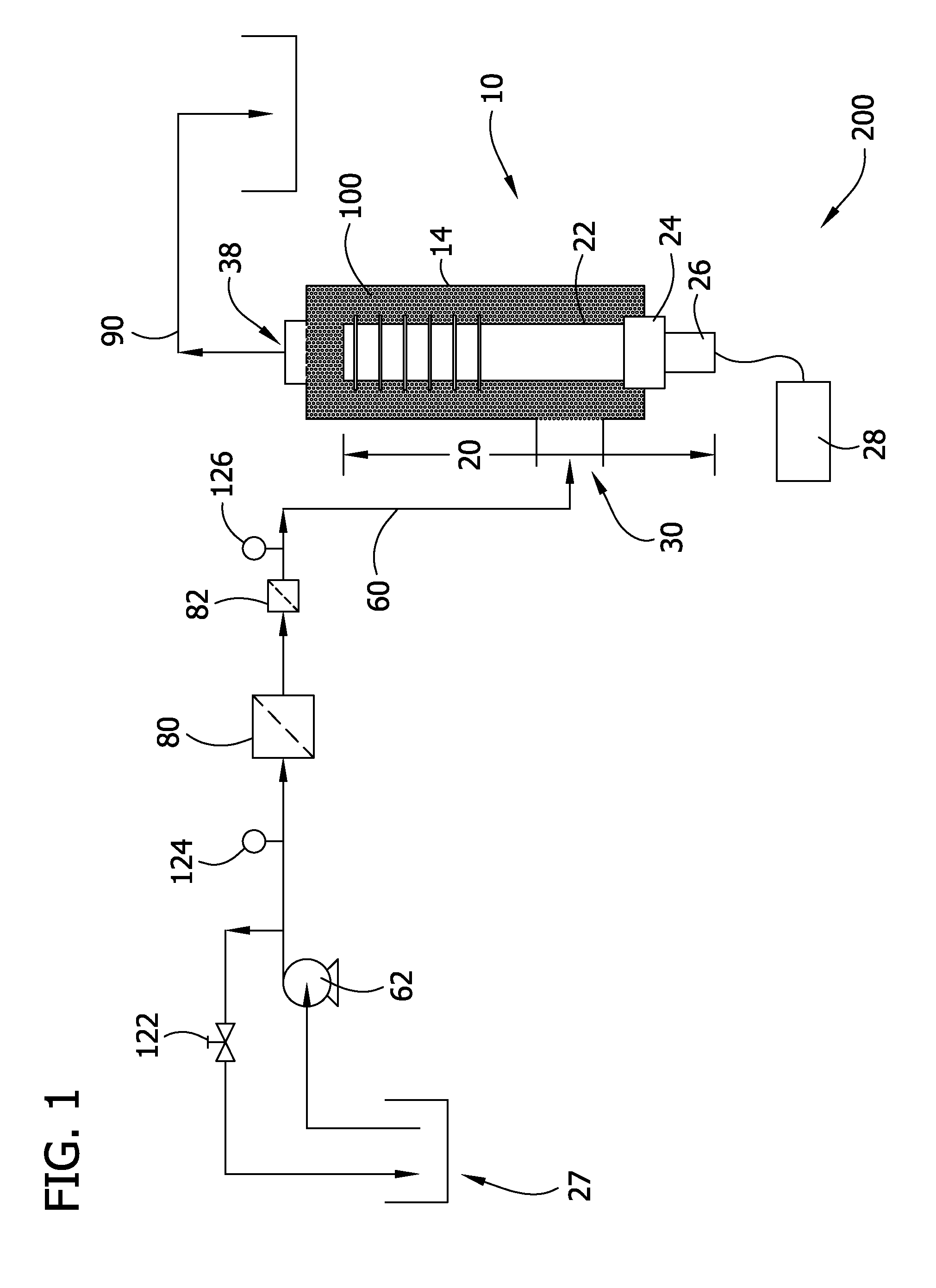

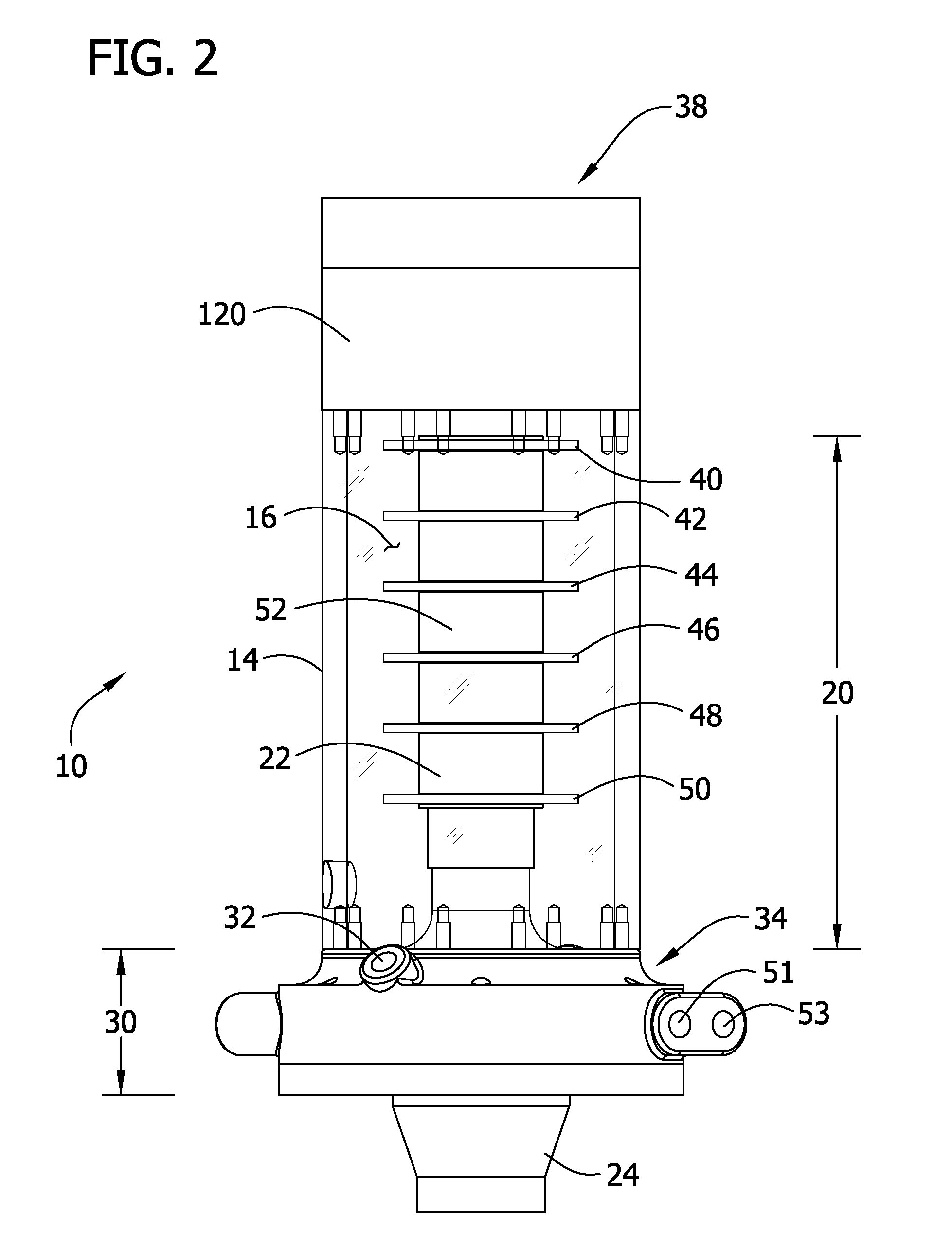

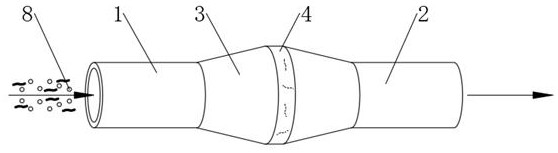

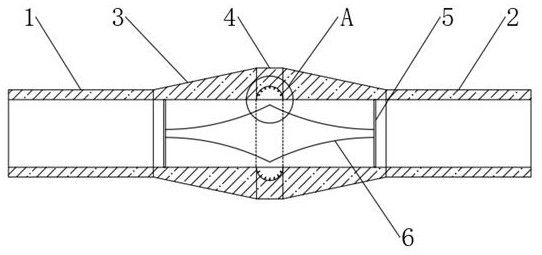

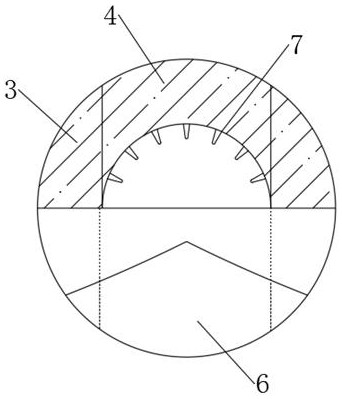

Ultrasonic Treatment System For Separating Compounds From Aqueous Effluent

ActiveUS20080061000A1Improve abilitiesThinner hydrodynamic boundary layerPaint waste treatmentSolid sorbent liquid separationSorbentTreatment system

Novel ultrasonic treatment systems for separating compounds in an aqueous effluent and processes for using the ultrasonic treatment systems are disclosed. More particularly, the ultrasonic treatment systems use ultrasonic energy to energize adsorbent to provide efficient and effective removal of compounds from aqueous effluents, such as textile effluents.

Owner:KIMBERLY-CLARK WORLDWIDE INC

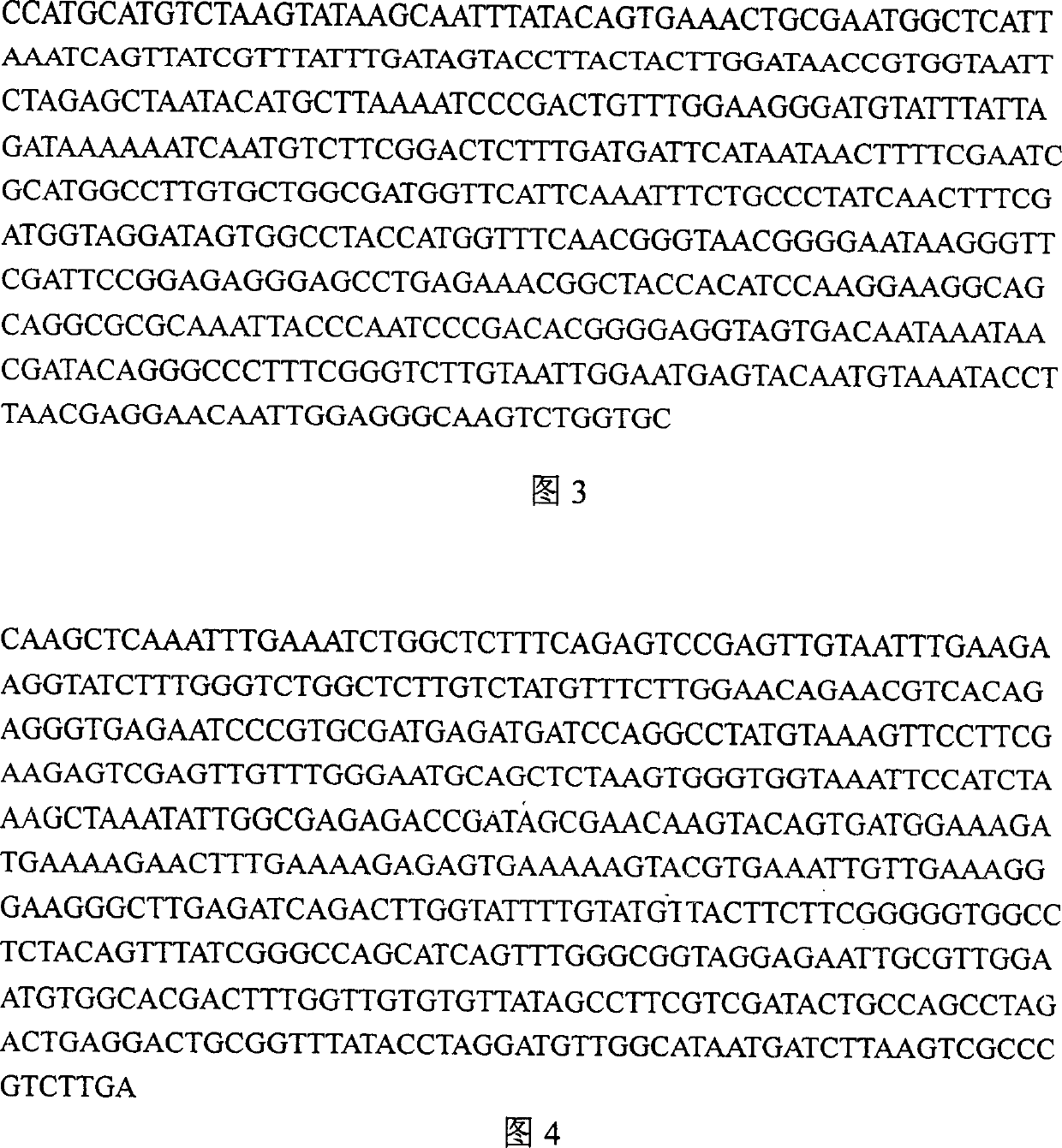

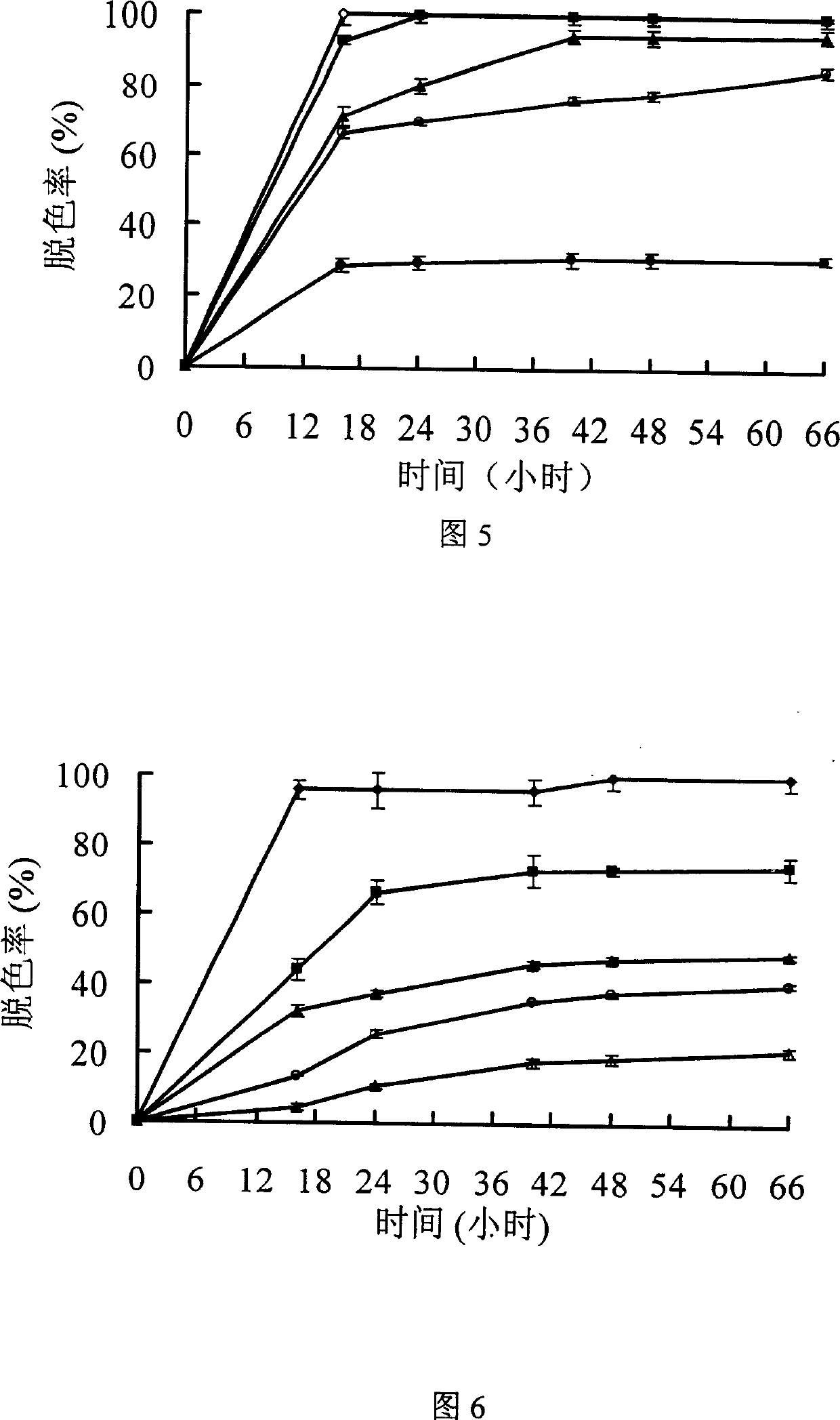

Decolur yeast of manganese producing depended pervxidase and its application

A decoloring yeast to generate the Mn-dependent peroxidase used to decolor and degradate the industrial sewage generated by textile, printing and dyeing, and preparing dye is obtained from natural environment through selective culture. It includes Debaryomyces polymorphus (CGMCC No.0813) and candiba tropicalis (CGMCC No.0814).

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Flocculating agent for textile sewage

InactiveCN104291424ACoagulation effect is fastGood decolorization effectSpecific water treatment objectivesWaste water treatment from textile industrySilicic acidAluminum sulphate

The invention discloses a flocculating agent for textile sewage. The flocculating agent for the textile sewage comprises polymerization aluminum sulphate, sodium aluminate, activated silicate, diatomite and borax; components in the polymerization aluminum sulphate, the sodium aluminate, the activated silicate, the diatomite and borax are used for treating textile and dyeing wastewater under the mutually coordination action; the effect of agglomeration function is fast; the decolorizing effect is good; dosing is small; the flocculating agent for the textile sewage is suitable for textile wastewater that is large in water quality change; the flocculating agent is good in acid resistance and heat resistance, thereby being adaptive to wastewater with relatively large change in water temperature variation.

