Textile wastewater purifying and recycling device

A technology of textile wastewater and standing still, which is applied in textile industrial wastewater treatment, grease/oily substance/suspton removal device, water/sewage treatment, etc. Particles cannot settle and other problems, to achieve the effect of solving the imbalance of pH, increasing the effect and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

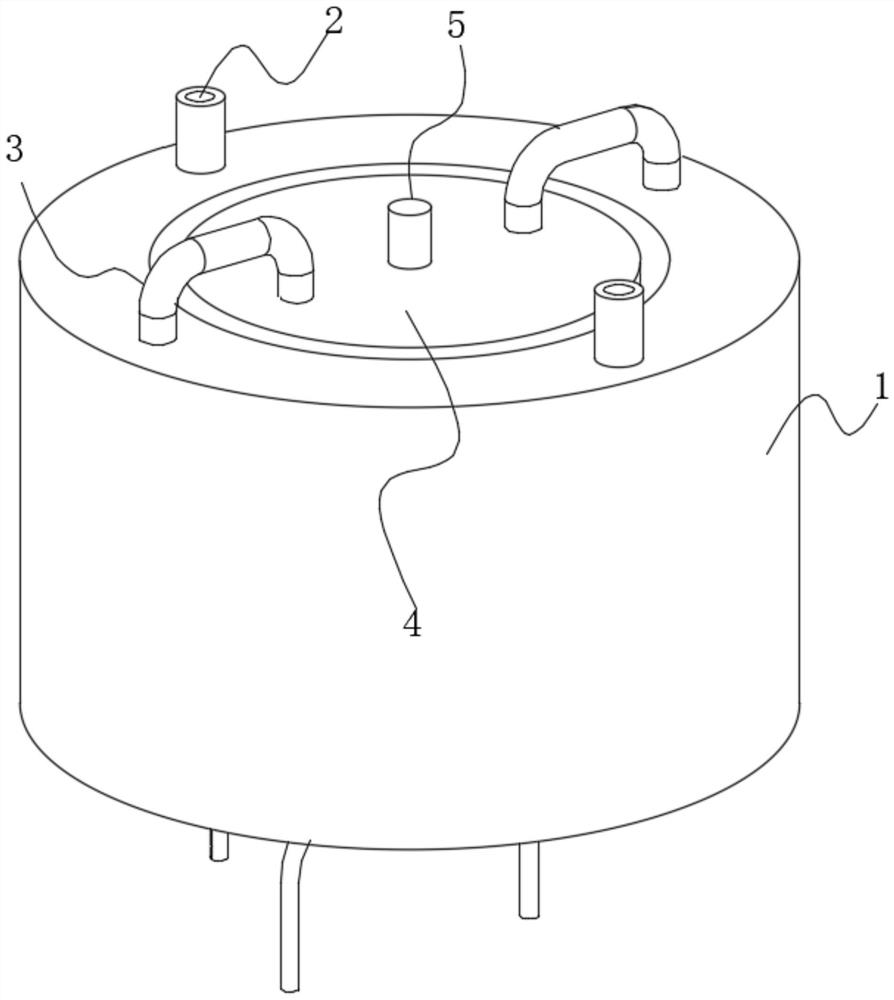

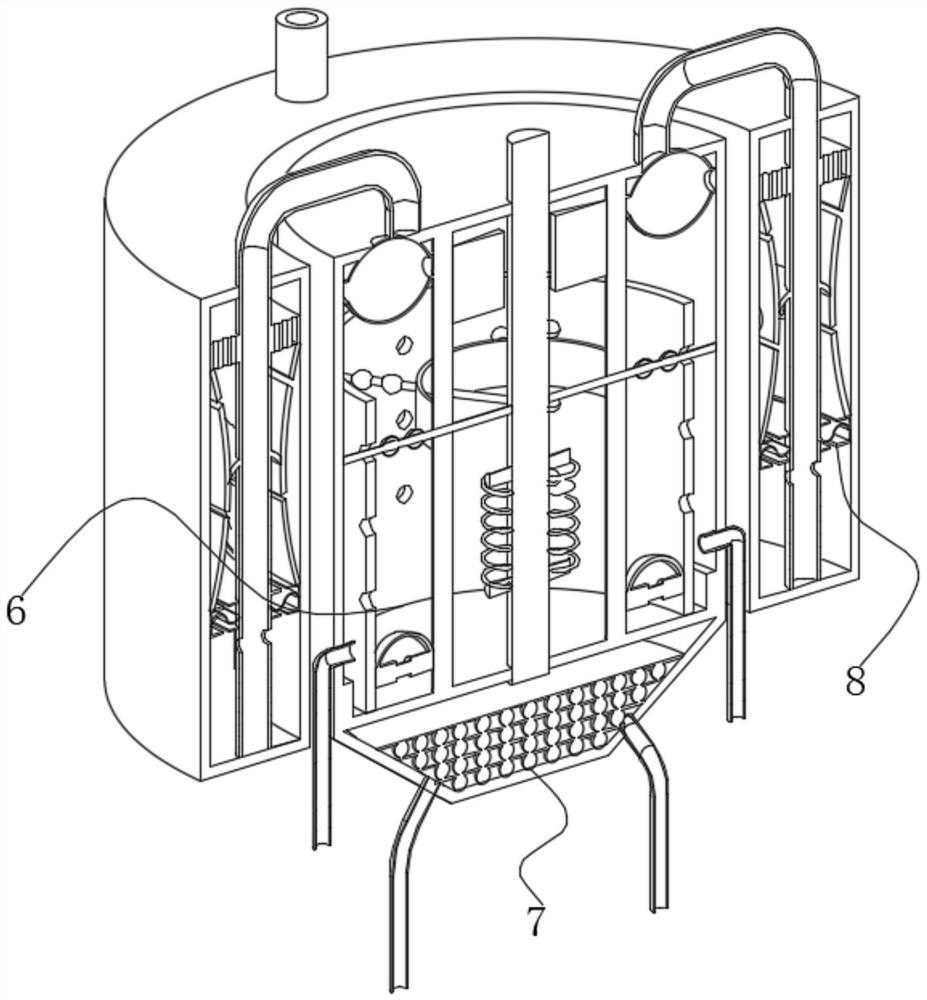

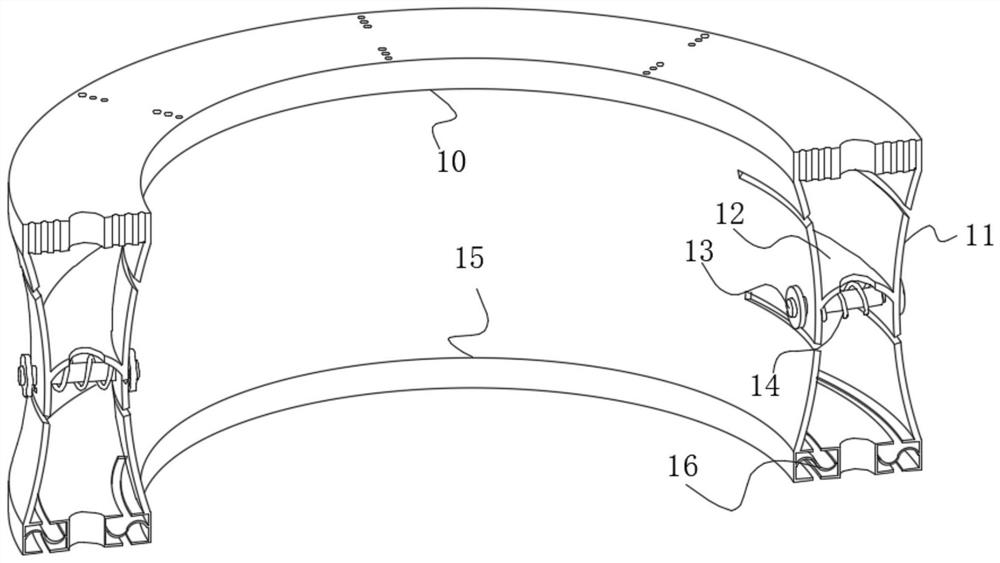

[0023] use Figure 1-Figure 6 A textile wastewater purification and reuse device according to an embodiment of the present invention is described as follows.

[0024] like Figure 1-Figure 6 As shown, a kind of textile wastewater purification and reuse device according to the present invention includes an outer cover 1; the upper surface of the outer cover 1 is fixedly connected with a water inlet pipe 2, and the upper surface of the outer cover 1 is fixedly connected with the organism 4 through the connecting pipe 3, and the body 4 The wall is rotatably connected with a transmission shaft 5, the outer surface of the transmission shaft 5 is movably connected with a centrifugal mechanism 6, the centrifugal mechanism 6 is located inside the body 4, the bottom of the centrifugal mechanism 6 is provided with a secondary sedimentation mechanism 7, and the secondary sedimentation mechanism 7 The outer surface is fixedly connected with the inner surface of the body 4 , and the body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com