A kind of treatment agent for textile wastewater, preparation method and treatment process thereof

A technology for textile wastewater and treatment process, applied in textile industry wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. Reduce the cost of wastewater treatment, reduce cost input, and achieve the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

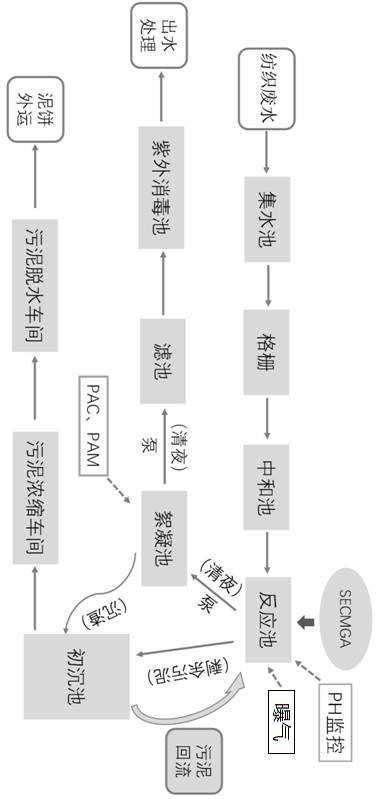

Image

Examples

preparation example Construction

[0042] In addition, the present invention also provides a method for preparing a treatment agent for textile wastewater, using the following steps:

[0043] 1) Prepare a composite material with a nano-microspherical structure as a carrier;

[0044] 2) Bacillus subtilis and activated sludge microorganisms that were separated, purified and cultured for several days were collected, and the mild method of comprehensive freeze-thawing and ultrasonic crushing was used to obtain the lysed active product of the bacteria, which was washed with pure water for later use, and the preparation process was mild and kept at low temperature;

[0045] 3) Dispersing the composite material with nano-microspherical structure obtained in step 1) into a phosphate buffer solution with a pH of 6-9 to form a low-viscosity solution, wherein the amount of the composite material is 0.2-2% of the phosphate buffer solution , and then add the lysate obtained in step 2), the amount of the lysate added is 0.1-...

Embodiment 1

[0068] A treatment agent for textile wastewater, comprising nanozyme SECMGA, and activator WRLL and activator BOJF for activating nanozyme SECMGA, the activator WRLL adopts dihydrogen phosphate, and the activator BOJF adopts ammonium Salt;

[0069] The treatment agent is prepared through the following steps:

[0070] 1) Using the existing patent "a composite material and its preparation method and its application in sewage biochemical treatment" (application number is CN201710784101.6), the composite material with nano-microspherical structure is prepared as the carrier of the present invention; for example, using

[0071] a) 100 grams of sodium silicate, 30 grams of clay (purchased from Qingdao Wanhong Mining Co., Ltd.), 30 grams of iron oxide (Fe 2 o 3 ), 30 grams of alumina (Al 2 o 3 ), 10ml of concentrated hydrochloric acid (commercially available) were mixed evenly, and the airtight reaction was carried out at 120°C for 6 hours;

[0072] b) Mix the reaction product i...

Embodiment 2

[0080] A preparation method for a treatment agent for textile wastewater, step 1), step 2) are the same as the steps in Example 1;

[0081] In step 3), the composite material with nano-microspherical structure obtained in step 1) is dispersed into a phosphate buffer solution with a pH of 8 to form a low-viscosity solution, wherein the amount of the composite material is 1% of the phosphate buffer solution , and then add the lysate obtained in step 2), the amount of the lysate added is 5% of the phosphate buffer, stirred at room temperature for 2 hours, passed through a 300-mesh net after low-frequency ultrasound, and packed into a specific water treatment device after measuring the encapsulation efficiency Inside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com