Owner:珠海立德环保科技有限公司

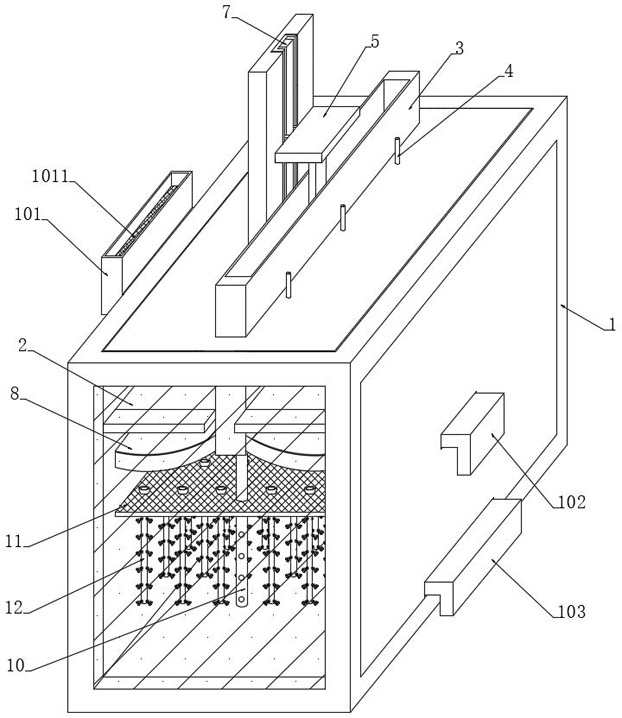

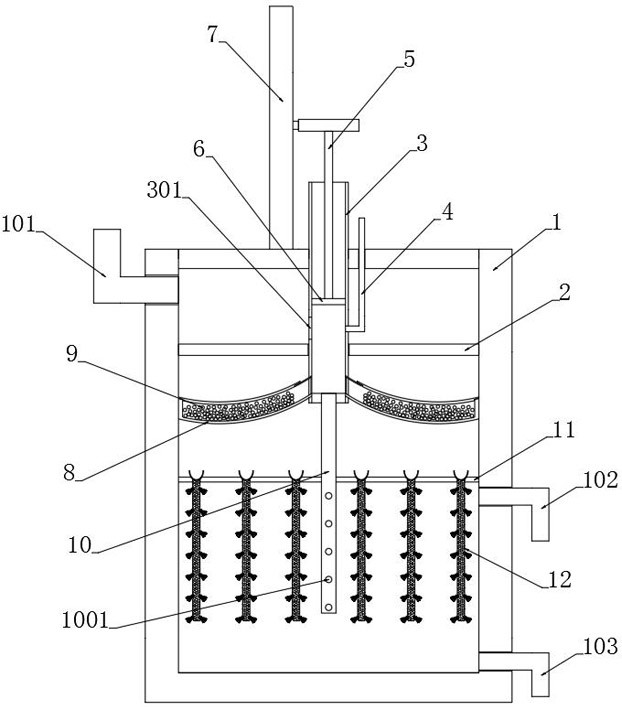

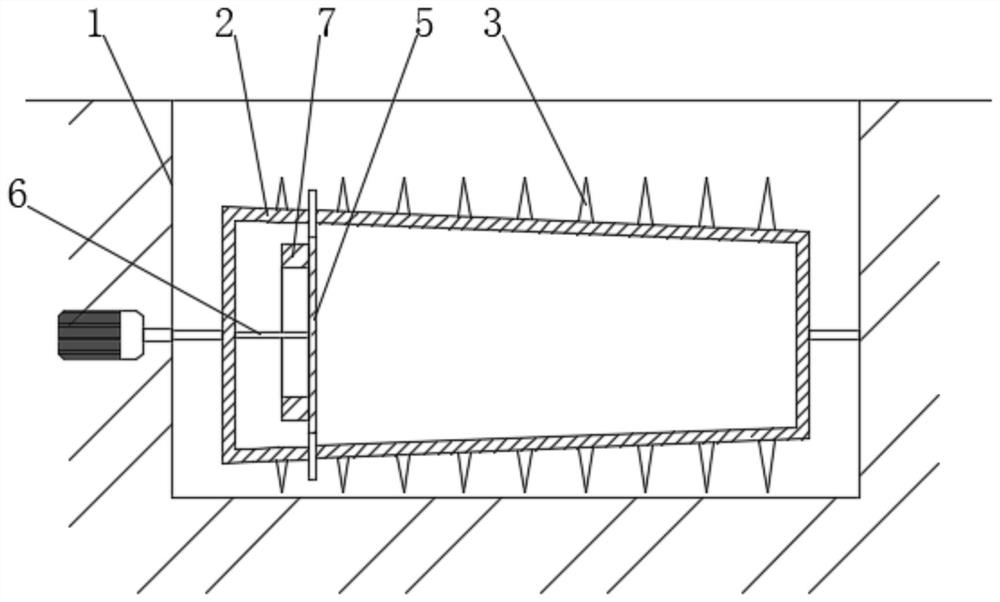

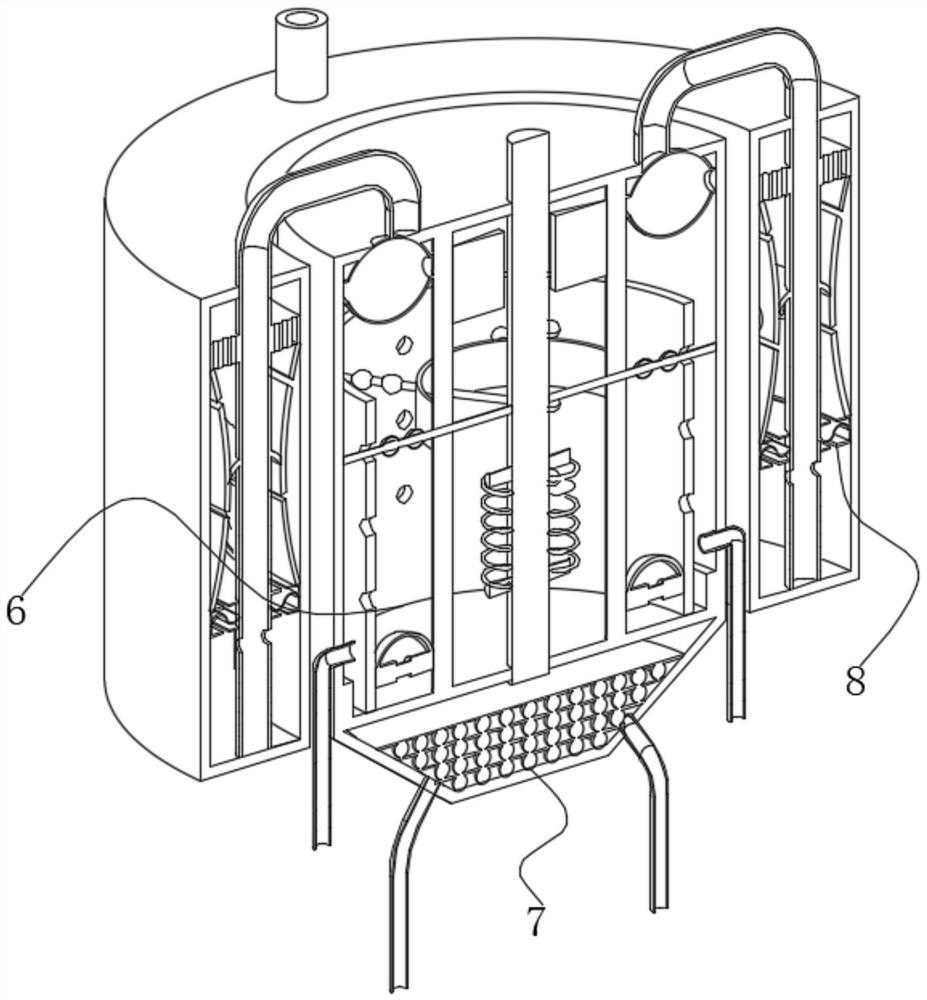

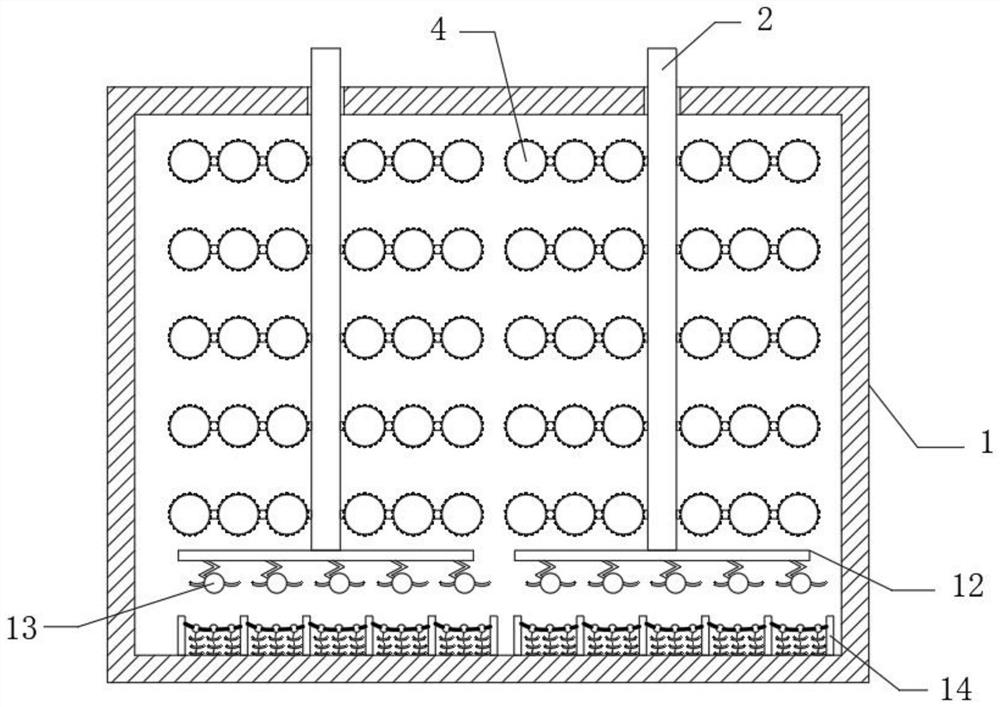

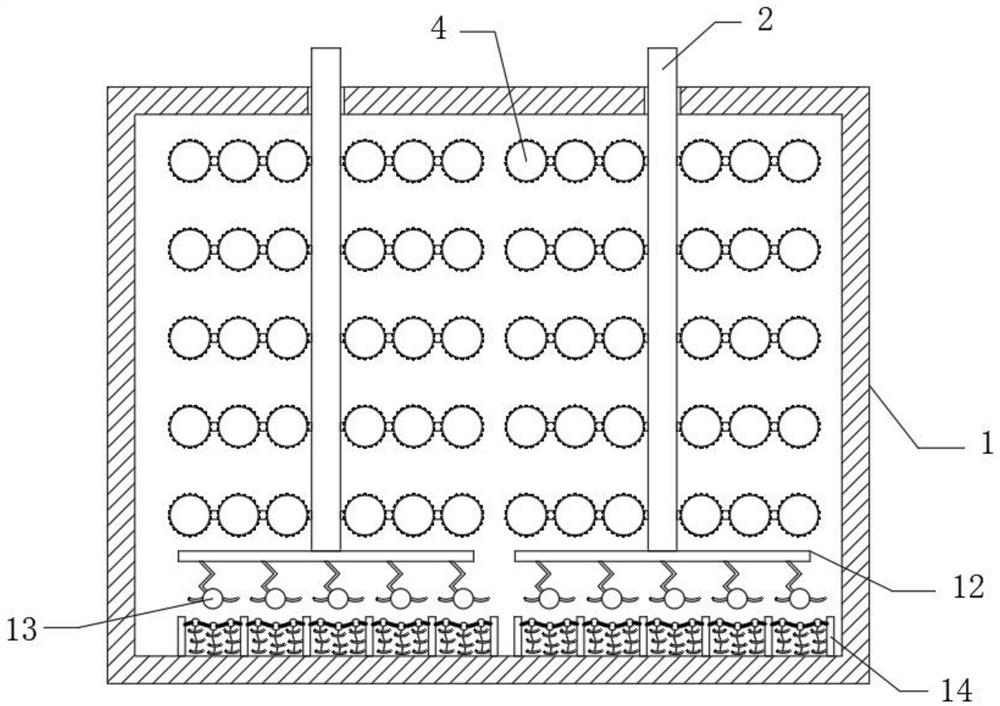

Treatment equipment for chemical fiber textile wastewater

InactiveCN111943428AIncrease the amount of bubblesFull contactTreatment using aerobic processesTreatment involving filtrationFiberMicroorganism

The invention discloses treatment equipment for chemical fiber textile wastewater, and belongs to the technical field of chemical fiber textile wastewater treatment. By cooperation of a drawing feeding mechanism and a drawing feeding channel, primarily filtered wastewater can be pressed into a pair of arc-shaped filtering channels by large impact force for adsorption and filtration; a plurality ofactivated carbon adsorption particles are used for adsorbing harmful impurities, then the wastewater subjected to secondary treatment is guided into a lower treatment cavity through a filter screen plate to be subjected to coagulation treatment precipitation, and the wastewater is downwards guided out and stamped at a coagulant releaser, so that the leaching of a coagulant is realized, and the coagulation uniformity is improved; furthermore, the attapulgite in the hollowed-out adsorption pipe adsorbs harmful dyes in the wastewater, a plurality of microorganism attachment bodies on the outer side wall of the hollowed-out adsorption pipe realize biological treatment on the wastewater, and the aeration mechanism is matched, so that on one hand, oxygen is supplied to the microorganism attachment bodies, and on the other hand, the bubble amount in the wastewater is effectively increased; therefore, full reaction contact between the coagulant and the wastewater is effectively realized.

Owner:熊英姿

Self-fading textile wastewater filtering device and using method thereof

ActiveCN111704177AImprove interception effectImprove pass rateTreatment involving filtrationSustainable biological treatmentStructural engineeringProcess engineering

The invention discloses self-fading textile wastewater filtering device and using method thereof. The invention belongs to the technical field of sewage treatment, the wool fibers can be comprehensively intercepted by the telescopic intercepting columns which are circumferentially distributed on the pre-shunting column; particularly, the intercepting effect of the telescopic intercepting column can be further improved through the inflated and hardened wound airbag rod; on the contrary, the winding characteristic of wool fibers is utilized to improve the fixing effect; after intercepting saturation or ending, the intercepted wool fibers are positioned and prevented from falling off through folding and shrinking of the telescopic interception columns; meanwhile, the passing rate of textile wastewater is improved; finally, the textile wastewater completely passes through; the telescopic interception column is unfolded again and reset; meanwhile, the winding air bag rod is deflated and softened and then is separated from the wound wool fibers, so that the telescopic interception column becomes a smooth cylinder, and the wool fibers automatically fall off from the telescopic interception column to be collected. By means of the device, the wool fiber treatment difficulty of textile wastewater is greatly reduced.

Owner:陈式好

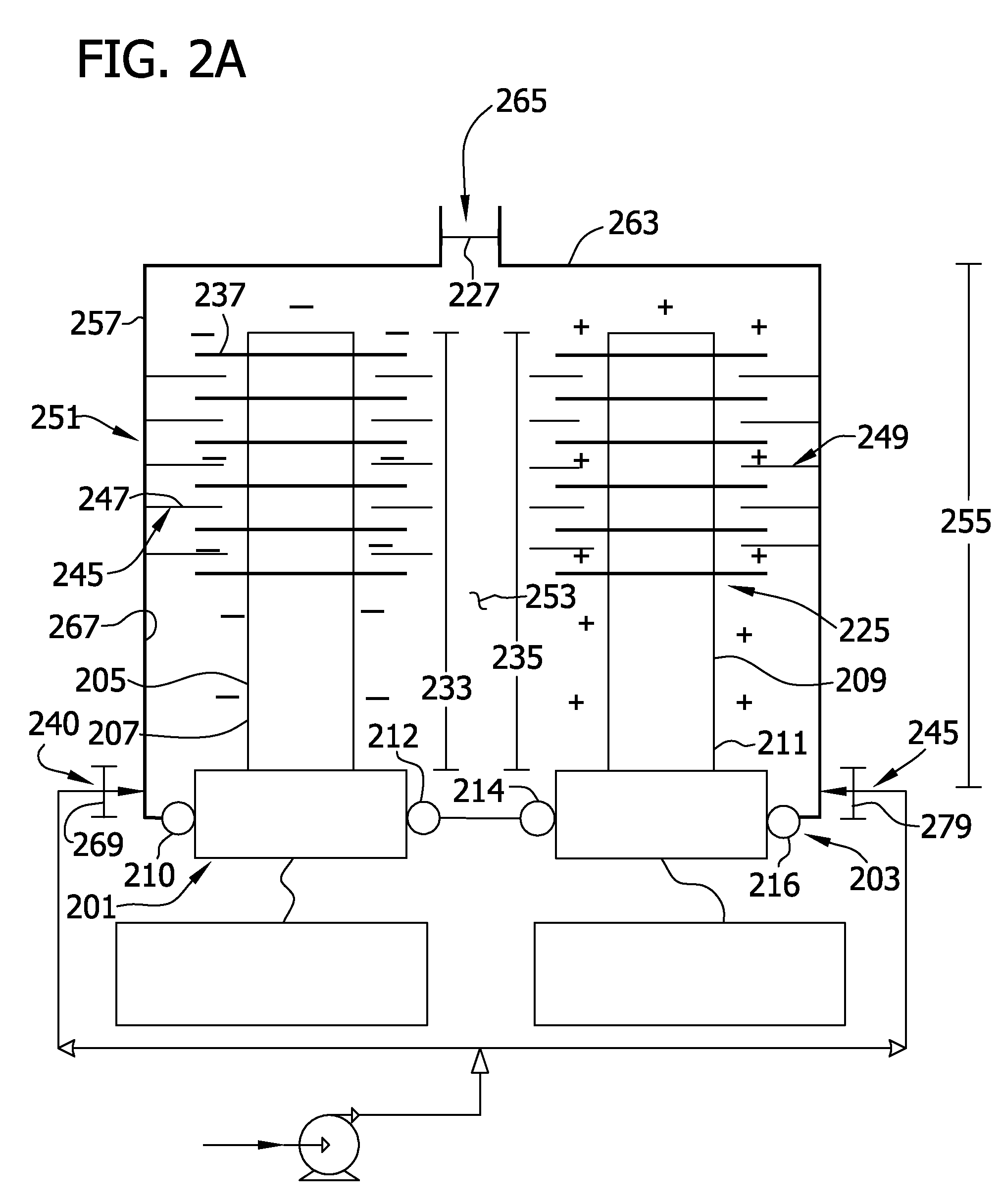

Treatment chamber for separating compounds from aqueous effluent

InactiveUS7947184B2Water/sewage treatment by irradiationWater contaminantsElectrode potentialNuclear chemistry

Owner:KIMBERLY-CLARK WORLDWIDE INC

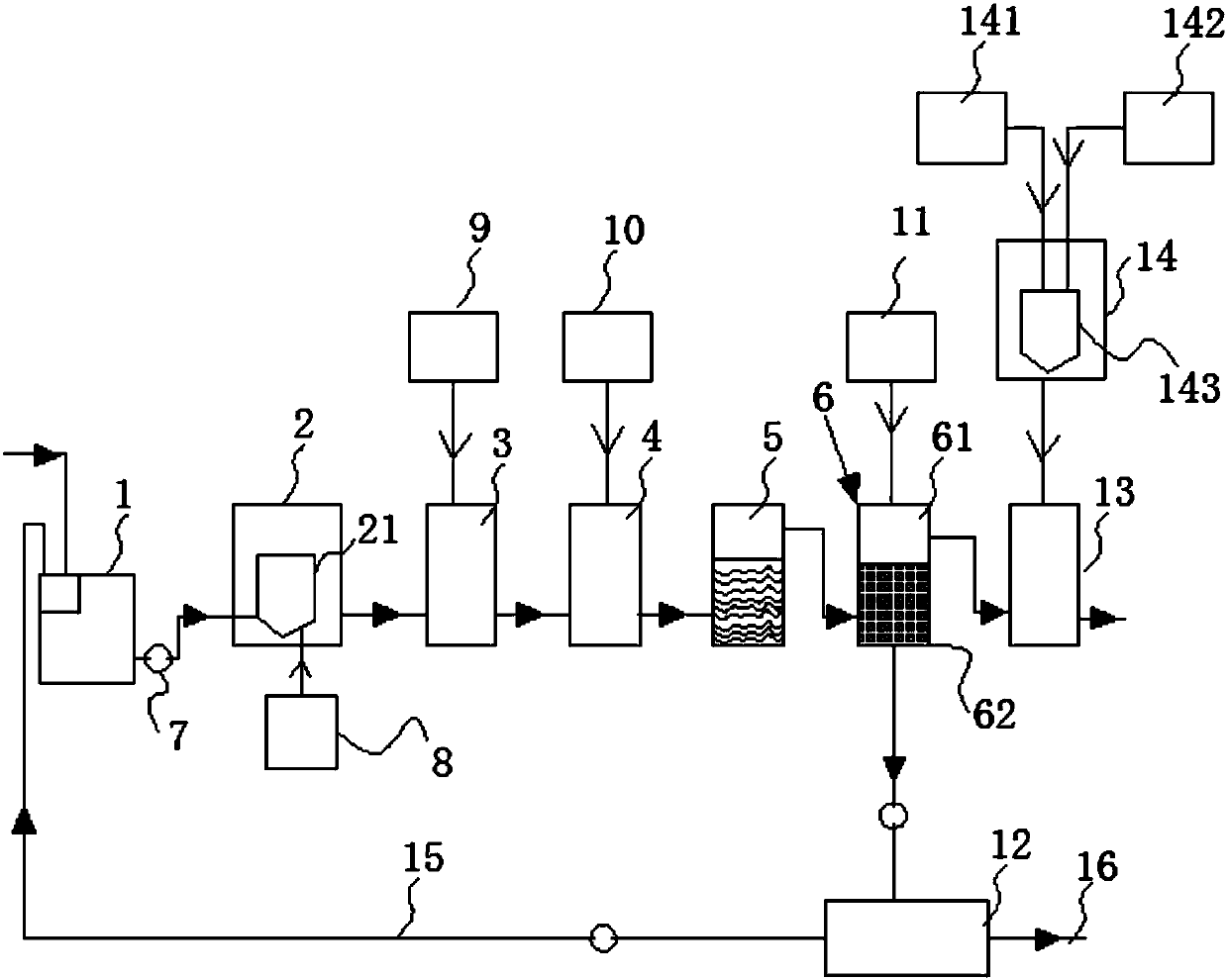

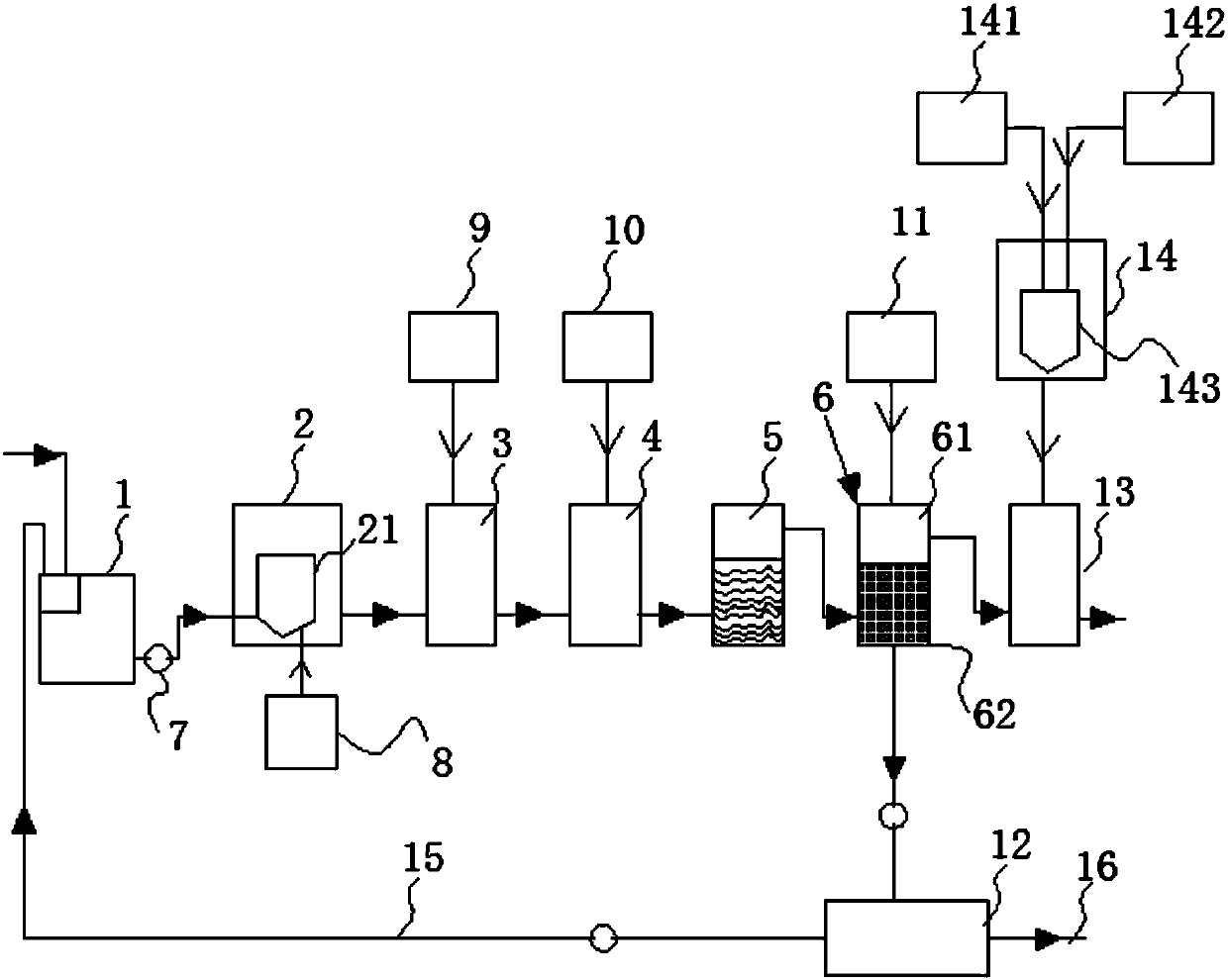

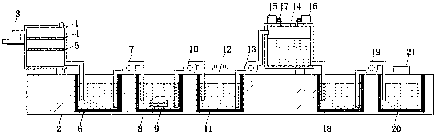

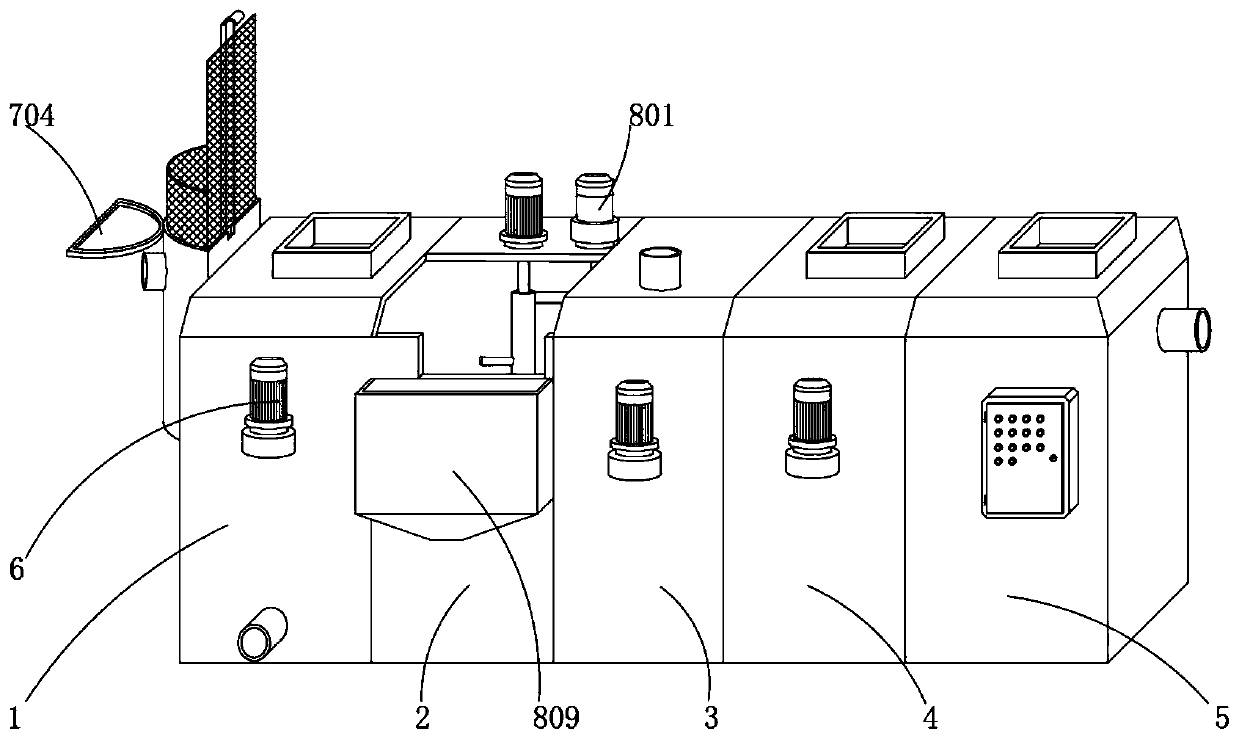

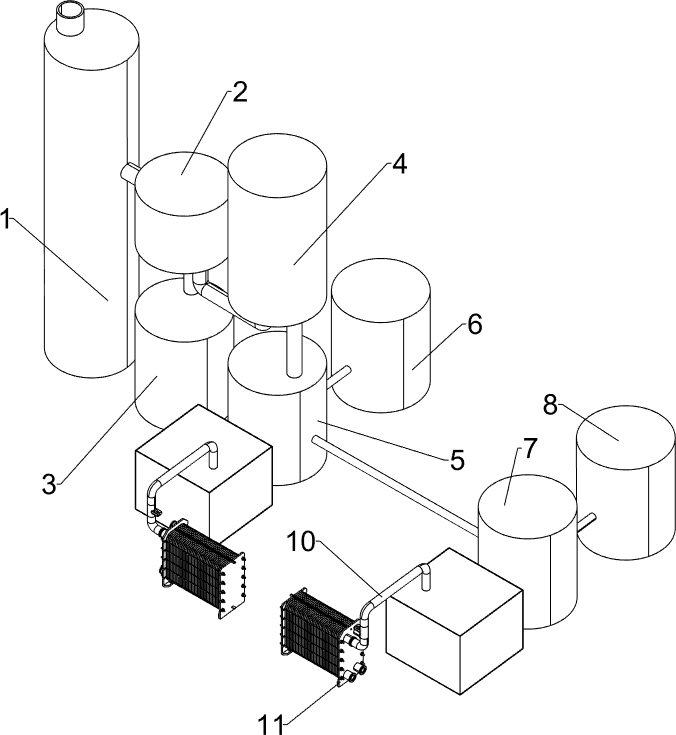

Textile wastewater treatment system<0}

InactiveCN106698867ALow costImprove processing efficiencyFatty/oily/floating substances removal devicesTreatment using aerobic processesAutomatic controlChlorine dioxide

The invention discloses a textile wastewater treatment system. The textile wastewater treatment system comprises a grid oil separator capable of collecting textile wastewater, as well as a decolorizing pretreatment pool, a regulating reservoir, a hydrolysis acidification pool, a contact oxidation pool and a reactive precipitation pool which are sequentially communicated with the grid oil separator through wastewater pipelines, wherein <0}the reactive precipitation pool comprises a top reaction zone and a bottom settling zone; the bottom settling zone is connected with a press filter through a sludge pipeline; the press filter is connected with the grid oil separator through a wastewater pipeline; the press filter discharges sludge through the sludge pipeline; the top reaction zone is connected with a disinfection pool through a wastewater pipeline; the periphery of the disinfection pool is provided with a chlorine dioxide generator; the textile wastewater treatment system further comprises a control system. <0}By virtue of reasonable combination of biochemistry and physical chemistry, a textile wastewater treatment system which is low in cost, high in treatment efficiency and stable in system operation is formed; furthermore, by virtue of a PLC (Programmable Logical Controller), a PH sensor, a flowmeter and the like, the system is automatic in dosage control, high in control process automation degree and accurate in control, and is capable of lowering the labor cost.

