Formaldehyde adsorbent for air purification and preparation method and application thereof

A formaldehyde adsorption and air purification technology, applied in the field of air purification, can solve the problems of insufficient adsorbent treatment capacity and long formaldehyde removal cycle, and achieve the effects of excellent photocatalytic degradation ability, excellent catalytic oxidation ability, and modified adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

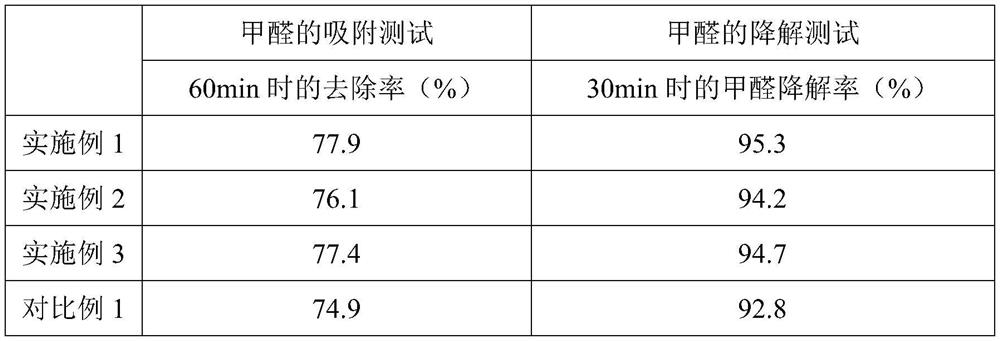

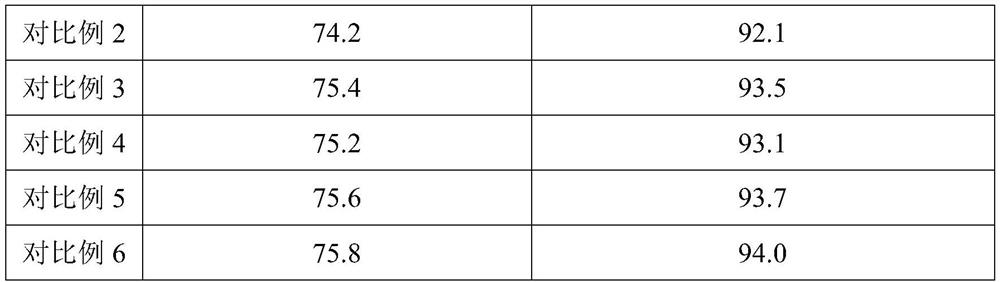

Examples

Embodiment 1

[0036] A preparation method thereof for a formaldehyde adsorbent for air purification, the preparation method comprises the following steps:

[0037] (1) Preparation of mesoporous carbon

[0038] Dissolve 12 mmol phenol and 36 mmol formaldehyde in 10 mL of 0.6 mol / L sodium hydroxide solution and stir evenly at 60 °C, cool to room temperature, then adjust the solution to neutrality by hydrochloric acid, and then remove moisture under vacuum at 90 °C, Then, the obtained phenolic resin was dissolved in ethanol to prepare a 35wt% phenolic resin ethanol solution; 1 g of P123, 0.3 mmol of manganese nitrate and 0.3 mmol of copper nitrate were dissolved in the mixed solution of phenolic resin, and then evaporated at room temperature and heated at 80°C thermally polymerized under helium, and then heat-treated at this temperature for 20 h to obtain a precursor; the precursor was heated to 800 °C at a heating rate of 6 °C / min under helium gas for calcination and carbonization, and kept f...

Embodiment 2

[0042] A preparation method thereof for a formaldehyde adsorbent for air purification, the preparation method comprises the following steps:

[0043] (1) Preparation of mesoporous carbon

[0044] Dissolve 14 mmol phenol and 56 mmol formaldehyde in 10 mL of 0.7 mol / L potassium hydroxide solution and stir evenly at 70 °C, cool to room temperature, then adjust the solution to neutrality by hydrochloric acid, and then remove moisture under vacuum at 100 °C, Then, the obtained phenolic resin was dissolved in ethanol to prepare a 30wt% phenolic resin ethanol solution; 1 g of F127, 0.4 mmol of manganese chloride and 0.2 mmol of copper acetate were dissolved in the mixed solution of phenolic resin, and then evaporated at room temperature and heated at 90 Thermal polymerization was carried out at ℃, and then heat-treated at this temperature for 16 h to obtain a precursor; the precursor was heated to 850 ℃ at a heating rate of 8 ℃ / min under an inert gas for calcination and carbonization...

Embodiment 3

[0048] A preparation method thereof for a formaldehyde adsorbent for air purification, the preparation method comprises the following steps:

[0049] (1) Preparation of mesoporous carbon

[0050] Dissolve 10 mmol phenol and 20 mmol formaldehyde in 10 mL of 0.5 mol / L sodium hydroxide solution and stir evenly at 50 °C, cool to room temperature, then adjust the solution to neutrality by hydrochloric acid, and then remove moisture under vacuum at 80 °C, Then the obtained phenolic resin was dissolved in ethanol to prepare a 20wt% phenolic resin ethanol solution; 1 g of P123, 0.2 mmol of manganese acetate and 0.4 mmol of copper chloride were dissolved in the mixed solution of phenolic resin, and then evaporated at room temperature and heated at 70 Thermal polymerization was carried out at ℃, and then heat-treated at this temperature for 24 h to obtain a precursor; the precursor was heated to 750 ℃ at a heating rate of 4 ℃ / min under helium gas for calcination and carbonization, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com