Textile wastewater oil absorption device based on low-temperature separation technology

A technology of textile wastewater and technology, applied in the textile field, can solve the problems of natural environment pollution, complexity, excessive surfactant, etc., and achieve the effects of improving adsorption effect, improving service life and improving magnetic insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

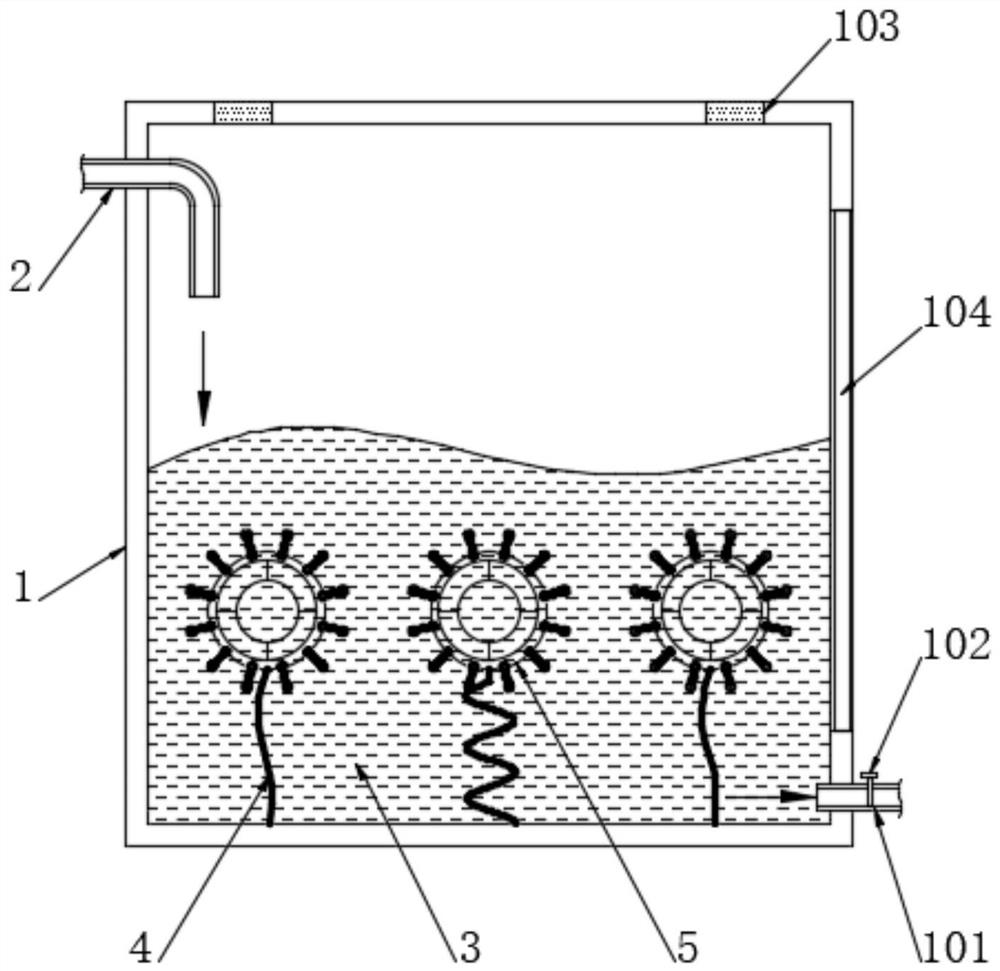

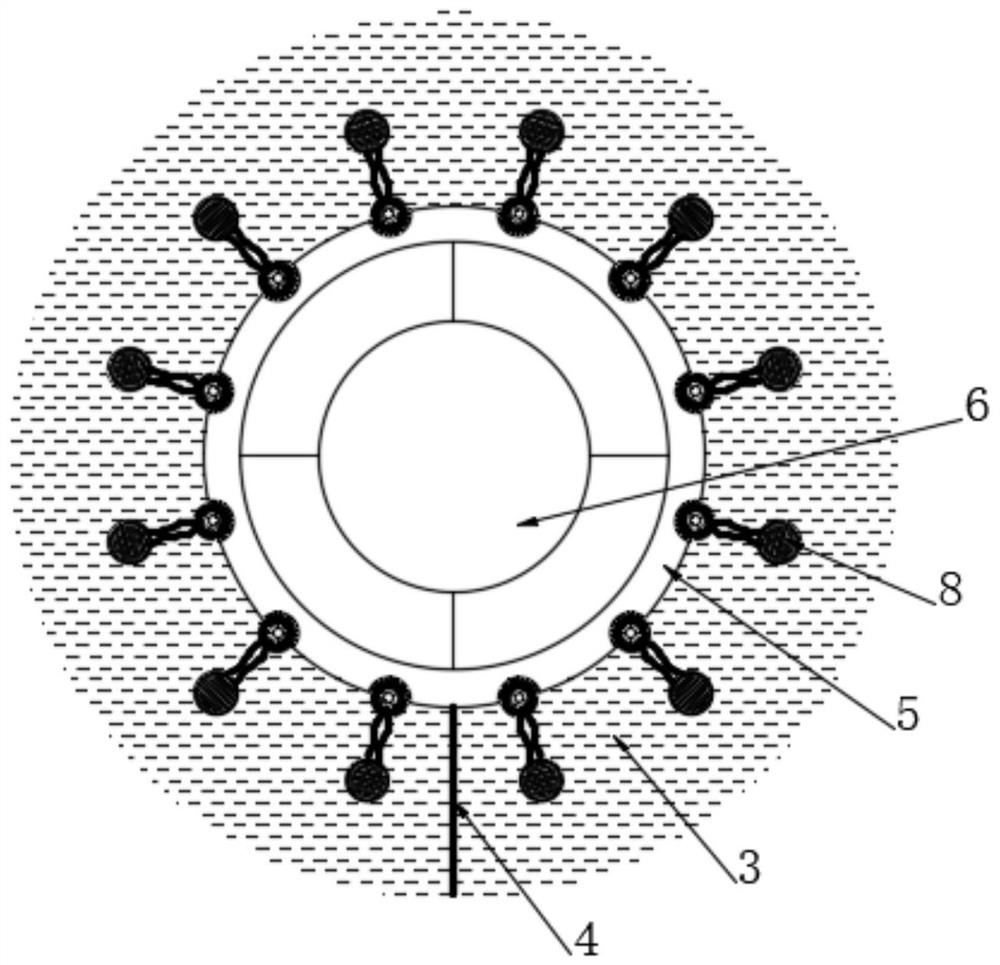

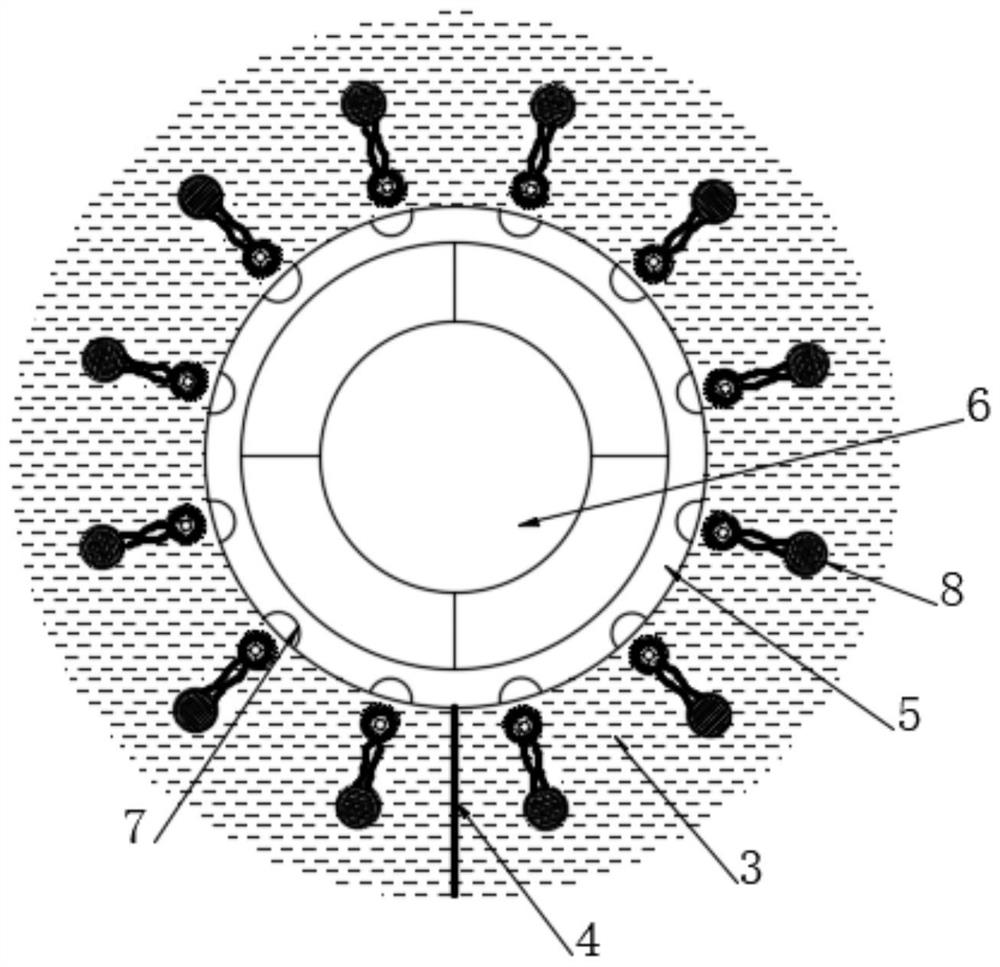

[0042] see Figure 1-5 , a textile wastewater oil absorption device based on low-temperature detachment technology, comprising an oil suction box 1, a water guide pipe 2 is embedded in the left end of the oil suction box 1, a semiconductor refrigeration chip is installed in the oil suction box 1, and textile wastewater 3 is filled in the oil suction box 1, The inner bottom of the oil suction box 1 is fixedly connected with a connecting rope 4, and the end of the connecting rope 4 away from the inner bottom of the oil suction box 1 is fixedly connected with an adsorption ball bearing frame 5, and the adsorption ball bearing frame 5 is bolted with a main magnet ball 6, and the main magnet ball 6 The outer end is excavated with a plurality of evenly distributed bearing grooves 7, and the bearing groove 7 is provided with a separation oil-absorbing double ball 8, and the separation oil-absorbing double ball 8 includes an adsorption ball 9 located in the bearing groove 7, and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com