Owner:JIANGSU YONGYI ENVIRONMENTAL PROTECTION TECH CO LTD

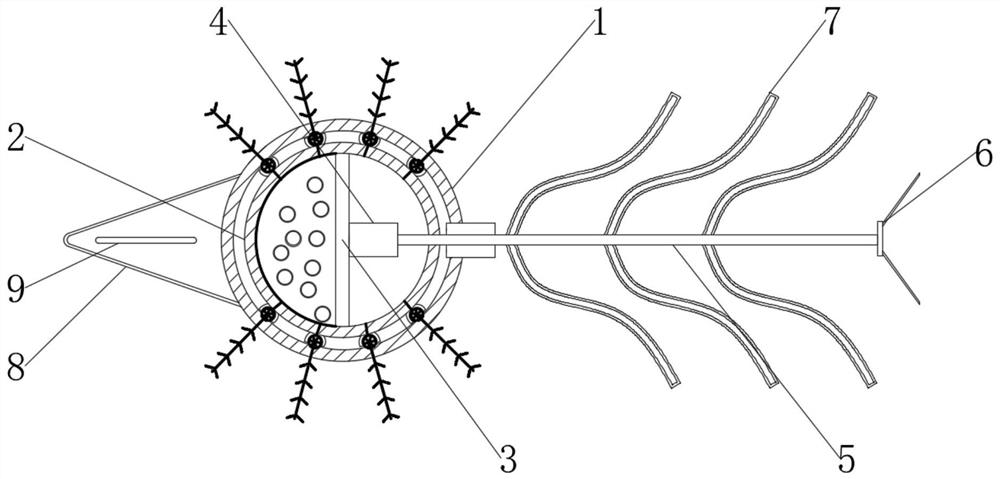

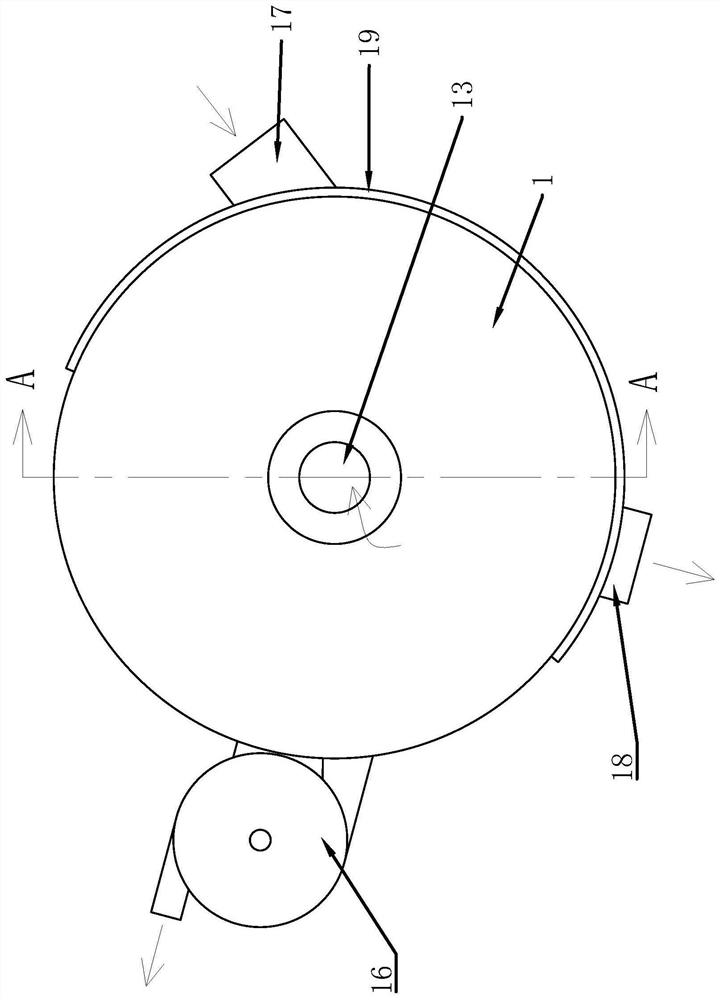

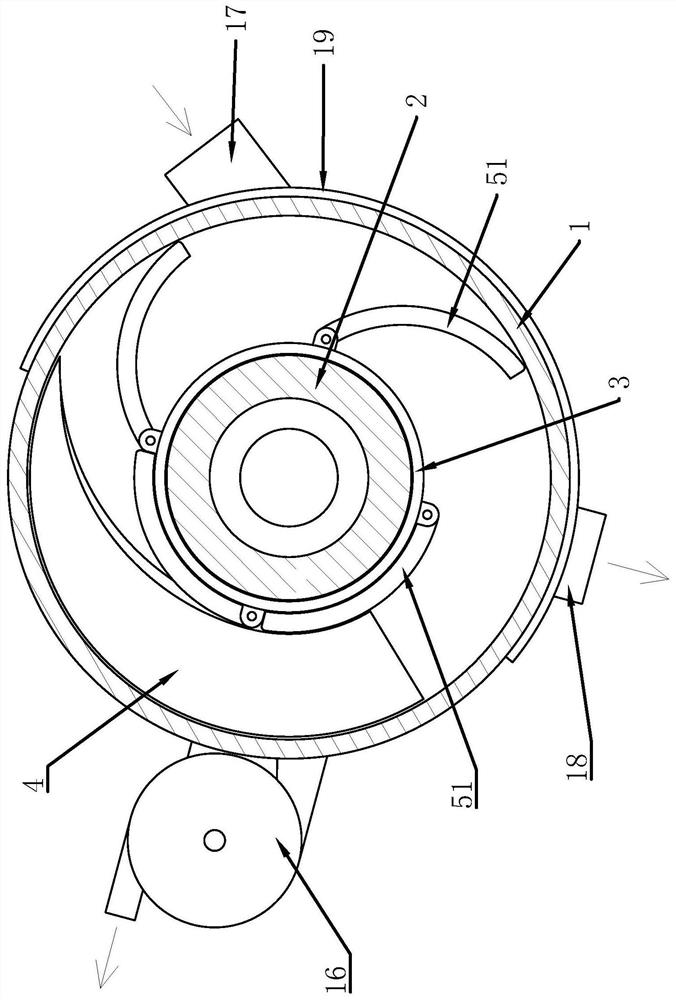

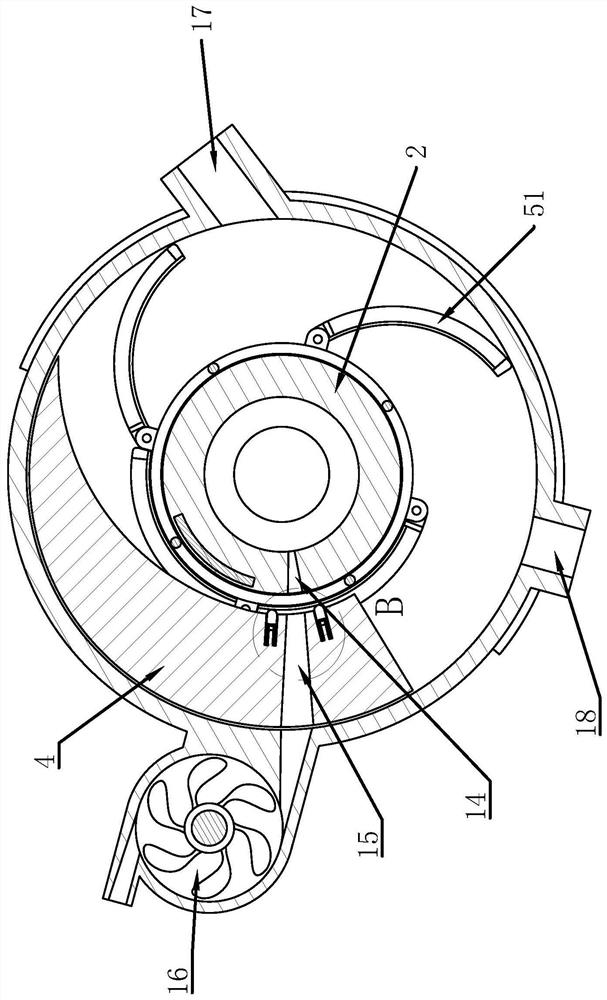

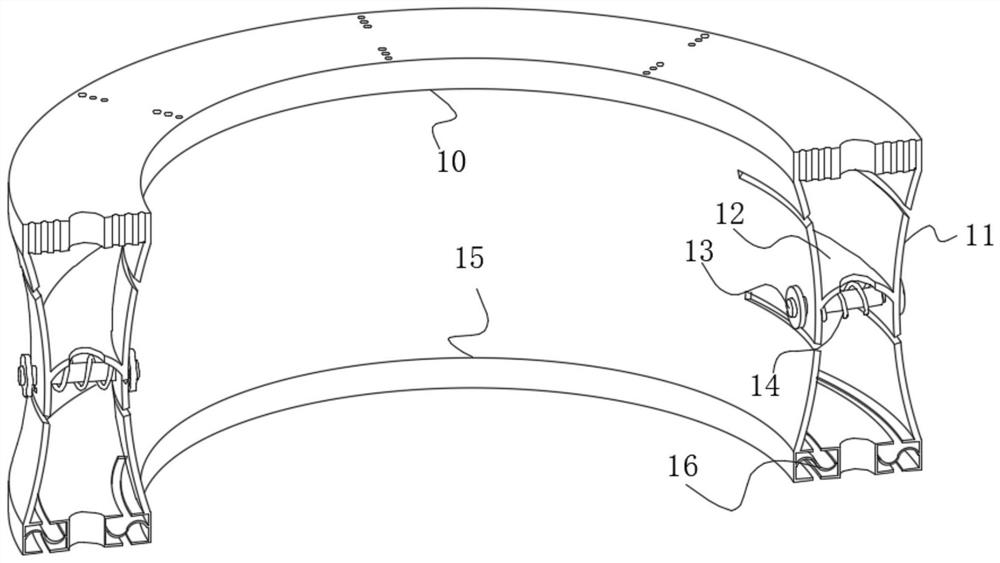

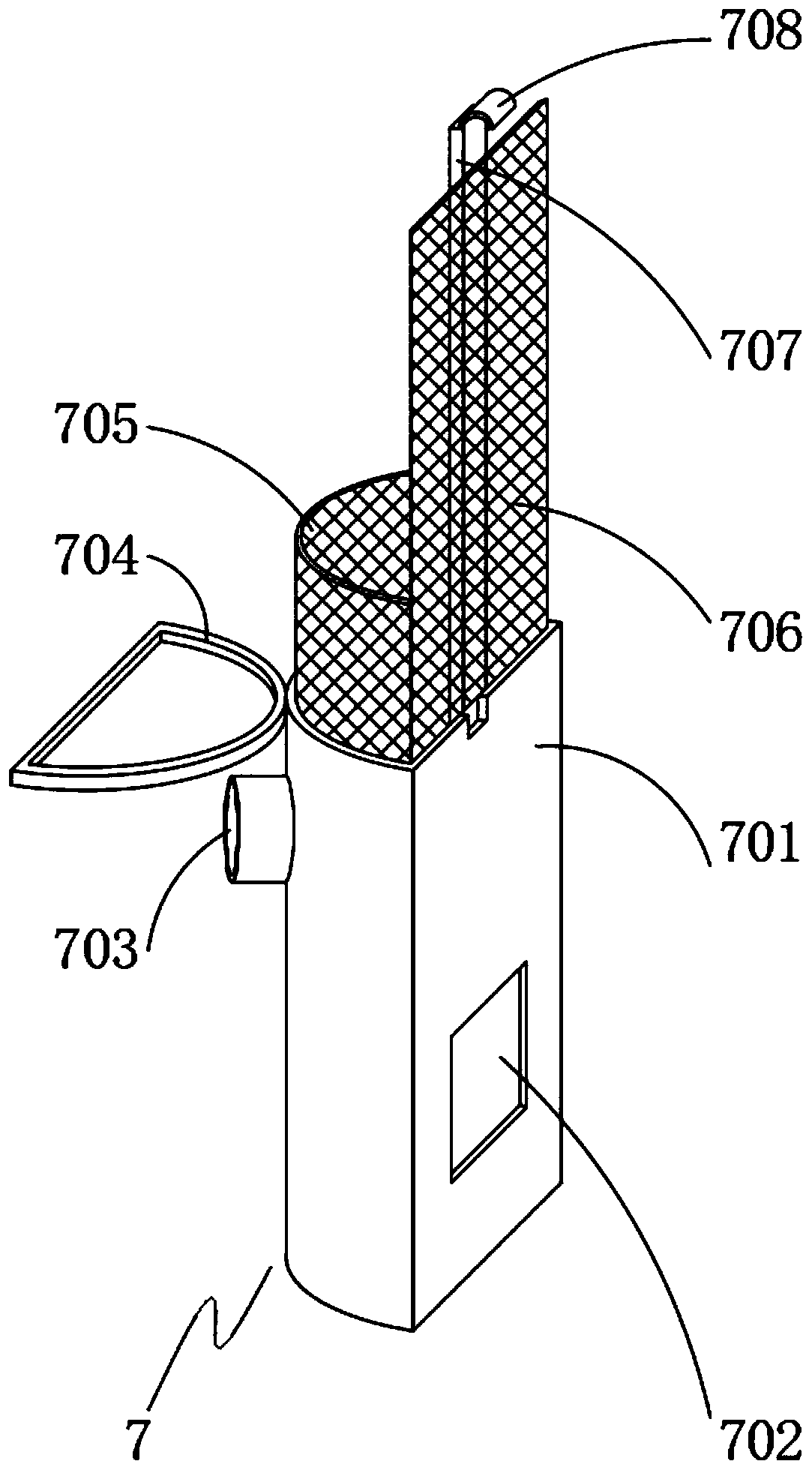

Rotary textile wastewater treatment device and use method

InactiveCN112209572AOxygen distributionSpread evenlyTreatment using aerobic processesWater contaminantsMicroorganismFiltration

The invention discloses a rotary textile wastewater treatment device and a use method, belongs to the field of sewage treatment, and can realize that textile wastewater is injected into a reaction treatment bin by technicians, then a rotary ring sleeve is arranged on a treatment stand column in a sleeving manner, the rotary ring sleeve falls down along with gravity, a water dissolving block is dissolved firstly, quicklime particles react with water to release heat, heat transfer accelerates movement of substances around textile wastewater, then a heat collecting plate is used for covering to transfer heat to enable an expansion air bag to expand, then the internal pressure of a compressed air film is increased, when a second dissolving block is dissolved, oxygen in the compressed air filmis jetted out due to increase of the pressure, the rotating ring sleeve is driven by a power paddle to rotate, oxygen is uniformly dispersed in the textile wastewater in order to increase the oxygen content of a water body and supply oxygen for subsequent purification of microorganisms, fibrous impurities in the textile wastewater are connected through an arc-shaped intercepting hook and a side branch hook to be wound and recycled, and collection and filtration are completed.

Owner:黄建秋

Floating type textile wastewater flocculent fiber recovery device

InactiveCN111874964AIncrease buoyancyEfficient separationTreatment involving filtrationWater/sewage treatment by heatingFiberProcess engineering

The invention discloses a floating type textile wastewater flocculent fiber recovery device, which belongs to the field of wastewater treatment, and is characterized in that a power distribution motoris started, a hollow main body ball is put into a wastewater treatment bin, a rotating shaft drives a propelling blade to rotate, and the hollow main body ball rotates forwards to stir wastewater, sothat flocculent fiber separation is more efficient; when the hollow main body ball moves forwards in a rotating mode, the friction heat generation ring generates heat with the annular friction stripin a friction mode, the expansion butt joint hemispheres and the thermal expansion extrusion balls generate thermal expansion, the pair of expansion butt joint hemispheres are in butt joint to block flocculent fibers, and the thermal expansion extrusion balls expand to extrude the flocculent fibers; therefore, the possibility of separation is reduced, and fine particles of wastewater are filteredby filtering strip-shaped membrane at same time; when heat generated by friction reaches the hot melting point of the release ball membrane, hydrogen peroxide released by hot melting of the release ball membrane reacts with manganese dioxide to be decomposed, so that gas is generated to improve the buoyancy of the hollow rotating ball, and the hollow main body ball and flocculent fibers are collected and treated.

Owner:姜玲华

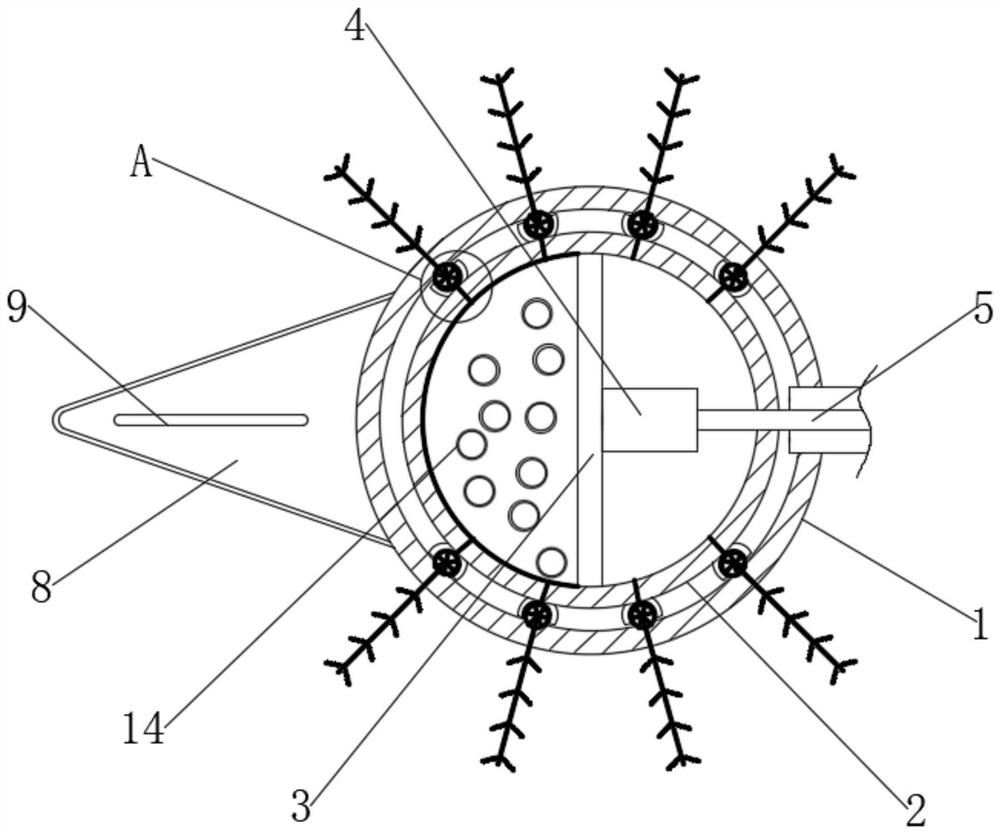

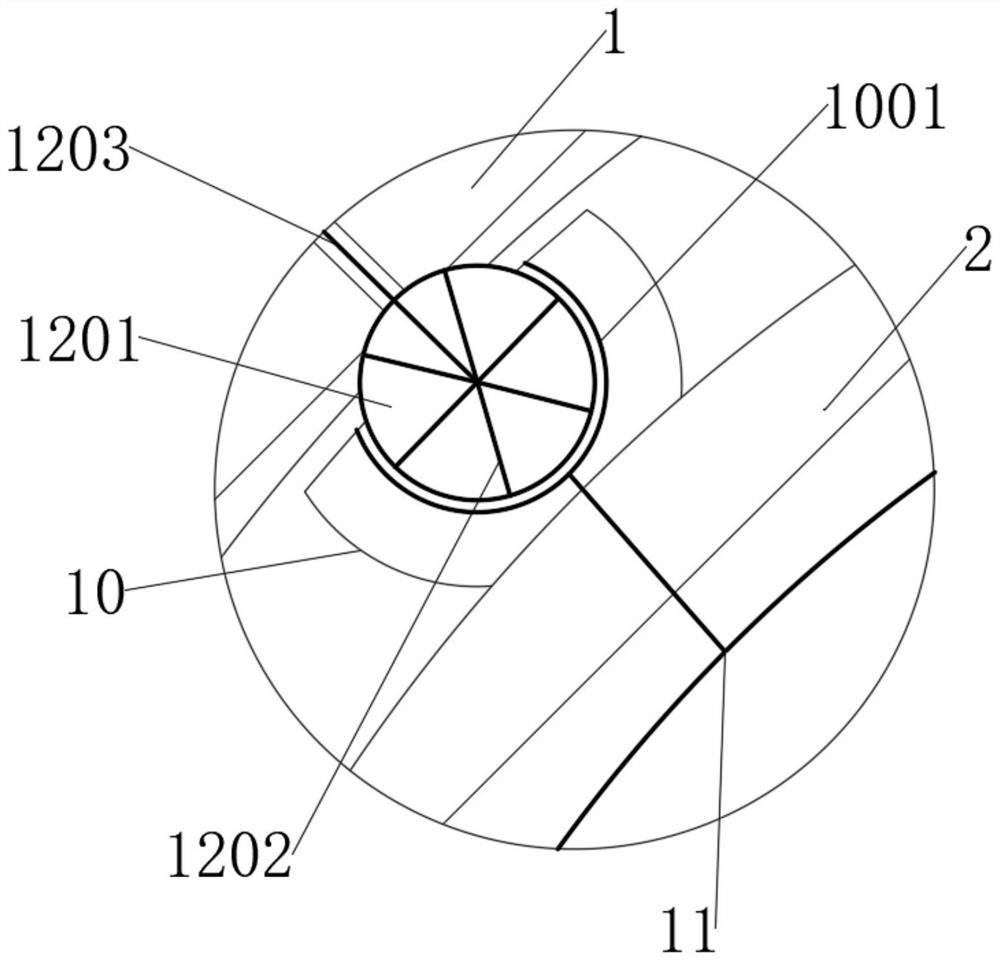

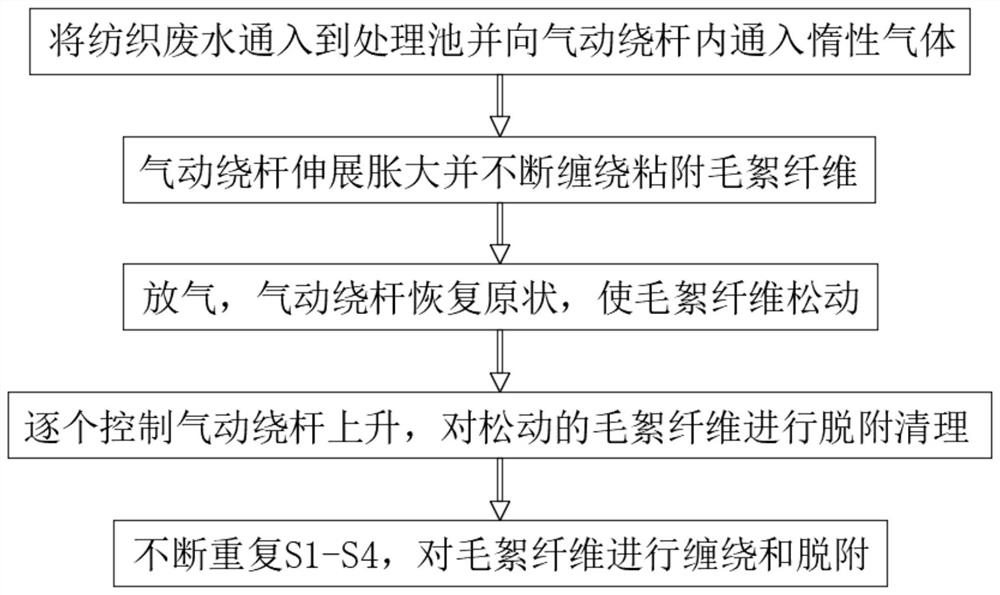

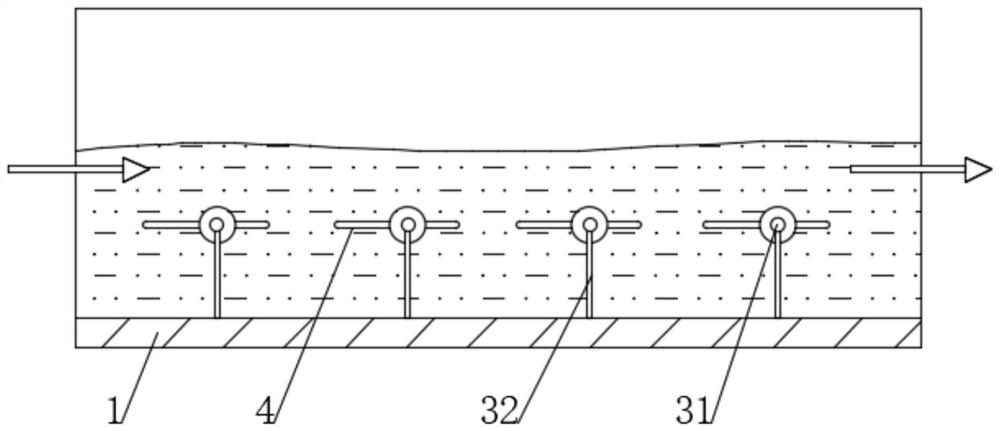

Fluff fiber treatment method for pneumatic desorption type textile wastewater

InactiveCN111792698AImprove processing efficiencyIncreased winding adsorptionWater treatment parameter controlSpecific water treatment objectivesFibre treatmentPhysical chemistry

