Rotary textile wastewater treatment device and use method

A textile waste water and treatment device technology, which is applied in textile industry waste water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of high pollutant concentration, high discharge standard, and difficult to handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

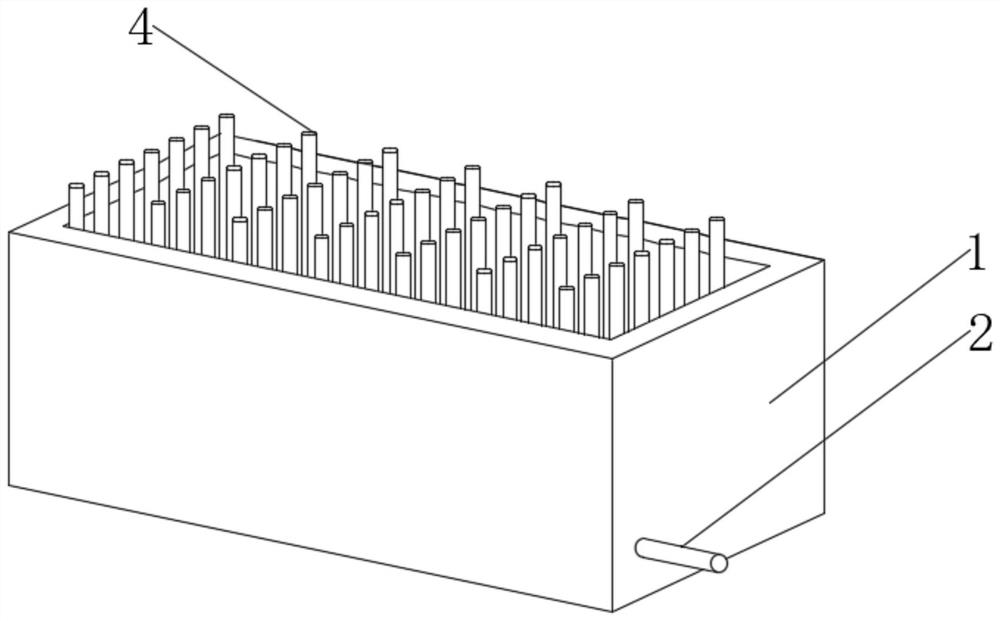

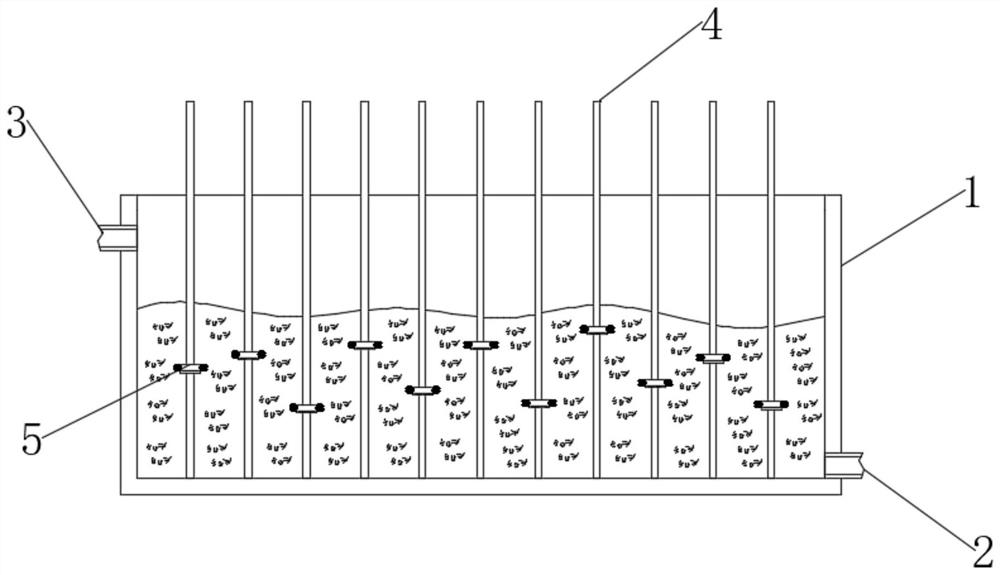

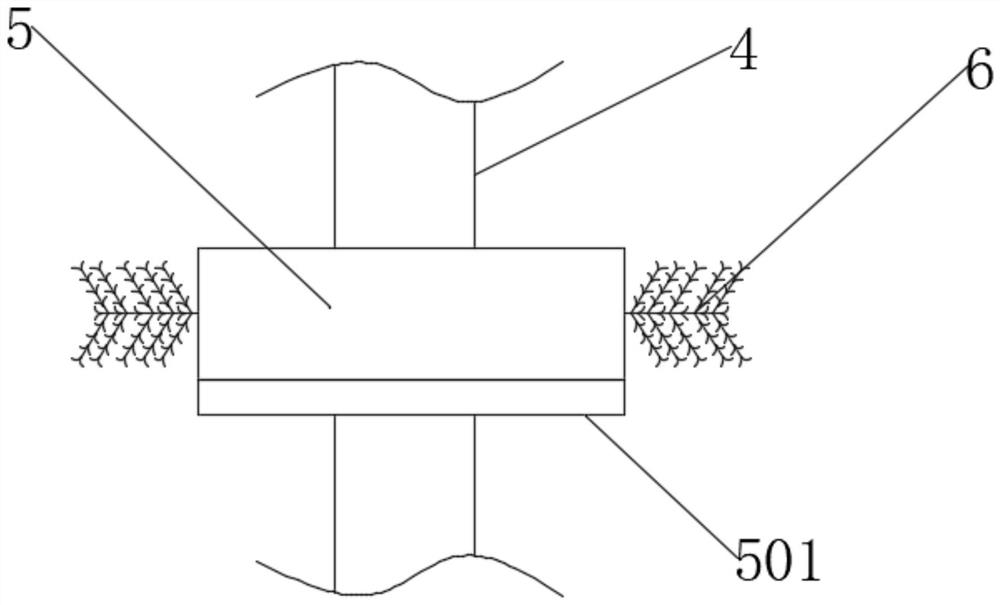

[0046] see Figure 1-4 , a rotary textile wastewater treatment device, including a reaction treatment chamber 1, the two ends of the reaction treatment chamber 1 are respectively connected with a discharge pipe 2 and a liquid inlet pipe 3, and the lower end wall of the reaction treatment chamber 1 is fixedly connected with a plurality of uniformly distributed treatment Upright column 4, the processing is carried out. The upper column 4 is provided with a rotating ring sleeve 5, and the outer end of the rotating ring sleeve 5 is fixedly connected with a plurality of evenly distributed side wing branches 6. Please refer to Figure 5-7 , the outer end of the rotating ring 5 is fixedly connected with a power function ball 7 spaced apart from the side wing branches and branches 6, the front end of the power function ball 7 is fixedly connected with a water dissolving block 701, and the inner wall of the power function ball 7 is fixedly connected with a covering heat collecting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com