The invention discloses a fluff fiber treatment method for pneumatic desorption type textile wastewater, and belongs to the field of wastewater treatment. In the fluff fiber treatment method for pneumatic desorption type textile wastewater, pneumatic winding rods are arranged, firstly, the pneumatic winding rods are inflated so as to be stretched and expanded, and the rotation of the pneumatic winding rods is controlled to carry out winding adsorption of fluff fibers; and in desorption, the pneumatic winding rod is deflated, the gas support is lost inside, the central winding rod and the extension side winding rod are in a flat state, at the moment, wound batting fibers are not tightly wound with the central winding rod and the extension side winding rod, meanwhile, through cooperation with the effects of the surface layer winding sheet and the embedded winding layer, the winding adsorption effect of the surface of the pneumatic winding rods on fluff fibers can be effectively improvedunder the condition that fluff fiber desorption is not affected, and then the treatment efficiency of the method on textile wastewater is remarkably improved.

Owner:罗培佳

Ultrasonic treatment system for separating compounds from aqueous effluent

Novel ultrasonic treatment systems for separating compounds in an aqueous effluent and processes for using the ultrasonic treatment systems are disclosed. More particularly, the ultrasonic treatment systems use ultrasonic energy to energize adsorbent to provide efficient and effective removal of compounds from aqueous effluents, such as textile effluents.

Owner:KIMBERLY-CLARK WORLDWIDE INC

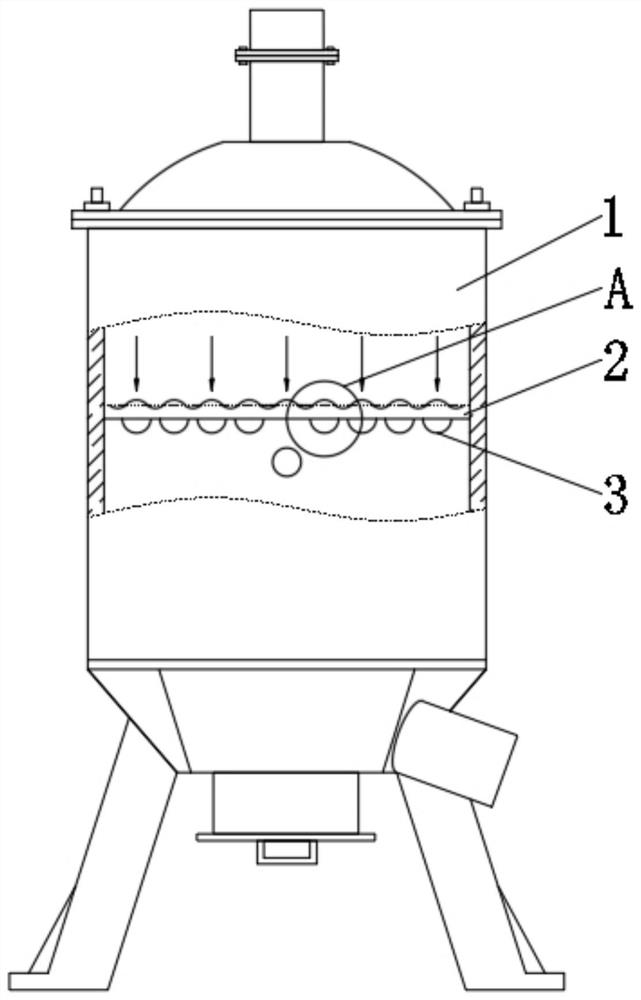

Textile wastewater filtering method

InactiveCN112569660AThe number of "slag removal" has increasedEasy to cleanStationary filtering element filtersTextile technologyWater flow

The invention provides a textile wastewater filtering method, and belongs to the technical field of textiles. Wherein when waste water with the small residue chip concentration is treated, a gear motor is firstly started to enable all rotating rings to slowly rotate in the direction opposite to the water flow direction, the rotating speed of the rotating rings is suitable for enabling the waste water not to enter the position where a limiting guide block is located as much as possible, and horizontal-flow textile waste water is conveyed into a water inlet connecting pipe; after the sensor is triggered at any position, a negative pressure pump is started, supply of waste water is suspended, a heating piece is powered on, fabric scraps adhering to the filter screens are burnt at high temperature to form scraps, the scraps are pumped away from the filter screens under the action of negative pressure, water is supplied again after the filter screens are cleaned multiple times, the negativepressure pump is turned off, and the heating piece is powered off; and when the wastewater with relatively high residue and scrap concentration is treated, the filter screen is cleaned in a state ofsuspending water supply. The method has the advantages of high efficiency and the like.

Owner:台州市涌星贸易有限公司

Textile wastewater oil absorption device based on low-temperature separation technology

InactiveCN111908709ANot easy to rustExtended service lifeSievingFatty/oily/floating substances removal devicesTextile technologySeparation technology

The invention discloses a textile wastewater oil absorption device based on a low-temperature separation technology, belongs to the technical field of textiles. Based on the scheme that a semiconductor chilling plate is started to cool textile wastewater in an oil absorption tank, nitrogen dioxide gas is promoted to be continuously converted into nitrogen tetroxide, and the magnetic insulation effect of the nitrogen dioxide gas on an auxiliary magnet ball is improved, so that the separation oil absorption double balls are separated from the adsorption ball carrying frame. In addition, the adsorption balls can be dragged to move towards oil stains by virtue of the oleophylic characteristic of Gordonia in a Gordonia culture solution, the oil stains are adsorbed by virtue of coke coarse grains, and the inner phase change ball frame can be forced to shrink due to temperature reduction until a deformed film is punctured by a puncture needle, so that the oil stains are adsorbed by virtue ofcoke coarse grains; therefore, water in the textile wastewater reacts with the sodium peroxide powder; on one hand, oxygen can be provided for life activities of the Gordonia culture solution, and onthe other hand, by means of heat released by the reaction and generated sodium hydroxide, dissolution of grease in the wastewater can be accelerated.

Owner:段孝辉

Failure self-desorption type textile wastewater treatment device

InactiveCN113058314AJamming is effectiveImprove congestionStationary filtering element filtersWater flowProcess engineering

The invention discloses a failure self-desorption type textile wastewater treatment device, and belongs to the technical field of wastewater treatment. A plurality of dredging balls can be adsorbed below a filter layer, gas can be triggered to generate actions after the dredging balls are in contact with filtered wastewater, and the gas is utilized to push a dredging chain to preliminarily dredge the filter layer; after dredging of the dredging chain is finished, the gas enters wastewater and then forms bubbles, the blocked filter layer is effectively dredged by means of instantaneous impact force generated when the bubbles burst, and the action is continuous, so that water flow at the filter layer is always in a fluctuating state within a long time period, and the blockage condition at the filter layer can be effectively improved; and meanwhile, after the dredging balls lose efficacy, the adsorption effect of the filter layer on the dredging balls can be lost, so that self-desorption to wait for recovery is realized, a new dredging ball is used for replacement and position complementing, and high-efficiency wastewater treatment can be always kept.

Owner:杭州罗松贸易有限公司

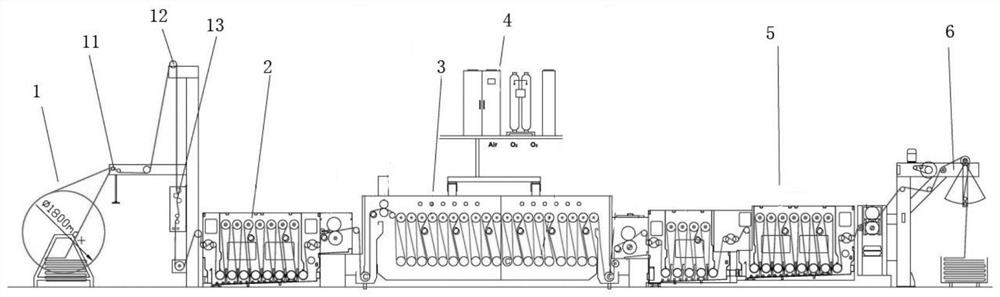

Ozone finishing method for textile cloth

PendingCN112853648ASimple processEmission reductionLiquid/gas/vapor treatment machines driving mechanismsFibre treatmentRinse waterPulp and paper industry

The invention provides an ozone finishing method for textile cloth. The ozone finishing method comprises the steps that 1, the textile cloth enters a pre-washing device assembly through a cloth feeding device for pre-washing of the textile cloth; 2, the textile cloth enters an ozone finishing assembly from the pre-washing device assembly through traction of the ozone finishing assembly; 3, an ozone production device continuously supplies ozone gas to the ozone finishing assembly for performing ozone finishing on the total textile cloth of the ozone finishing assembly; 4, the textile cloth is pulled by a washing device assembly to enter the washing device assembly from the ozone finishing assembly to be washed; and 5, the washed textile cloth is pulled by a cloth discharging device to enter the cloth discharging device to be discharged and placed. According to the ozone finishing method disclosed by the invention, the textile cloth enters the ozone finishing assembly to be subjected to ozone finishing, so that a rinsing mode combining water washing with preparations in a traditional technology is replaced, a large amount of rinsing water is saved, and meanwhile, a large amount of textile wastewater is reduced; and the process flow of the textile cloth is simplified.

Owner:博格曼(江苏)纺织科技有限公司

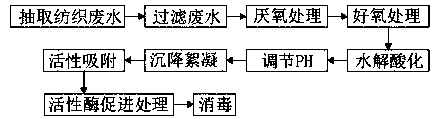

Treatment process for textile wastewater

ActiveCN104291494AGood effectAdapt to a wide pH rangeWater treatment compoundsTreatment involving filtrationProcess engineeringSewage treatment

The invention discloses a treatment process for textile wastewater. The treatment process for the textile wastewater comprises the following steps: after textile wastewater is filtered via a grizzly screen, the textile wastewater sequentially enters a first sedimentation tank and a second sedimentation tank; the textile wastewater is treated by coagulants and is filtered. According to the treatment process for the textile wastewater provided by the invention, only the coagulant is adopted to treat the textile wastewater and a favorable wastewater treatment effect can be reached; generated condensation objects are solid and less prone to damages; the precipitation performance is good; the decolorizing effect and oil removing effect are good; moreover, the coagulant provided by the invention is adapted to large range of PH values; the thermal stability is high and the effect is stable.

Owner:浙江腾马纺织有限公司

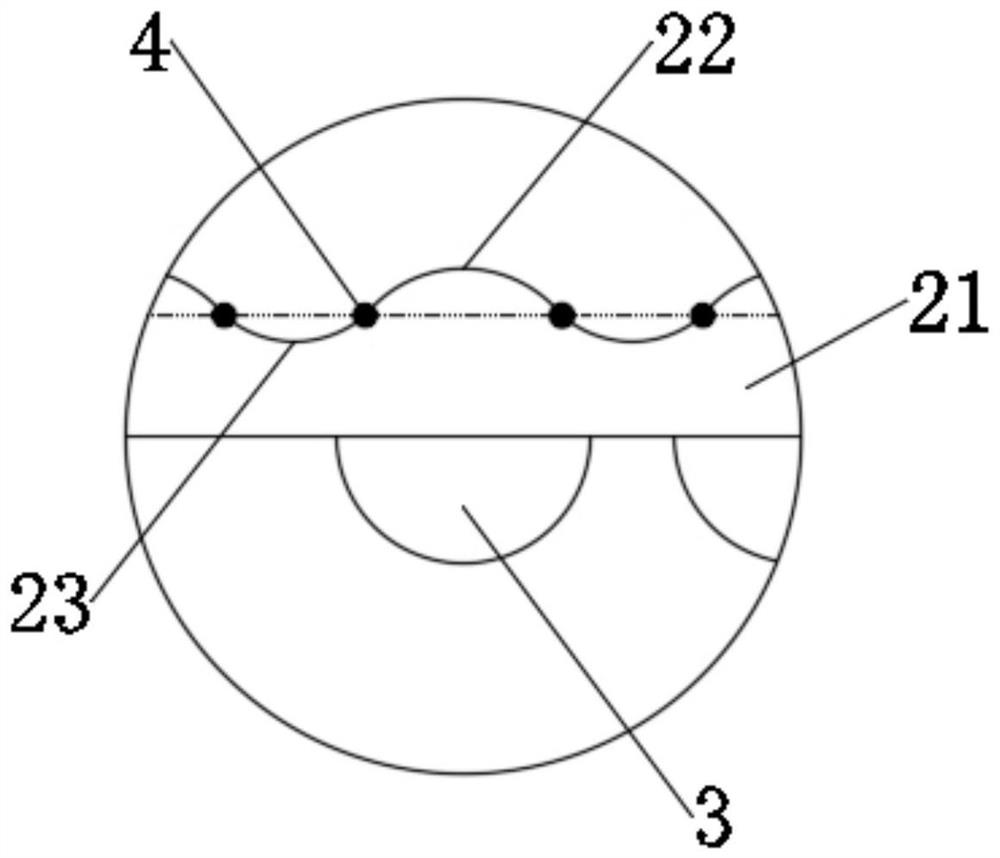

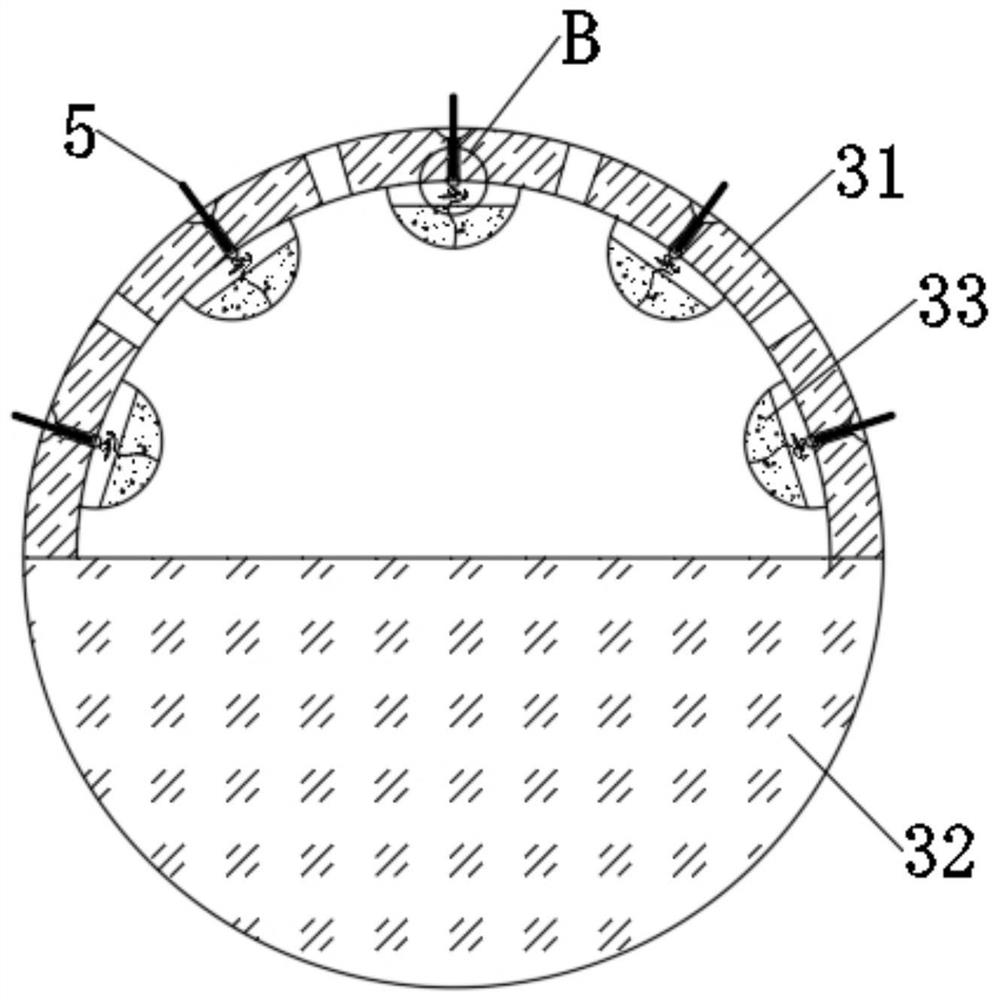

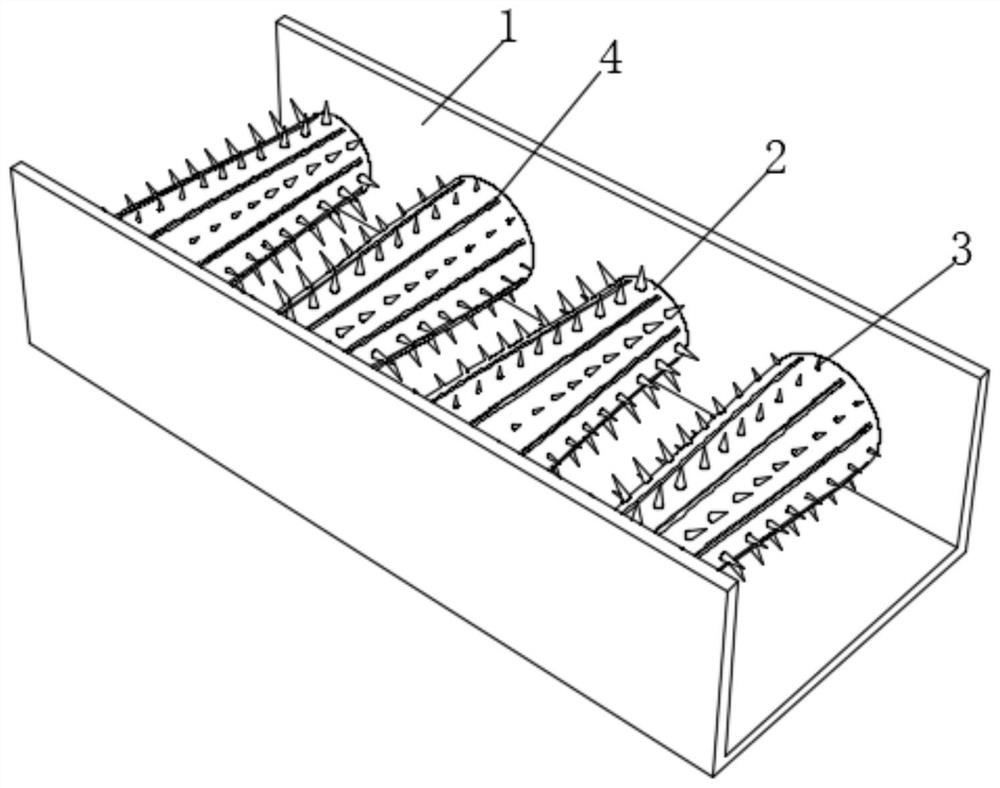

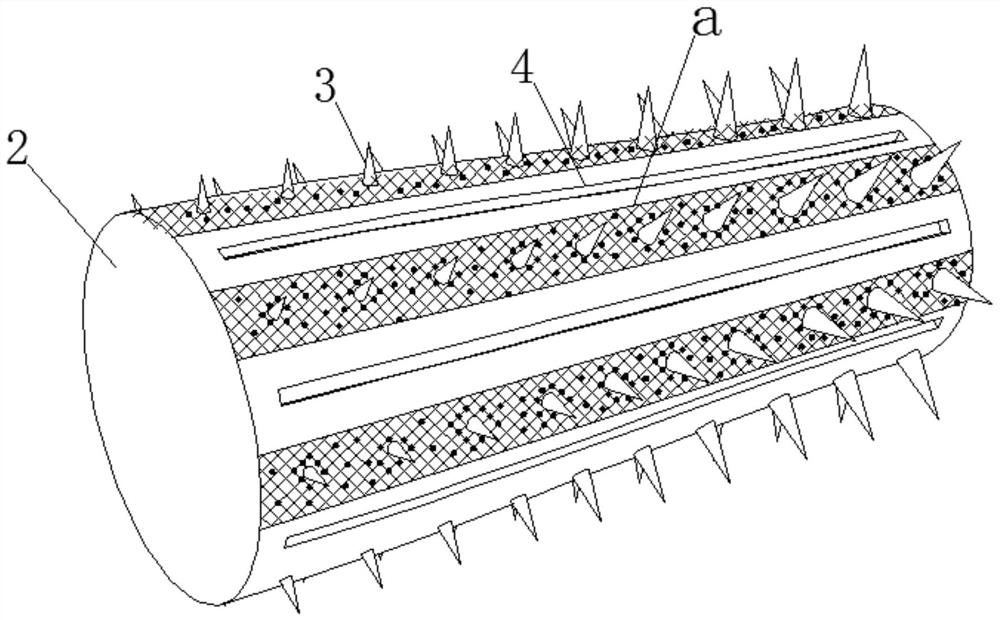

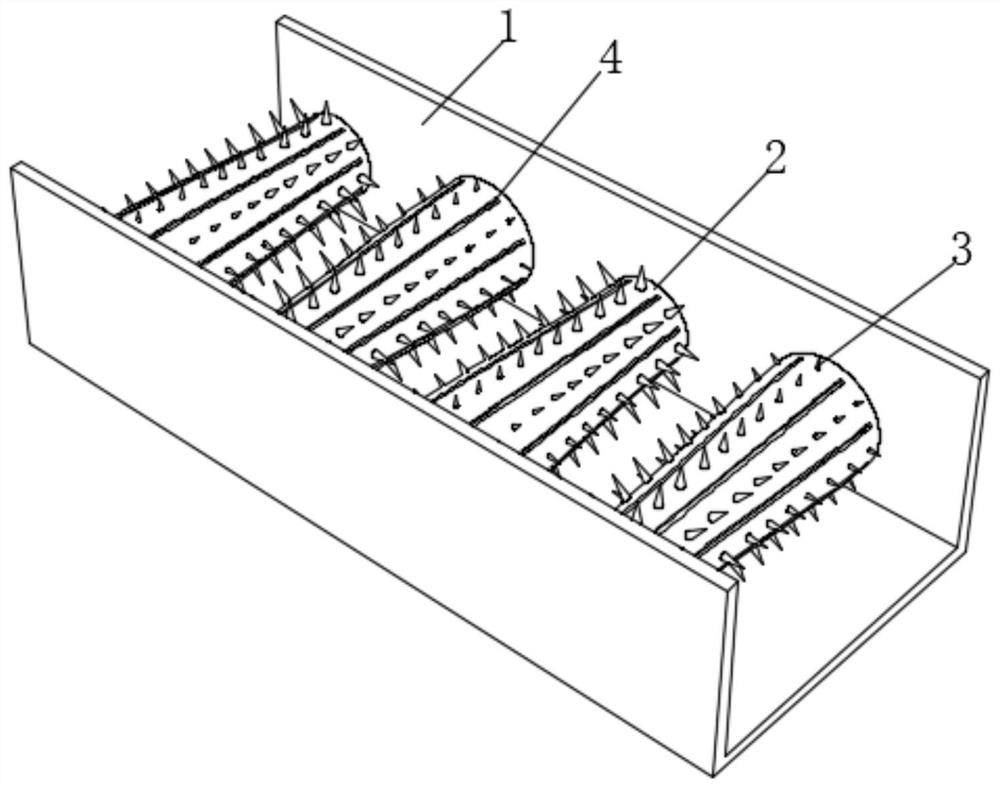

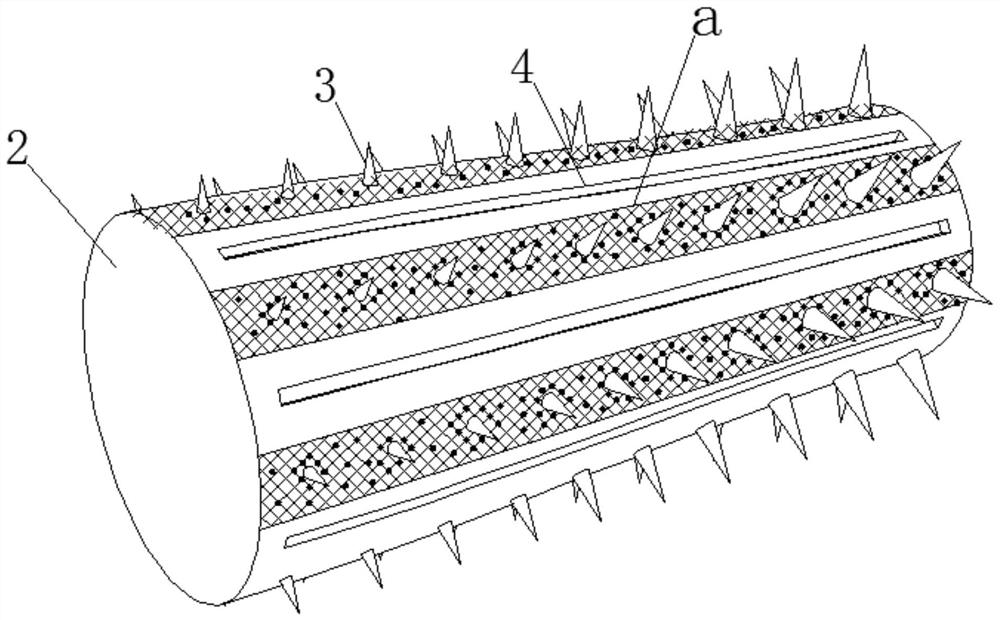

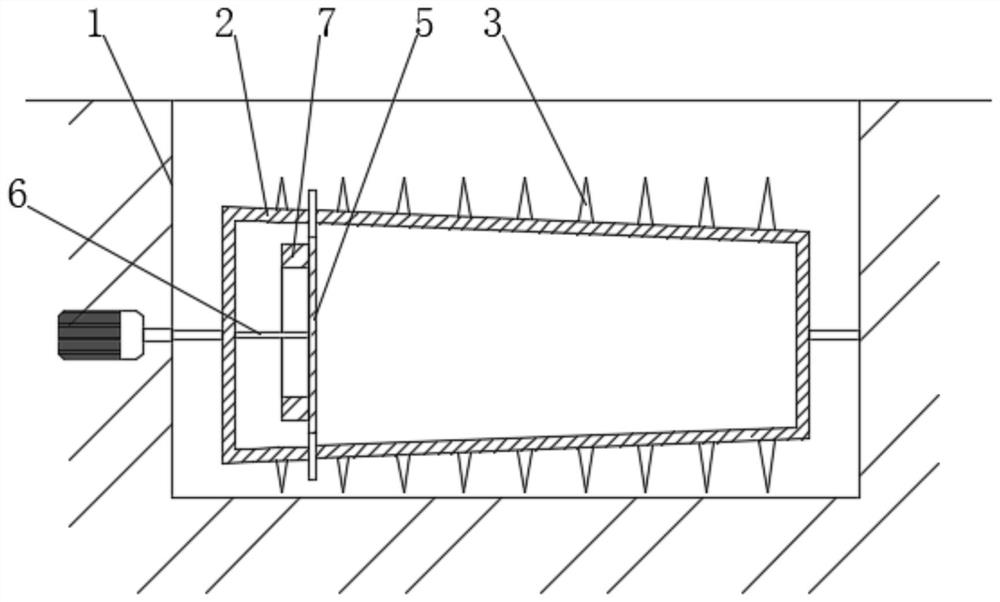

Wall-attached undulating textile effluent fiber intercepting and crushing device

ActiveCN111659496ATop works obviouslyGood effectSpecific water treatment objectivesWater/sewage treatmentPolymer scienceEngineering

The invention discloses a wall-attached undulating textile effluent fiber intercepting and crushing device, and belongs to the field of textile effluent treatment. According to the wall-attached undulating textile effluent fiber intercepting and crushing device, by arranging transverse crushing edges inside uneven crushing cylinders, wool fibers intercepted on the surfaces of the uneven crushing cylinders can be transversely cut off in the direction of the uneven crushing cylinders, and thus the winding degree between the wool fibers is effectively lowered; and meanwhile, in the cutting and crushing processes, due to the mutual repulsion action between undulating magnetic-control rings and magnetic points, the undulating magnetic-control rings can continuously jack up wall-attached loosening pieces from the inside in the process of moving rightwards with transverse crushing blades, so that the wall-attached loosening pieces drive the wool fibers to undulate continuously, the wool fibers are effectively loosened, the adhesion degree between the wool fibers and the uneven crushing cylinders is effectively lowered, and thus the difficulty of clearing the wool fibers wound around the uneven crushing cylinders is effectively reduced.

Owner:山东西盟罗盾服饰有限公司

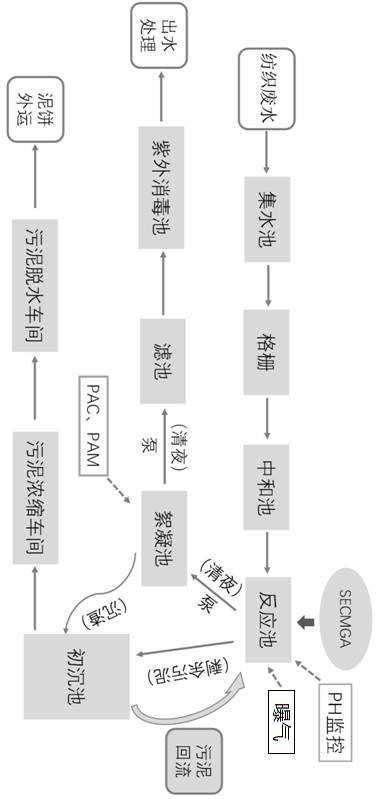

A kind of treatment agent for textile wastewater, preparation method and treatment process thereof

ActiveCN108658251BStrong catalytic oxidation abilityProcess improvement and perfectionSludge treatmentWater/sewage treatment by irradiationBiochemical engineeringProcess engineering

The invention discloses a treatment agent for textile waste water, a preparation method and a treatment process thereof, belonging to the technical field of sewage treatment, including nano-enzyme SECMGA, and activator WRLL and activator BOJF for activating nano-enzyme SECMGA; the nano-enzyme The enzyme SECMGA is activated before use, and the activator WRLL and the activator BOJF are respectively the required agents for activating the original ecological SECMGA; the activator WRLL is also the required agent for activating the transition state SECMGA to the activated state SECMGA . The treating agent of the invention has simple technical process for textile wastewater treatment, low equipment investment, automatic control, flexible operation and convenient management, and is suitable for large-scale use in wastewater treatment workshops of textile enterprises.

Owner:南京乐透思高新材料科技有限公司

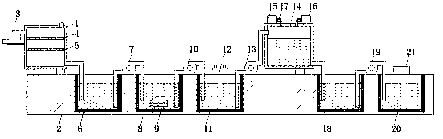

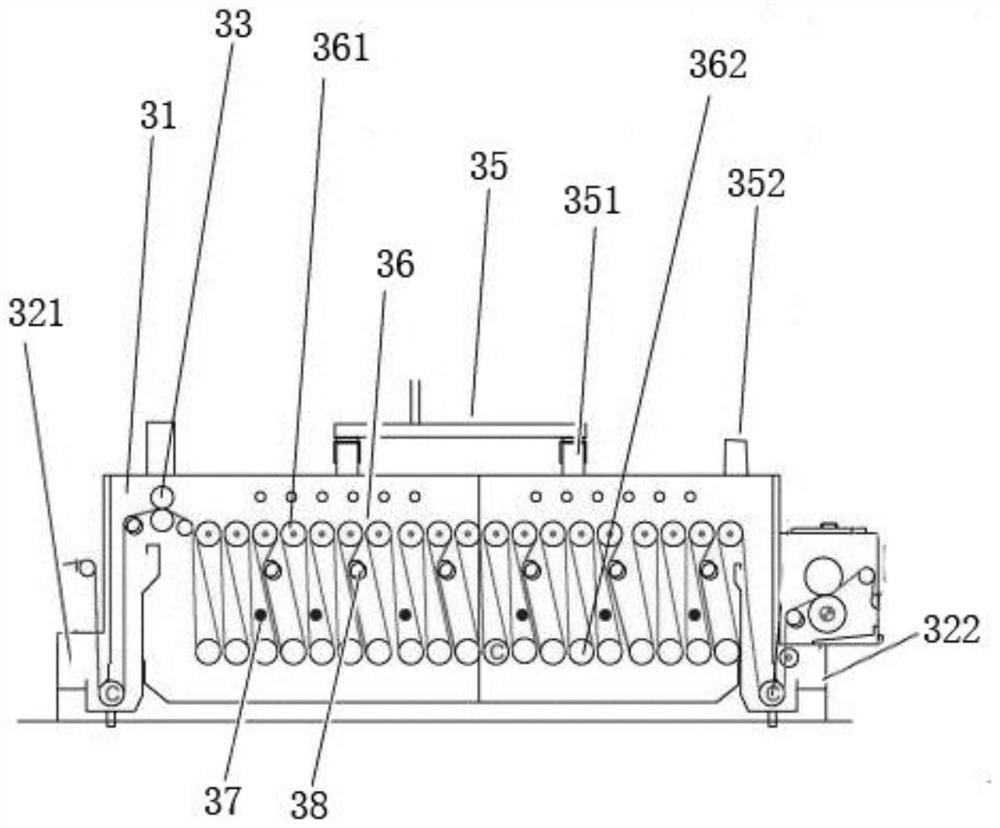

Yarn dyeing and finishing wastewater treatment equipment and treatment process thereof

InactiveCN109836019AImprove processing efficiencyMeet emission standardsMultistage water/sewage treatmentWaste water treatment from textile industryFiberYarn

The invention discloses an yarn dyeing and finishing wastewater treatment equipment and a treatment process thereof, and the wastewater treatment process comprises the following steps: step 1, extracting textile wastewater, to be more specific, a first sewage pump is used for pumping the textile wastewater to the inner cavity of a filter box, and the flow rate is controlled to be 1500-2000 m<3> / hduring extraction; and step 2, filtering the wastewater, to be more specific, when the wastewater passes through a first filter screen and a second filter screen, the first filter screen is used for primarily filtering residual large solid particle impurities or fibers in the wastewater, and the second filter screen is used for carrying out secondary filtration on residual small solid particle impurities or fibers in the wastewater. The process solves the problems that an existing yarn dyeing and finishing wastewater treatment process is poor in treatment effect, and an emission standard is difficult to achieve in practical application, the yarn dyeing and finishing wastewater treatment process is simple, the wastewater treatment effect is good, the wastewater can rapidly reach the emission standard in practical application, the treatment stability is high, the treatment effect is good, and the wastewater treatment efficiency is improved.

Owner:平湖市三禾染整股份有限公司

A wall-attached undulating textile wastewater fiber interception and crushing device

ActiveCN111659496BReduce entanglementPlay a role in looseningSpecific water treatment objectivesWater/sewage treatmentEngineeringPulp and paper industry

The invention discloses a wall-adhering undulating textile wastewater fiber intercepting and crushing device, which belongs to the field of textile wastewater treatment. A wall-adhering and undulating textile wastewater fiber intercepting and crushing device passes through the transverse crushing blade inside the uneven crushing cylinder. The setting of the uneven crushing cylinder can cut the wool fibers intercepted on its surface transversely along the direction of the uneven crushing cylinder, thereby effectively reducing the degree of entanglement between the wool fibers. At the same time, during the cutting and crushing process, due to the undulating magnetic ring Mutual repulsion with the magnetic point makes the ups and downs control magnetic ring continuously lift up the wall-adhering loosening piece from the inside when moving to the right with the transverse crushing knife, so that the wall-attaching helping loosening piece carries the wool fiber Continuous undulations can effectively loosen the wool fibers, effectively reduce the adhesion between the wool fibers and the uneven crushing cylinder, and then effectively reduce the difficulty of cleaning the wool fibers entangled on the uneven crushing cylinder.

Owner:山东西盟罗盾服饰有限公司

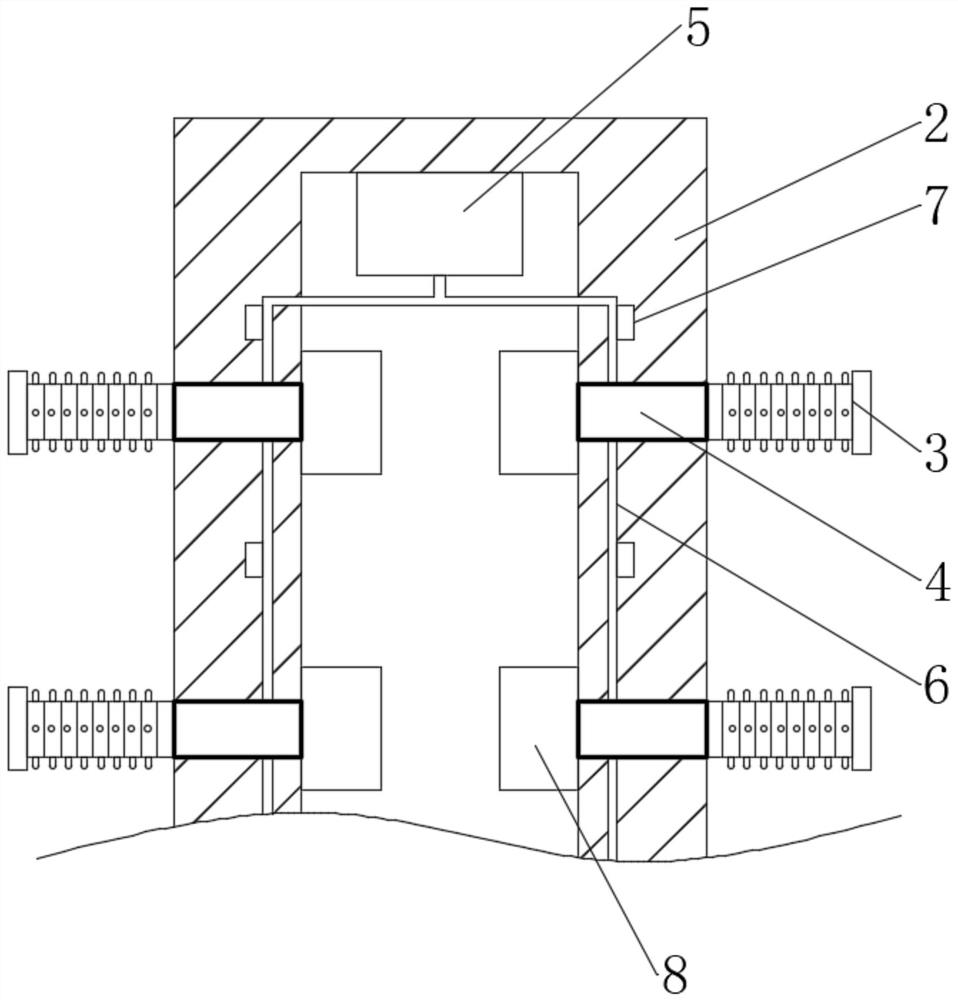

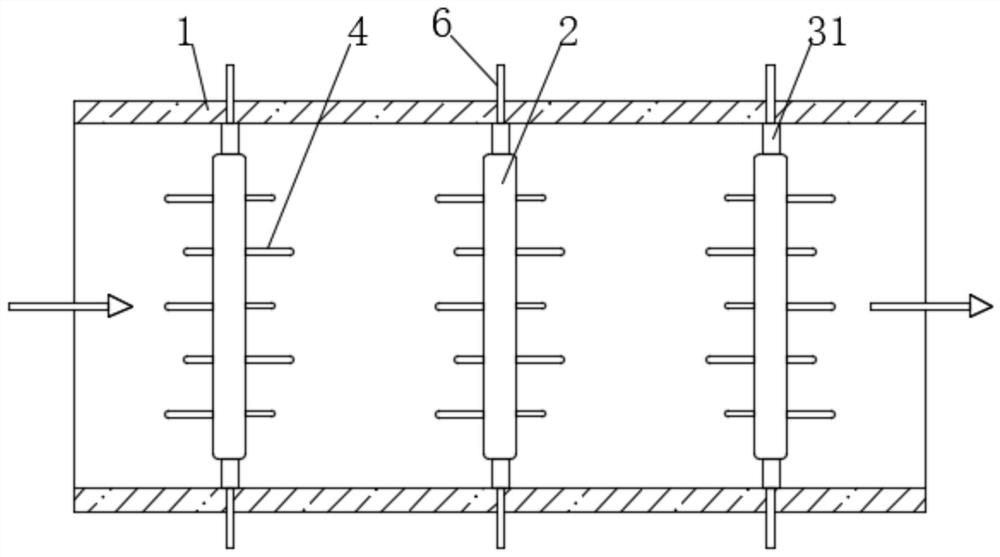

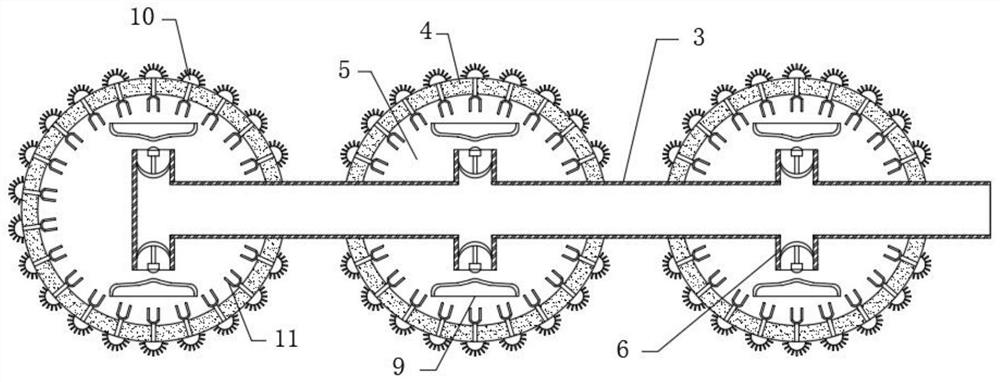

Textile wastewater interception type pretreatment equipment

ActiveCN113443777AEfficient retentionReduce sheddingTreatment involving filtrationWater/sewage treatment by magnetic/electric fieldsFiberWater flow

The invention discloses textile wastewater interception type pretreatment equipment, and belongs to the technical field of wastewater treatment.The interception type pretreatment equipment can guide and distribute the textile wastewater through a guide core column, accelerate and guide the textile wastewater to a preset annular interception groove, and fibers in the annular interception groove can make full contact with an interception magnetic column by means of impact of water flow, therefore, the interception magnetic column can effectively intercept the fibers in the wastewater; meanwhile, a plurality of magnetic wrapping balls are arranged at a water inlet pipe and can enter the annular interception groove along with the wastewater, and the magnetic wrapping balls can be tightly arranged on the interception magnetic column in a sleeving manner to wrap the intercepted fibers by utilizing the magnetic attraction force of the interception magnetic column to the magnetic wrapping balls, therefore, the possibility that the fibers fall back into water again under the action of water flow is reduced, the interception effect on the fibers is improved, and the filtering pressure of follow-up treatment equipment can be greatly relieved.

Owner:青山绿水(南通)检验检测有限公司

Textile wastewater purifying and recycling device

InactiveCN113582421AExtend the rest timeIncrease contact areaWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesActivated carbonLiquid water

The invention belongs to the field of textile wastewater recycling, and particularly relates to a textile wastewater purifying and recycling device which comprises an outer cover. The upper surface of the outer cover is fixedly connected with a water inlet pipe, and the upper surface of the outer cover is fixedly connected with a machine body through a connecting pipe. According to the textile wastewater purifying and recycling device, a secondary settling chamber is arranged, after impurities are discharged from a through hole, the accumulated impurities are discharged out of the device from a blow-off pipe, residual liquid water is adsorbed by a multilayer plate and activated carbon, pigments and toxins in the water body are absorbed, large-particle impurities are separated from the water through standing of the standing mechanism, small-particle impurities are separated out while the pH value of the water body is changed through the centrifugal effect and thermal denaturation of organic matter through a centrifugal mechanism, and finally harmful substances in the water body are adsorbed through sedimentation of the secondary sedimentation chamber, so that the purification effect is improved compared with traditional single-stage purification and multi-stage purification, and the problem that a traditional single-stage purification device is poor in purification effect is solved.

Owner:颜茗

Energy-saving washing system for textile cloth

PendingCN112853659AEmission reductionSave rinse waterSucessive textile treatmentsDispersed particle separationRinse waterProcess engineering

The invention provides an energy-saving washing system for textile cloth. The energy-saving washing system comprises a cloth feeding device through which the textile cloth enters the washing system; a pre-washing device assembly connected to the cloth feeding device; an ozone finishing assembly connected to the pre-washing device assembly; an ozone production device in communication with the ozone finishing assembly to supply ozone to the ozone finishing assembly; a washing device assembly connected to the ozone finishing assembly to pull the textile cloth into the washing device assembly from the ozone finishing assembly so as to wash the textile cloth; and a cloth discharging device connected to the washing device assembly so as to pull the textile cloth out of the washing device assembly. According to the energy-saving washing system for the textile cloth, ozone finishing is carried out through the ozone finishing assembly, the rinsing mode that in the traditional technology, washing is adopted in cooperation with a preparation is replaced, a large amount of rinsing water is saved, and meanwhile discharge of a large amount of textile waste water is reduced.

Owner:博格曼(江苏)纺织科技有限公司

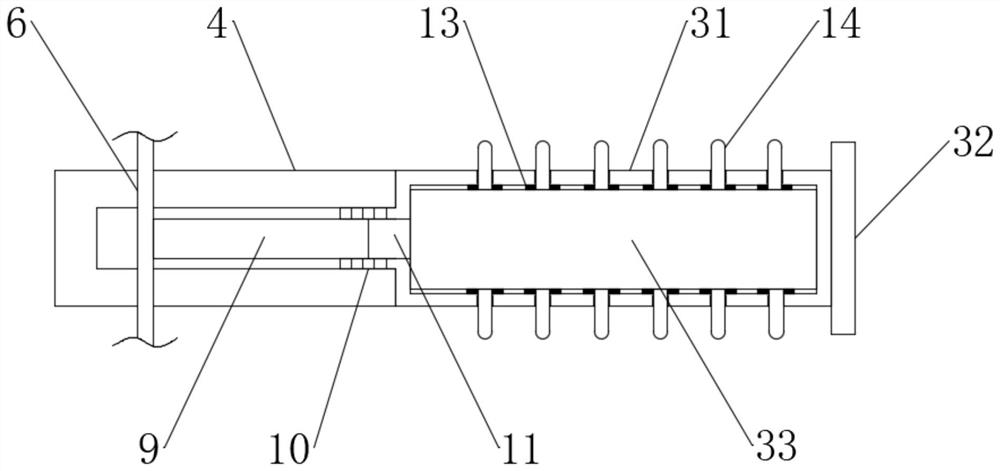

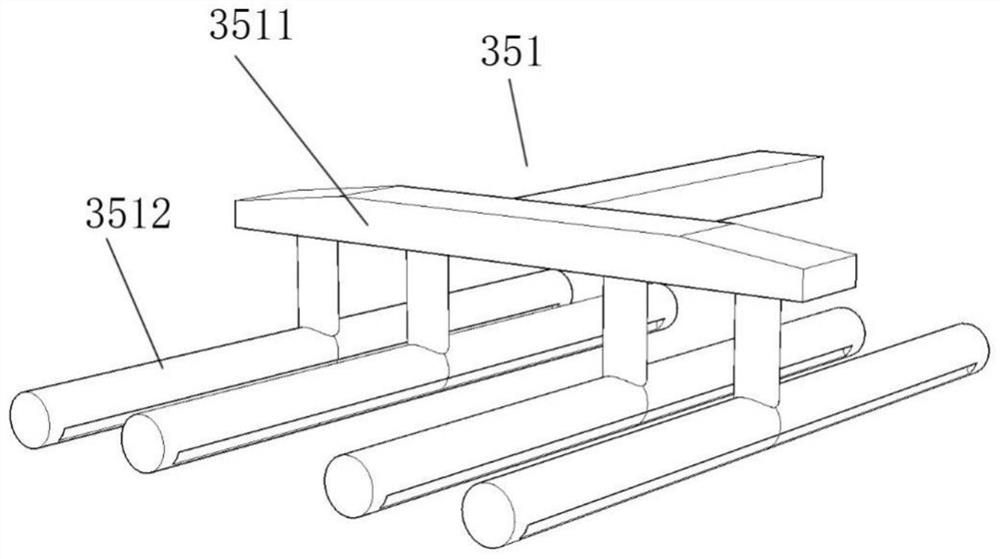

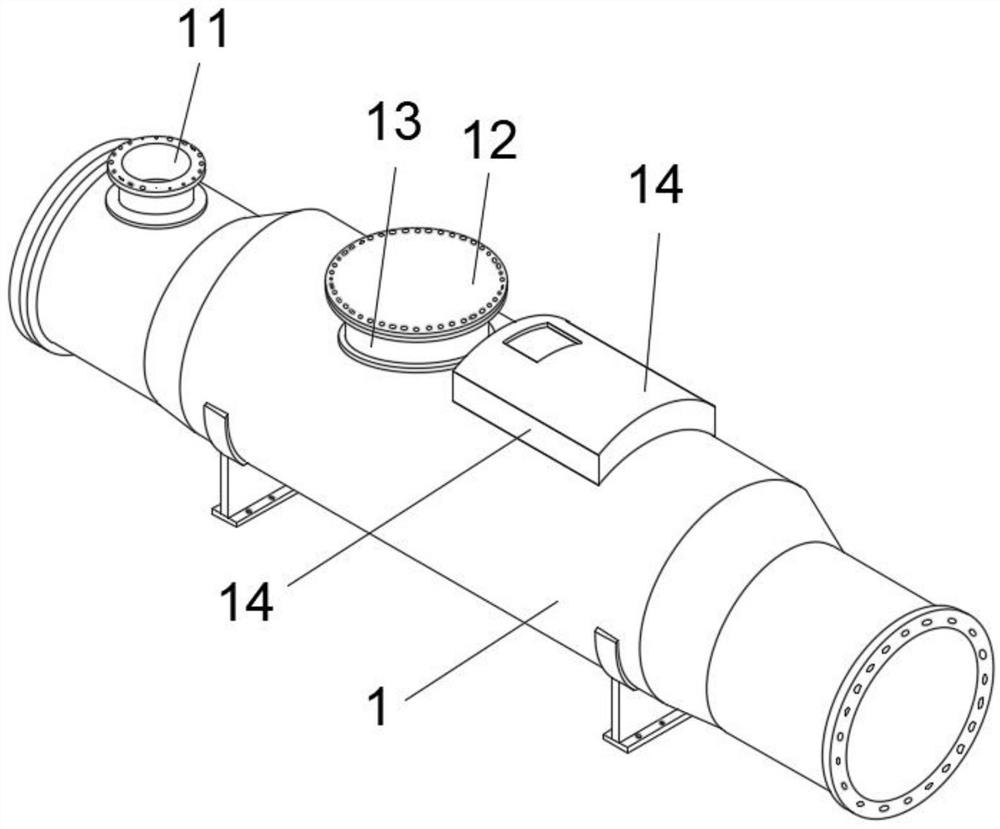

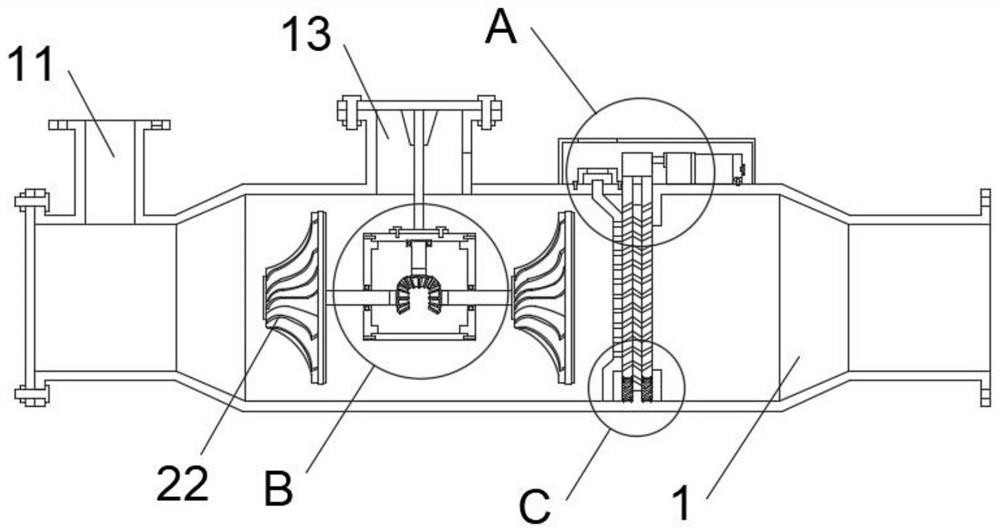

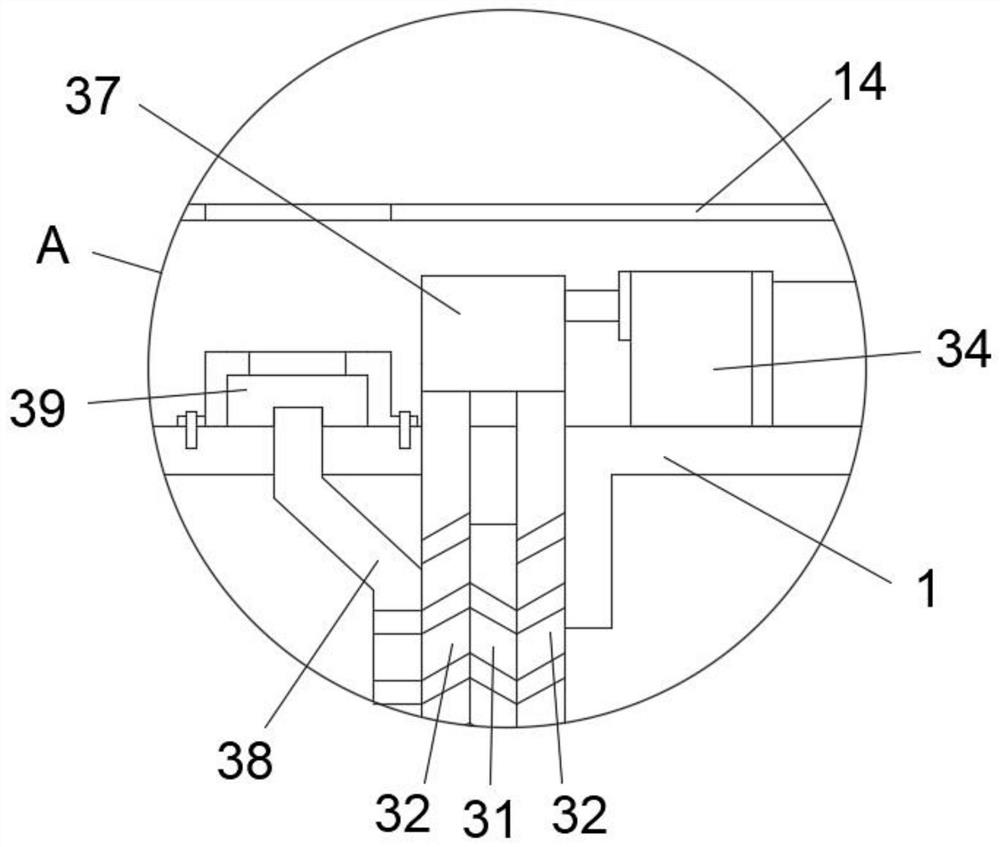

Textile production wastewater treatment flocculation and cutting device

InactiveCN112892072AIncreased turbulenceEasy and quick passGrain treatmentsFiltration circuitsFiberForeign matter

The invention relates to the technical field of textile wastewater treatment equipment, in particular to a textile production wastewater treatment flocculation and cutting device which structurally comprises a pipe body, a turbulent flow device and a flocculation and cutting device. The turbulent flow device is used for reducing the flow speed of large batting and long fibers of foreign matter, and the situation that the large batting and long fibers directly pass through filter holes under the impact of water flow can be avoided, the large batting and long fibers are hinged off through cooperation of the movable filter plate and the fixed filter plate, the problems that small batting and short fibers cannot pass through filter holes of the filter plates and the filter screen needs to be replaced when the filter screen is quickly scrapped due to the fact that the filter holes of the filter screen and the filter plate are blocked by fluff and fibers can be effectively solved, and the device has practical significance and popularization value and is expected to generate good economic benefits.

Owner:泉州永春信凯机械设备有限公司

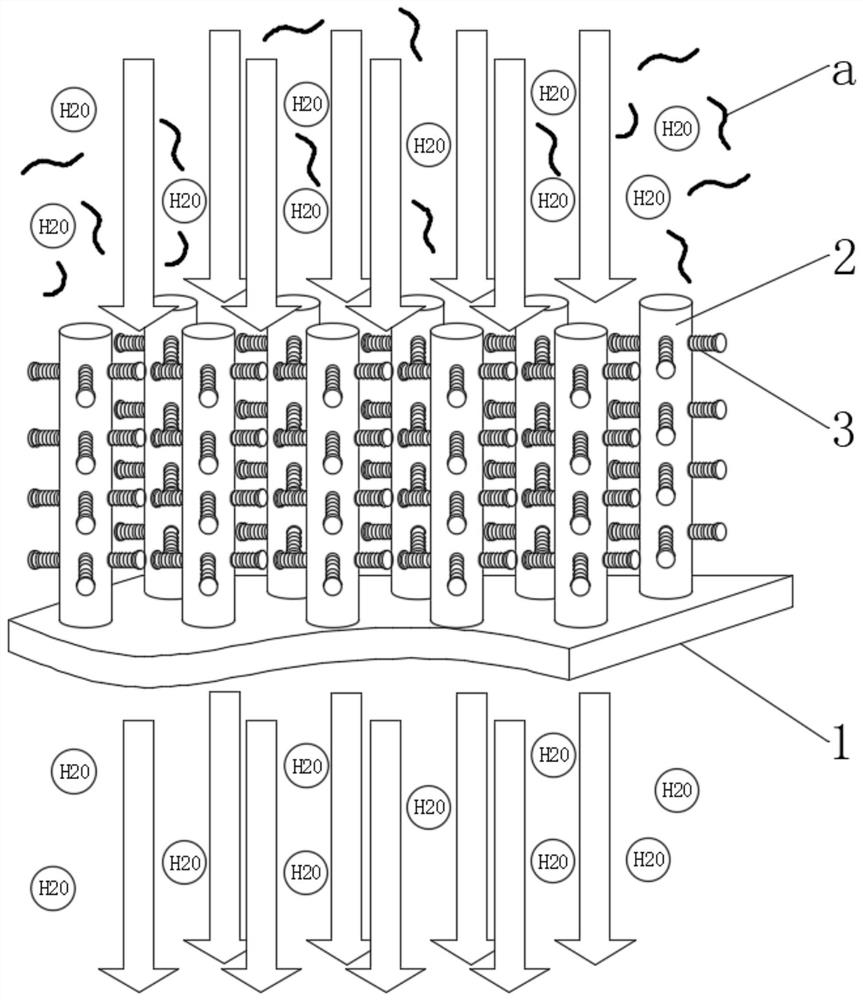

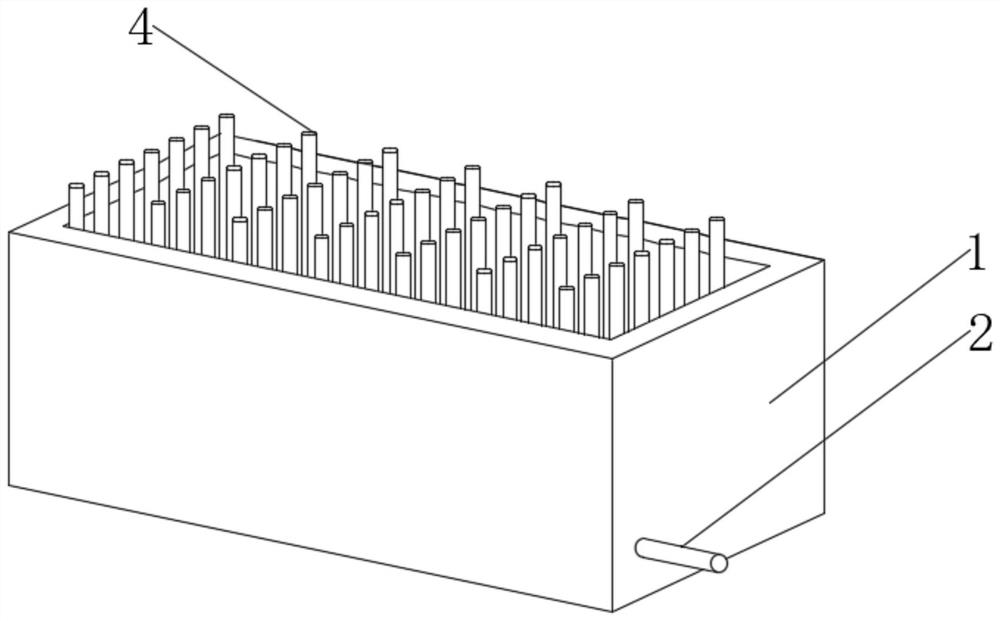

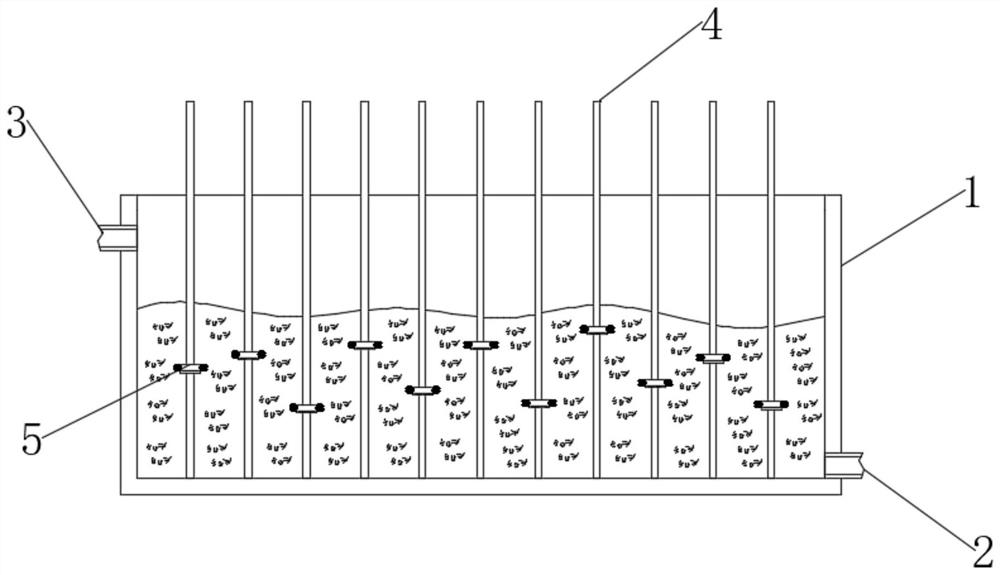

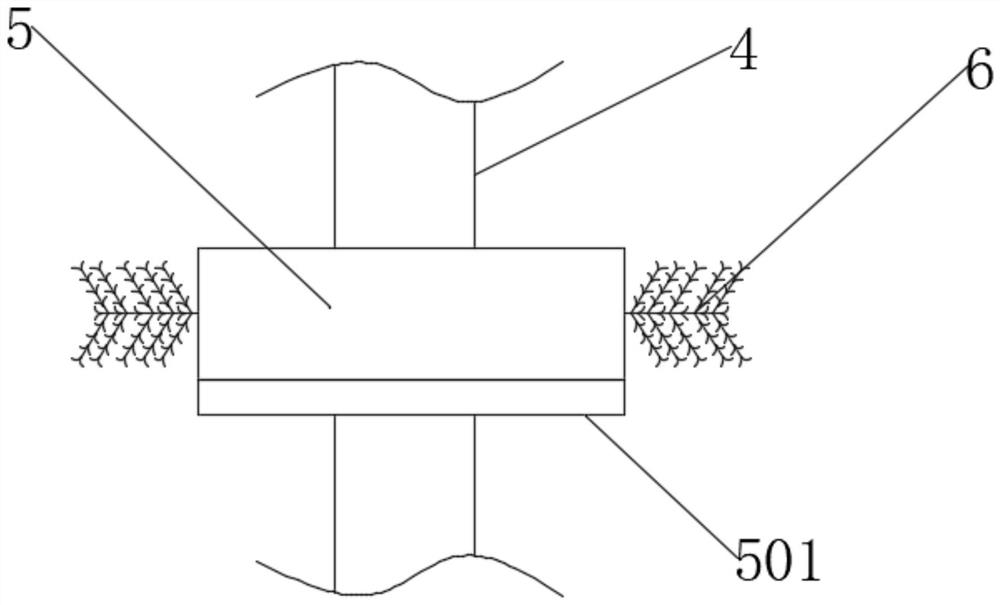

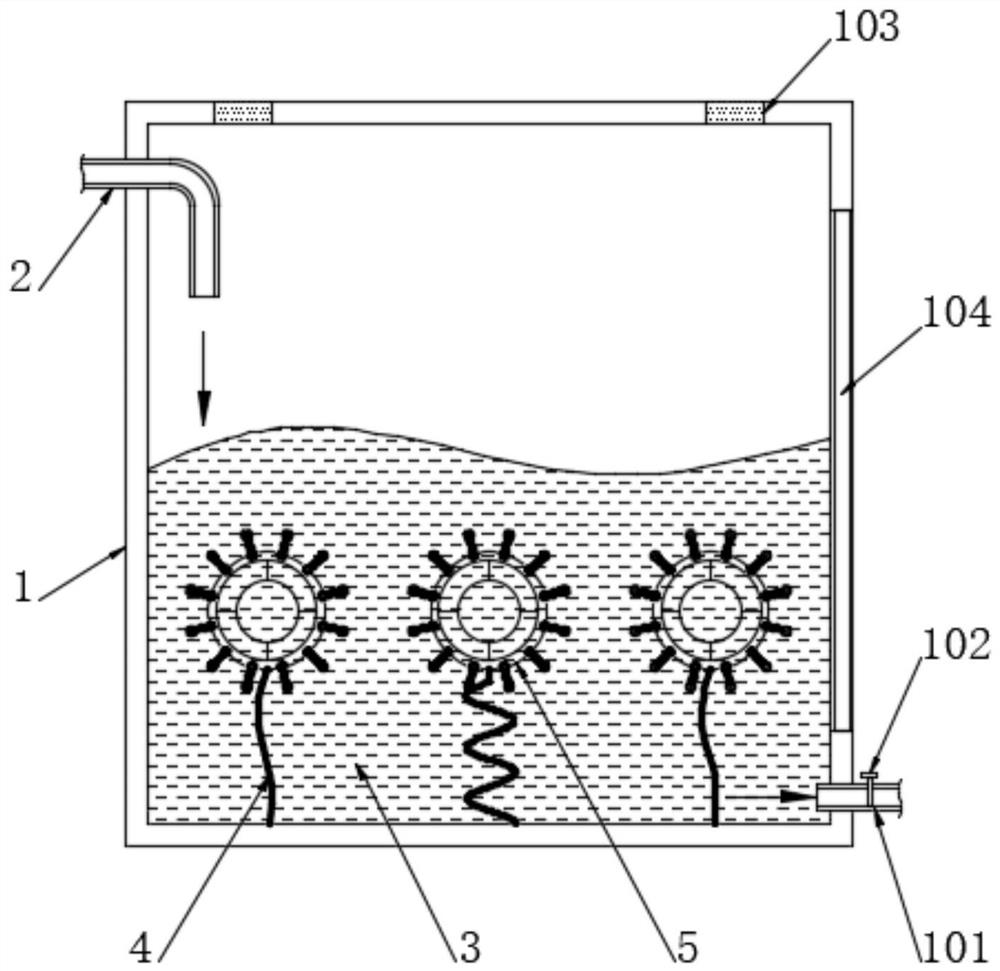

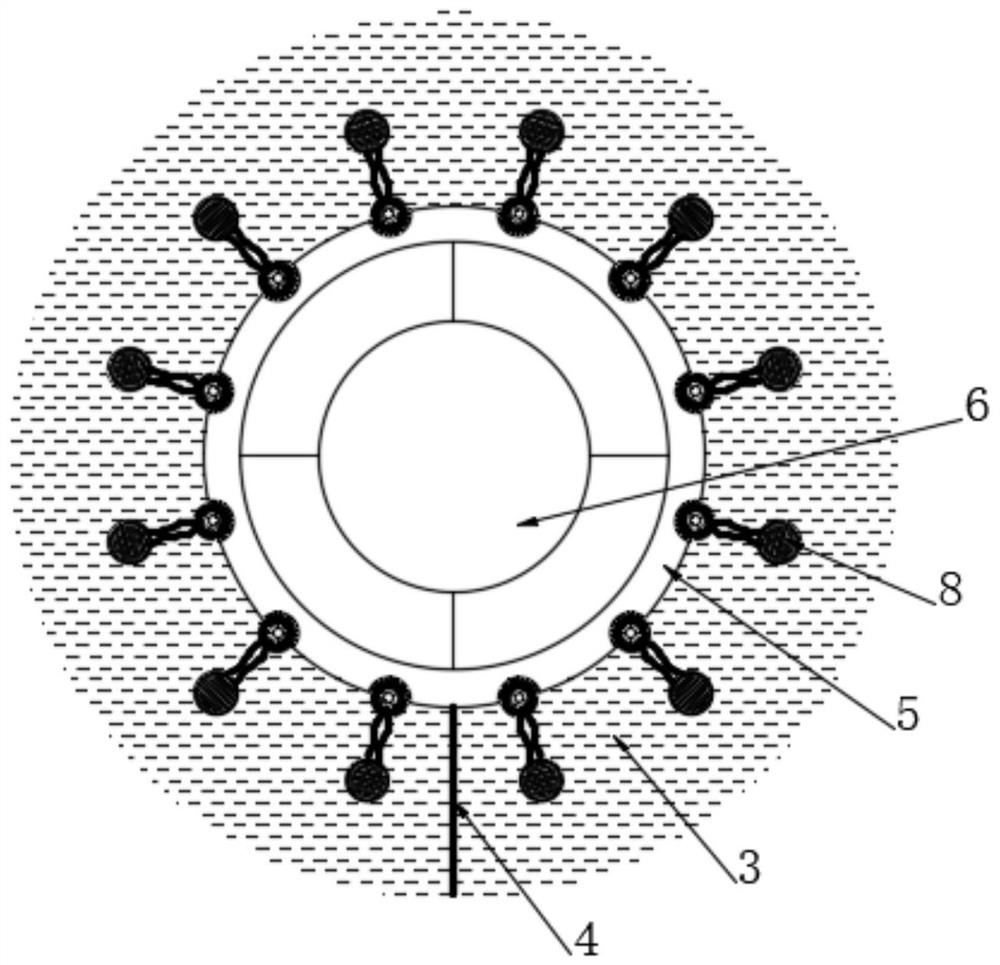

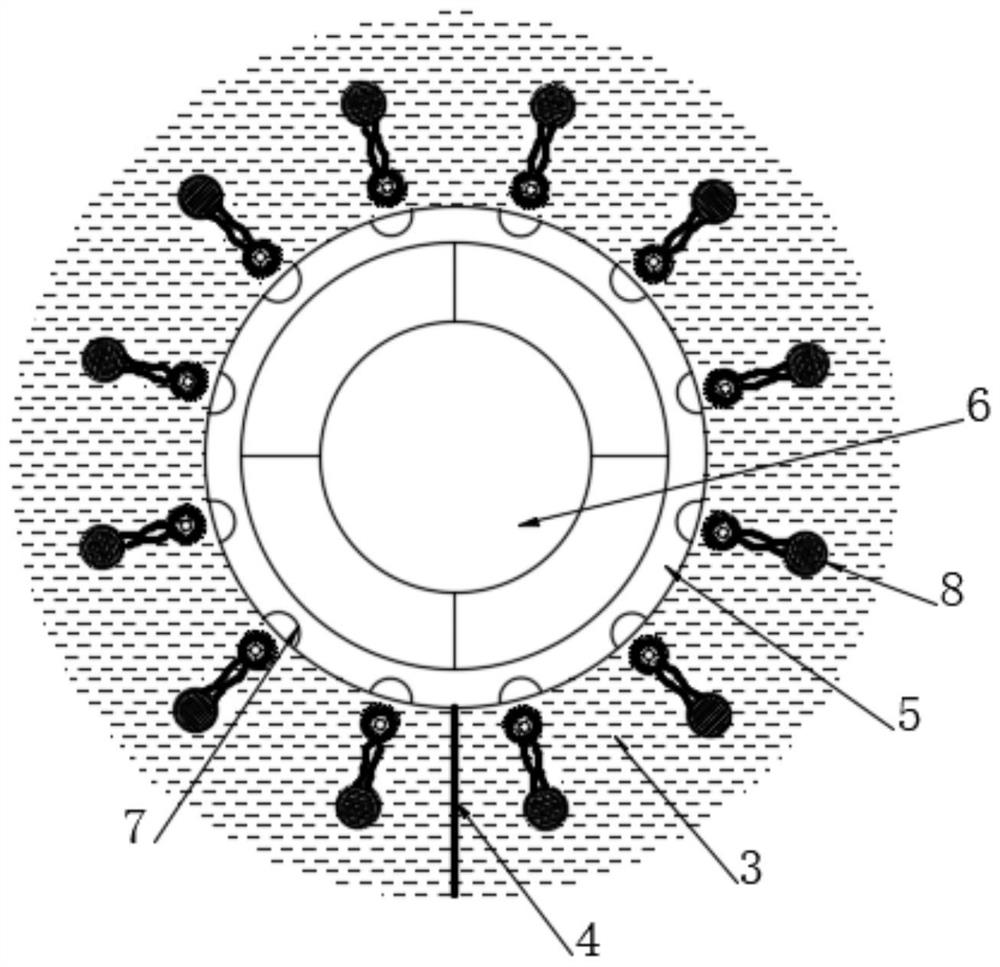

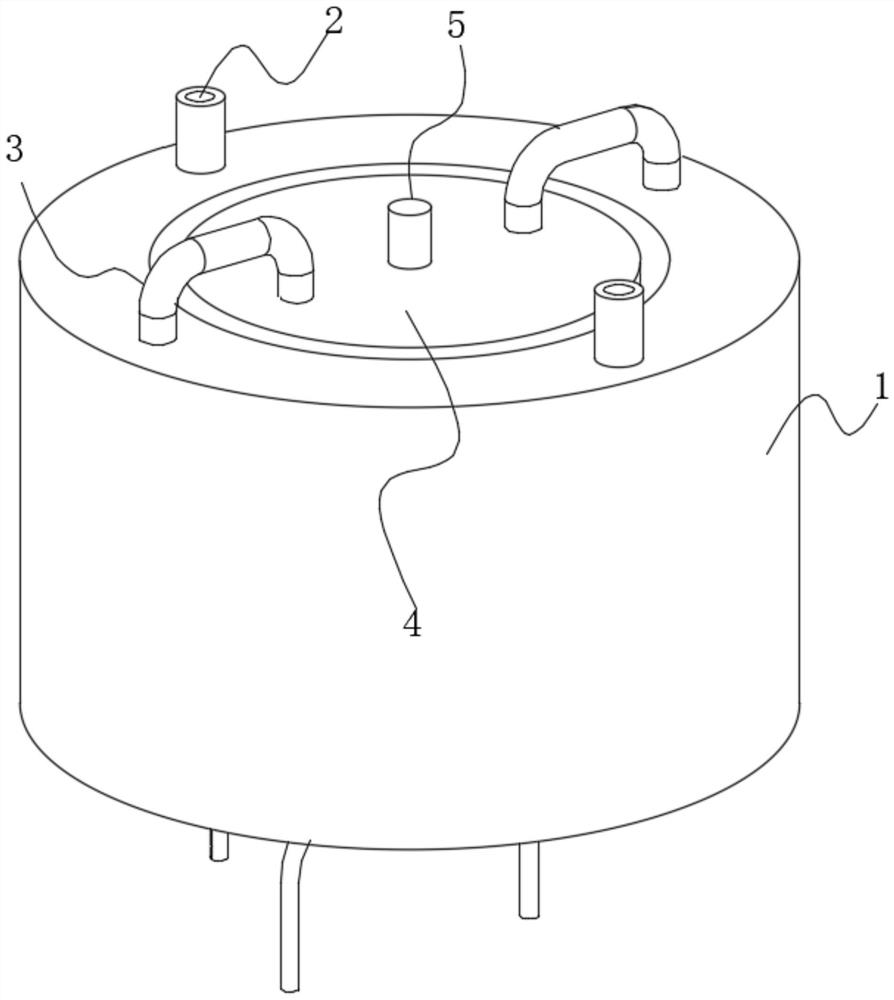

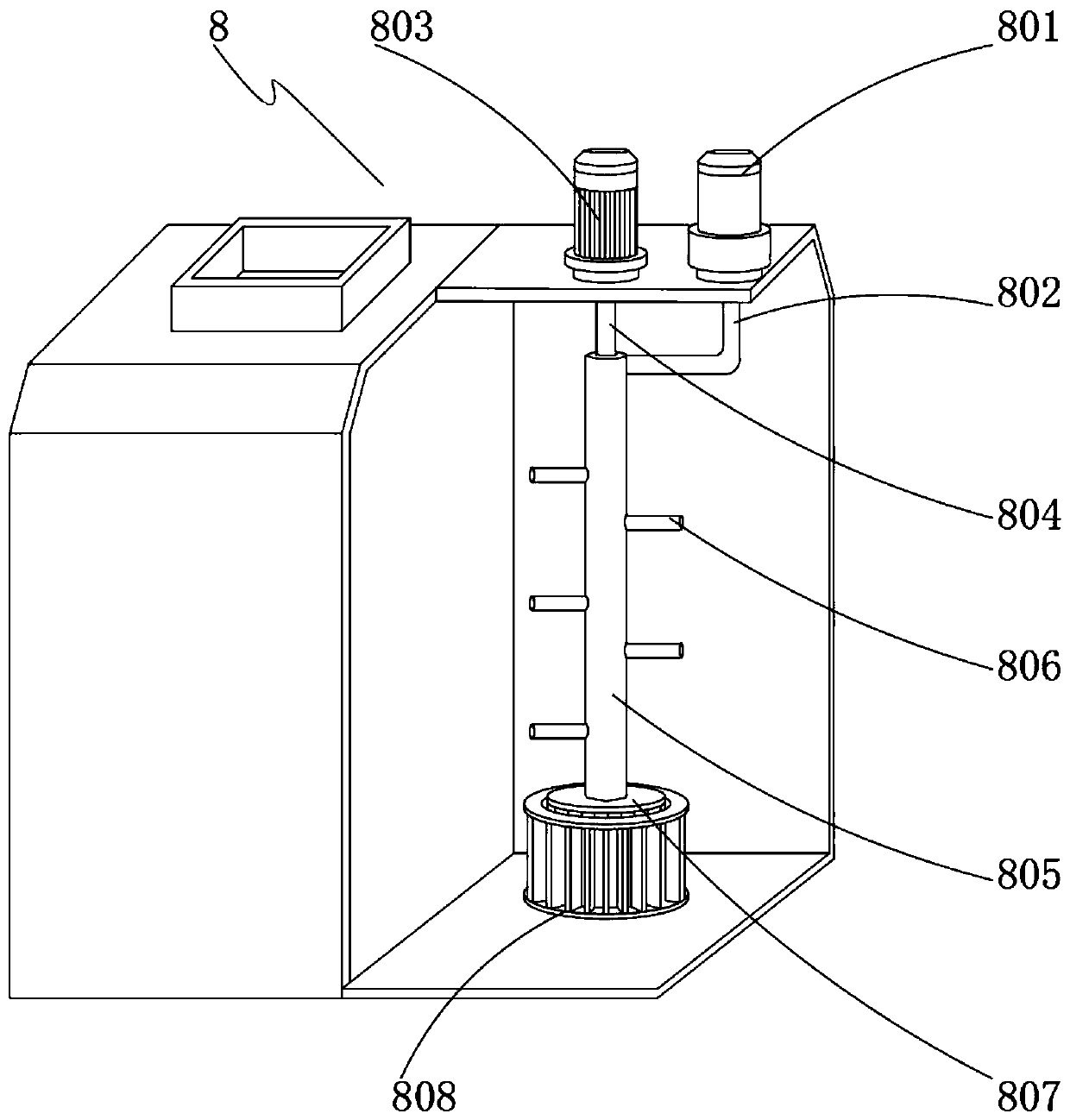

Textile wastewater treatment mechanism based on microbial technology and using method thereof

InactiveCN112320923ALarge specific surface areaIncreased attachment growthSpecific water treatment objectivesBiological treatment apparatusBiotechnologyBiofilm

The invention discloses a textile wastewater treatment mechanism based on a microbial technology and a using method thereof, and belongs to the field of textile wastewater treatment. The textile wastewater treatment mechanism based on the microbial technology comprises a pool body, a plurality of rotating rods are rotatably connected in the pool body, the rotating rods penetrate through the side wall of the upper end of the pool body, and the rotating rods are hollow rod bodies; the side walls of the rotating rods communicate with a plurality of breather pipes, each breather pipe is connectedwith a plurality of biological membrane loading balls in series, cavities are formed in the biological membrane loading balls, and the specific surface areas of the biological membrane loading balls are increased through microorganism attachment parts, so that microorganisms are easier to attach and grow; and large magnetic balls and small magnetic balls attract each other to enable sewage at thebottom to be turned up, so that the sewage treatment depth is effectively increased, pressurized gas is intermittently introduced to enable an elastic pneumatic membrane to strike a vibrating part toenable the microorganism attachment part to vibrate, accordingly, an aged biological membrane quickly falls off, and the updating speed of the biological membrane is effectively increased.

Owner:张蓉琪

Textile wastewater recycling treatment system

InactiveCN110655245AScientific and reasonable structureEasy to useWater/sewage treatment by irradiationSpecific water treatment objectivesFiberElectric machinery

The invention discloses a textile wastewater recycling treatment system. A primary filtering assembly is arranged on one side of a settling tank; a connecting opening is formed in the bottom end of one side, close to the settling tank, of a primary filtering cylinder; a filter screen cylinder is arranged in the primary filter cylinder; hooks are fixedly mounted at the top ends of supporting rods;a floating removal assembly is mounted in a floating removal box; a rotating shaft is mounted at the bottom of a driving motor; the top of a sleeve is fixedly connected to the bottom of a breather pipe; fan blades are fixedly connected to the bottom end of the rotating shaft; a deslagging box is fixedly mounted in the middle of the front surface of the floating removal box; according to the invention, wastewater is filtered by the primary filter cylinder and then treated; larger fibrous materials are blocked by the filter screen cylinder; the filter screen cylinder can be cleaned by pulling the supporting rods and taking out the filter screen cylinder, cleaning is convenient, the filter screen cylinder is not prone to being blocked, high-pressure air is introduced into water, water molecules and the air are mixed and micronized, granular pollutants and fine fibers in the water are separated from raw water in a floating mode to form a floating layer state, removal of the granular pollutants and the fine fibers is facilitated, and the treatment effect is better.

Owner:长兴钱振纺织有限公司

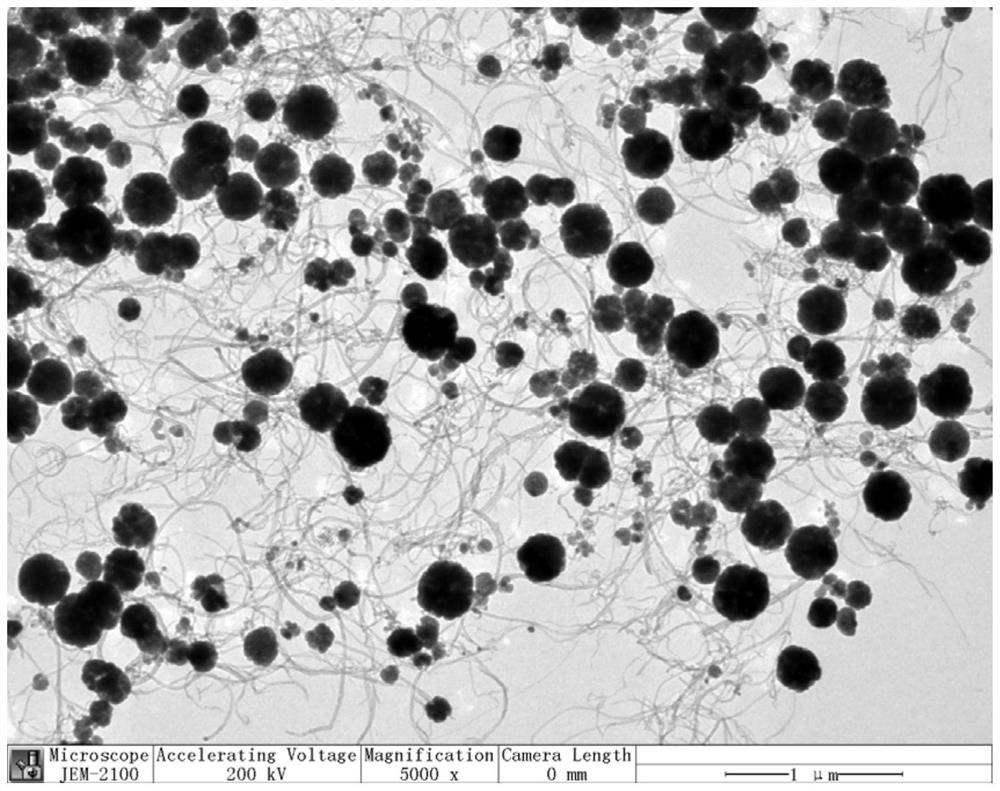

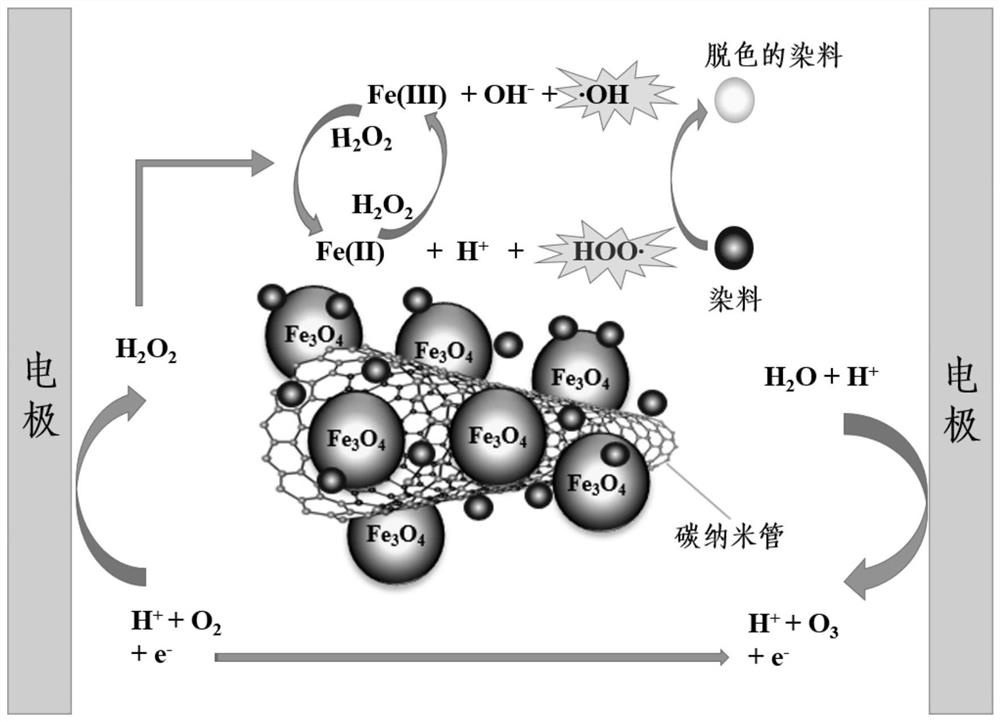

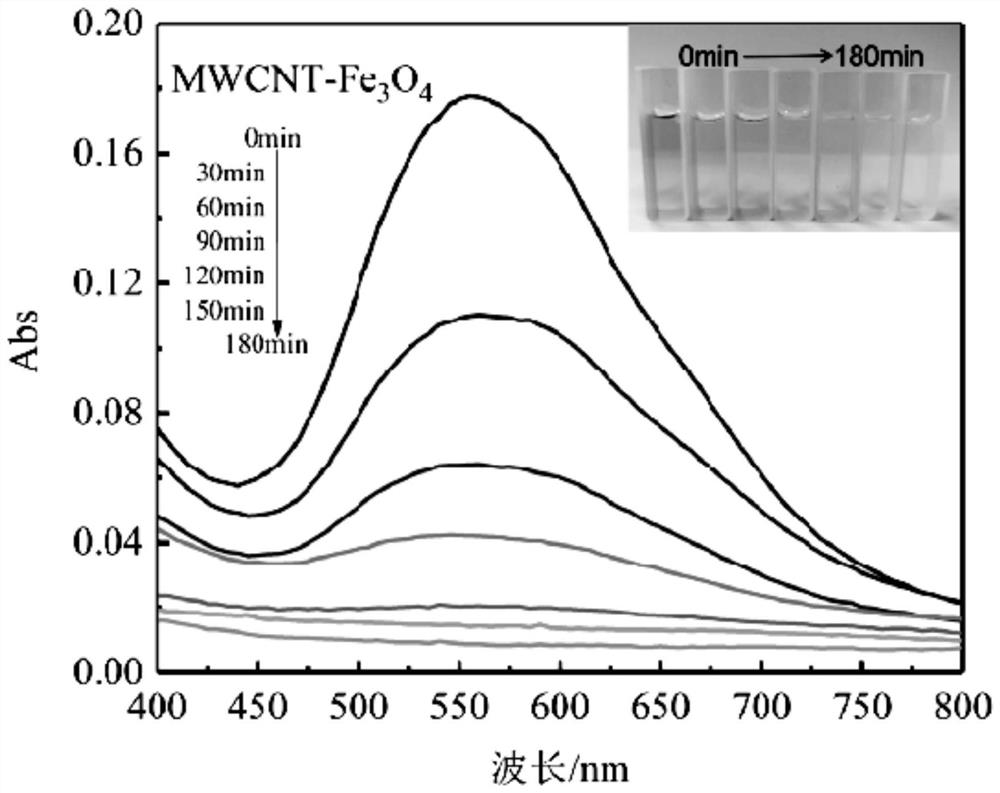

Textile wastewater treatment method based on Fe3O4/CNTs composite dispersed electrode

InactiveCN112079416AIncrease electrode areaIncrease the current intensityWater/sewage treatmentWaste water treatment from textile industryEngineeringThree dimensional electrode

The invention discloses a textile wastewater treatment method based on a Fe3O4 / CNTs composite dispersed electrode, and belongs to the field of chemical and environmental protection. According to the invention, a ferroferric oxide / carbon nanotube composite material is used as a dispersed electrode, and the textile wastewater is treated by a three-dimensional electrode electrolytic cell, so that themethod has the advantages of high current efficiency, good treatment effect, large treatment capacity and low energy consumption, and can solve the problems of high COD, high pH value, large chromaticity, large water temperature and large water quantity of the textile wastewater. The ferroferric oxide / carbon nanotube composite material is used as the dispersion electrode, a disperse blue 2BLN solution is decolored under the conditions that the voltage is 17V, the electrolytic salt concentration is 1mol / L and the concentration of ferroferric oxide / carbon nanotubes is 75mg / L, the decoloring rate can reach 98.79 percent after 3 hours, and a better decoloring effect is achieved.

Owner:JIANGNAN UNIV

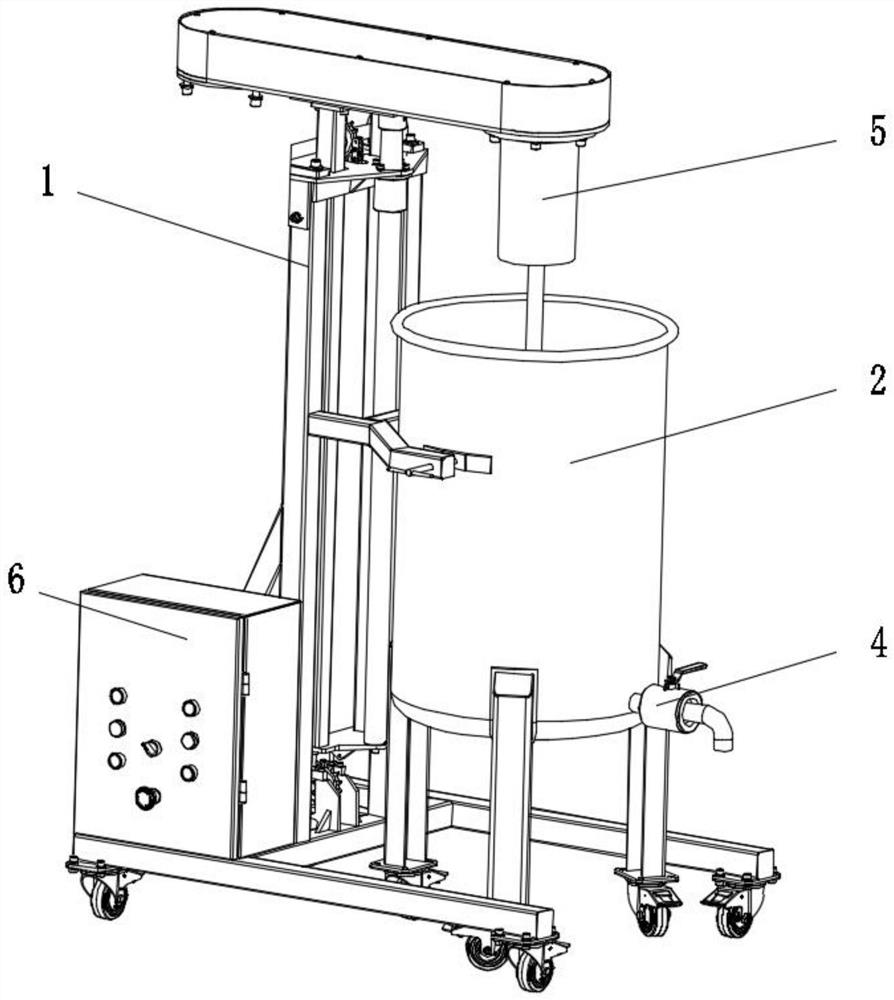

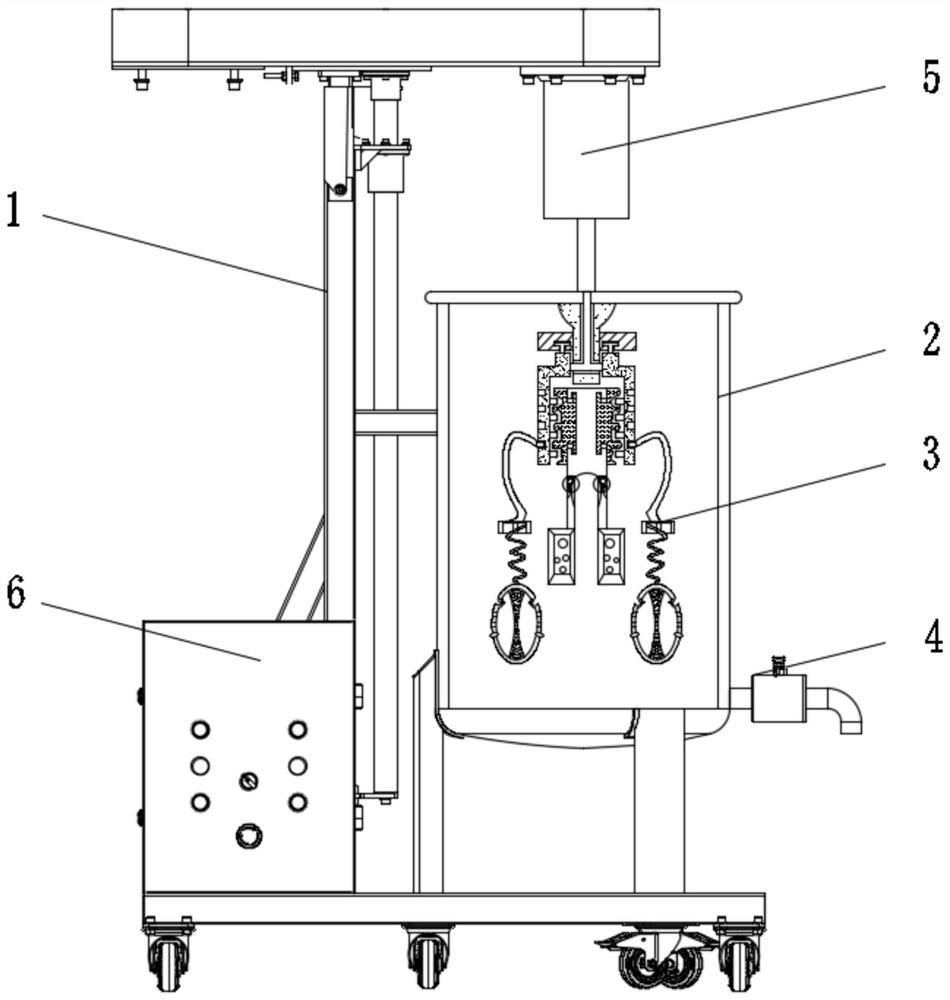

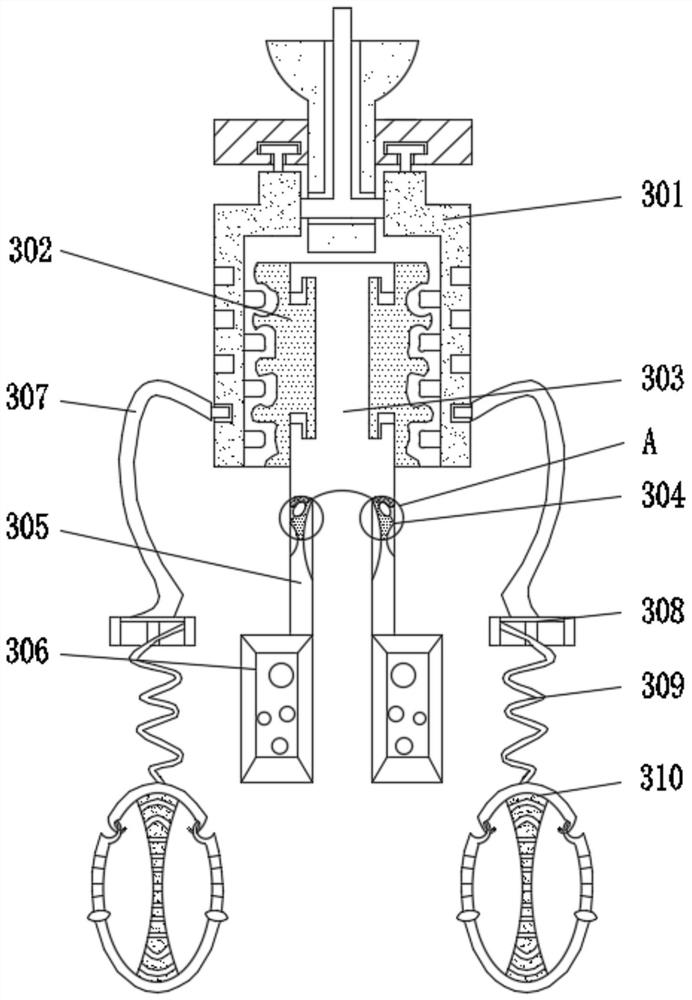

Textile wastewater treatment device

InactiveCN113023854AEfficient collectionImprove stabilityWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationProcess engineeringPower apparatus

The invention discloses a textile wastewater treatment device, and relates to the technical field of textile machinery, the textile wastewater treatment device comprises a support, a tank body, a wastewater treatment device, a water outlet pipe, a power device and a control device, the tank body is installed at the middle position of the support, the water outlet pipe is installed at the lower position of the tank body, the power device is installed at the upper position of the support, the control device is mounted below the support, and the wastewater treatment device is mounted in the tank body. According to the textile wastewater treatment device, through cooperative use of the rotating mechanism, the flexible connecting body, the collecting box and other mechanisms, the purpose of effectively collecting harmful colloids in textile wastewater through a flocculation method is achieved, the rotating mechanism is driven to rotate through the power device, the top of the slotting block is in a large-area circle shape, and therefore good supporting force can be improved; instability during operation of the device is reduced, the T-shaped blocks are in sliding connection with the slotting disc through the slots, and the stability of the rotating drum in the rotating process is improved.

Owner:曹立伟

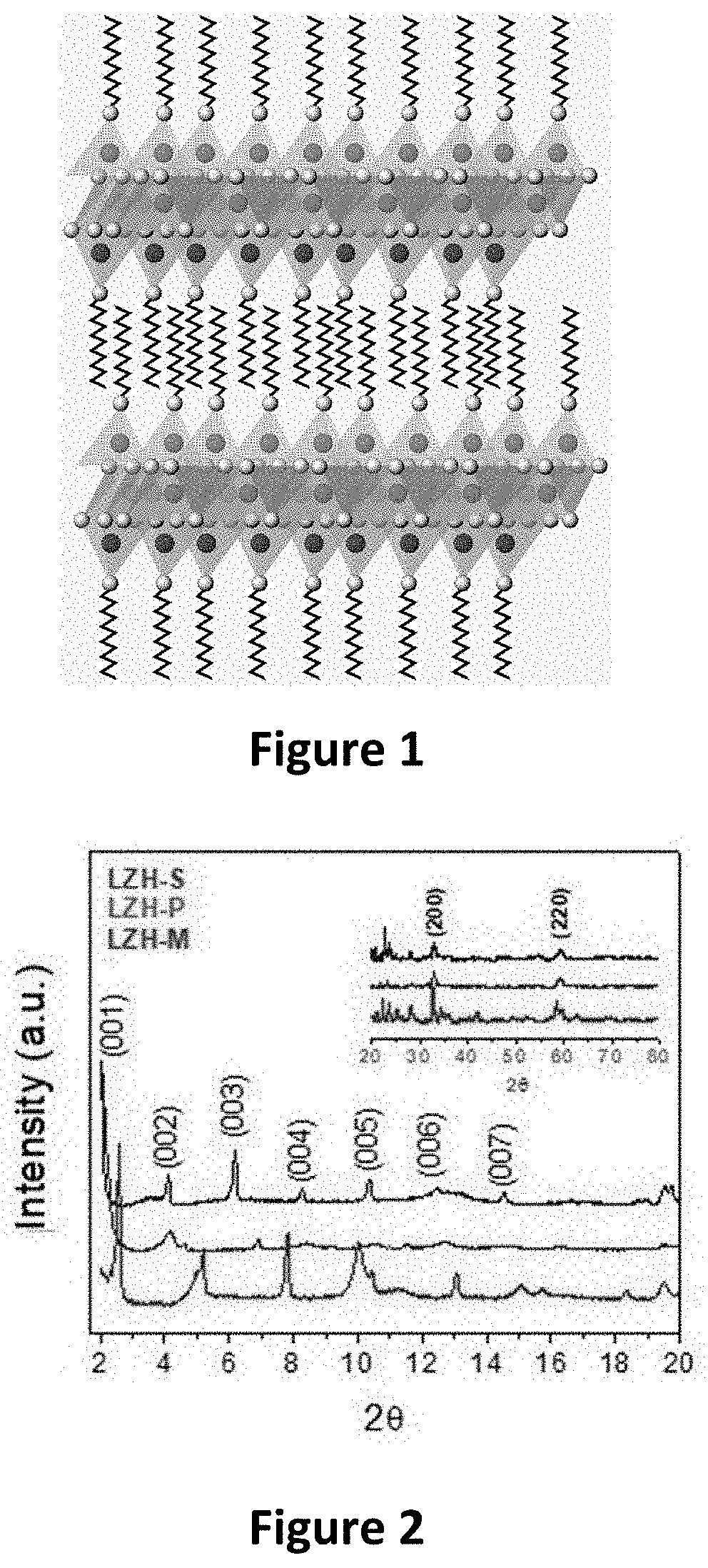

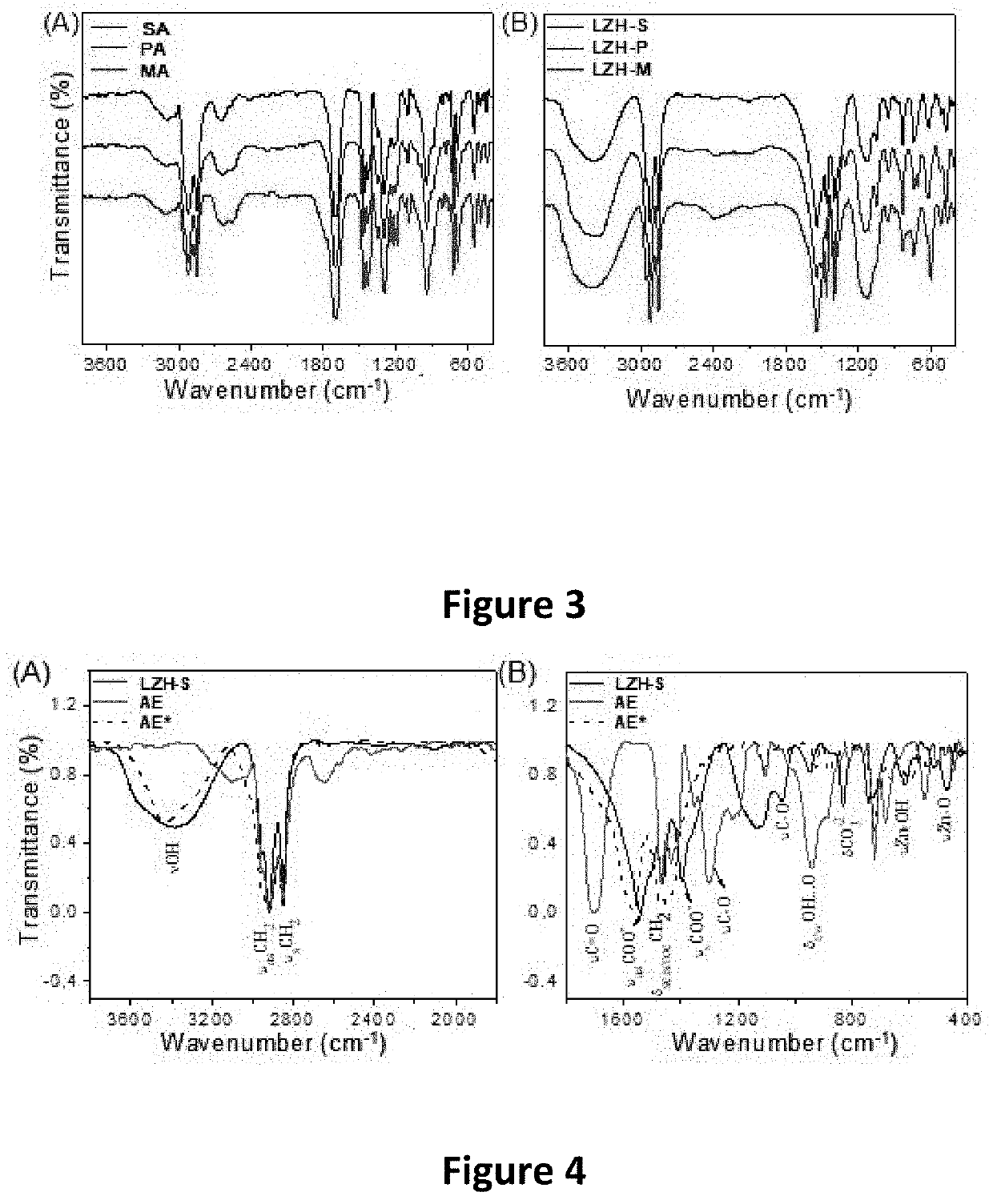

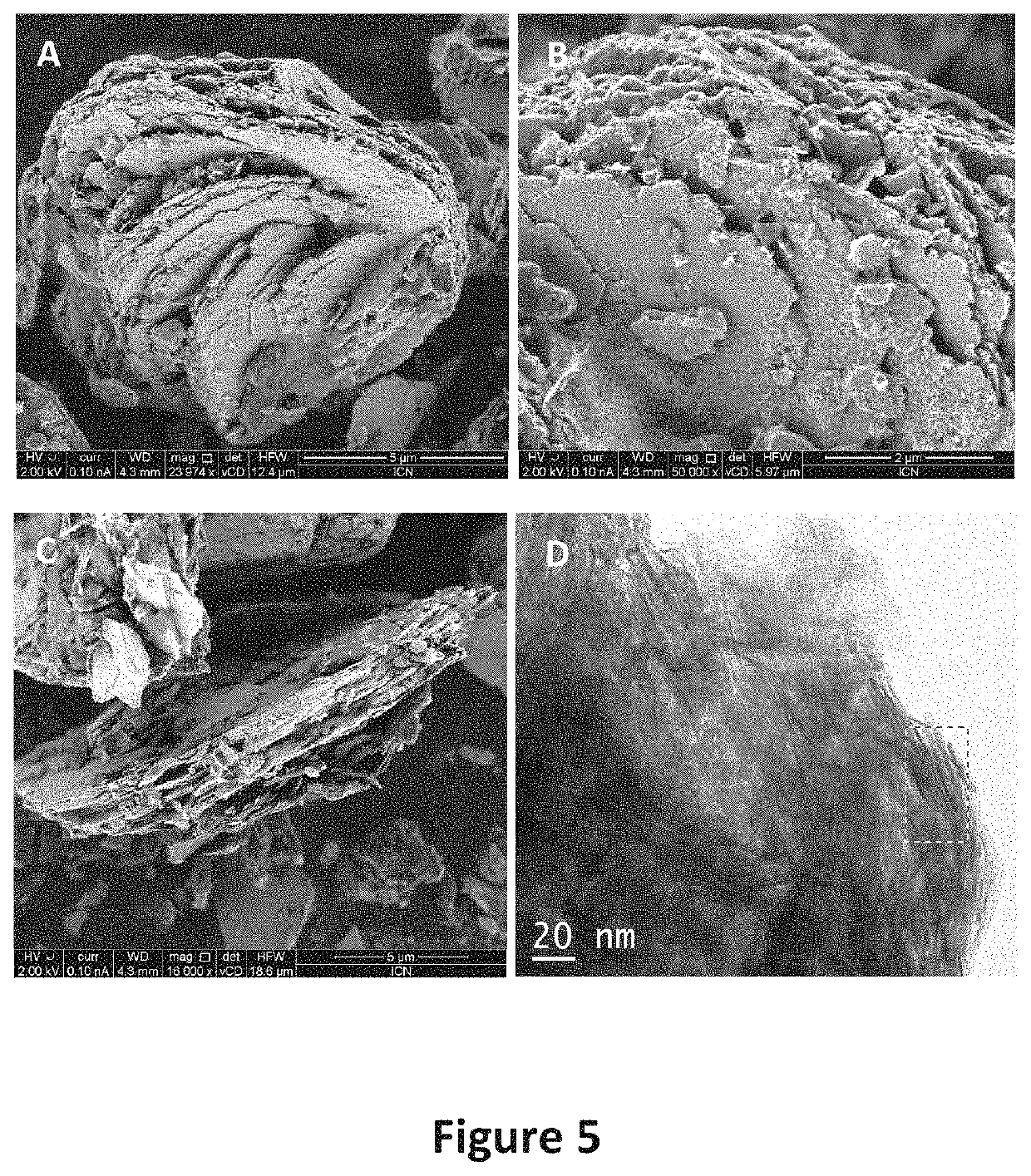

Method for preparing laminar zinc hydroxide organic-inorganic nanocomposites for use in the removal and degradation of dyes from textile effluents

ActiveUS10987663B2Low cost-precursorsImprove adsorption capacityWater/sewage treatment by irradiationWater treatment compoundsZinc hydroxideSimple Organic Compounds

The present invention relates to a method for removing dyes from textile effluents and other organic substances using nanocomposites based on zinc hydroxides and carboxylic acids capable of adsorbing and degrading. More specifically, the present invention consists of a method to generate new zinc hydroxide-based materials, which allows removal and degradation of methylene blue and other organic compounds from wastewater from industrial effluents, particularly those from textile industry.

Owner:UNIVERSITY OF CHILE

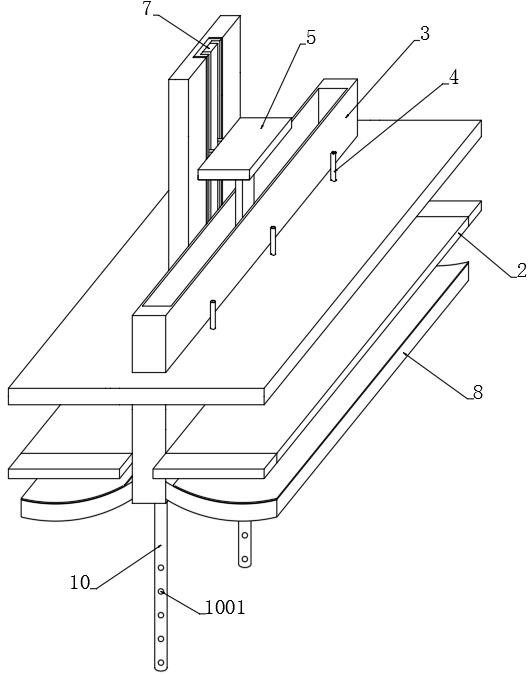

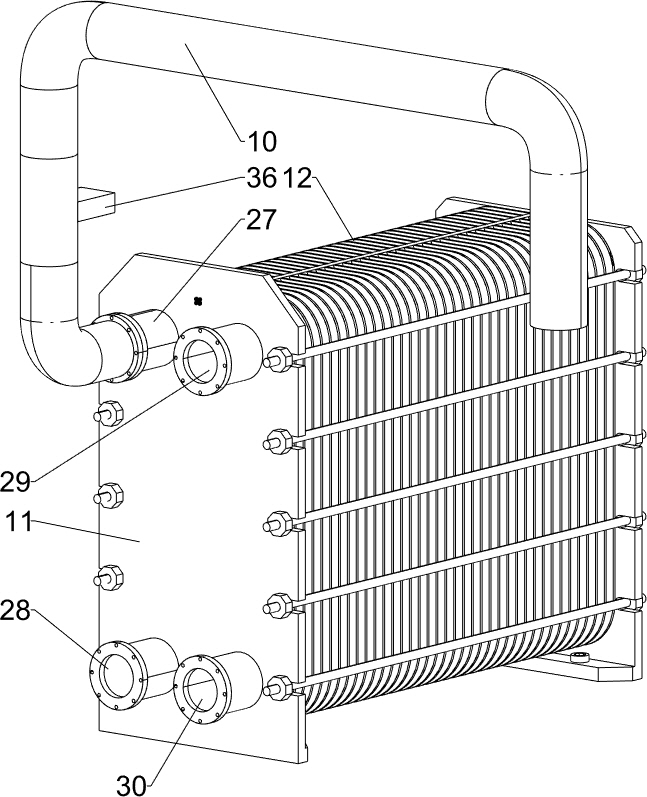

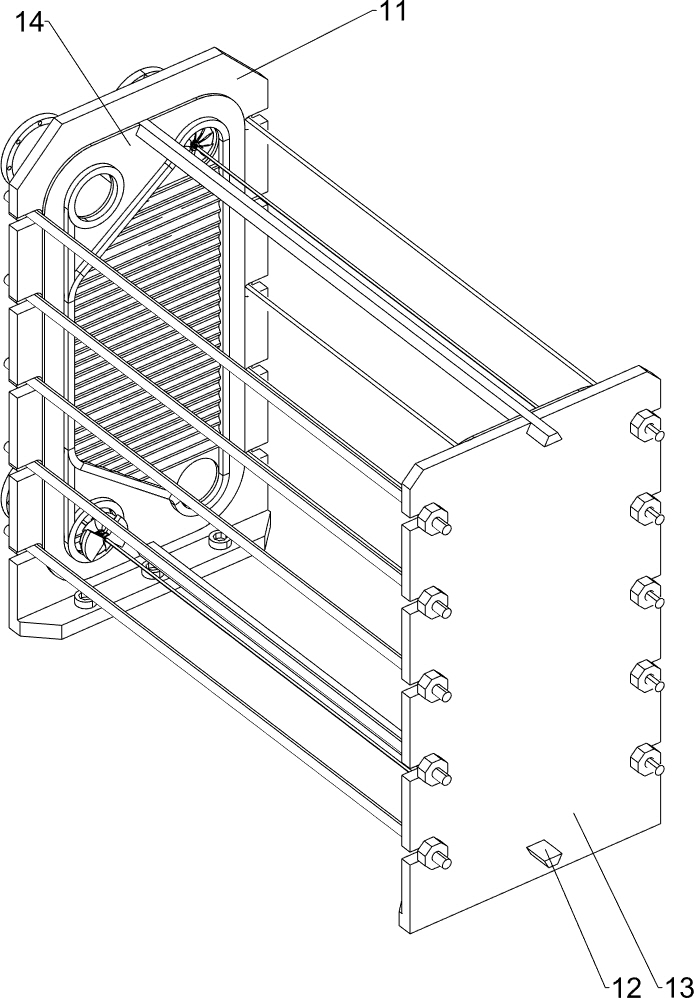

An environmentally friendly Tencel solvent purification treatment device with a self-cleaning plate heat exchanger

ActiveCN113912210BLow fluidityPrevent leakageTreatment involving filtrationWater/sewage treatment by ion-exchangeThermodynamicsPlate heat exchanger

The invention relates to a heat exchanger, in particular to an environment-friendly Tencel solvent purification treatment device with a self-cleaning plate heat exchanger. The technical problem of the present invention is to provide an environmentally friendly Tencel solvent purification treatment device with a self-cleaning plate heat exchanger that prevents the deformation of the sealing gasket and improves the heat conversion efficiency. The technical embodiment of the present invention is: an environment-friendly Tencel solvent purification treatment device with a self-cleaning plate heat exchanger, comprising a conveying pipe and a heat exchange mechanism; the conveying pipe is connected with a heat exchange mechanism. The invention cleans the scale adhering to the board wall by cleaning the components, slows down the flow of textile waste water, avoids deformation and leakage caused by the continuous impact of the sealing gasket, and at the same time avoids the increase of the thickness of the board wall due to the accumulation of scale, and realizes the improvement of the board replacement. Heat transfer efficiency of the heater.

Owner:YIXING GLOBAL WATER TREATMENT EQUIP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com